Are you curious about the proper care for power tools? Well, you’ve come to the right place! Today, we’re going to explore which of the following statements is not a proper care for power tools. So, grab your safety goggles and let’s dive into the world of tool maintenance!

Now, you might be thinking, “Hey, why is proper care important for power tools anyway?” Well, my friend, taking care of your tools not only ensures their longevity but also keeps you safe during your DIY adventures. So, let’s sharpen our knowledge and find out which statement should be avoided when it comes to taking care of power tools.

Power tools can be your best buddies in getting those projects done, but like any friend, they need some TLC. So, without further ado, let’s uncover the statement that doesn’t belong in the realm of proper power tool care. Ready? Let’s roll!

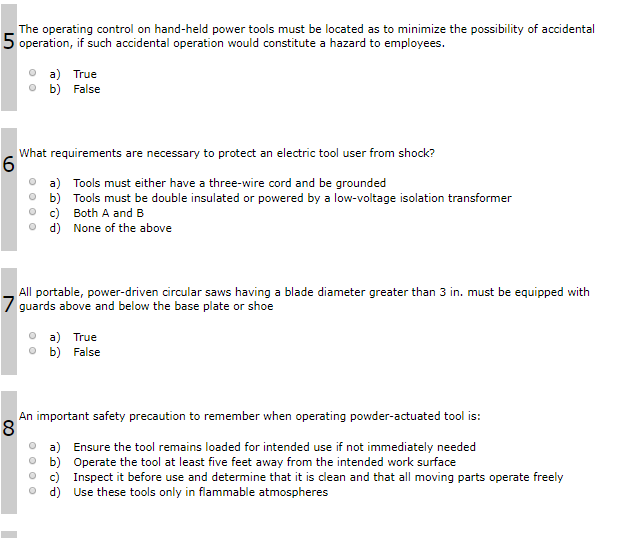

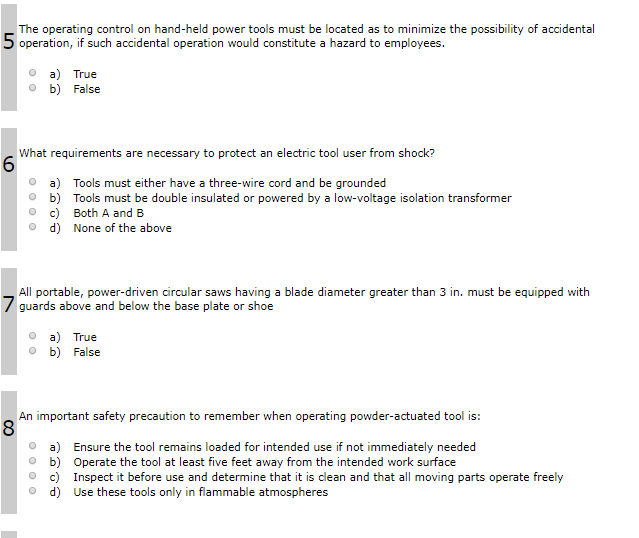

1. Neglecting regular maintenance and cleaning.

2. Using the tool for purposes it’s not intended for.

3. Ignoring safety precautions and not wearing protective gear.

4. Failing to inspect the tool for any damage before use.

5. Storing the tool in a damp or humid environment.

Remember, proper care and maintenance are essential for the optimal performance and safety of power tools.

The Importance of Proper Care for Power Tools

Power tools are essential for various projects, from DIY home repairs to professional construction work. However, it’s crucial to understand the importance of proper care and maintenance to ensure their longevity and safe operation. In this article, we will explore the dos and don’ts of power tool care. We will specifically look at which statements are not considered proper care for power tools and why. By following these guidelines, you can maximize the lifespan of your tools and prevent accidents or damage.

Common Misconceptions About Power Tool Care

A common misconception when it comes to power tool care is that they don’t require much attention. Some might believe that power tools are built to last without any additional care. However, neglecting proper care and maintenance can lead to reduced performance, increased risk of accidents, and the need for costly repairs or replacements. Let’s debunk some statements that are not considered proper care for power tools.

Statement 1: “I don’t need to clean my power tools regularly.”

Regular cleaning is crucial for maintaining power tool performance. Dust, debris, and other contaminants can accumulate on various components, such as blades or motors, affecting their efficiency and potentially causing malfunctions. Cleaning your power tools after each use can prevent clogging, extend their lifespan, and ensure optimal performance. It’s recommended to use compressed air, a soft brush, or a vacuum cleaner to remove dust and debris.

Additionally, paying attention to the storage of your power tools is essential. Leaving them exposed to moisture, extreme temperatures, or other damaging conditions can lead to rust, corrosion, and overall deterioration. Store your tools in a dry and secure area, using protective cases or covers if necessary.

Statement 2: “It doesn’t matter if the power tool’s cord is damaged.”

A damaged power cord should never be disregarded. When a power tool cord is frayed, cut, or exposed, it poses a significant risk of electric shock or fire hazards. Inspect the cords of your power tools regularly, checking for any signs of damage. If you notice any issues, replace them immediately or seek professional help to avoid accidents or further damage. It’s essential to use the right extension cords with the appropriate ampere rating to provide ample power to the tool and prevent overheating.

Remember to unplug the power tool from the electrical outlet before starting any inspection or repair work on the cord. Safety precautions should always be the top priority when dealing with power tools.

Statement 3: “I can ignore regular lubrication of my power tools.”

Lubrication is a crucial aspect of power tool care that should never be overlooked. Regularly lubricating your tools, especially those with moving parts like drills and saws, helps reduce friction and prevent wear and tear. It also extends the lifespan of the tool by minimizing heat build-up, which can cause damage.

Refer to the manufacturer’s guidelines for the recommended lubrication schedule and the type of lubricant to use. Use a small amount of the appropriate lubricant on the designated points, ensuring not to overdo it. Proper lubrication of power tools will not only improve their efficiency but also reduce noise levels and provide smoother operation.

Statement 4: “I don’t need to inspect the safety features of my power tools.”

Power tools often come equipped with various safety features, such as blade guards, safety switches, and trigger locks. It is crucial to inspect these safety features regularly to ensure they are functioning correctly. Ignoring or disabling these safety mechanisms can lead to accidents and injuries.

Before each use, check if the safety features of your power tools are in proper working order. Ensure that the guards, switches, and locks are intact and functioning as intended. If you notice any defects or malfunctions, refrain from using the tool until it has been repaired or replaced.

Statement 5: “I can store my power tools anywhere.”

Improper storage can have a detrimental impact on your power tools. Storing them in damp or humid environments can cause rust and corrosion, while exposing them to extreme temperatures can lead to motor damage or battery deterioration. It is essential to store your power tools in a clean, dry, and well-ventilated space.

If possible, use the original cases or specially designed storage solutions to protect your tools from dust, moisture, and other potentially damaging elements. By taking the necessary steps to store them safely, you can enhance their lifespan and ensure they are always ready for use.

Key Takeaways: Which of the following statement is not a proper care for power tools?

- Always wear appropriate safety gear when using power tools.

- Regularly inspect power tools for any signs of wear or damage.

- Keep power tools clean and free of dust and debris.

- Store power tools in a dry and secure location.

- Do not use power tools if you are tired or under the influence of drugs or alcohol.

Frequently Asked Questions

When it comes to caring for power tools, it’s important to handle them properly to ensure their longevity and safety. Here are some common questions about proper care for power tools:

1. How can I ensure the safety of power tools?

Ensuring the safety of power tools is crucial to prevent accidents and injuries. Here are a few steps you can take:

First, always read the manufacturer’s instructions and familiarize yourself with the tool’s safety features. Secondly, wear appropriate personal protective equipment (PPE) like safety goggles, gloves, and ear protection. Thirdly, inspect the power tool before and after use for any damage or worn-out parts. Finally, store the power tools in a safe and dry place, away from children’s reach.

2. Is it necessary to clean power tools after each use?

Yes, it is necessary to clean power tools after each use to ensure their proper functioning and longevity. Cleaning power tools helps remove dust, debris, and other particles that can lead to clogging or damage. To clean your power tools, start by unplugging them or removing the battery. Use a soft cloth or brush to gently wipe away any dirt or dust from the surface. For hard-to-reach areas, you can use compressed air or a small brush. Once clean, store the tools in a dry place to prevent rust or corrosion.

3. Can power tools be used in wet conditions?

No, power tools should never be used in wet conditions as it can pose serious safety hazards. Moisture can cause electrical shorts or increase the risk of electrocution. If you need to work in wet conditions, make sure to use tools specifically designed for that purpose, such as waterproof power tools with appropriate safety features. Always prioritize your safety and follow the manufacturer’s instructions and guidelines.

4. How often should I lubricate my power tools?

Lubricating power tools is essential to keep them running smoothly and minimize friction. The frequency of lubrication depends on the type of power tool and how frequently it is used. Typically, it is recommended to lubricate moving parts, such as gears and bearings, every 3-6 months. However, it’s important to consult the manufacturer’s instructions for specific recommendations. Use the appropriate lubricant recommended by the manufacturer to ensure optimal performance and longevity of your power tools.

5. Can I replace or repair power tool parts on my own?

Replacing or repairing power tool parts should only be done by trained professionals or individuals with expertise in power tool repair. Power tools contain complicated mechanisms and electronics that require specific knowledge and skills to handle. Attempting to replace or repair parts without proper training can not only void any warranties but also result in damage to the tool or increase the risk of accidents. It is best to contact the manufacturer’s authorized service center or a professional repair technician to ensure the proper replacement or repair of power tool parts.

Summary

Taking proper care of power tools is important to stay safe and keep them working well. There are a few statements that are not proper care for power tools. Avoid using damaged tools, as they can be dangerous. Don’t ignore safety instructions and always wear the right protective gear. Remember to clean and maintain your tools regularly to prolong their lifespan. Lastly, never leave power tools unattended, especially around children. By following these guidelines, you can ensure the safe and efficient use of power tools.

In conclusion, it is crucial to handle power tools responsibly. By following the correct care guidelines, such as avoiding damaged tools, using protective gear, cleaning and maintaining regularly, and keeping them away from children, you can protect yourself and others from accidents. Stay safe!