Are you wondering which TPI bandsaw blade is the right choice for your woodworking projects? Well, look no further! In this guide, we’ll dive into the world of bandsaw blades and help you find the perfect one to meet your needs. Whether you’re a beginner or a seasoned woodworker, choosing the right TPI (teeth per inch) can make a world of difference in your cutting experience. So let’s get started and find the TPI bandsaw blade that will take your woodworking to new heights!

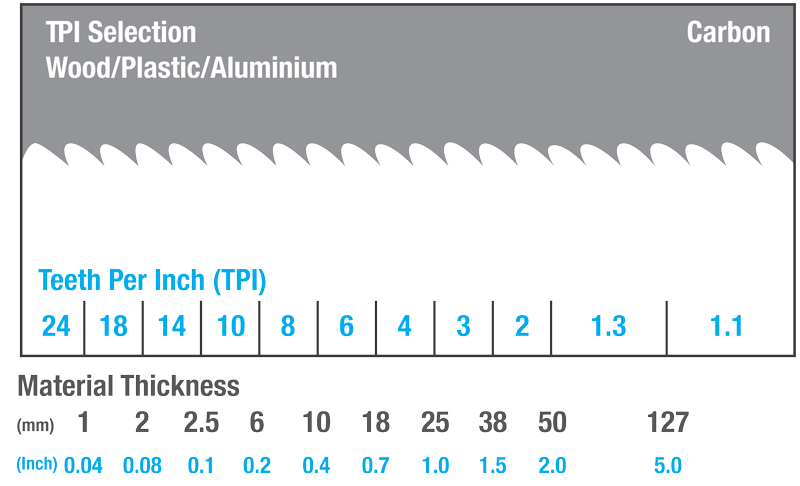

When it comes to TPI bandsaw blades, the options can seem overwhelming. But fear not, we’re here to break it down for you. TPI refers to the number of teeth on the bandsaw blade per inch. Different TPI blades are designed for different types of cuts. For instance, blades with a lower TPI are ideal for making rough cuts through thick materials, while higher TPI blades are better suited for smooth cuts in thinner materials. By understanding the different TPI options, you can ensure that you’re using the right blade for your specific woodworking project.

Now, you might be thinking, “But how do I choose the right TPI for my bandsaw blade?” Well, that’s where things get interesting. The ideal TPI will depend on several factors, such as the type of material you’re cutting, the thickness of the material, and the desired finish. It’s like solving a puzzle, but don’t worry, we’ll guide you through it step by step. So grab your thinking cap and get ready to discover the secrets of choosing the perfect TPI bandsaw blade for your woodworking needs!

Which TPI Bandsaw Blade? Choosing the Right Blade for Your Needs

Welcome to our guide on choosing the right TPI (teeth per inch) bandsaw blade for your specific needs. When it comes to bandsaw blades, finding the right TPI can make all the difference in achieving the desired cut quality and efficiency. In this article, we will explore the factors to consider when selecting a bandsaw blade and provide valuable insights to help you make an informed decision.

Understanding TPI and its Impact on Cutting

TPI refers to the number of teeth per inch on a bandsaw blade. The right TPI will depend on the material you are cutting and the desired result. For example, a higher TPI is suitable for cutting thin materials such as metal or plastic, while a lower TPI is more appropriate for thicker and softer materials like wood. The TPI affects the smoothness of the cut, the speed of the operation, and the heat generated during cutting.

When selecting the TPI for your bandsaw blade, consider the thickness and hardness of the material. Thin and hard materials require a higher TPI to prevent overheating and reduce the risk of blade damage. Conversely, thicker and softer materials require a lower TPI to allow for efficient chip removal and prevent clogging.

In addition to material considerations, the type of cut also influences the choice of TPI. A fine finish cut, such as making furniture components, calls for a higher TPI, while rough cuts for resawing or splitting logs might require a lower TPI.

Choosing the Right TPI for Different Materials

Now that we understand the basics of TPI, let’s explore the suitable TPI ranges for different materials:

1. Wood:

For general woodworking purposes, a 4–6 TPI blade is recommended. This TPI range strikes a balance between efficient chip removal and a smooth finish. However, when rough-cutting thicker wood or performing heavy-duty resawing, a 2–3 TPI blade may be more appropriate for faster material removal.

2. Metal:

When cutting metal, a higher TPI is needed to avoid damaging the blade and the workpiece. For thin sheet metal, a 14–24 TPI blade is recommended. For thicker metal, a 10–14 TPI blade will be more suitable. It’s essential to lubricate the blade when cutting metal to minimize friction and heat buildup.

3. Plastic and Acrylic:

For cutting plastic and acrylic materials, a blade with a higher TPI is ideal to achieve cleaner cuts with reduced chipping and melting. A 14–18 TPI blade is typically recommended for these applications.

4. Composite Materials:

Composite materials like fiberglass or carbon fiber require a blade with a lower TPI to prevent delamination and ensure a clean cut. A 3–4 TPI blade is commonly used for cutting composites.

5. Non-Ferrous Metals:

When cutting non-ferrous metals like aluminum or brass, a blade with a higher TPI is preferred to minimize heat buildup and achieve smoother cuts. A 10–18 TPI blade is commonly recommended for these materials.

6. Other Materials:

Depending on your specific needs, there are bandsaw blades available for cutting materials like rubber, foam, or even meat. Consider consulting the manufacturer’s recommendations or seeking expert advice for these unique applications.

Tips for Optimizing Your Bandsaw Blade Performance

To ensure optimal performance and extend the lifespan of your bandsaw blade, consider the following tips:

1. Proper Blade Tension:

Keep your blade correctly tensioned to avoid blade damage and achieve accurate cuts. A loose blade can result in wavy cuts, while an overly tight blade can lead to premature wear and overheating.

2. Blade Quality and Maintenance:

Invest in high-quality blades to ensure durability and longevity. Regularly inspect and clean your bandsaw blade, and replace it as soon as signs of wear or damage appear.

3. Feed Rate:

Adjust the feed rate to maintain an optimal balance between speed and cutting efficiency. A feed rate that is too slow can cause burning, while a feed rate that is too fast may result in rough cuts.

4. Use the Right Blade Width:

The width of the blade should match the machine’s guides and the material being cut. Using the correct blade width will prevent blade bending and ensure accurate cuts.

5. Safety Precautions:

Always follow safety guidelines and wear appropriate protective equipment when operating a bandsaw. This includes safety glasses, gloves, and hearing protection.

6. Consult the Manufacturer’s Recommendations:

Each bandsaw manufacturer may have specific recommendations for TPI and blade selection. Be sure to consult the manufacturer’s guidelines for optimal performance and safety.

Conclusion:

Choosing the right TPI bandsaw blade is crucial for achieving the desired cut quality and optimizing cutting efficiency. Consider the material, cut type, and blade width when selecting the appropriate TPI. Remember to follow proper maintenance practices and safety guidelines to ensure optimal performance and longevity of your bandsaw blade. Happy cutting!

Key Takeaways: Which TPI Bandsaw Blade?

- 1. The TPI (teeth per inch) of a bandsaw blade determines the type of cut it can make.

- 2. For rough cuts, a lower TPI blade (around 3-6 TPI) is ideal.

- 3. For general-purpose cutting, a medium TPI blade (around 10-14 TPI) works well.

- 4. For fine cuts or intricate designs, a higher TPI blade (around 18-24 TPI) is recommended.

- 5. It’s essential to choose the right TPI bandsaw blade based on the material and the desired cut quality.

Frequently Asked Questions

When it comes to choosing the right TPI bandsaw blade, it can be overwhelming with all the options available. Don’t fret! We’ve got you covered with answers to some common questions that will help you navigate through the selection process.

1. What factors should I consider when choosing a TPI bandsaw blade?

When selecting a TPI (Teeth Per Inch) bandsaw blade, there are a few factors to keep in mind. First, consider the thickness and type of material you’ll be cutting. Thicker materials require blades with lower TPI, while thinner materials can be cut with blades of higher TPI. Additionally, consider the type of cut you want to achieve. A higher TPI blade will provide a smoother finish, while a lower TPI blade will cut faster but leave a rougher surface. Finally, take into account the specific requirements of your bandsaw machine, such as the blade length and width it can accommodate.

In summary, consider the material thickness, desired finish, and bandsaw machine specifications to choose the right TPI bandsaw blade.

2. Are there different TPI bandsaw blades for different materials?

Yes, there are different TPI bandsaw blades designed for cutting different materials. Cutting wood, metal, or plastic requires blades with varying TPI. For cutting wood, a blade with a TPI between 3 and 6 is generally suitable. When cutting metal, a higher TPI blade, usually between 14 and 24, is recommended. Plastic, being a softer material, can be cut with a blade of moderate TPI, around 6 to 10. It’s important to choose a blade specifically designed for the material you are working with to ensure optimal cutting performance.

Remember to match the TPI of your bandsaw blade to the material you’re cutting to get the best results and prolong the blade’s lifespan.

3. Can I use a higher TPI blade when cutting thicker materials?

Using a higher TPI blade when cutting thicker materials is generally not recommended. Thicker materials require a lower TPI blade to efficiently clear the chips and prevent clogging. A higher TPI blade is designed for thinner materials and will struggle to effectively remove the material being cut, resulting in slower cutting speeds and potential overheating of the blade. Moreover, using a higher TPI blade on thicker materials may lead to premature wear and a shorter blade lifespan.

To ensure optimal performance, choose a properly matched TPI blade for the thickness of the material you are cutting.

4. Is it necessary to change the bandsaw blade TPI for different curves?

While it is not necessary to change the TPI bandsaw blade when cutting different curves, it can be beneficial in achieving better results. Blades with higher TPI provide a smoother cutting action, making them more suitable for intricate curves and delicate work. Conversely, blades with lower TPI are better suited for straight cuts and rougher curves. It’s important to note that changing the TPI for different curves depends on the specifics of your project and the desired level of precision and finish.

Consider the complexity of the curves and the level of precision needed to determine whether changing the TPI blade is necessary for your specific cutting application.

5. How do I know when it’s time to replace my TPI bandsaw blade?

There are a few signs that indicate it’s time to replace your TPI bandsaw blade. First, if you notice visible signs of wear, such as missing or dull teeth, it’s a good indication that the blade needs to be replaced. Additionally, if you experience increased cutting times or difficulty in achieving smooth cuts, it may be a sign of a worn-out blade. Unusual vibrations or strange noises during cutting can also indicate a problem with the blade. Lastly, if you’ve tried sharpening the blade multiple times and it still doesn’t perform well, it’s likely time for a new one.

Regularly inspect your bandsaw blade and replace it when signs of wear or deterioration become apparent to maintain optimal cutting performance.

Summary

Choosing the right TPI bandsaw blade is important for getting clean and precise cuts.

The blade with fewer teeth per inch (TPI) is best for thicker materials, while more teeth per inch is ideal for thinner materials. Remember to choose a blade that matches the type of cutting you’ll be doing.