If you’re curious about lathes and their different types, you’ve come to the right place! Today, we’re going to delve into the world of machining and explore a fascinating question: which type of lathe is also known as a center lathe? Let’s embark on this learning journey together!

Now, you might be wondering why we’re discussing lathes. Well, lathes are incredibly versatile machines used in various industries to shape and cut materials like wood and metal. Different types of lathes exist, each with its own unique features and capabilities. Among them, there’s one particular type that goes by the name “center lathe.” But why is it called that?

In this article, we’ll uncover the answer to this intriguing question and explore the fascinating world of center lathes. So, put on your thinking caps and let’s get started!

Which Type of Lathe is Also Known as Centre Lathe?

Lathe machines are a common tool in machining operations, used for shaping and cutting materials like wood, metal, and plastic. Among the different types of lathes, one popular variety is the centre lathe. Centre lathe, also known as a “engine lathe” or “bench lathe,” is a versatile machine that can perform a wide range of operations with precision. In this article, we will explore the details and features of the centre lathe, its uses, and why it is often regarded as the go-to lathe for many craftsmen and machinists.

The Features and Capabilities of Centre Lathe

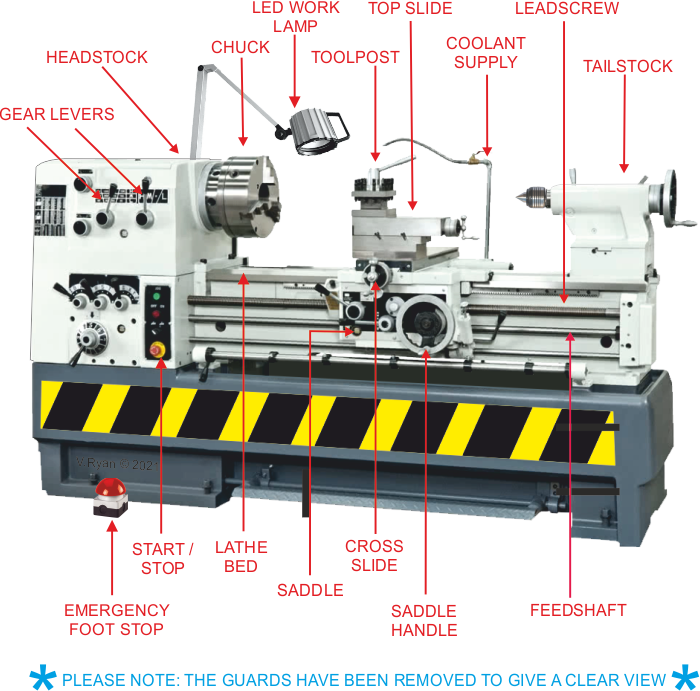

The centre lathe is characterized by its construction, mobility, and range of operations. It typically consists of a bed, headstock, tailstock, saddle, carriage, and other components that contribute to its functionality. The bed is the base of the lathe, providing stability and support for the workpiece, while the headstock houses the spindle and motor. The tailstock serves as a support for long workpieces and house the live center or dead center.

The versatility of the centre lathe is unmatched, allowing craftsmen and machinists to perform various turning operations such as facing, taper turning, chamfering, thread cutting, and drilling. The lathe can be operated manually or with the assistance of automated controls, making it suitable for both traditional and modern machining practices. Additionally, the wide range of available attachments and accessories further enhance the capabilities of the centre lathe, enabling the machinist to achieve intricate and precise designs.

The Importance of Centre Lathe in Woodworking

Woodworking is one field where the centre lathe finds extensive use. Craftsmen working with wood rely on the centre lathe to shape and refine their creations. With the help of specialized lathe tools, woodturners can create beautiful furniture components, decorative items, and even intricate wood sculptures. The flexibility and precision of the centre lathe make it the ideal choice for woodworking projects of all sizes and complexities.

Woodturning on a centre lathe involves spinning the workpiece at a high speed while the lathe tool is held against it, shaping and smoothing the material. Turners can perform operations like spindle turning, bowl turning, and thread cutting to achieve various designs and finishes. The use of different lathe chisels and gouges allows woodworkers to add details and create unique textures on their turned pieces. Whether it’s creating ornate table legs or crafting one-of-a-kind bowls, the centre lathe enables woodworking artisans to unleash their creativity.

The Role of Centre Lathe in Metalworking

In the metalworking industry, the centre lathe is a prized machine due to its precision and versatility. Machinists rely on this type of lathe for a wide array of operations, from basic turning and facing to complex threading and grooving. The centre lathe is particularly useful for small to medium-sized workpieces and can handle a variety of metals, including steel, aluminum, brass, and more.

By securing the workpiece between the headstock and tailstock, machinists can rotate the material and carefully shape it using specialized cutting tools. With the help of indexing and threading attachments, the centre lathe can create precise threads on screws and bolts, ensuring their compatibility and functionality. The lathe can also be used for multiple operations in a single setup, reducing production time and increasing efficiency in metalworking processes.

The Benefits of Centre Lathe over Other Types of Lathes

While there are other types of lathes available, the centre lathe has several advantages that make it the preferred choice for many machinists. One significant benefit of the centre lathe is its simplicity and ease of use. With a straightforward setup and intuitive controls, machinists can quickly learn to operate a centre lathe and start producing quality workpieces. This makes it an ideal choice for beginners in the machining field.

Another advantage lies in the versatility of the centre lathe. Its ability to perform various operations and accommodate different materials and workpieces allows machinists to handle a wide range of projects. From simple turning tasks to complex multi-axis operations, the centre lathe can adapt to the needs of the user, making it a valuable asset in any workshop or production facility.

Additionally, the centre lathe is relatively budget-friendly compared to specialized lathes designed for specific operations. This makes it accessible to a broader range of individuals and businesses, ensuring that craftsmanship and machining remain accessible to enthusiasts and professionals alike.

Different Attachments and Accessories for Centre Lathe

In addition to its standalone capabilities, the centre lathe can be equipped with various attachments and accessories to further expand its functionalities. These attachments allow machinists to carry out specific operations more efficiently and produce intricate designs with ease. Some common attachments include:

1. Chuck Attachment

A chuck attachment replaces the need for a faceplate and allows for secure clamping of the workpiece. Chucks come in different sizes and types to accommodate various shapes and sizes of materials.

2. Taper Turning Attachment

A taper turning attachment enables the centre lathe to create tapered shapes accurately and consistently. Machinists can achieve smooth tapers on cylindrical workpieces, adding functionality and aesthetic appeal to their designs.

3. Thread-Cutting Attachment

With a thread-cutting attachment, the centre lathe becomes capable of producing precise threads on screws, bolts, and other threaded components. This attachment simplifies the process and ensures thread compatibility.

4. Steady Rest

A steady rest is used to support long and slender workpieces during turning operations. It helps prevent vibration and deflection, ensuring accurate and smooth machining.

Tips for Getting the Most Out of Your Centre Lathe

To maximize the benefits of your centre lathe and achieve exceptional results, consider the following tips:

1. Proper Tool Selection

Choose the appropriate cutting tools for your desired operation and material. Different types of tools, such as carbide-tipped or high-speed steel, offer varying cutting characteristics, ensuring optimal performance and longevity.

2. Regular Maintenance

Maintain your centre lathe by cleaning it regularly and lubricating moving parts. This helps prevent wear and tear, ensures smooth operation, and prolongs the lifespan of the machine.

3. Take Safety Precautions

Always prioritize safety when operating a centre lathe. Wear appropriate protective gear, follow safe work practices, and familiarize yourself with emergency procedures to prevent accidents and injuries.

In Closing

The centre lathe, also known as a “engine lathe” or “bench lathe,” is a versatile and reliable machine used in various industries, including woodworking and metalworking. Its wide range of operations, simplicity, and affordability make it a go-to choice for many craftsmen, machinists, and hobbyists. By understanding the features, capabilities, and accessories of the centre lathe, enthusiasts can unleash their creativity and achieve exceptional results in their projects. Remember to follow proper maintenance and safety practices to ensure long-term success and enjoyment with your centre lathe.

Key Takeaways: Which type of lathe is also known as centre lathe?

- A centre lathe is a type of lathe that is commonly known as a centre lathe.

- The centre lathe is one of the most widely used types of lathes in metalworking.

- Centre lathe is so named because the workpiece is held between two centers.

- Centre lathes are used for various turning operations, such as facing, turning, and taper turning.

- Centre lathes have a wide range of applications in industries like automotive, aerospace, and construction.

Frequently Asked Questions

When it comes to different types of lathes, there is one that is commonly referred to as a “centre lathe.” Find out more about this type of lathe and its characteristics in the following frequently asked questions.

What is a centre lathe?

A centre lathe, also known as an engine lathe or a bench lathe, is a type of lathe that is designed to handle a wide range of machining operations. It is called a centre lathe because it uses centers to support the workpiece being turned.

This type of lathe is commonly used in workshops and small-scale manufacturing industries for various tasks, such as turning, facing, threading, and drilling. It is versatile and can be operated manually or with the help of computer numerical control (CNC) systems.

What are the main features of a centre lathe?

A centre lathe typically has several key features that enable it to perform different machining operations. These features include a bed, headstock, tailstock, carriage, cross slide, and toolpost.

The bed is the main foundation of the lathe, providing support and rigidity. The headstock houses the main spindle and the drive mechanism, while the tailstock supports the other end of the workpiece. The carriage holds the cutting tool and can be moved manually or automatically along the bed’s length. The cross slide allows for movement perpendicular to the bed, while the toolpost holds the cutting tool securely in place.

What are the advantages of using a centre lathe?

A centre lathe offers several advantages that make it a popular choice for machining operations. Firstly, it allows for great precision and accuracy in turning and shaping workpieces. The use of centers ensures proper alignment and reduces the chances of errors.

Secondly, a centre lathe is versatile and can handle a wide range of materials, including metal, wood, and plastic. It can be used for both small-scale and large-scale projects, making it suitable for various industries. Additionally, it is relatively easy to operate and maintain, making it accessible to beginners and seasoned operators alike.

Are there any limitations to using a centre lathe?

While a centre lathe is a versatile and capable machine, it does have some limitations. One of the main limitations is the size of the workpieces it can handle. Centre lathes are generally designed for smaller to medium-sized workpieces. Large and heavy workpieces may require specialized equipment.

Another limitation is the speed of production. While centre lathes can produce high-quality results, they may not be as efficient as other machines, such as CNC lathes, for high-volume production. The manual operation and setup time can slow down the production process.

Is a centre lathe suitable for beginners?

Yes, a centre lathe is often recommended for beginners in machining and woodworking. It offers a hands-on approach to learning the fundamentals of turning and shaping workpieces. The manual operation allows beginners to understand the different components and processes involved in using a lathe.

Furthermore, a centre lathe is relatively safer for beginners compared to more complex machines. It has fewer moving parts and can be operated at slower speeds, reducing the risk of accidents. However, proper training and supervision are still essential to ensure safety and proper usage of the machine.

Summary

So, what did we learn about lathes? The centre lathe is also known as the engine lathe. It’s the most common type of lathe used for various machining operations. It has a fixed tool and a rotating workpiece, allowing you to shape and cut materials with precision. Whether you’re making small parts or big ones, the centre lathe is a versatile tool you can rely on.