Curious about which way the teeth on a bandsaw point? Well, you’re in the right place! Let’s dive into this fascinating topic together.

So, you might be wondering, why is the direction of the teeth on a bandsaw important? Well, it has a significant impact on how the blade cuts through materials, whether it’s wood, metal, or even plastic.

Now, let’s get to the heart of the matter. Are you ready to discover the secret behind the direction of the teeth on a bandsaw blade? Let’s go!

Which Way Do the Teeth Point on a Bandsaw?

A bandsaw is a popular tool used in woodworking and metalworking industries for cutting various materials. One common question that arises when operating a bandsaw is which way do the teeth point? Understanding the direction of the teeth is essential for achieving the best results and ensuring the safety of the operator. In this article, we will explore the significance of the teeth orientation on a bandsaw and provide a comprehensive guide on which way the teeth should point to maximize efficiency and effectiveness.

The Importance of Tooth Orientation

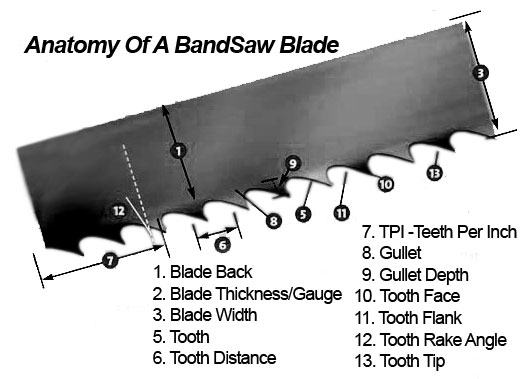

When it comes to using a bandsaw, the direction in which the teeth point plays a crucial role in the cutting process. Each tooth on a bandsaw blade is designed to remove a specific amount of material, and the orientation determines the efficiency and quality of the cut. The teeth on a bandsaw blade can be set to either face toward or away from the operator, depending on the desired outcome.

If the teeth are set to face towards the operator, it is referred to as a “downward tooth orientation.” This configuration is commonly used when cutting through softer materials like wood or plastic. On the other hand, if the teeth are set to face away from the operator, it is known as an “upward tooth orientation.” This setup is typically used when cutting through harder materials such as metal or thick plastics.

Benefits of Downward Tooth Orientation

When the teeth on a bandsaw blade face towards the operator, it offers several advantages. Firstly, a downward tooth orientation allows for a smoother and cleaner cut on materials like wood. The teeth are pulling the material down into the table, which minimizes the likelihood of splintering or tear-out. This makes it ideal for creating precise cuts that require minimal finishing and sanding.

Additionally, a downward tooth orientation promotes better control and stability while cutting. The operator can visually monitor the cut more easily and adjust as needed. The downward orientation also reduces the risk of the blade binding, as the tooth’s cutting action helps prevent the material from getting caught or pinched during the cut.

Furthermore, using a downward tooth orientation on a bandsaw blade helps distribute the load evenly across the teeth. This prevents premature wear and tear, ensuring a longer lifespan for the blade. It also reduces the chances of clogging and overheating, as the teeth are effectively clearing the material away from the cut.

Advantages of Upward Tooth Orientation

While a downward tooth orientation is ideal for cutting softer materials, there are situations where an upward tooth orientation is preferred. When working with harder materials like metal or thick plastics, an upward tooth orientation provides several benefits. Firstly, it allows for more aggressive cutting action, making it easier to remove material quickly.

An upward tooth orientation also helps prevent the material from binding. Since the teeth are facing away from the operator, the cutting action pushes the material down against the table, minimizing the risk of it getting caught or stuck. This ensures a smoother cutting process and reduces the chances of blade damage or accidents.

Furthermore, an upward tooth orientation can help improve chip evacuation. The cutting action pushes the chips away from the cut, preventing them from accumulating and causing clogging or overheating. This is especially important when working with metal, as overheating can lead to premature blade dulling and reduced cutting performance.

Factors to Consider When Choosing Tooth Orientation

Now that we have discussed the benefits of both downward and upward tooth orientations, it’s essential to consider certain factors when choosing the appropriate tooth orientation for your bandsaw blade. These factors include the material being cut, the desired cut quality, and the experience level of the operator.

Material: Different materials have different hardness levels, and selecting the appropriate tooth orientation can significantly affect the cutting performance. Softer materials like wood or plastic generally benefit from a downward tooth orientation, while harder materials like metal require an upward tooth orientation to achieve optimal results.

Cut Quality: The quality of the cut also plays a role in determining the suitable tooth orientation. If you are looking for a smoother and cleaner cut with minimal finishing required, a downward tooth orientation is recommended. On the other hand, if speed and material removal are your primary concern, an upward tooth orientation may be more suitable.

Operator Experience: The experience level of the operator should also be taken into account when choosing the tooth orientation. Those new to bandsaw operations may find it easier to control and monitor the cut with a downward tooth orientation, as it offers better visibility and stability. However, experienced operators can confidently handle an upward tooth orientation, taking advantage of its more aggressive cutting action.

Conclusion

The direction in which the teeth point on a bandsaw plays a critical role in the cutting process. A downward tooth orientation is beneficial for cutting softer materials like wood, offering smoother cuts, better control, and increased blade lifespan. Conversely, an upward tooth orientation is preferable when working with harder materials like metal, providing more aggressive cutting action and effective chip evacuation.

When choosing the appropriate tooth orientation, consider factors such as the material being cut, desired cut quality, and operator experience. By selecting the right tooth orientation for the task at hand, you can maximize the performance and efficiency of your bandsaw and achieve outstanding results in your woodworking or metalworking projects.

Key Takeaways: Which Way Do the Teeth Point on a Bandsaw?

– The downward direction of the teeth helps to cut through materials smoothly and efficiently.

– It is important to ensure that the teeth are properly aligned and facing the correct direction before operating the bandsaw.

– The teeth should be pointing towards the table or workpiece, not away from it.

– Regular maintenance, such as sharpening and proper tensioning of the blade, is crucial to maintain the cutting effectiveness of the bandsaw.

Frequently Asked Questions

Welcome to our frequently asked questions section where we answer common inquiries about bandsaw teeth. Below, you’ll find helpful information related to the direction in which the teeth on a bandsaw point.

1. How should the teeth of a bandsaw blade point?

When it comes to the direction of the teeth on a bandsaw blade, they should be pointing downwards. This means that the teeth should be facing the table or workpiece you are cutting. The downwards-facing teeth help to ensure efficient and clean cuts by allowing the blade to slice smoothly through the material.

The angle and shape of the teeth may vary depending on the specific bandsaw blade and its intended use. However, the general principle remains the same – the teeth should be oriented in a downward direction to facilitate effective cutting.

2. Why do the teeth on a bandsaw blade point downwards?

The reason the teeth on a bandsaw blade point downward is to achieve optimal cutting performance. This design allows the blade to create clean and precise cuts by efficiently removing material as it passes through the workpiece. By pointing the teeth downward, the blade can make continuous contact with the material, preventing it from riding up and potentially causing uneven cuts or kickback.

Additionally, the downward orientation of the teeth helps to remove debris and waste material away from the blade and the workpiece, reducing the chance of clogging and increasing cutting efficiency. This design choice ensures that the bandsaw operates smoothly and effectively, resulting in accurate and smooth cuts for a wide range of applications.

3. Can bandsaw blades have teeth pointing in different directions?

No, bandsaw blades should have teeth pointing in the same direction for optimal cutting performance. Having teeth pointing in different directions would disrupt the balance and smooth operation of the blade, resulting in poor cutting performance and potential damage to the material being cut.

Uniformly pointing teeth in a specific direction also ensures consistent and precise cuts, allowing the bandsaw blade to efficiently slice through the material without grabbing or causing unnecessary strain on the blade or the machine itself.

4. How can I determine the direction of the teeth on a bandsaw blade?

To determine the direction of the teeth on a bandsaw blade, you can inspect the blade and observe the orientation of the teeth. The teeth should be facing downward or towards the table or workpiece you are cutting. You can use a magnifying glass or a well-lit area to get a closer look at the blade and confirm the direction of the teeth.

If you’re unsure or need further assistance, you can also refer to the manufacturer’s guidelines or consult the user manual for your specific bandsaw model. These resources usually provide detailed information on blade installation and proper tooth direction to ensure optimal performance.

5. Are there any exceptions where the teeth on a bandsaw blade point in a different direction?

In general, the teeth on a bandsaw blade should point downward for most cutting applications. However, there may be specialized bandsaw blades that have teeth pointing in different directions or have specific tooth configurations for unique cutting purposes.

For example, certain bandsaw blades may have reverse teeth or alternating tooth patterns that serve specific cutting needs, such as reducing tear-out or improving chip clearance in certain materials. These specialized blade designs are typically used in specialized industries or applications and may require specific instructions and techniques for optimal performance.

Summary

If you’re wondering which way the teeth on a bandsaw should face, here’s the answer! The teeth should always point downwards towards the table. This helps the bandsaw cut smoothly and prevents any accidents.

Remember, safety should always be a priority when using a bandsaw. Make sure you have the right blade for the type of material you’re cutting, and keep your fingers away from the blade. By following these guidelines, you’ll be able to use a bandsaw safely and effectively for all your cutting needs.