Have you ever wondered which way the bandsaw blade goes? Well, you’re in the right place!

Using a bandsaw can be an exciting and rewarding experience, but it’s important to know the proper orientation of the blade for optimal performance and safety.

In this article, we’ll explore the answer to the question, “Which way does the bandsaw blade go?” and provide you with all the information you need to use your bandsaw effectively. So, let’s dive in and find out the correct direction for your bandsaw blade!

Discover the correct way to install a bandsaw blade without breaking a sweat. Follow these simple steps:

- First, loosen the tension on the bandsaw.

- Next, remove the old blade from the bandsaw.

- Identify the teeth direction on the new blade.

- Place the blade on the bandsaw, ensuring the teeth are facing downwards.

- Tighten the tension on the bandsaw to secure the blade.

By aligning the teeth correctly, you’ll maximize the performance of your bandsaw and achieve precise cuts. Happy woodworking!

Which Way Does Bandsaw Blade Go? Understanding and Installing Bandsaw Blades

Bandsaws are versatile power tools commonly used in woodworking. One crucial aspect of using a bandsaw is knowing the correct way to install the blade. The direction in which the bandsaw blade is installed can significantly impact cutting efficiency and safety. In this article, we will explore the importance of correctly installing a bandsaw blade, discuss the best practices for blade orientation, and offer tips for optimal performance.

Understanding the Anatomy of a Bandsaw Blade

Before delving into the correct orientation of a bandsaw blade, it is essential to understand its anatomy. Bandsaw blades consist of a continuous loop with teeth along one edge. The teeth of the blade are responsible for cutting through materials, while the back of the blade supports the cutting action and provides stability. The teeth are angled in one direction, which determines the cutting motion of the blade.

Typically, bandsaw blades have a toothed edge, known as the “toothy side” or “teeth side,” and a smooth edge called the “back” or “gullet side.” The toothy side faces down towards the tabletop or work surface, while the back faces towards the blade guide system. Understanding this orientation is crucial for proper installation and efficient cutting.

The Correct Way to Install a Bandsaw Blade

To install a bandsaw blade correctly, follow these steps:

1. Ensure the bandsaw is unplugged and turned off before attempting to install or change the blade. This is a vital safety precaution.

2. Open the bandsaw’s blade tensioning system. On most models, this involves loosening a knob or lever to release the tension on the blade. Refer to your bandsaw’s manual if you’re unsure about the specific method for your machine.

3. Remove the old blade by sliding it off the bandsaw’s wheels and disengaging it from the blade guides.

4. Examine the new bandsaw blade to identify the toothy side and the back. The toothy side should be facing down on the work surface, and the back should be facing towards the blade guide system.

5. Slide the new blade onto the bandsaw’s wheels, ensuring that the teeth are facing down and aligned towards the tabletop.

6. Thread the blade through the blade guide system and ensure it sits correctly in the guides. Refer to your bandsaw’s manual for guidance on adjusting the guides.

7. Close the blade tensioning system and tighten it according to the manufacturer’s instructions. Proper tensioning is crucial for accurate cuts and safe operation.

Tips for Optimal Bandsaw Blade Performance

Now that you understand the correct orientation and installation of a bandsaw blade let’s explore some additional tips for achieving optimal performance:

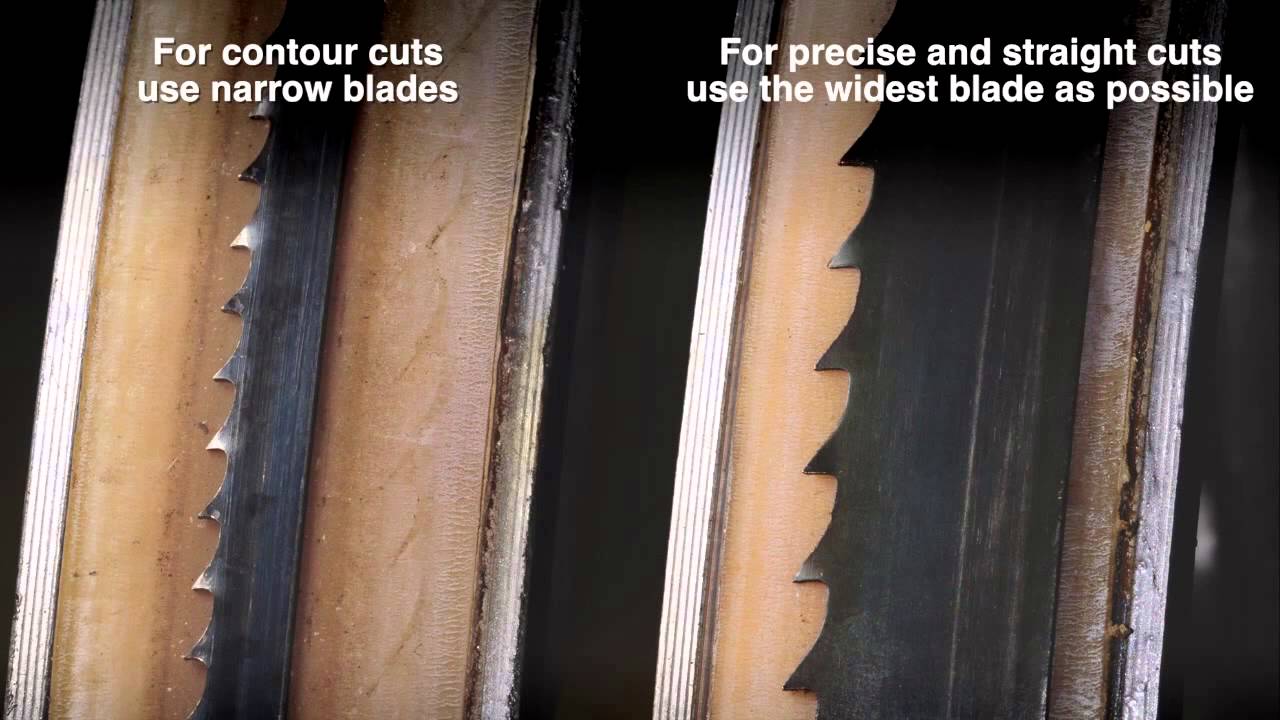

1. Choose the right blade for the material and task at hand. Bandsaw blades come in different widths, tooth configurations, and materials. For example, blades with fewer teeth per inch are ideal for resawing thick stock, while blades with more teeth per inch provide smoother cuts on thinner materials.

2. Maintain proper blade tension. The tension of the blade affects both cutting accuracy and safety. Check and adjust the tension regularly, following the manufacturer’s guidelines.

3. Ensure the bandsaw blade is properly aligned with the bandsaw’s wheels. Misalignment can cause premature wear and decrease cutting efficiency. Consult your bandsaw’s manual for instructions on adjusting the blade tracking.

4. Keep the blade clean and free from debris. Sawdust and residue can accumulate on the blade, affecting its performance and longevity. Regularly clean the blade using a brush or air compressor.

5. Monitor blade wear and replace it when necessary. Over time, bandsaw blades can become dull or damaged, leading to poor cutting performance. Replace the blade as soon as it shows signs of wear, such as excessive vibration or burning marks on the wood.

Remember, safety is paramount when operating a bandsaw. Always use protective gear, follow the manufacturer’s instructions, and exercise caution while working with this powerful tool.

Common Bandsaw Blade Installation Mistakes

While understanding the correct way to install a bandsaw blade is essential, it is equally important to identify and avoid common installation mistakes. Here are a few errors to watch out for:

Incorrect Tooth Orientation

Installing the bandsaw blade with the toothy side facing incorrectly towards the blade guide system or the tabletop can lead to poor cutting results. Make sure to orient the blade properly, with the teeth facing down towards the work surface.

Insufficient Blade Tension

Insufficient tension can cause the blade to slip, resulting in inaccurate cuts and potential safety hazards. Always ensure that the blade has the appropriate tension as recommended by the manufacturer.

Poor Blade Tracking

Improper alignment between the bandsaw blade and the wheels can cause the blade to ride off its intended track. This misalignment can lead to increased wear on the blade and reduced cutting efficiency. Regularly check and adjust the blade tracking according to the manufacturer’s instructions.

Inadequate Blade Cleaning

Failing to clean the bandsaw blade regularly can result in decreased performance and premature wear. Dust, debris, and pitch can accumulate on the blade, affecting its ability to cut cleanly. Take the time to clean the blade after each use to maintain optimal performance.

By avoiding these common mistakes and following proper installation techniques, you can ensure that your bandsaw blade performs at its best, resulting in accurate cuts and a safer working environment.

Bandsaw Blade Maintenance and Care

Proper maintenance and care are essential for prolonging the life of your bandsaw blade and ensuring its optimal performance. Here are some tips to help you maintain your bandsaw blade:

Regular Cleaning

After each use, clean the blade thoroughly to remove dust, debris, and pitch. This can be done using a brush or compressed air. Additionally, you can soak the blade in a mild cleaning solution to remove any stubborn residue.

Blade Lubrication

Applying lubrication to the bandsaw blade reduces friction and heat buildup during cutting. Use a bandsaw blade lubricant or a silicone-based lubricant spray. Apply the lubrication before and during extended cutting sessions to prevent blade dulling and prolong blade life.

Blade Storage

When not in use, store the bandsaw blade properly to prevent damage. Coil the blade carefully and place it in a protective case or hang it on a blade rack. This prevents the blade from bending or getting entangled with other tools.

Regular Inspections

Regularly inspect the bandsaw blade for any signs of wear, damage, or dullness. Look for chips, missing teeth, or excessive wear along the cutting edge. Replace the blade if any issues are detected to maintain optimal performance and safety.

Proper Tensioning

Maintaining proper blade tension is crucial for accurate cuts and safe operation. Regularly check and adjust the tension according to the manufacturer’s recommendations. An improperly tensioned blade can lead to blade fatigue, breakage, or poor cutting results.

In Summary

Understanding the correct way to install a bandsaw blade is essential for optimal performance and safety. Always install the blade with the toothy side facing down towards the work surface. Avoid common mistakes like insufficient tension, poor blade tracking, and inadequate cleaning. By following proper installation techniques, practicing regular maintenance, and caring for your bandsaw blade, you can ensure accurate cuts and a long-lasting blade life.

Key Takeaways: Which Way Does Bandsaw Blade Go?

- Make sure the teeth on the bandsaw blade are facing down

- The sharp edge of the teeth should face forward

- Check the manufacturer’s instructions for any specific guidelines

- Always use proper safety precautions when handling and installing bandsaw blades

- If unsure, consult the owner’s manual or seek advice from a professional

Frequently Asked Questions

Welcome to our frequently asked questions section about the orientation of bandsaw blades! Whether you’re a beginner or a seasoned woodworker, understanding the proper direction of a bandsaw blade is crucial for safe and efficient use. Below, you’ll find answers to common questions related to the correct way to install a bandsaw blade.

1. How do I determine the correct orientation for a bandsaw blade?

The orientation of a bandsaw blade depends on the type of bandsaw you’re using. In general, the teeth on the blade should be pointing downward and facing the front of the saw. This allows the saw to cut through the material efficiently. However, there are instances where a reverse-tooth blade is used, which can be installed differently. To determine the correct orientation, consult your bandsaw’s manual or contact the manufacturer for guidance.

It’s important to note that in some cases, bandsaw blades can be installed with the teeth pointing upward. This is often done for specific cutting tasks, such as resawing or cutting thick materials. Again, refer to your bandsaw’s manual or consult with an expert to ensure proper installation.

2. What problems can occur if I install a bandsaw blade in the wrong direction?

Installing a bandsaw blade in the wrong direction can lead to various issues. If the teeth are facing the wrong way, the blade’s cutting efficiency will be significantly reduced. This can result in rough cuts, excessive vibrations, and even potential damage to the bandsaw and the workpiece. Additionally, the blade may become more prone to overheating, causing premature wear and tear.

In some cases, installing a blade in the wrong direction can be dangerous. It can lead to kickbacks, where the workpiece is forcefully thrown back towards the operator. Kickbacks can cause serious injuries, so it’s crucial to ensure the blade is installed correctly to minimize this risk.

3. Are there specific bandsaw blades that require a different orientation?

Yes, there are specialized bandsaw blades that require a different orientation. One example is the reverse-tooth blade, where the teeth face upward instead of downward. This type of blade is commonly used for cutting materials that are prone to chipping, such as melamine or veneer plywood. By having the teeth face upward, the blade helps minimize chipping and produce cleaner cuts on the top surface of the material.

It’s important to note that even when using specialized blades, always refer to the manufacturer’s instructions for proper installation. The correct orientation may vary depending on the specific type and brand of blade you’re using.

4. Can I use a bandsaw blade with the teeth facing backward?

No, you should not use a bandsaw blade with the teeth facing backward. The teeth of a bandsaw blade are specifically designed to cut in a specific direction. Installing the blade with the teeth facing backward will result in improper cutting action and can lead to poor performance, rough cuts, and potential damage to the material being cut. Always ensure that the blade is correctly oriented to achieve clean and efficient cuts.

5. Are there any additional precautions I should take when installing a bandsaw blade?

When installing a bandsaw blade, there are a few precautions you should keep in mind. Firstly, ensure that the blade is properly tensioned according to the manufacturer’s recommendations. This will help prevent the blade from slipping or coming off during operation. Secondly, make sure the bandsaw’s guides and bearings are properly adjusted to support the blade and minimize vibrations.

It’s also a good practice to wear appropriate personal protective equipment, such as safety glasses and gloves, when handling the bandsaw blade. This will protect you from any potential injuries or accidents. Lastly, regularly inspect the blade for any signs of damage or wear, and replace it if necessary. A well-maintained blade will ensure optimal performance and safety during your woodworking projects.

Summary

So, remember, when you’re using a bandsaw, the teeth should face down. This allows for smoother cuts and better control. Plus, it helps prevent kickback and accidents. Make sure to take the time to double-check the direction of the blade before you start cutting. Safety first!

To determine the right way for the blade to go, look for the arrows or markings on the bandsaw blade. These indicators will show you which way the teeth should be facing. Following these simple guidelines will ensure that you use the bandsaw correctly and get the best results from your woodworking projects. Happy sawing!