Are you wondering which way does plywood go? Don’t worry, I’ve got you covered! Plywood is a versatile material used in many construction and DIY projects. Understanding the proper orientation of plywood is crucial for its structural integrity and appearance. In this article, we’ll explore the different factors that determine which way plywood should go, so you can confidently tackle your next project.

When it comes to plywood, there’s a right way and a wrong way to orient it. The direction in which the grain runs can affect its strength, stability, and overall performance. We’ll delve into the details of how to identify the grain direction and make informed decisions based on the specific application.

Whether you’re using plywood for subflooring, cabinets, furniture, or any other project, knowing which way plywood goes is an essential piece of knowledge. So let’s dive in and unravel the mysteries of plywood orientation together!

Which Way Does Plywood Go? Understanding the Grain Direction

What is Plywood and its Grain Direction?

Plywood is a versatile and widely used material in construction, furniture-making, and other woodworking projects. It is made by layering thin plies of wood veneer and bonding them together with adhesive. These layers are typically arranged at right angles to each other, creating a strong and stable panel. Understanding the grain direction of plywood is crucial for its proper usage and installation.

Plywood has a distinct grain pattern due to its construction. The direction of this grain refers to the orientation of the face veneer, which can be either cross-grain or long-grain. Cross-grain plywood has the face veneer perpendicular to the length of the sheet, while long-grain plywood has the face veneer parallel to the length of the sheet. The grain direction affects the strength, stability, and appearance of the plywood.

It’s important to note that the grain direction of plywood is different from solid wood. In solid wood, the grain refers to the alignment of the wood fibers along the length or width of the board, whereas in plywood, it pertains to the face veneer orientation.

Importance of Grain Direction

The grain direction of plywood plays a significant role in its performance and application. Here are a few key reasons why understanding the grain direction is essential:

- Strength and Stability: The grain direction affects the strength and stability of plywood. Cross-grain plywood tends to be stronger and stiffer, making it suitable for structural applications. Long-grain plywood, on the other hand, is more flexible and is often used for curved surfaces or in situations where flexibility is required.

- Compatibility with Joinery: Joinery techniques such as butt joints, dado joints, and rabbet joints can be affected by the grain direction of plywood. Proper alignment of the grain ensures stronger and more durable joints.

- Appearance and Finishing: The grain direction impacts the visual appearance of plywood. Depending on the desired aesthetic, choosing the right grain direction can result in a more pleasing and cohesive look. It also affects how finishes and stains interact with the plywood surface.

How to Determine the Grain Direction?

Determining the grain direction of plywood is relatively simple. Here are a few methods to help you identify it:

- Look at the Veneer End: Examine the exposed end of the plywood sheet. The lines you see running across the width indicate the grain direction. If the lines are parallel to the short edge, it is cross-grain plywood. If they are parallel to the long edge, it is long-grain plywood.

- Observe the Plywood Edges: The edges of plywood will also reveal the grain direction. If the layers are visible and running perpendicular to the edge, it is cross-grain plywood. If they are running parallel to the edge, it is long-grain plywood.

- Check the Manufacturer’s Label: The grain direction is often indicated on the manufacturer’s label or packaging. This information can be helpful, especially when the other methods are inconclusive.

Tips for Using Plywood with the Grain Direction

Now that you understand the importance of the grain direction of plywood, here are a few tips to keep in mind when using it:

- Align Grain for Strength: When joining plywood pieces together, ensure that the grain direction is aligned for maximum strength and durability.

- Consider Aesthetic Appeal: If the visual appearance of the plywood is a priority, choose the grain direction that complements your desired aesthetic. This is particularly important when the plywood will be left unfinished or lightly finished.

- Plan for Flexibility: If you anticipate the need for flexibility in your project, opt for long-grain plywood to accommodate bending or curving.

- Use Proper Joinery Techniques: Depending on the grain direction, select appropriate joinery techniques that make the most of the plywood’s strength and stability.

Beyond Grain Direction: Essential Considerations for Working with Plywood

Choosing the Right Plywood Grade for Your Project

Not all plywood is created equal, and selecting the right grade is vital for the success of your project. Plywood grades are determined by the quality and appearance of the face veneer, as well as the number of defects it may have. Here are some common plywood grades:

| Grade | Description | Applications |

|---|---|---|

| A | Smooth, sanded finish with minimal defects | Furniture, cabinetry, high-end projects |

| B | More prominent defects compared to grade A | Structural applications, subflooring |

| C | More noticeable defects, often with visible patches | Non-visible structural applications, sheathing |

| D | Contains numerous defects and knots | Temporary structures, rough shelving |

Consider the grade that suits your project requirements and budget.

Plywood Thickness Matters

The thickness of plywood is another crucial factor to consider. It influences the overall strength, weight, and rigidity of the material. Common plywood thicknesses range from 1/8 inch (3mm) to 3/4 inch (19mm), with intermediate sizes available. Thicker plywood is generally sturdier, but it may not be necessary for every application. Assess the load-bearing requirements and structural demands of your project before selecting the appropriate thickness.

Finishing Techniques for Plywood

While plywood is often used as a structural material, it can also be a prominent design feature when finished correctly. Here are a few popular finishing techniques:

- Painting: Plywood can be painted with various types of paint, allowing you to customize its appearance to match your project or decor.

- Staining: For a more natural, wood-like look, consider staining the plywood. It enhances the grain and brings out the beauty of the material.

- Veneering: Veneer sheets can be applied to plywood to mimic the look of solid wood or achieve unique patterns and designs.

- Clear Finish: If you want to showcase the natural beauty of the plywood, a clear finish such as varnish or lacquer can be applied to protect the surface while maintaining its original appearance.

Caring for and Maintaining Plywood

Protecting Plywood from Environmental Factors

Plywood is susceptible to damage from moisture, temperature fluctuations, and exposure to the elements. Here are some tips for protecting plywood:

- Sealing: Apply a water-resistant sealer or preservative to the plywood surface, paying special attention to the edges and any exposed areas.

- Proper Storage: Store plywood in a dry area, away from direct sunlight and moisture. Stack it vertically to prevent warping.

- Accurate Installation: Ensure proper installation with appropriate fasteners and adequate ventilation to prevent moisture buildup.

Regular Maintenance and Inspection

Regular maintenance and inspection will help prolong the lifespan of plywood and ensure its structural integrity. Follow these guidelines:

- Cleanliness: Regularly clean the plywood surface using a mild detergent and a non-abrasive cloth or sponge.

- Surface Protection: Use coasters, placemats, or protective pads to shield plywood from scratches, heat, and moisture.

- Watch for Signs of Damage: Inspect the plywood for any signs of delamination, rot, mold, or other issues. Address them promptly to prevent further damage.

In conclusion, understanding the grain direction of plywood is crucial for achieving optimal strength, stability, and aesthetics in your projects. Whether you’re working with cross-grain or long-grain plywood, aligning the grain for optimal performance and selecting the right grade, thickness, and finish are essential considerations. By following proper installation techniques and maintaining plywood properly, you can ensure its longevity and make the most of this versatile material. Remember to seek professional advice when necessary and always prioritize safety in your woodworking endeavors.

Here are the key takeaways on “which way does plywood go?” in a conversational tone for a 13-year-old kid:

Key Takeaways:

- Plywood can be oriented either vertically or horizontally, depending on the project’s needs.

- If plywood is used for sheathing, it’s typically installed horizontally to provide stability and strength to the structure.

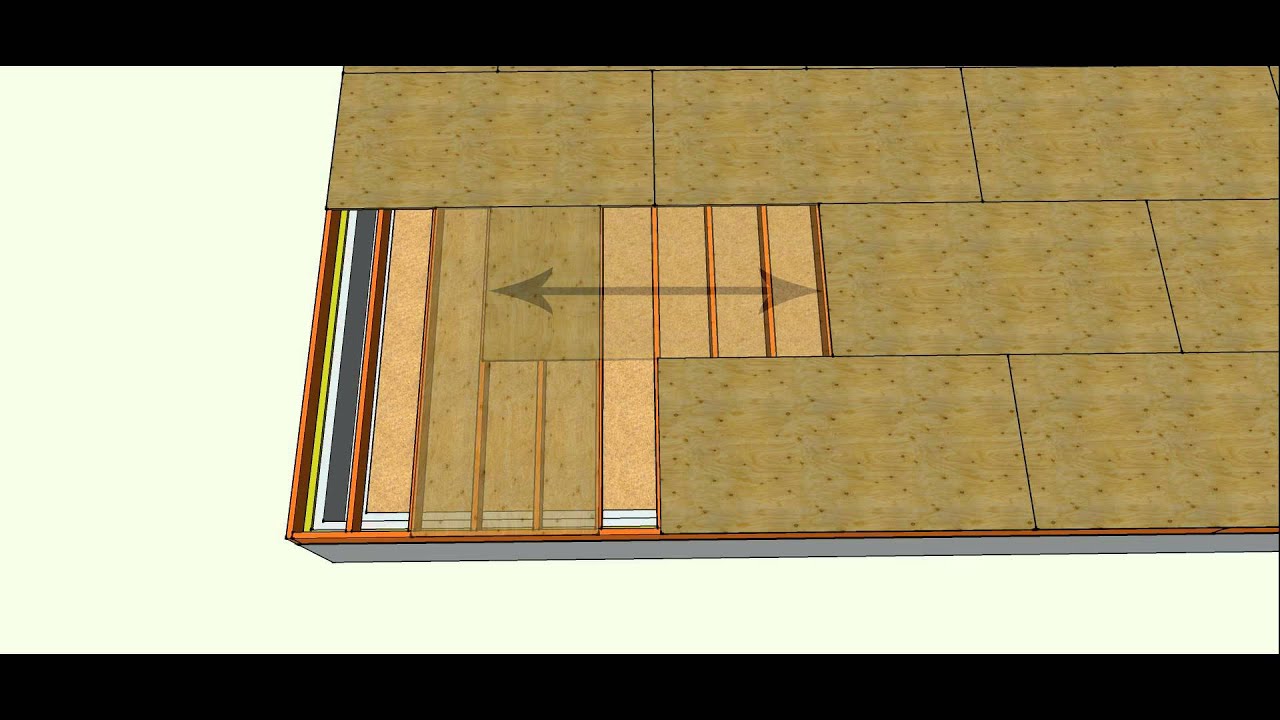

- For subflooring, plywood should be laid with the long side perpendicular to the floor joists for optimum stability.

- When using plywood for fine woodworking projects, the direction of the grain may be considered for aesthetic purposes.

- Always refer to the project plans or consult with an experienced professional to determine the best orientation for plywood in your specific project.

Frequently Asked Questions

Welcome to our FAQ section where we answer your most pressing questions about the orientation of plywood. Read on to find out which way plywood should go to ensure proper installation and optimal performance.

Does plywood have a specific direction it should face during installation?

Yes, plywood does have a preferred direction during installation. The long edges, also known as the grain or the direction of the veneer strips, should be perpendicular to the framing below. This means that the plywood should be oriented with the long edges running perpendicular to the floor joists or wall studs. By positioning the plywood in this way, it helps to distribute the weight evenly across the framing and enhances the structural integrity of the installation.

Orienting the plywood perpendicular to the framing also helps to minimize issues such as sagging, flexing, and squeaking in the floor or wall. It provides better support and stability, especially when heavy loads are placed on the surface. Additionally, this orientation also facilitates a stronger bond between the plywood and the framing, reducing the risk of nails or screws loosening over time.

What happens if plywood is installed in the wrong direction?

If plywood is installed in the wrong direction, it can lead to several problems. One common issue is sagging or flexing of the surface, especially when weight is applied. This can result in a bouncy or uneven floor/wall, which can be both uncomfortable and potentially hazardous. Incorrect orientation can also increase the likelihood of squeaks and creaks when walking or moving on the surface.

Furthermore, installing plywood in the wrong direction may compromise the strength and stability of the installation. It can weaken the bond between the plywood and the framing, making it more susceptible to movement and damage. Over time, the fasteners (nails or screws) may loosen, causing the plywood to shift or detach from the framing. This can lead to a decrease in the overall structural integrity of the surface and may require costly repairs.

Can plywood be installed diagonally or at an angle?

Yes, plywood can be installed diagonally or at an angle, but it requires additional considerations and techniques. Diagonal installation can add visual interest to a surface and may be preferred for certain aesthetic reasons. However, it is important to note that diagonal installation typically requires more plywood and can be more complex to install, as it involves cutting and fitting the plywood at specific angles.

When installing plywood diagonally, it is crucial to ensure proper support and proper attachment to the framing. Additional blocking or bridging may be necessary to provide sufficient stability and prevent sagging or flexing. It’s also important to follow manufacturer guidelines and building codes to ensure the correct installation method for diagonal plywood. Consulting with a professional or experienced contractor is advisable for diagonal or angled installations.

Are there specific considerations for plywood installation on a subfloor?

Yes, when installing plywood as a subfloor, there are specific considerations to keep in mind. In addition to following the recommended orientation with the long edges perpendicular to the floor joists, it’s important to consider the subfloor thickness and the type of plywood being used. The thickness of the plywood should be appropriate for the span between the floor joists to prevent surface deflection or sagging.

It’s also crucial to ensure a secure attachment of the plywood subfloor to the floor joists. This typically requires using appropriate fasteners, such as nails or screws, and spacing them according to the manufacturer’s guidelines. Properly securing the subfloor helps to reduce movement, minimize squeaking, and enhance the overall stability and durability of the floor. Following building codes and consulting with professionals can provide valuable guidance for plywood subfloor installations.

Is there a recommended orientation for plywood on walls?

Yes, there is a recommended orientation for plywood on walls. Similar to the installation on floors, the long edges of the plywood should be perpendicular to the wall studs. This orientation helps to ensure better structural integrity, stability, and proper attachment of the plywood to the wall framing. The perpendicular orientation also allows for a stronger bond between the plywood and the studs, minimizing the risk of nails or screws loosening over time.

When installing plywood on walls, it’s essential to follow building codes and guidelines specific to your region. Additionally, it’s important to consider the purpose of the wall and any specific requirements for load-bearing capacity or moisture resistance. Consulting with professionals or experienced contractors can provide valuable insights and ensure that the plywood is installed correctly to meet your specific needs.

Summary

So, to sum it up, when it comes to plywood, there are a few things to keep in mind. Firstly, the direction of the grain is important – make sure it runs parallel with the longest side of your project. Secondly, check for any imperfections like knots and voids, as these can weaken the wood. Lastly, don’t forget to sand and seal the edges to prevent moisture damage.

By following these tips, you’ll be on your way to using plywood confidently in your projects. Remember, plywood is a versatile and cost-effective material that can be used for a variety of purposes. Whether you’re building furniture, shelves, or even a small DIY project, knowing which way to place your plywood will ensure a strong and durable end result. Happy building!