If you’ve ever wondered, “Which way should a lathe turn?” you’ve come to the right place. The direction a lathe turns is a fundamental question for anyone interested in woodworking or metalworking. In this article, we’ll explore the answer in a way that’s easy to understand and apply. So, let’s dive in and demystify the mystery of lathe rotation!

Understanding the proper direction for a lathe to turn is crucial for achieving accurate and safe results. Whether you’re a beginner or a seasoned craftsman, knowing which way to go can make all the difference. Stick around as we break down the basics and provide you with a clear understanding of lathe rotation. Get ready to spin, learn, and create amazing things with your lathe in no time!

So, are you ready to discover the secrets of lathe rotation? Join us as we unravel the mystery behind this important aspect of woodworking and metalworking. From understanding the basics to choosing the right direction for your lathe, we’ve got you covered. Let’s embark on this exciting journey together and unlock the immense potential of your lathe machine!

Which Way Should a Lathe Turn?

Introduction:

When operating a lathe, one of the most important considerations is understanding the direction in which the lathe should turn. The rotation of the lathe can have a significant impact on the outcome of your machining project. In this article, we will explore the correct direction for a lathe to turn, the reasons behind it, and the implications for different cutting operations. Whether you are a beginner or an experienced machinist, understanding the proper rotation of the lathe will help you achieve precise and efficient results.

The Standard Direction: Clockwise Rotation

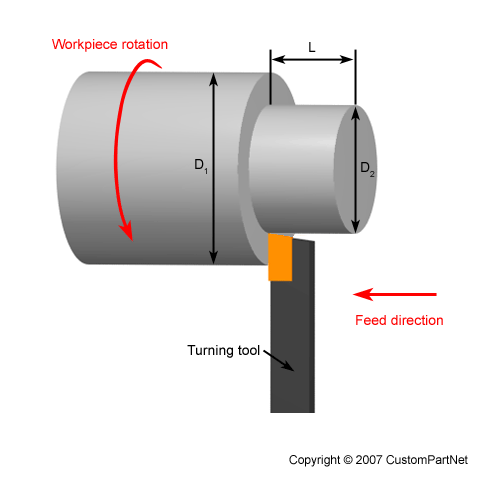

In most situations, the standard direction for a lathe to turn is a clockwise rotation. This means that when facing the machine, the workpiece will rotate in a clockwise direction. There are several reasons why clockwise rotation is the norm in lathe operations.

Firstly, the clockwise rotation aligns with the conventional way in which threads are cut. When cutting external threads on a lathe, the cutting tool moves from left to right, creating threads that spiral in a clockwise direction. By rotating the workpiece clockwise, it ensures that the threads are properly formed.

Secondly, the clockwise rotation also facilitates chip removal. When machining a workpiece, chips are generated as the cutting tool engages with the material. The clockwise rotation helps the chips to be efficiently evacuated from the cutting zone, reducing the risk of chip buildup and improving the efficiency of the cutting process.

Lastly, the direction of clockwise rotation is consistent with the majority of lathes available in the market. Manufacturers design their machines and cutting tools with the assumption that the lathe will rotate in a clockwise direction. Therefore, following the standard rotation ensures compatibility and maximizes the availability of tooling options.

Exceptions to the Standard Rotation

While the standard direction for a lathe to turn is clockwise, there are a few exceptions where counterclockwise rotation may be necessary or beneficial. Let’s explore some of these exceptions and understand the factors influencing the choice of rotation direction.

One such exception is when using single-point threading tools with a left-hand cutting edge. These tools are specifically designed for counterclockwise rotation. If you need to cut left-hand threads or have a particular cutting operation that requires the use of left-hand tools, you would need to reverse the rotation of the lathe, turning it counterclockwise.

Additionally, some specialized machining operations, such as certain types of milling and drilling, may require counterclockwise rotation for optimal results. It is important to consult the manufacturer’s guidelines and the specific requirements of your machining process to determine if counterclockwise rotation is necessary or beneficial.

Maintaining Consistency in Rotation

Consistency in rotation direction is crucial to ensure accurate and repeatable machining results. It is recommended to establish a standard direction of rotation for your lathe and adhere to it consistently. This minimizes the chance of errors, simplifies tooling selection, and allows for better process control.

To maintain consistency, it is helpful to mark the lathe spindle or the chuck with an arrow indicating the proper rotation direction. This serves as a visual reminder for operators and prevents accidental rotation in the wrong direction. Regular training and communication with machine operators are also essential to ensure awareness and adherence to the standard rotation direction.

The Role of Lathe Reversibility

Some lathes come equipped with a feature called “lathe reversibility.” This feature allows the operator to change the direction of rotation easily. While lathe reversibility can provide flexibility, it is important to exercise caution when using it.

When switching the rotation direction, it is crucial to ensure that the cutting tool and workpiece are securely held in place and that the machine components can handle the reversed forces. Improper setup or insufficient rigidity can lead to tool breakage, workpiece damage, or even accidents. Always refer to the lathe’s user manual and follow the manufacturer’s instructions for safe operation when utilizing lathe reversibility.

Choosing the Right Cutting Tools

To achieve optimal results in lathe operations, it is essential to select the appropriate cutting tools for the desired rotation direction. Ensure that the cutting tools you use are designed for the specific direction of rotation, as mismatched tooling can lead to poor surface finish, chatter, or premature tool wear.

When selecting cutting tools, consider factors such as tool geometry, rake angles, and chip evacuation capabilities. Matching the tool specifications to the intended rotation direction will help you achieve better cutting performance, longer tool life, and superior machining outcomes.

Conclusion

Understanding the correct direction for a lathe to turn is fundamental for achieving accurate and efficient machining results. In the majority of cases, the standard direction is a clockwise rotation, which aligns with conventional threading methods, aids chip removal, and ensures compatibility with tools and machines. However, there are exceptions where counterclockwise rotation may be necessary or beneficial, especially for specific cutting operations. By maintaining consistency in rotation, utilizing lathe reversibility with caution, and selecting the right cutting tools, you can optimize your lathe operations and enhance the quality of your machined components.

Key Takeaways: Which Way Should a Lathe Turn?

- A lathe should turn in a counter-clockwise direction, also known as the “standard rotation.”

- Turning a lathe in the wrong direction can damage the workpiece and result in an unsafe working environment.

- Always consult the lathe’s user manual or manufacturer for specific instructions on the direction of rotation.

- In general, lathes are designed to rotate towards the operator for better visibility and control.

- If unsure, ask an experienced lathe operator or seek guidance from a professional.

Frequently Asked Questions

When operating a lathe, it is crucial to know the correct direction in which it should turn. Here are some common questions and answers regarding the direction of a lathe.

1. Which way should the spindle of a lathe turn?

The spindle of a lathe should typically turn clockwise when viewed from the operator’s side. This direction is referred to as “normal rotation” for most lathes. Clockwise rotation ensures that the cutting tool moves from right to left, allowing for smoother cutting and better control.

However, it’s important to note that there are some instances where a lathe may have reverse rotation, such as for specific operations or as specified by the manufacturer. Always consult the lathe’s manual or instructions for the specific direction of rotation.

2. What could happen if a lathe turns in the wrong direction?

If a lathe turns in the wrong direction, it can lead to various issues. For example, if the spindle turns counterclockwise instead of clockwise (assuming normal rotation), it can cause the cutting tool to dig into the material, resulting in rough cuts, tool breakage, and even damage to the lathe itself.

Turning in the wrong direction can also impact the accuracy of the cuts and negatively affect the surface finish of the workpiece. Additionally, if the lathe has specific reverse rotation functions and it is not utilized correctly, it may compromise the intended outcome of the operation. Therefore, it is crucial to understand and follow the correct direction of rotation for your particular lathe.

3. Can the direction of a lathe be changed?

In most cases, the direction of a lathe’s rotation can be changed. This can be done by adjusting the lathe’s motor or by flipping an electrical switch to reverse the motor’s direction. However, it’s important to remember that changing the direction should be done with caution, following the manufacturer’s instructions and guidelines.

Before attempting to change the direction of rotation, ensure that the lathe is turned off and unplugged from the power source. Additionally, consult the lathe’s manual or contact the manufacturer to determine the correct procedure for your specific lathe model. Incorrectly changing the direction of rotation can lead to operational issues and potentially cause damage to the lathe.

4. Why is it important to know the direction of lathe rotation?

Knowing the direction of lathe rotation is important for several reasons. Firstly, it ensures the smooth and controlled movement of the cutting tool across the workpiece, resulting in accurate cuts and improved surface finish. Secondly, it helps to prevent potential damage to the lathe, the cutting tool, and the workpiece.

Understanding the correct direction of rotation also plays a vital role in maintaining safety standards. By following the recommended rotation, operators can minimize the risk of accidents and injuries. Additionally, when working on complex projects or using specific cutting techniques, knowing the direction of rotation enables efficient planning and execution of the desired outcome.

5. How can I determine the rotation direction of a lathe?

Determining the rotation direction of a lathe can be done by visual inspection. Stand in front of the lathe, facing the side where the operator controls are located. If the spindle rotates clockwise when turned on, it indicates normal rotation. If it rotates counterclockwise, the rotation is reversed.

If you are unsure about the direction or need confirmation, consult the lathe’s manual or contact the manufacturer for guidance. It is always better to be safe and certain when it comes to operating machinery, especially if you are unfamiliar with a particular lathe model.

The Wood Turning Lathe A to Z for Beginners, a Roger Webb easy learning tutorial

Summary

When operating a lathe, the direction it should turn depends on the type of material being worked on. For softer materials like wood, the lathe should turn clockwise. For harder materials like metal, it should turn counterclockwise. This is because different materials require different cutting actions to achieve the best results.

Furthermore, the direction of the lathe’s rotation affects the direction of the cutting tool’s movement. Clockwise rotation causes the tool to cut from left to right, while counterclockwise rotation cuts from right to left. It’s important to match the rotation and cutting direction to ensure smooth and precise cuts. So, remember, when it comes to lathes, the rule of thumb is: soft materials, clockwise; hard materials, counterclockwise.