Picture this: you’re all set to tackle a DIY project or help out with a household repair, armed with your trusty power drill. But as you go to insert the drill bit, you notice something strange—they’re so short! You might be scratching your head, wondering, “Why are drill bits so short?” Well, my curious friend, let’s delve into the world of drilling and discover the reasons behind this intriguing phenomenon.

Drill bits have a fascinating history, and their design has evolved over time to meet specific needs. The short length of drill bits actually serves a purpose. You see, drill bits are designed to be used with power tools like drills, which provide the necessary force and rotation needed for drilling holes. Their shorter length allows for increased stability and control when using these power tools.

But that’s not all—shorter drill bits are also more efficient. By reducing the length of the bit, manufacturers can optimize the cutting angle and improve the overall drilling speed. This means you can get your drilling tasks done faster and with less effort. So the next time you wonder why drill bits are so short, remember that it’s all about maximizing precision, control, and speed for your drilling adventures. Time to grab that power drill and get to work!

Have you ever wondered why drill bits are so short? Well, there are a few reasons for this. Firstly, shorter drill bits provide greater control and precision when drilling into a material. Additionally, shorter bits reduce the risk of breakage or bending, especially when drilling through hard surfaces. Finally, shorter bits are more portable and easier to store. So, even though they may seem small, short drill bits are designed to offer optimal performance and convenience.

Why Are Drill Bits So Short?

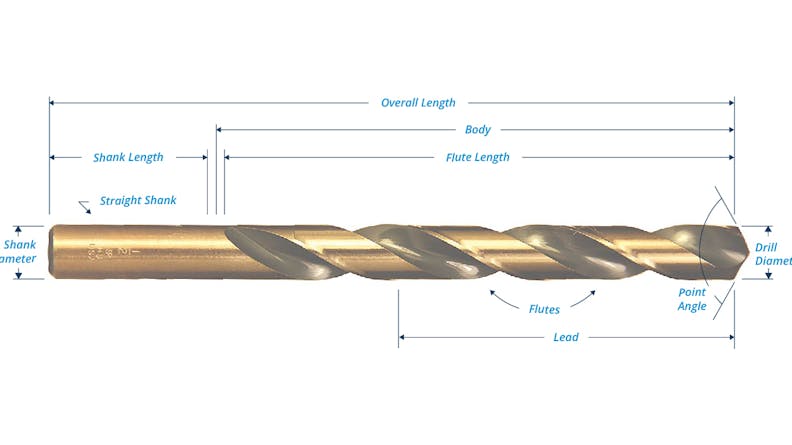

Drill bits are essential tools in various industries, from construction to woodworking. These cylindrical cutting tools are designed to create holes in different materials, such as wood, metal, or plastic. However, one common characteristic of drill bits that often raises questions is their short length. In this article, we will delve into the reasons why drill bits are typically shorter in size, explore the advantages of shorter drill bits, and provide tips for using them effectively.

1. Precision and Control

One of the main reasons why drill bits are often short is to provide better precision and control during drilling. Shorter drill bits allow for more stability as they have less tendency to flex or wobble. This is particularly important when drilling delicate materials or when you need to maintain accuracy and avoid damaging the workpiece. The shorter length gives the user better control over the drilling process, ensuring consistent and accurate results.

Shorter drill bits are also less prone to breakage or damage compared to longer ones. The shorter length reduces the chances of the bit bending or snapping, especially when drilling through harder materials. Additionally, shorter drill bits are more sturdy and less likely to waver or deviate from the intended drilling path.

While longer drill bits may be necessary for certain applications, such as drilling deep holes or reaching inaccessible areas, the shorter length provides a more reliable and manageable tool for everyday drilling tasks.

2. Efficient Chip Removal

Another advantage of shorter drill bits is their ability to efficiently remove chips or waste materials during the drilling process. Shorter drill bits generate less heat and friction, resulting in smaller and more manageable chips. The shorter length allows for better chip evacuation as the chips have a shorter distance to travel out of the hole.

In contrast, longer drill bits have a higher risk of chip clogging and inadequate chip removal. This can lead to overheating and reduced cutting performance. Shorter drill bits are particularly beneficial when drilling in materials prone to chip clogging, such as PVC or certain metals. The efficient chip removal helps to maintain the drill bit’s cutting efficiency and prolong its lifespan.

Additionally, shorter drill bits reduce the likelihood of chips tangling around the flutes, which can cause the bit to jam or break. The shorter length ensures a smoother drilling experience, saving time and effort.

3. Versatility and Maneuverability

Shorter drill bits offer greater versatility and maneuverability in various drilling scenarios. The compact size allows for easier access to tight spaces, corners, and hard-to-reach areas. This is particularly valuable in woodworking or construction projects where precision and accessibility are crucial.

Shorter drill bits also provide enhanced maneuverability when operating handheld or portable drills. The reduced length minimizes the risk of the drill bit hitting obstacles or causing damage in confined spaces. It allows users to navigate around obstacles and work with greater flexibility, ensuring accurate and efficient drilling operations.

Furthermore, shorter drill bits are compatible with a wider range of drills, including those with limited chuck capacities or designed for shorter tool lengths. This increases the compatibility and versatility of the drill bits, making them accessible to a wider range of users and applications.

4. Tips for Using Short Drill Bits Effectively

When working with short drill bits, it is essential to follow some tips to maximize their effectiveness and ensure a successful drilling experience:

- Select the appropriate drill bit size and type for the material you are working with. Consider the hardness and thickness of the material to choose the right bit.

- Secure the workpiece firmly to prevent it from moving or vibrating during drilling. This helps to maintain accuracy and avoid potential accidents.

- Apply steady and consistent pressure when drilling, avoiding excessive force that can damage the drill bit or the material.

- Use short bursts of drilling followed by clearing out any debris or chips to maintain optimal cutting performance.

- If drilling deep holes, periodically remove the drill bit to clear out the chips and prevent overheating.

- Regularly inspect the drill bit for any signs of wear or damage. Replace worn or damaged drill bits to ensure safe and efficient drilling.

- Always wear appropriate safety gear, including safety goggles and gloves, when operating power tools.

Why Choose Short Drill Bits?

Short drill bits offer several advantages that make them a preferred choice for many drilling tasks:

1. Increased Precision and Control

The shorter length of drill bits provides better precision and control, reducing the likelihood of errors or damage to the workpiece. This is particularly important for precise and delicate drilling operations where accuracy is crucial.

2. Efficient Chip Removal

Short drill bits excel in chip removal, ensuring smooth and uninterrupted drilling. The shorter length allows for efficient evacuation of chips, preventing clogging and overheating.

3. Versatility and Maneuverability

Short drill bits are highly versatile and maneuverable, making them suitable for various drilling scenarios, including tight spaces and hard-to-reach areas. Their compact size also enhances compatibility with different types of drills.

Choosing the Right Drill Bit Length

When choosing drill bits, it is essential to consider the specific drilling requirements and the material you will be working with. While short drill bits provide numerous benefits, there are instances where longer drill bits may be more appropriate.

For drilling deep holes or accessing tight spaces within a workpiece, longer drill bits may be necessary. Additionally, when using drilling machines or specialized drilling equipment, longer bits are often used to accommodate the machine’s design and capabilities.

It is advisable to have a mix of short and long drill bits in your toolkit to cater to different projects and applications. This ensures that you always have the right tool for the job, whether it requires precision and control or accessibility to confined areas.

Maintaining Your Drill Bits

Proper maintenance is essential for extending the lifespan and ensuring the optimal performance of your drill bits:

- Regularly clean the drill bits after each use to remove debris and prevent it from accumulating.

- Inspect the cutting edges for any signs of wear, dullness, or damage. Sharpen or replace the bits as necessary.

- Store the drill bits in a clean and dry place to prevent rust or corrosion.

- Use lubrication or cutting oil when drilling through hard materials to reduce heat and extend the drill bits’ lifespan.

By following these maintenance tips, you can keep your drill bits in top condition, ensuring optimal performance and longevity.

The Art of Short Drilling

Short drill bits play a vital role in various industries, offering precision, control, and efficiency in drilling operations. Understanding the advantages of shorter drill bits and learning how to use them effectively can greatly enhance your drilling experience.

Remember to choose the appropriate drill bit size and type for your specific needs, secure the workpiece properly, and maintain your drill bits regularly. By harnessing the benefits of short drill bits and employing proper techniques, you can achieve accurate, efficient, and successful drilling results.

Key Takeaways: Why Are Drill Bits So Short?

- Drill bits are short because they need to fit inside a drill’s chuck, which is a tight space.

- Shorter drill bits offer better stability and control while drilling, especially in tight or confined spaces.

- Shorter drill bits reduce the chances of the bit wandering or breaking during drilling.

- The length of a drill bit is determined by the thickness of the material it is designed to drill through.

- For longer holes or deeper drilling, longer drill bits or drill bit extensions can be used.

Frequently Asked Questions

When it comes to drill bits, you may have noticed that they are often shorter than you would expect. You might be wondering why this is the case. In this section, we will answer some common questions about why drill bits are so short and explore the reasons behind it.

1. Why do drill bits have a short length?

The primary reason why drill bits are short is because they need to be rigid and robust. A shorter length allows for more stability, reducing the chances of bending or breaking during drilling. Longer drill bits have a higher risk of flexing or wobbling, which can lead to inaccurate holes or even accidents.

Additionally, a shorter length provides more control over the drilling process. It allows the user to maintain better balance and precision, especially when working in tight spaces. So, while longer drill bits may seem more versatile, shorter ones are designed for greater strength and accuracy.

2. Can longer drill bits be used for all applications?

Longer drill bits certainly have their uses, but they are not suitable for all applications. While they may be necessary for drilling deep holes or reaching inaccessible areas, their longer length can make them prone to flexing or breaking, especially when used with handheld power drills.

Moreover, longer drill bits may not fit well in standard drill chucks or smaller drills. They require more power, stability, and control, which may not be achievable with certain tools. Shorter drill bits, on the other hand, offer versatility and compatibility across a wide range of drilling tasks, making them the go-to choice for most applications.

3. Are there any disadvantages to using shorter drill bits?

While shorter drill bits provide numerous advantages, such as stability, control, and compatibility, they do have some limitations. One of the main drawbacks is their reduced reach. As they are shorter, they can only drill to a certain depth, which may be insufficient for certain projects that require drilling through thick materials or deep holes.

Additionally, shorter drill bits may not be ideal for drilling through multiple layers of materials, where a longer bit would be necessary to reach the desired depth. In such cases, alternative drilling methods or specialized longer drill bits may be required.

4. Can shorter drill bits drill through thick materials?

Shorter drill bits are indeed capable of drilling through thick materials, but there are certain factors to consider. The material being drilled, the hardness of the material, and the type of drill bit used all play a role in determining the effectiveness of the drilling process.

For harder materials like metal or concrete, shorter drill bits with specialized coatings or high-speed steel construction may be required. These bits are designed to withstand the rigors of drilling through tough surfaces. However, for extremely thick materials, longer drill bits or specialized drilling techniques may be more appropriate.

5. Are there longer drill bits available for specific applications?

Absolutely! There are longer drill bits available for specific applications where a deeper reach or increased flexibility is necessary. For example, when drilling through walls, longer drill bits can reach through the insulation and studs to create holes for wiring, plumbing, or mounting purposes.

These longer drill bits are often used in conjunction with drill extensions or other specialized tools to achieve the desired depth. They are commonly utilized in construction, woodworking, and other industries where precision and longer reach are essential.

11 DRILLING TIPS AND TRICKS (And Mistakes To Avoid!)

Summary

Drill bits are short because they need to be strong and sturdy to withstand drilling. The shorter length helps to prevent bending and breaking. Additionally, shorter bits offer better control and accuracy when drilling into materials.

Longer drill bits are more likely to wobble and vibrate, leading to less precise drilling. Shorter bits also allow for better visibility and access in tight spaces. So, while drill bits may be short, they are designed that way to ensure efficient and effective drilling.