If you’ve ever wondered why drill bits are so short, you’ve come to the right place! In this article, we’ll explore the reasons behind this common feature of drill bits. So if you’re ready to unravel the mystery, let’s dive in!

Now, you might be thinking, “Why does it even matter? Can’t longer drill bits reach deeper?” Well, my curious friend, there are a few factors at play here. We’ll discuss why drill bits are typically designed to be short and how it affects their performance.

So, grab your hard hat, put on your safety goggles, and let’s embark on this exploration into the fascinating world of drill bits! Let’s find out why they’re shorter than you might expect and uncover the secrets they hold!

Ever wondered why drill bits are so short? The length of drill bits is designed for maximum strength and stability during drilling. Shorter drill bits reduce the chance of bending or breaking, especially when drilling through tough materials. By keeping the length shorter, the bit is less prone to wobbling and ensures precise drilling. So, next time you use a drill bit, remember that its short length is a deliberate design choice for efficiency and durability.

Why Are Drill Bits So Short?

Drill bits are an essential tool in various industries and for DIY enthusiasts. They come in different lengths, but it’s common to wonder why drill bits are often so short. In this article, we will explore the reasons behind the shorter length of drill bits and how it affects their functionality and use. By understanding the reasons for their design, you can make informed decisions when selecting and using drill bits for your projects.

Short Drill Bits: Advantages and Applications

While the short length of drill bits may seem limiting, it actually offers several advantages and is suitable for specific applications. One advantage is increased stability and reduced flexing during drilling. Shorter drill bits experience less bending and are less likely to break, making them ideal for materials that require precise drilling, such as metal or hard plastic. Additionally, the compact size allows for easy maneuverability, especially in tight spaces or when working with handheld drills.

In terms of applications, short drill bits are commonly used in woodworking, cabinetry, electrical work, and general home repairs. The shorter length allows for greater control and accuracy when drilling pilot holes or creating shallow recesses for screws. They are also suitable for tasks that require drilling through thin materials or when you need to avoid going too deep, such as when installing hinges or mounting brackets.

The Importance of Flute Length

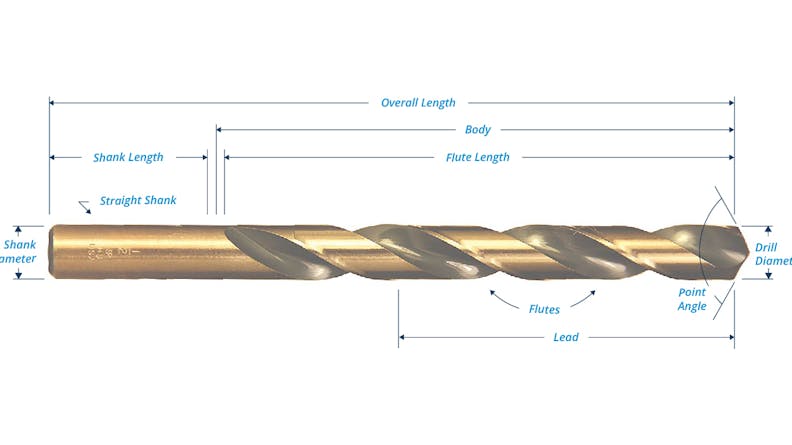

When discussing drill bit length, it’s important to understand the concept of flute length. The flute is the length of the drill bit that consists of spiral grooves, which help to remove excess material during drilling. The shorter the flute length, the more rigid the drill bit becomes. Rigid drill bits are less prone to wobbling or bending, resulting in cleaner and more accurate holes. However, it’s important to note that the flute length should be appropriate for the material being drilled. Using a drill bit with a flute length that is too short for a certain material may cause overheating or ineffective removal of debris.

Short drill bits with shorter flute lengths are commonly used for drilling shallow holes, such as when creating holes for dowels or aligning pieces of wood. Longer flute lengths are typically found in drill bits designed for deep drilling or when drilling through thick materials, like concrete or masonry. Therefore, when selecting a drill bit, consider the material and depth of the hole you need to create to ensure optimum performance.

Material Considerations for Short Drill Bits

The length of a drill bit also depends on the material it’s made from. Common materials used for drill bits include high-speed steel (HSS) and carbide. HSS drill bits are versatile and suitable for a wide range of materials, including wood, plastic, and softer metals. They are often shorter in length, making them more rigid and durable. On the other hand, carbide drill bits are known for their exceptional hardness and are primarily used for drilling through hard materials like concrete, masonry, or tiles. Due to the nature of these materials, carbide drill bits may have longer lengths to accommodate the specific requirements of drilling into tough surfaces.

It’s crucial to select the right drill bit material for your project to ensure efficient and effective drilling. Consider the material being drilled, its hardness, and the specific requirements of the job. Short drill bits made from HSS are a reliable option for most DIY projects, while longer carbide drill bits are better suited for specialized and heavy-duty applications.

Choosing the Right Length for Your Project

Selecting the appropriate drill bit length is essential for achieving accurate and successful drilling. Consider the thickness of the material you are drilling into, as well as the desired depth of the hole. For shallow holes, short drill bits are sufficient and provide better control. Conversely, for deeper holes or drilling through thick materials, longer drill bits are necessary to reach the desired depth.

Another factor to consider is the equipment you are using. Handheld drills have limitations in terms of the length they can accommodate. If you are using a handheld drill, ensure that the drill bit length is compatible with the drill’s chuck capacity. For projects requiring deeper holes, a drill press may be necessary, as it allows for greater depth control and can handle longer drill bits.

Maintaining and Storing Short Drill Bits

Proper maintenance and storage of drill bits, regardless of their length, is crucial to prolong their lifespan and maintain their performance. After each use, clean the drill bit thoroughly to remove any debris or residue that may affect future drilling. Regularly inspect the cutting edges and flute of the drill bits for signs of wear or damage. If any defects are detected, replace the drill bit to prevent potential accidents or subpar results.

To store drill bits, consider using a dedicated drill bit case or organizer. These containers are designed to hold the different sizes and types of drill bits securely, preventing them from getting lost or damaged. Alternatively, you can use a labeled toolbox or drawer with compartments to keep your drill bits organized and easily accessible when needed.

Efficient Drilling Tips and Safety Precautions

Whether you are using short drill bits or longer ones, it’s essential to follow proper drilling techniques and safety precautions. Here are a few tips to ensure efficient drilling and protect yourself during the process:

- Wear appropriate safety gear, including safety glasses, gloves, and a dust mask if necessary.

- Secure the material you are drilling into to prevent slipping or movement during drilling.

- Start drilling at a slow speed, gradually increasing the speed as the bit gains momentum.

- Apply consistent, gentle pressure without forcing the drill bit. Let the bit do the work.

- Use cutting oil or lubricant when drilling into metal or other hard materials to reduce heat and friction.

- Keep your hands away from the drilling area and ensure a stable footing to maintain balance.

- Before drilling, double-check that the drill bit is compatible with your drilling equipment.

By following these tips and taking the necessary precautions, you can achieve optimal drilling results and ensure your safety throughout the process.

Longevity and Versatility of Drill Bits

While short drill bits may not be suitable for all drilling situations, they have unique advantages in terms of stability, control, and maneuverability. By understanding the reasons behind their design and the appropriate applications, you can maximize their efficiency and achieve accurate drilling results. Remember to choose the right drill bit length based on the material, depth requirements, and the equipment you are using. With proper maintenance and adherence to safety guidelines, your drill bits, regardless of their length, can serve you well for a long time and prove to be a versatile tool in your toolbox.

Drill Bit Materials: Comparing HSS and Carbide

When it comes to drill bits, two common materials used are high-speed steel (HSS) and carbide. Understanding the differences between HSS and carbide drill bits can help you select the most suitable one for your specific drilling needs. In this section, we will compare HSS and carbide drill bits in terms of their composition, hardness, durability, and suitability for different materials and applications.

High-Speed Steel (HSS) Drill Bits

HSS drill bits are widely used and versatile, making them suitable for a wide range of drilling applications. They are composed of carbon steel, alloyed with elements such as tungsten, chromium, and vanadium. These alloys enhance the hardness and heat resistance of the drill bit.

One of the main advantages of HSS drill bits is their ability to withstand high temperatures generated during drilling. This makes them suitable for drilling into various materials, including wood, plastic, softer metals, and even some composites. HSS drill bits are available in different lengths to accommodate different drilling depths and are often shorter in length, ensuring better stability and reduced flexing during drilling.

Key Features of HSS Drill Bits:

- Versatile and suitable for many materials

- Good heat resistance

- Available in different lengths for specific drilling depths

- More affordable compared to carbide drill bits

Applications of HSS Drill Bits:

- Woodworking

- General construction and repairs

- Metalworking (for softer metals)

- Plastic fabrication

Carbide Drill Bits

Carbide drill bits are known for their exceptional hardness and heat resistance. They are composed of tungsten carbide, a compound of tungsten and carbon. This composition gives carbide drill bits their superior strength and durability, making them ideal for drilling into hard materials, such as concrete, masonry, tiles, and hardened steel.

One of the significant advantages of carbide drill bits is their ability to maintain sharpness and cutting efficiency even when subjected to high-speed drilling or drilling into tough surfaces. Carbide drill bits typically have longer lengths to account for the deeper holes required in some applications. It’s important to note that carbide drill bits are more brittle compared to HSS drill bits, making them susceptible to breakage if excessive force or pressure is applied during drilling.

Key Features of Carbide Drill Bits:

- Exceptionally hard and durable

- Retains sharpness and cutting efficiency

- Ideal for drilling into hard materials

- Longer lengths for deep drilling

Applications of Carbide Drill Bits:

- Concrete and masonry drilling

- Tile installation

- Drilling through hardened steel

- Specialized industrial applications

Choosing Between HSS and Carbide Drill Bits

When deciding between HSS and carbide drill bits, consider the materials you will be drilling into and the specific requirements of your project. HSS drill bits are versatile and suitable for a wide range of materials, making them a reliable choice for most DIY projects. On the other hand, if you frequently work with hard materials like concrete or need to drill into hardened steel, carbide drill bits will offer superior performance and durability.

It’s important to note that carbide drill bits are generally more expensive than HSS drill bits. Therefore, if your projects primarily involve softer materials, investing in carbide drill bits may not be necessary. HSS drill bits are more cost-effective and can still provide satisfactory results for most applications.

Ultimately, the choice between HSS and carbide drill bits depends on the specific demands of your projects, your budget, and the materials you regularly work with. Having a selection of both HSS and carbide drill bits in your toolbox ensures that you are adequately equipped to handle a variety of drilling tasks.

Choosing the Right Drill Bit Diameter

Choosing the right diameter of a drill bit is crucial for achieving accurate and efficient drilling results. The diameter refers to the width of the drill bit, which determines the size of the hole it creates. In this section, we will explore the factors to consider when selecting the appropriate drill bit diameter and how it affects drilling performance.

Matching the Drill Bit Diameter to the Screw Size

When drilling pilot holes for screws, it’s essential to match the drill bit diameter to the size of the screw. Using the correct diameter ensures a proper fit, prevents splitting or damaging the material, and ensures the screw holds securely. For common screw sizes, such as the popular #8 or #10, a drill bit with a diameter slightly smaller than the screw size is typically recommended. It’s advisable to consult a drill bit size chart or use a screw and drill bit gauge to determine the appropriate diameter for your specific screw size.

Drill Bit Diameter and Material Type

The material you are drilling into also influences the diameter of the drill bit you should use. Soft materials like wood or plastic often require a smaller diameter to prevent excessive removal of material and maintain stability during drilling. Larger diameters are suitable for drilling into harder materials like metal or concrete, as they provide sufficient space for the debris to be removed and reduce the risk of the drill bit binding or overheating.

It’s important to ensure that the diameter of the drill bit is appropriate for the material being drilled. Using a larger diameter than necessary can result in a hole that is too large, compromising the structural integrity of the material or weakening the grip of fasteners. Conversely, using a smaller diameter drill bit may cause the bit to become stuck or bind during drilling, leading to inefficient results or potential damage to the drill bit, material, or equipment.

Considerations for Deep Drilling

When drilling deeper holes, it’s essential to consider the drill bit diameter in relation to the hole size and its intended purpose. Smaller diameter drill bits are more rigid and less prone to bending or wobbling but may require more time and effort to achieve the desired depth. Conversely, larger diameter drill bits may provide faster drilling but are more susceptible to flexing or may require additional precision and control.

For deep drilling situations, it’s advisable to use a drill bit with a longer flute length. The flute length determines the amount of material the drill bit can remove and affects both the cutting performance and the effective drilling depth. The longer flute length ensures effective chip evacuation and prevents clogging, enabling efficient drilling and minimizing the risk of overheating or premature wear of the drill bit.

Considerations for Spade Bits and Hole Saws

When using spade bits or hole saws, which are designed for larger-diameter holes, it’s crucial to select the right bit for the job. These specialized drill bits have a specific range of diameters and are commonly used for tasks like creating large holes for plumbing or electrical conduits. It’s important to match the size of the spade bit or hole saw to the specific requirements of your project and ensure that your drill is compatible with the selected size.

With spade bits, it’s best to start with a pilot hole drilled by a smaller-diameter bit to guide the larger spade bit. This prevents the spade bit from wandering or slipping during the initial stages of drilling. Similarly, when using a hole saw, it’s important to have a pilot hole for its central drill bit to align and guide the saw’s cutting action. This approach ensures accurate and clean hole creation, especially when working with thicker materials or laminated surfaces.

Final Tips for Selecting Drill Bit Diameter

To recap, here are some final tips to help you choose the appropriate drill bit diameter for your drilling needs:

- Match the drill bit diameter to the size of the screw when drilling pilot holes for screws.

- Consider the material being drilled and select a diameter appropriate for its hardness and density.

- Ensure the drill bit diameter is compatible with the depth and purpose of the hole being drilled.

- For deep drilling, use a drill bit with a longer flute length for efficient chip evacuation and reduced heat buildup.

- When using spade bits or hole saws, start with a smaller-diameter pilot hole to guide the larger bit or saw.

By following these tips and considering the specific requirements of your project, you can select the right drill bit diameter and achieve precise and successful drilling results.

#Conclusion

Drill bits are available in various lengths, including shorter options that offer unique advantages such as increased stability and maneuverability. The short length is especially useful in applications where precise drilling is required, such as in woodworking, cabinetry, and electrical work. The flute length of a drill bit also plays a crucial role, with shorter flute lengths providing increased rigidity and cleaner holes.

It’s important to consider the material being drilled, as different materials may require varying flute lengths and drill bit materials. High-speed steel (HSS) and carbide are two common materials used for drill bits, each with its own set of advantages and applications. HSS drill bits are versatile and suitable for a wide range of materials, while carbide drill bits are known for their exceptional hardness and are primarily used for drilling into hard materials.

When selecting a drill bit diameter, it’s essential to match it to the size of the screw or the specific requirements of the hole being drilled. Consider the material and its hardness, as well as the depth and purpose of the hole. For deeper drilling, longer flute lengths and appropriate equipment may be necessary. Spade bits and hole saws also require careful consideration to ensure accurate hole creation.

By understanding the reasons why drill bits are often short and considering the specific requirements of your projects, you can choose the right drill bits and achieve accurate and efficient drilling results. Proper maintenance, storage, and adherence to safety guidelines will help prolong the lifespan and maintain the performance of your drill bits, ensuring they remain a versatile and reliable tool in your arsenal.

Key Takeaways: Why Are Drill Bits So Short?

- Drill bits are short to provide better control and precision while drilling.

- Shorter bits reduce the risk of breaking or bending during drilling.

- Short drill bits are suitable for shallow holes and tight spaces.

- Shorter length allows for easier maneuverability when working in confined areas.

- Longer drill bits are available for deeper holes or specialized tasks.

Frequently Asked Questions

Drill bits come in various sizes, including short ones. Below are some commonly asked questions related to the length of drill bits:

1. Can I use short drill bits for all drilling tasks?

Short drill bits are designed for specific tasks that require drilling shallow holes or working in tight spaces. They might not be suitable for deep holes or heavy-duty drilling. It is crucial to use the appropriate drill bit length based on the specific drilling requirements.

Using short drill bits for tasks they are not designed for can result in inefficient drilling, reduced accuracy, and even damage to the drill bit, the drilling surface, or the drilling equipment. It is always recommended to use the right drill bit length for the job at hand.

2. Why are some drill bits shorter than others?

Drill bits are available in various lengths to cater to different drilling needs. Short drill bits provide advantages in certain situations. They are specifically designed for tasks that require drilling shallow holes or working in confined spaces where longer bits cannot easily reach.

Short drill bits offer better control, stability, and precision in these situations. They are commonly used in woodworking, metalworking, and general DIY projects. Longer drill bits, on the other hand, are suitable for drilling deep holes or accessing hard-to-reach areas.

3. Are short drill bits less durable than longer ones?

The durability of a drill bit does not solely depend on its length but also on its quality and material composition. Short drill bits can be just as durable as longer ones if they are made from high-quality materials and designed to withstand the intended drilling applications.

However, it is important to note that shorter drill bits may have smaller shanks, which could affect their overall strength. It is advisable to select reputable brands and choose drill bits that match the intended drilling tasks for optimal durability and performance.

4. Can short drill bits produce the same level of accuracy as longer ones?

Short drill bits can provide a high level of accuracy, especially in applications that require precision. Being shorter in length, they offer better control and stability during drilling, resulting in more accurate holes. This makes them suitable for tasks where precision is crucial, such as woodworking, crafting, and fine detailing.

However, when drilling deeper holes or working on large-scale projects, longer drill bits may be more appropriate as they can reach greater depths and cover larger surface areas. The choice of drill bit length depends on the specific project requirements and the level of precision desired.

5. Are short drill bits only meant for handheld drills?

Short drill bits can be used with both handheld drills and drill presses. They are versatile tools that can accommodate a wide range of drilling equipment. Whether it’s a compact cordless drill or a powerful drill press, short drill bits can be mounted and used effectively.

However, it is crucial to ensure compatibility between the drill bit and the drill or drill press being used. Checking the chuck size, the drill’s maximum bit capacity, and the manufacturer’s recommendations will help ensure efficient and safe drilling operations.

11 DRILLING TIPS AND TRICKS (And Mistakes To Avoid!)

Summary

Ever wondered why drill bits are so short? Well, it’s to make them sturdy and strong.

Drill bits have to be short so they don’t wobble or break when drilling into hard materials. Plus, being short allows for better control and accuracy. So next time you pick up a drill, remember that short and mighty goes a long way!