Welcome to the fascinating world of Milwaukee tools! Ever wondered why these popular tools are made in China? Well, you’ve come to the right place. In this article, we’ll explore the reasons behind why Milwaukee tools are manufactured in China. So, let’s dive in and find out the story behind it!

Now, you might be thinking, “Why are Milwaukee tools made in China?” It all comes down to a combination of factors like cost-effectiveness, global supply chains, and market demand. China has long been known as the manufacturing hub of the world, offering affordable labor and resources to produce goods at competitive prices.

But it’s not just about cost. Milwaukee, like many other companies, recognizes the importance of reaching a wider customer base. By manufacturing their tools in China, they can tap into the massive Chinese market and expand their global presence. It allows them to cater to the growing demand for quality tools not just in the United States, but across the globe.

So, the next time you pick up a Milwaukee tool and wonder why it’s made in China, remember that it’s a strategic decision that benefits both the company and its customers. It’s all about providing high-quality tools at reasonable prices while also meeting the demands of a global market.

Why Are Milwaukee Tools Made in China?

When it comes to power tools, Milwaukee has established itself as a leading brand known for durability and performance. However, some consumers may be surprised to learn that many Milwaukee tools are actually made in China. In this article, we will explore the reasons behind this manufacturing decision and address any concerns or misconceptions surrounding the quality and reliability of these tools.

1) Cost-Effectiveness and Global Supply Chains

The primary reason why Milwaukee tools are made in China is cost-effectiveness. China has long been a global manufacturing hub, offering low labor costs and economies of scale that make production more affordable. By manufacturing in China, Milwaukee can keep its operating costs down and remain competitive in the market.

Furthermore, China has a well-developed infrastructure and an established supply chain network that supports efficient production and distribution. This allows Milwaukee to access a wide range of quality components and raw materials at competitive prices, ensuring that their tools meet the high standards expected by professionals and consumers alike.

It’s important to note that while manufacturing in China may lower production costs, it does not necessarily imply a compromise in quality. Milwaukee maintains stringent quality control measures and invests in research and development to ensure that their tools meet the same standards as those produced in other manufacturing locations.

2) Access to Skilled Labor and Technological Expertise

China boasts a large pool of skilled labor and a well-trained workforce in the manufacturing sector. This availability of skilled labor allows Milwaukee to tap into a talent pool that possesses the necessary expertise to produce high-quality power tools.

In addition to skilled labor, China also offers advanced technological capabilities. Chinese manufacturers invest heavily in research and development, continuously improving their manufacturing processes and adopting cutting-edge technologies. This technological expertise allows Milwaukee to leverage innovation and produce tools that meet the evolving needs of professionals.

By leveraging the expertise and technological advancements available in China, Milwaukee can create tools that are not only durable and reliable but also incorporate features and technologies that enhance the overall user experience.

3) Global Market Reach and Customer Preferences

Milwaukee is a global brand catering to customers around the world. Manufacturing in China allows the company to have a local presence in a strategically important market. This proximity to customers in China and other Asian countries enables Milwaukee to better understand and cater to their specific needs and preferences.

While Milwaukee manufactures tools in China, it is crucial to understand that the company enforces stringent quality control measures across all its manufacturing locations. This ensures that there is consistency in the quality and performance of their tools, regardless of where they are manufactured.

Additionally, manufacturing in China allows Milwaukee to access a vast consumer base in the Asian market. As the demand for power tools in this region continues to grow, producing tools locally ensures faster delivery times and reduces logistical costs, ultimately benefitting both Milwaukee and its customers.

4) Mitigating Supply Chain Disruptions

Another factor contributing to Milwaukee’s decision to manufacture tools in China is the need to diversify its supply chain and mitigate potential disruptions. By having manufacturing facilities in different regions, the company can better respond to geopolitical or economic challenges that may impact the supply of raw materials or components.

Having production facilities in China provides Milwaukee with a level of flexibility to adapt to changing market conditions and minimize the impact of any disruptions on its operations. This approach ensures that Milwaukee can continue to meet customer demand consistently and maintain a strong market position even during uncertain times.

It’s worth noting that Milwaukee continuously evaluates its manufacturing and supply chain strategies to optimize efficiency and maintain a high level of quality. As market dynamics evolve, the company may make adjustments to its manufacturing locations to best serve its customers and ensure long-term success.

Impact of “Made in China” Label on Consumer Perception

The label “Made in China” has often been associated with inferior quality and durability. However, it is important to recognize that this perception is not always accurate, especially in the case of respected brands like Milwaukee. While Milwaukee tools are made in China, the company maintains strict quality control measures to ensure that their products meet the same high standards regardless of the manufacturing location.

The Future of Milwaukee Tools Production

As Milwaukee continues to innovate and expand its product offerings, it is likely that the company will further optimize its manufacturing strategies. This may involve the establishment of production facilities in additional locations or adjustments to its existing manufacturing footprint based on market demands and supply chain considerations.

Ultimately, the goal of Milwaukee is to provide professionals and consumers around the world with high-quality, reliable power tools that meet their needs and expectations. By leveraging the advantages offered by manufacturing in China and other strategic locations, Milwaukee remains committed to delivering on this promise and maintaining its position as a leading brand in the industry.

Key Takeaways: Why are Milwaukee Tools Made in China?

- Milwaukee Tools are made in China due to the lower cost of labor and manufacturing.

- China has a well-developed infrastructure and skilled workforce, making it an attractive location for production.

- Milwaukee Tools maintains strict quality control measures to ensure the durability and performance of their products.

- Manufacturing in China allows Milwaukee Tools to meet the high demand for their products more efficiently.

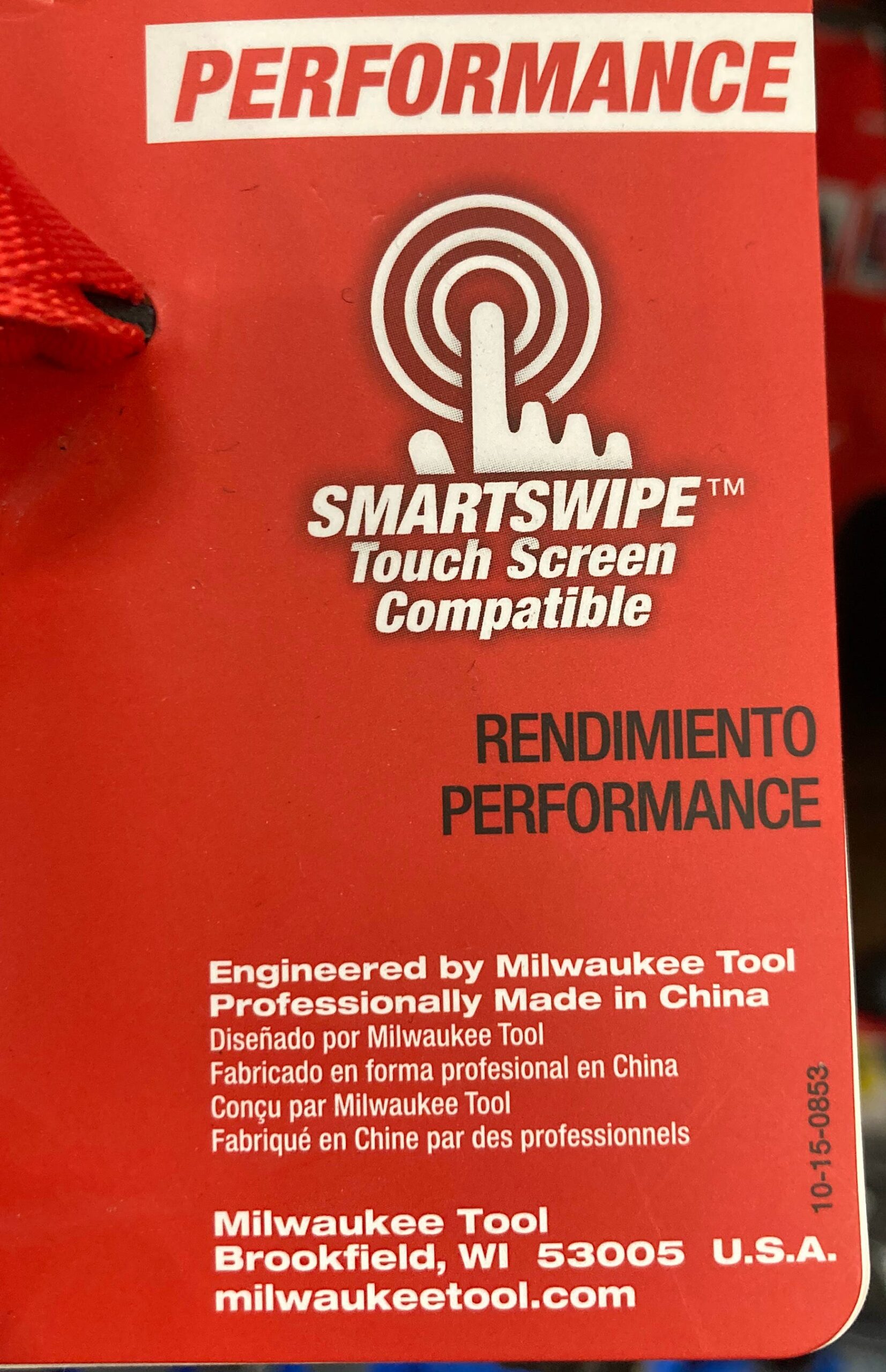

- Despite being made in China, Milwaukee Tools are designed and engineered in the United States.

Frequently Asked Questions

When it comes to Milwaukee tools, there may be some questions about why they are made in China. Here are some common inquiries regarding this topic:

Q1: How is the quality of Milwaukee tools manufactured in China?

A1: Milwaukee is a well-known brand that prides itself on producing high-quality tools. While some of their tools are made in China, the brand ensures that their manufacturing processes adhere to strict quality standards. Milwaukee has stringent quality control measures in place to guarantee that their tools meet the same quality criteria, regardless of where they are manufactured. This ensures that customers can trust in the reliability and performance of their tools, regardless of the manufacturing location.

It’s important to note that manufacturing in China does offer certain cost advantages, including access to advanced technology and skilled labor. This allows Milwaukee to provide tools at competitive prices without compromising on quality.

Q2: Are there any U.S.-made Milwaukee tools available?

A2: Yes, there are Milwaukee tools that are made in the USA. Milwaukee Tool has manufacturing facilities not only in China but also in the United States. They have factories located in Greenwood, Mississippi, and Jackson, Tennessee, among other locations. These U.S.-based facilities produce a range of tools, ensuring that customers have options when it comes to choosing domestically manufactured Milwaukee products.

By having manufacturing facilities in both China and the United States, Milwaukee Tool can optimize their production capabilities, meet market demand, and offer a wide range of tools to consumers. This allows them to cater to the needs of different customers while maintaining control over the manufacturing process.

Q3: Why does Milwaukee choose to manufacture some tools in China?

A3: There are several reasons why Milwaukee chooses to manufacture some of their tools in China. Firstly, China has a well-established manufacturing infrastructure and is known for its skilled workforce. This allows Milwaukee to leverage advanced technology and skilled labor, resulting in efficient production processes and high-quality tools.

Additionally, manufacturing in China offers cost advantages. The country has a competitive manufacturing industry that enables Milwaukee to optimize production costs and remain competitive in the market. By producing some tools in China, Milwaukee can offer customers a wide range of products at various price points, making their tools more accessible to a broader audience.

Q4: Does Milwaukee still stand behind the warranty for tools made in China?

A4: Yes, Milwaukee stands behind the warranty for all their tools, regardless of where they are manufactured. The brand takes pride in the quality and durability of their products, and they offer a comprehensive warranty to ensure customer satisfaction. If there are any defects or issues with a Milwaukee tool, regardless of its manufacturing location, customers can rely on the brand’s warranty for support and resolution.

It’s important to note that Milwaukee has a strong reputation for customer service and support, ensuring that their customers have a positive experience and that any warranty claims are handled promptly and efficiently.

Q5: Are Milwaukee tools made in China available outside the United States?

A5: Yes, Milwaukee tools made in China are available worldwide. Milwaukee Tool is a global brand with a wide distribution network that spans across multiple countries. Their tools, including those manufactured in China, are sold in various markets worldwide, including Europe, Asia, and Australia, among others.

Regardless of the manufacturing location, Milwaukee maintains consistent quality standards and ensures that their tools meet the requirements and regulations of different markets. This allows customers around the world to have access to Milwaukee tools, regardless of where they are made.

Is Milwaukee tools made in China?

Summary

Milwaukee Tools being made in China is because of a few reasons. First, it helps reduce production costs, making the tools more affordable for customers. Second, China has a large manufacturing capacity and skilled labor force, making it an attractive option. However, this decision has also sparked concerns about quality control and potential job losses in the US. While the move may benefit the company financially, it raises questions about the impact on American workers and the overall quality of the tools. Ultimately, it is a complex issue with various factors to consider.