Got a bandsaw but struggling to cut a straight line? Wondering why it’s so elusive? Well, my young woodworking enthusiast, let’s dive into the world of bandsaws and find out why achieving that perfect straight cut can be a real challenge. So, why can’t you cut a straight line with your bandsaw? Let’s explore!

When it comes to cutting precise lines with a bandsaw, several factors come into play. First off, the blade tension plays a crucial role. If the blade is not tensioned properly, it can wander off course, leading to crooked cuts. But that’s not all! The blade’s sharpness, feed rate, and blade drift can also contribute to this conundrum. Let’s unravel this mystery step by step.

Ready to demystify the art of cutting straight lines with your bandsaw? We’ll uncover the secrets behind blade tension, sharpness, feed rate, and how to counteract the infamous blade drift. By the end of this guide, you’ll be slicing through your woodworking projects with precision and confidence. So let’s get started and unlock the secrets to achieving those coveted straight cuts!

Are you struggling to cut a straight line with your bandsaw? Fear not! Achieving a precise cut requires attention to a few key factors:

1. Blade Tension: Ensure the blade is properly tensioned to prevent drift.

2. Blade Quality: Invest in a high-quality blade for cleaner cuts.

3. Fence Alignment: Make sure the fence is parallel to the blade.

4. Feed Rate: Maintain a steady, controlled feed rate to prevent blade wandering.

5. Blade Guides: Check that the blade guides are properly adjusted for optimal performance.

By following these steps, you’ll be on your way to cutting straight lines with your bandsaw like a pro!

Why Can’t I Cut a Straight Line with My Bandsaw?

Have you ever found yourself frustrated by the fact that you just can’t seem to cut a straight line with your bandsaw? You’re not alone. Many woodworkers struggle with this issue, but the good news is that there are several common reasons why it might be happening. In this article, we’ll explore the most common causes of crooked cuts and provide you with some practical tips to help you achieve straighter lines on your next project.

Lack of Proper Blade Tension

One of the primary reasons why you might be struggling to cut a straight line with your bandsaw is inadequate blade tension. When the blade is not properly tensioned, it will deflect from its intended path, resulting in a crooked cut. To ensure proper tension, you should adjust the tension according to the manufacturer’s guidelines for your specific bandsaw. It’s also important to regularly check and adjust the tension as the blade can stretch over time.

In addition to tension, the condition of the blade can also affect the cutting accuracy. Dull or damaged blades can cause the wood to bind, leading to erratic cuts. Make sure to regularly inspect and replace blades as needed to maintain optimal cutting performance.

Finally, it’s essential to check that the blade is properly aligned with the guides and wheels of the bandsaw. Misalignment can result in the blade wandering off course, causing uneven cuts. To correct this, consult your bandsaw’s manual for instructions on aligning the blade and make any necessary adjustments.

Poor Blade Selection

The type and condition of the blade you choose for your bandsaw can have a significant impact on the quality of your cuts. Different blades are designed for specific tasks, and using the wrong blade for the job can lead to less-than-straight cuts. For example, a blade with a low tooth count is better suited for ripping thick stock, while a blade with a higher tooth count is ideal for fine, intricate cuts.

Consider the thickness and type of wood you’re working with and choose the appropriate blade accordingly. Additionally, ensure that the teeth of the blade are sharp and intact. Dull or damaged teeth can cause the blade to wander off course and result in uneven cuts.

If you frequently make a variety of cuts, investing in a selection of blades to suit different applications can greatly improve the accuracy of your bandsaw cuts.

Improper Feed Rate

The speed at which you feed the wood into the bandsaw, also known as the feed rate, can affect the straightness of your cuts. Feeding the wood too quickly can cause the blade to deflect, resulting in a crooked cut. On the other hand, feeding the wood too slowly can cause the blade to bind, leading to a similar outcome.

It’s important to find the right balance between a steady yet controlled feed rate. Practice feeding the wood at a consistent speed, allowing the blade to perform its cutting action smoothly. You may need to experiment with different feed rates to find the optimal speed for the best results.

Another consideration is the type of wood you’re cutting. Softer woods may require a faster feed rate, while harder woods may require a slower pace. Take note of the wood species and adjust your feed rate accordingly for more accurate cuts.

Choosing the Right Blade Width

When it comes to bandsaw blades, the width of the blade can play a role in the accuracy of your cuts. A wider blade tends to be more stable and less prone to wandering off course, resulting in straighter cuts. However, a wider blade also requires greater tension, so be sure to adjust the tension accordingly.

On the other hand, a narrower blade is more suitable for intricate or curved cuts, but it may be more prone to deflection and inaccuracies when attempting straight cuts. Consider the type of cuts you frequently make and choose the blade width that best suits your needs.

Remember that the width of the blade is just one factor to consider. It’s crucial to ensure that the blade is of high quality, properly tensioned, and in good overall condition to achieve the best cutting results.

Key Takeaways: Why Can’t I Cut a Straight Line with My Bandsaw?

- Blade tension: Incorrect tension in the bandsaw blade can cause it to wander and result in crooked cuts.

- Blade quality: Poor quality blades can flex or warp, leading to inaccurate cuts.

- Blade alignment: If the blade is not properly aligned with the saw’s guides, it can cause the cut to veer off course.

- Feed rate: Pushing the material too quickly through the bandsaw can cause the blade to deviate and create an uneven cut.

- User technique: Inexperience or improper technique, such as not keeping a steady hand or applying uneven pressure, can also contribute to cutting inaccuracies.

Frequently Asked Questions

Are you struggling to cut a straight line with your bandsaw? Don’t worry, we’ve got answers to some commonly asked questions that may help you understand why this is happening and how to improve your cuts.

1. Why does my bandsaw blade keep drifting off course?

There could be a few reasons why your bandsaw blade is drifting off course. First, check the tension of the blade. A loose blade can cause it to wander during the cutting process. Ensure that the blade is properly tensioned according to the manufacturer’s recommendations.

Another factor to consider is blade alignment. Make sure the blade is properly centered on the bandsaw wheels. If the blade is not aligned correctly, it can cause the cut to veer off course. Adjust the tracking and guides as necessary to ensure proper alignment.

2. Why is my cut not straight even though I’m using a fence?

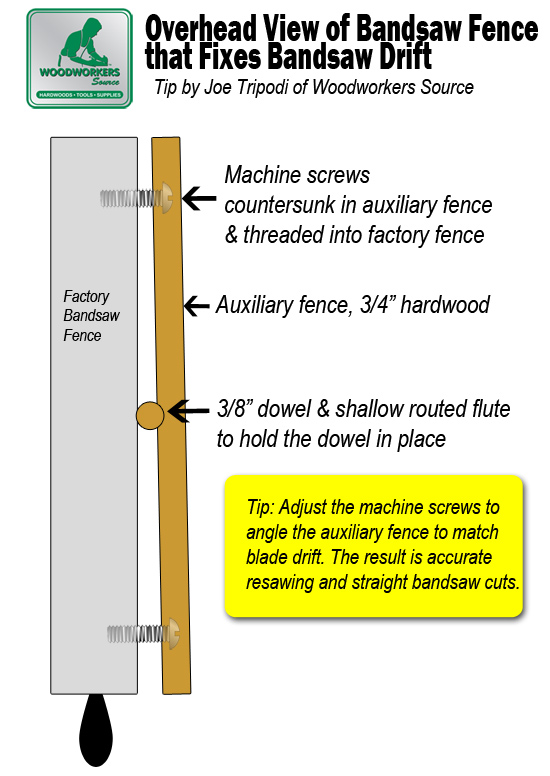

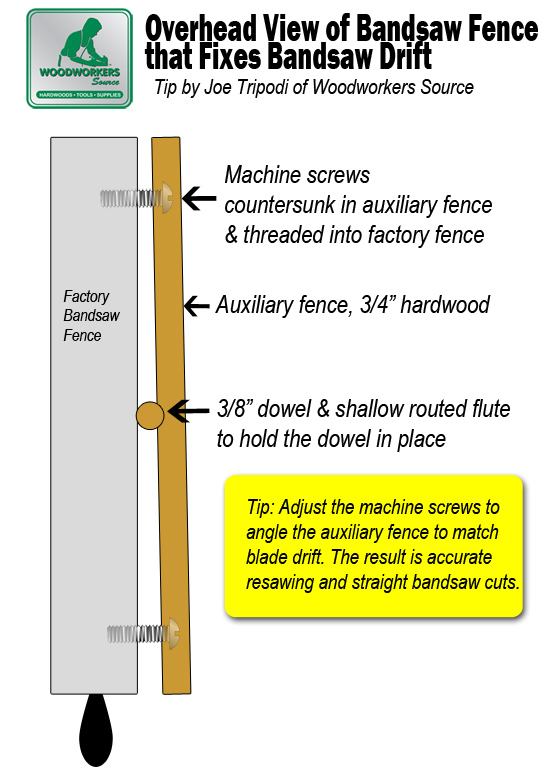

Using a fence can help guide your cut and ensure it remains straight, but there are a few things to consider. Check the alignment of the fence itself. It should be parallel to the blade and securely locked in place. A misaligned or loose fence can lead to inaccurate cuts.

Additionally, pay attention to the pressure you’re applying against the fence while cutting. Too much pressure can cause the blade to deflect, resulting in an uneven cut. Allow the saw’s weight to do most of the work and use a light touch against the fence to maintain control.

3. What are some common mistakes that can affect the accuracy of bandsaw cuts?

One common mistake is using a dull blade. A dull blade will not cut efficiently and can cause the blade to veer off course. Make sure to regularly sharpen or replace your bandsaw blade to maintain optimal performance.

Another mistake is feeding the material too quickly. Trying to rush through a cut can result in a wobbly, uneven line. Take your time and let the blade do the work at its own pace. Smooth and controlled feeding will lead to straighter cuts.

4. Why are my bandsaw cuts leaving rough edges?

Rough edges on bandsaw cuts can be caused by several factors. One possibility is a dull blade or one with a low tooth count. A sharper blade with more teeth per inch will produce cleaner cuts. Consider using a blade specifically designed for fine cuts.

Improper blade tension can also contribute to rough edges. If the blade is too loose, it may vibrate during the cut, resulting in a rough finish. Check the tension and make adjustments accordingly.

5. How can I improve the accuracy of my bandsaw cuts?

One way to improve the accuracy of your cuts is to use a bandsaw fence or a guide. These attachments provide additional support and guidance for the material, helping to keep the cut on track. Make sure the fence is properly aligned and secured before making your cut.

Additionally, practice makes perfect. Take the time to familiarize yourself with your bandsaw, experiment with different techniques, and make adjustments as needed. As you gain experience, you’ll develop a better feel for how to achieve straighter cuts.

Summary

Cutting a straight line with a bandsaw can be tricky, but there are a few reasons why it might not be working out for you. Firstly, the blade on your bandsaw might be dull or not properly aligned, which can cause the cut to veer off course. Secondly, using too much force or not having a steady hand can also contribute to a crooked cut. Finally, if the wood you are cutting is not properly supported or if you are not using a guide, it can be difficult to maintain a straight line.

To improve your bandsaw cutting skills, make sure your blade is sharp and aligned correctly. Take your time and use steady pressure, avoiding the temptation to force the cut. Use a guide or fence to help guide the wood and ensure a straight line. With practice and attention to these details, you’ll be cutting straight lines with your bandsaw in no time!