Have you ever wondered why circular saws are so good at cutting things up? Well, get ready to dive into the fascinating world of these powerful tools!

So, why do circular saws have such impressive cutting abilities? It all comes down to their design and the way they harness the power of rotation.

Through the magic of spinning blades, circular saws can effortlessly slice through various materials, making them a go-to tool for carpenters, construction workers, and DIY enthusiasts alike.

Get ready to uncover the secrets behind the cutting power of circular saws in this exciting exploration of their inner workings. Let’s get started!

Exploring the Function of Circular Saws

In this article, we will delve into the fascinating world of circular saws and uncover the reasons behind their ability to cut up materials with precision and efficiency. From the mechanics of the tool to the design features that enable its cutting prowess, we will explore the various aspects that make circular saws such indispensable tools in the construction and woodworking industries. So, let’s dive in and uncover the secrets of why circular saws excel at cutting up materials!

The Cutting Power of Circular Saws

When it comes to cutting up materials, circular saws are renowned for their exceptional performance. The key to their cutting power lies in the circular motion of the saw blade. Unlike other cutting tools, circular saws utilize a rotating motion to penetrate the material, ensuring a smooth and efficient cut. The blades on circular saws are equipped with sharp teeth that bite into the material, swiftly removing excess material with each rotation.

In addition to the circular motion, the speed at which the blade rotates also contributes to the cutting power of circular saws. The high RPM (revolutions per minute) of the blade allows it to make quick work of even the toughest materials. Coupled with the sharp teeth, the high rotational speed ensures that the circular saw is able to cut through various materials, including wood, metal, and even plastic, with ease.

Furthermore, the design of the blade itself plays a crucial role in the cutting ability of circular saws. The teeth on the blade are strategically positioned and shaped to suit the specific material being cut. Different types of blades are available for different purposes, such as ripping through lumber or making precision cuts on delicate materials. This versatility makes circular saws a go-to tool for a wide range of cutting tasks.

The Mechanics of Circular Saws

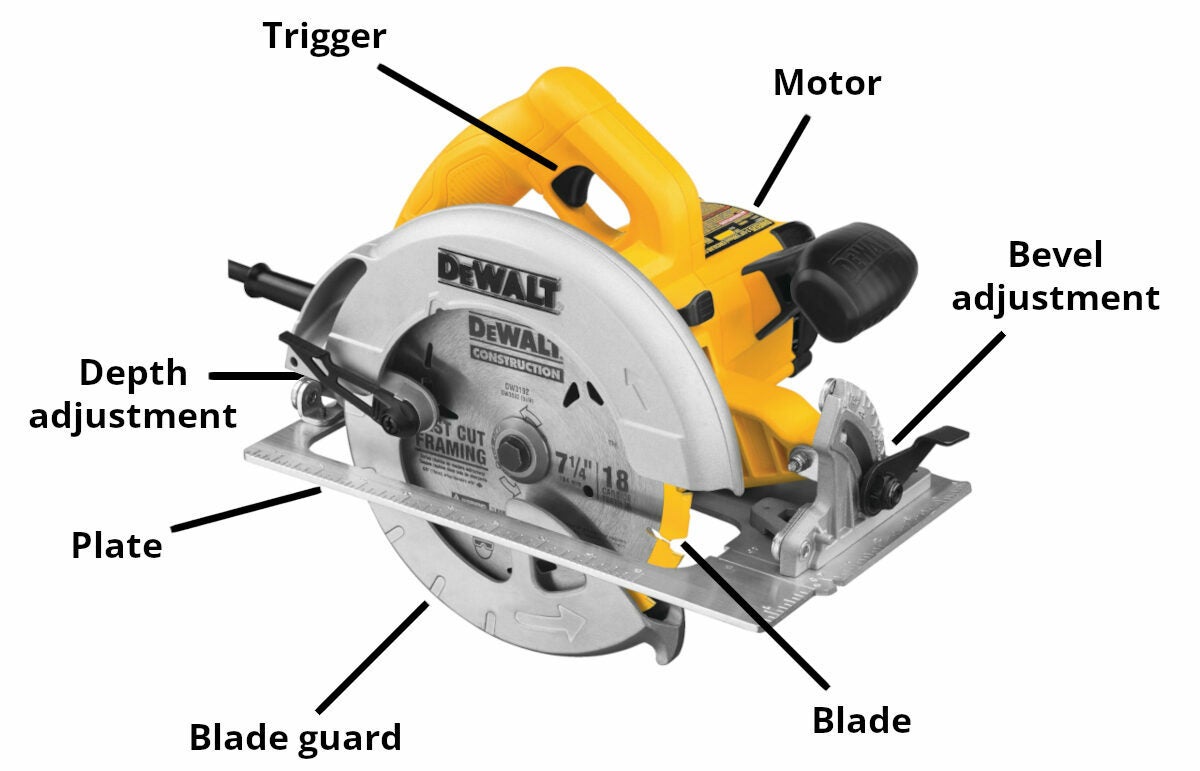

Understanding the mechanics of circular saws can provide further insights into why they are so effective at cutting up materials. Circular saws consist of several key components that work together to deliver exceptional cutting performance. The motor, located at the core of the saw, powers the rotation of the blade. The power of the motor can vary depending on the specific model and intended use of the saw.

The blade, as mentioned earlier, is one of the most important parts of a circular saw. Made from high-quality materials such as carbide or steel, the blade is designed to withstand the rigors of cutting and maintain its sharpness over time. The size and diameter of the blade also influence the cutting capacity of the saw, with larger blades being suitable for thicker materials.

Another crucial component of circular saws is the base, or shoe, which acts as a stable platform for the saw. The base is typically made from durable materials such as aluminum or magnesium and is designed to provide stability and precision during cutting. Some circular saws also feature adjustable bases, allowing for angled or bevel cuts.

Circular Saw Blades: A Versatile Cutting Solution

One of the reasons why circular saws are so popular is their versatility, which is largely attributed to the wide variety of blades available. Circular saw blades come in different sizes, tooth configurations, and materials, making them suitable for cutting through various materials and achieving different types of cuts.

For cutting wood, blades with carbide-tipped teeth are commonly used. These blades are designed to withstand the constant impact with hard wood fibers and are able to maintain their sharpness for longer periods of time. For cutting metal, blades with specialized tooth designs and materials are employed to ensure clean and precise cuts.

Furthermore, circular saw blades can be customized for specific cutting tasks. Some blades are designed for ripping, which involves cutting along the length of the material, while others are better suited for crosscutting, which involves cutting across the width of the material. The ability to switch out blades depending on the task at hand makes circular saws a highly versatile cutting solution.

Additional Information on Circular Saws

The Importance of Safety Measures

When using circular saws, it is essential to prioritize safety. Here are some important tips to keep in mind:

- Always wear protective gear such as safety glasses and gloves.

- Ensure the work area is well-lit and free of clutter.

- Secure the material being cut firmly to prevent kickbacks.

- Follow the manufacturer’s instructions for blade replacement and maintenance.

Choosing the Right Circular Saw

With a wide range of options available in the market, choosing the right circular saw can be overwhelming. Here are a few factors to consider:

- Determine the intended use of the saw (e.g., woodworking, construction).

- Consider the power and RPM of the motor for efficient cutting.

- Check the size and material of the blade for compatibility with your cutting tasks.

- Look for additional features such as dust extraction systems and laser guides for enhanced convenience and accuracy.

Proper Maintenance for Longevity

To ensure the longevity and optimal performance of your circular saw, regular maintenance is crucial. Here are some maintenance tips:

- Clean the saw after each use to remove dust and debris.

- Regularly check and tighten any loose screws or parts.

- Keep the blade sharp and replace it when signs of wear are observed.

- Store the saw in a dry and secure place to prevent damage.

In conclusion, circular saws are powerful cutting tools that owe their cutting-up abilities to the circular motion and high rotational speed of the blade, as well as the design of the blade itself. By understanding the mechanics of circular saws and the importance of using the right blades, users can harness the full potential of this versatile tool. However, safety should always be a priority when operating circular saws, and regular maintenance can prolong their lifespan and ensure their continued performance. So, whether you’re a professional woodworker or a DIY enthusiast, a circular saw is an indispensable tool to have in your arsenal.

Key Takeaways: Why Do Circular Saws Cut Up?

- Circular saws have sharp, rotating blades that cut through different materials.

- The teeth on the blade grip the material and create a clean and precise cut.

- Circular saws are versatile tools used in woodworking, construction, and DIY projects.

- They are powered by electricity or batteries and can be handheld or mounted on a table.

- It’s essential to follow safety precautions and wear protective gear when using a circular saw.

Frequently Asked Questions

Welcome to our FAQ section where we will address common inquiries about circular saws and why they are able to cut through various materials. Below, you’ll find engaging questions with detailed answers to satisfy your curiosity.

How do circular saws cut through materials?

Circular saws are equipped with a circular blade that has sharp teeth along its edge. When the saw is powered on, the motor rotates the blade rapidly, causing the teeth to cut through the material. The blade’s sharp teeth create a slicing motion, allowing it to easily cut through wood, metal, or other materials with minimal effort. The speed and power of the motor, coupled with the design of the teeth, enable circular saws to effectively cut through different materials.

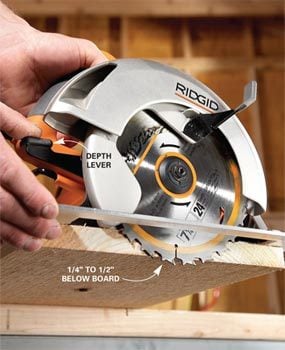

Additionally, circular saws often have adjustable depth settings, allowing users to control how deep the saw cuts into the material. This feature is particularly useful when precision and accuracy are required, as it allows for clean and consistent cuts.

What safety measures should I take when using a circular saw?

When using a circular saw, it’s important to prioritize safety to prevent accidents or injuries. Here are some key safety measures to consider:

First, always wear appropriate personal protective equipment (PPE) such as safety goggles, ear protection, and gloves. This will help protect you from flying debris and excessive noise. Additionally, ensure that the work area is well-lit and clear of any potential hazards.

Second, follow the manufacturer’s instructions and guidelines for operating the circular saw. Familiarize yourself with the saw’s features, such as the on/off switch and depth adjustment, before using it. Never remove safety guards or use the saw for purposes it wasn’t designed for.

Can circular saws cut through different types of materials?

Yes, circular saws are versatile tools that can cut through various materials. The type of blade used determines the saw’s cutting capabilities. For example, there are specific blades designed for cutting wood, metal, plastic, and other materials. It’s important to select the appropriate blade based on the material you intend to cut.

Some circular saws also have adjustable speed settings, allowing users to adapt to different materials. Lower speeds are typically recommended for cutting denser materials, while higher speeds are more suitable for softer materials. It’s important to choose the right blade and speed setting to achieve clean and efficient cuts.

What maintenance is required for circular saws?

Maintaining your circular saw properly is important for its longevity and optimal performance. Here are some maintenance tips:

First, regularly clean the saw to remove dust, chips, and debris that may accumulate along the blade or in the housing. Ensure the saw is disconnected from the power source before cleaning. You can use a soft brush or compressed air to remove the debris effectively.

Second, keep the blade sharp by regularly inspecting it for dull or damaged teeth. If the blade becomes dull, it may cause the saw to overheat or produce rough cuts. You can either sharpen or replace the blade, depending on its condition. Additionally, check the saw’s other components, such as the guard and handles, to ensure they are in good working condition.

Are circular saws suitable for beginners?

Circular saws can be used by beginners, but it’s essential to take the necessary precautions and practice proper techniques. If you’re new to using a circular saw, start with smaller, manageable projects to familiarize yourself with the tool. Take the time to read the user manual and understand the different features and settings of the saw.

It’s also helpful to seek guidance from experienced users or take a woodworking or DIY class to learn basic cutting techniques. As you gain more experience and confidence, you can gradually tackle more complex projects. Remember, safety should always be a priority, so never rush or attempt cuts beyond your skill level.

11 WORST CIRCULAR SAW MISTAKES!! And How To Avoid them…(DON’T DO THESE THINGS! Kickback/Binding)

Summary

Circular saws are able to cut through materials because of their sharp teeth and high-speed rotation. The teeth on the blade create a slicing motion, breaking down the material as it spins. The saw’s motor provides the power to keep the blade spinning at a fast speed, allowing for efficient cutting.

Circular saws are commonly used in construction and woodworking projects because they can cut through a variety of materials, such as wood, metal, and plastic. It’s important to use the correct blade for each material to achieve the best results. By understanding how circular saws work, we can appreciate their ability to make precise and clean cuts in different materials.