Hey there! Have you ever wondered why circular saws cut up instead of down? Well, let’s dive right into this fascinating topic to find out!

Picture this: you’re working on a woodworking project and you grab your trusty circular saw. But have you ever noticed that the blade spins in a way that cuts from the bottom up instead of the other way around? It might seem counterintuitive at first, but there’s a good reason behind it.

You see, circular saws are designed this way for a couple of important reasons. First, cutting from the bottom up helps to reduce splintering and tearing of the material being cut. Second, it ensures better control over the saw and reduces the risk of kickback, which can be dangerous. So, there’s actually some smart engineering at play here!

Now that we know why circular saws cut up instead of down, let’s explore the details and science behind this fascinating mechanism. It’s time to uncover the secrets of the circular saw and understand the magic from below. So, let’s get started!

Stay tuned to uncover the fascinating world of circular saws and gain some valuable insights along the way. From the science behind the blade motion to the advantages of cutting from the bottom up, we’ll explore it all in the next few paragraphs. So, let’s begin this exciting journey together!

Why Do Circular Saws Cut Up Instead of Down?

When it comes to woodworking and construction, circular saws are one of the most versatile and widely used power tools. However, if you’ve ever used a circular saw, you may have noticed that the blade spins in a direction that may seem counterintuitive: it cuts up instead of down. This may leave you wondering why that is. In this article, we will explore the reasons why circular saws cut up instead of down and the benefits of this design choice.

How Do Circular Saws Work?

Before we delve into why circular saws cut up, let’s first understand how they work. Circular saws consist of a round blade with sharp teeth that spins rapidly, driven by an electric motor. The blade’s teeth engage with the material being cut, creating a clean and precise cut. The design of the blade, including the number of teeth and their shape, is optimized for specific types of cuts and materials.

Now that we have a basic understanding of how circular saws work, let’s explore the reasons why they cut up instead of down.

The Safety Factor

One of the primary reasons why circular saws are designed to cut up is safety. When you operate a circular saw, you typically hold it with both hands and have a clear line of sight to the cutting area. Cutting up allows the sawdust and debris to be directed away from your face and body, reducing the risk of injury. If circular saws were designed to cut down, the sawdust would be propelled upwards towards the operator, increasing the chances of eye injuries and inhalation of dust particles.

Additionally, the cutting action of the saw is more stable and controlled when cutting up. Gravity helps to keep the saw pressed against the material being cut, minimizing the risk of kickbacks. Kickbacks occur when the blade catches on the material and propels the saw backwards towards the operator, which can be dangerous and cause severe injuries.

By cutting up, circular saws prioritize operator safety and ensure a clear line of sight while minimizing the risk of kickbacks.

Efficient Chip Removal

Another reason why circular saws cut up is to facilitate efficient chip removal. As the blade engages with the material, it creates chips or shavings that need to be cleared away for the blade to continue cutting smoothly. When cutting up, the chips are propelled out of the cut and away from the blade, allowing for a cleaner and more efficient cutting process.

This design choice also reduces the likelihood of the blade getting clogged or stuck in the material, which could result in a less accurate cut and potentially damage the saw.

Therefore, cutting up ensures optimal chip removal and contributes to the overall performance and longevity of the circular saw.

Better Control and Accuracy

In addition to safety and chip removal, cutting up also provides better control and accuracy when operating a circular saw. When cutting up, the weight of the saw and gravity help to guide the blade along the intended cutting line. This allows for more precise cuts, especially when following a marked line or cutting intricate shapes.

Cutting up also provides better visibility of the cutting line, as the sawdust and debris are directed away from the cut, ensuring a clear view of the workpiece.

Ultimately, cutting up enhances control and accuracy, making it easier for woodworkers and professionals to achieve the desired results with their circular saw.

The Role of Blade Teeth

It’s worth mentioning that the design and orientation of the blade teeth also contribute to the direction of the cut. Circular saw blades typically have teeth that are angled in a way that pulls the saw into the material when rotating in the cutting direction. This design further enhances the cutting action when the saw is positioned to cut up.

It is important to choose the right blade for the specific task at hand, taking into consideration factors such as the type of material being cut, the desired finish, and the depth of the cut.

By considering the design of the blade teeth, in addition to the other factors mentioned, circular saws are optimized for safe, efficient, and accurate cutting by cutting up instead of down.

The Benefits of Cutting Up with Circular Saws

Now that we understand why circular saws are designed to cut up, let’s explore the benefits of this design choice:

- Safety: Cutting up directs sawdust and debris away from the operator’s face and body, reducing the risk of injuries.

- Efficient chip removal: Cutting up allows for effective removal of chips, ensuring a clean and efficient cutting process.

- Better control and accuracy: Cutting up improves control and visibility, resulting in more precise cuts with clear visibility of the cutting line.

- Optimized performance: By cutting up, circular saws are designed to ensure optimal performance, minimize the risk of kickbacks, and facilitate the longevity of the saw.

Tips for Using Circular Saws Safely

While circular saws are incredibly useful tools, it is important to prioritize safety when using them. Here are some tips to ensure safe operation:

- Always wear appropriate safety gear, including safety glasses, hearing protection, and a dust mask.

- Inspect the saw and blade for any damage before use.

- Securely clamp down the material being cut to prevent movement.

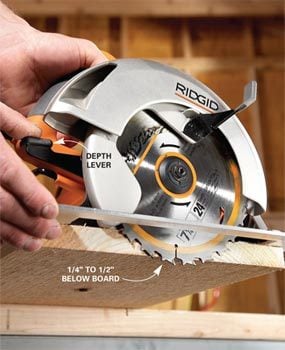

- Ensure that the depth setting of the blade is properly adjusted according to the thickness of the material.

- Use a sharp, appropriate blade for the specific task.

- Maintain a firm grip on the saw with both hands and keep a balanced stance.

- When making a cut, start the saw and allow it to reach full speed before engaging with the material.

- Always follow manufacturer’s instructions and guidelines for safe use of the circular saw.

In conclusion, circular saws cut up instead of down for multiple reasons, including safety, efficient chip removal, and better control and accuracy. By understanding the design choices and benefits associated with cutting up, users can make the most of their circular saws while ensuring safe and effective operation. Remember to prioritize safety and follow best practices when using any power tool, including circular saws.

Key Takeaways: Why Do Circular Saws Cut Up Instead of Down?

- 1. Circular saws cut up instead of down because of the way the blades are designed.

- 2. The teeth on a circular saw blade are angled in a way that pushes the wood up and away from the blade.

- 3. This design helps prevent kickback, where the saw blade gets caught and thrown back towards the user.

- 4. Cutting up also allows for better control and visibility, as the rotation of the blade pulls the saw into the wood.

- 5. Additionally, cutting up reduces splintering, as the saw teeth enter the wood from the bottom, minimizing tear-out on the top surface.

So, the next time you use a circular saw, remember that it cuts up instead of down for safety, control, and better results!

Frequently Asked Questions

When it comes to circular saws, you may be wondering why they cut up instead of down. In this section, we’ll answer some common questions to shed light on this topic and help you understand the mechanics behind circular saws.

1. How do circular saws cut through materials?

Circular saws are designed with sharp, circular blades that rotate at high speeds. These blades have teeth that are specially crafted to cut through different materials like wood, metal, or plastic. When the blade spins, the sharp teeth make contact with the material, effectively slicing through it.

While the cutting motion of circular saws may appear to be downward, it’s actually the rotation of the blade combined with the sideways movement of the saw that allows it to cut through materials. Instead of purely downward force, the rotational motion ensures consistent cutting action across the material’s thickness.

2. Why is the blade positioned above the material?

The blade of a circular saw is positioned above the material to provide better visibility and control. With the blade on top, the user can clearly see the cutting line and adjust the saw’s movement accordingly. This positioning also minimizes the risk of the blade getting stuck or causing kickback during the cutting process.

By having the blade above the material, the circular saw also enables a more natural cutting motion. It allows the user to push the saw forward smoothly while maintaining a comfortable grip on the handle, ensuring safer and more efficient cutting.

3. What are the benefits of cutting up instead of down?

There are several benefits to cutting up instead of down with circular saws. One advantage is that cutting upward tends to generate less tear-out or splintering on the surface of the material. This is particularly important when working with delicate materials like plywood or laminates.

Another benefit is that cutting up allows the sawdust to be directed away from the user, improving visibility and reducing the risk of inhaling fine particles. Additionally, cutting up keeps the material firmly in place, minimizing the chances of the saw getting stuck or causing kickback.

4. Can circular saws cut downwards if needed?

Yes, circular saws can cut downwards if needed. While the default cutting action is upward, some circular saws can be adjusted to perform downward cuts. This feature is often used in specific applications or when working with certain materials that require a downward cutting motion.

It’s important to note that when cutting downward with a circular saw, extra precautions should be taken to ensure safety. This includes securing the material firmly, using appropriate cutting techniques, and wearing protective gear.

5. Are there any alternative tools that primarily cut downwards?

Yes, there are alternative tools that primarily cut downwards. One example is the jigsaw, which features a reciprocating blade that moves up and down to cut through various materials. Jigsaws are commonly used for intricate cuts, curved lines, or plunge cuts.

Another tool capable of downward cuts is the scroll saw, which operates similarly to a jigsaw but with a smaller, fine-toothed blade. Scroll saws are often used in intricate woodworking projects that require detailed and precise cuts.

11 WORST CIRCULAR SAW MISTAKES!! And How To Avoid them…(DON’T DO THESE THINGS! Kickback/Binding)

Summary

Circular saws cut up instead of down because of the design of the teeth on the blade. The teeth on a circular saw point in the opposite direction of the rotation, which allows the saw to effectively and safely cut material.

When the circular saw spins, the teeth grab onto the material and pull it upward into the blade. This upward motion prevents the saw from kicking back and helps to create a cleaner and smoother cut. So, next time you see a circular saw cutting up, remember that it’s all about the design of the teeth!