Do you find yourself constantly breaking scroll saw blades? It can be frustrating when you’re in the middle of a project and your blades keep snapping. But fear not, my friend, because today we’re going to dive into the reasons behind this blade-breaking phenomenon. So sit tight, grab your favorite snack, and let’s unravel the mystery together.

Now, I know what you might be thinking: “Why do I keep breaking scroll saw blades?” Well, the answer isn’t always as simple as it seems. There could be several factors at play causing this issue. But worry not, we’re here to break it down for you in simple terms that even a 13-year-old can understand.

So, without further ado, let’s roll up our sleeves and get ready to solve the mystery of why those scroll saw blades just can’t seem to stay intact. Get ready to become a scroll saw blade expert in no time!

Why Do I Keep Breaking Scroll Saw Blades?

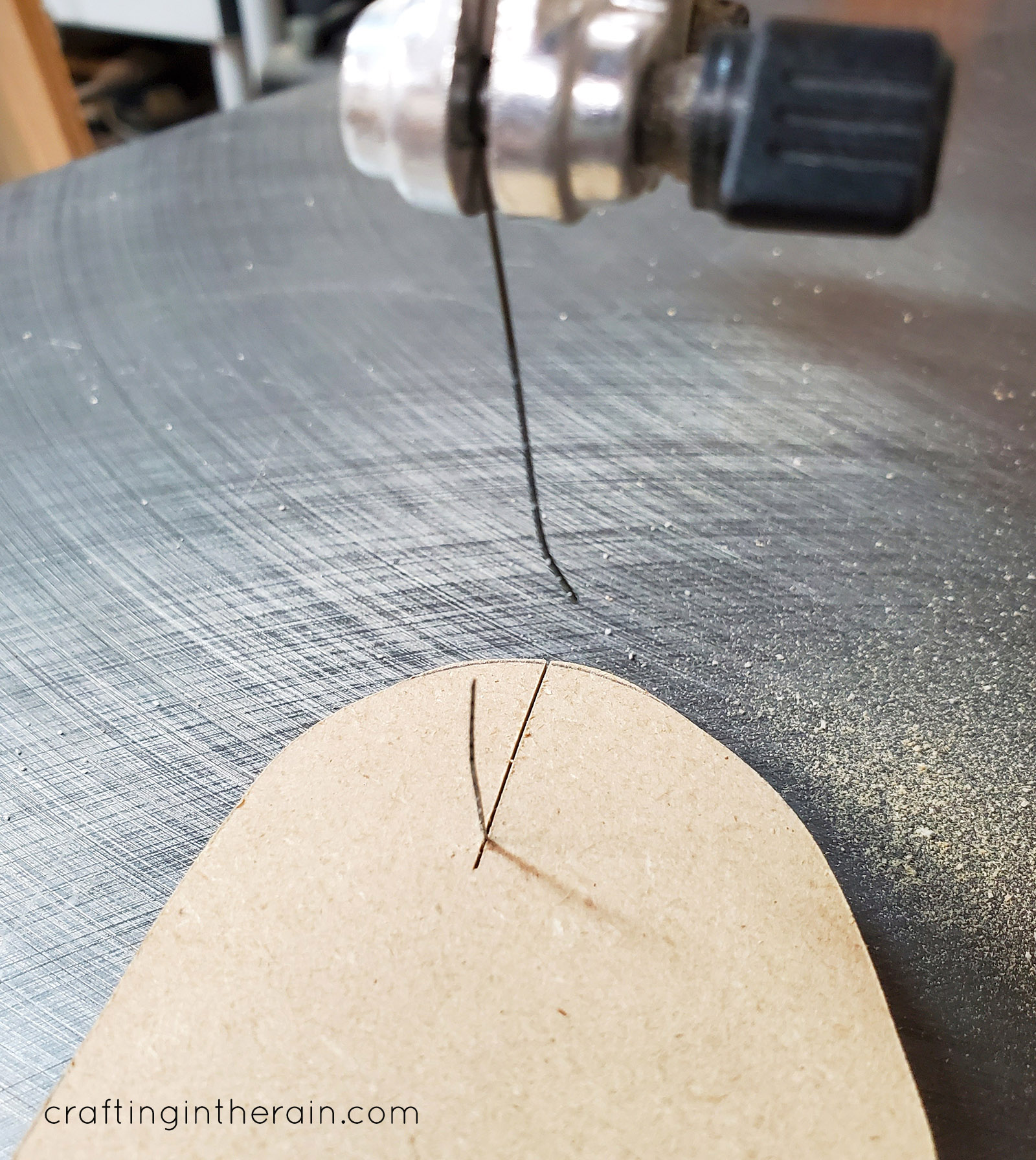

Scroll sawing is a popular and enjoyable hobby for many woodworking enthusiasts. However, one frustrating issue that can arise is the frequent breaking of scroll saw blades. It can be disheartening to invest time and effort into a project, only to have a blade snap at a crucial moment. In this article, we will explore the common reasons why you may be experiencing this problem and provide practical tips to help you prevent future blade breakage.

Improper Blade Selection

One possible reason for consistently breaking scroll saw blades is using the wrong type or size of blade for your project. Blades come in different sizes and teeth per inch (TPI) counts, each designed for specific cutting techniques and materials. Using a blade with too few TPI for intricate work or too many TPI for thicker materials can put excessive strain on the blade, leading to breakage. It is essential to choose the appropriate blade for your intended task to ensure optimal performance and reduce the risk of breakage.

Additionally, the quality of the blades can also play a significant role in their durability. Investing in high-quality blades from reputable manufacturers can make a noticeable difference in their performance and longevity. Cheap or inferior blades may be more prone to breaking, resulting in frustration and wasted time.

Incorrect Blade Tension

Another factor that can contribute to scroll saw blade breakage is improper blade tension. The blade must be correctly tensioned to ensure smooth and controlled cutting. If the tension is too loose, the blade can oscillate excessively, leading to bending and eventual breakage. On the other hand, excessive tension can cause the blade to be overstressed, resulting in premature failure.

To ensure proper tension, consult your scroll saw’s manual for specific instructions. Most machines have a tension adjustment knob or mechanism that allows you to tighten or loosen the blade. Take the time to adjust the tension before starting a project, ensuring that it is within the recommended range for the type of blade you are using. Regularly checking and maintaining proper tension will help to prevent blade breakage.

Inadequate Blade Lubrication

Lubrication is often overlooked but is crucial for optimal blade performance and longevity. When cutting through materials, friction is generated, causing heat to build up. Without proper lubrication, this heat can cause the blade to become brittle and prone to breaking.

To prevent this, apply an appropriate lubricant to the blade before starting your project. There are specialized blade lubricants available, but some woodworkers also find success with alternatives such as paraffin wax or silicone sprays. Be sure to follow the manufacturer’s recommendations for application to ensure sufficient lubrication throughout the cutting process. Proper lubrication will help to reduce friction, heat, and the risk of blade breakage.

Excessive Feed Rate or Pressure

Pushing the workpiece too quickly or applying excessive pressure while cutting can also result in frequent blade breakage. The scroll saw blade is designed to cut through materials at a specific rate. Forcing the blade to work faster than it is intended can cause it to twist or buckle, leading to breakage.

It is important to find the right balance between the feed rate and the pressure applied. Take your time and let the blade do the work without forcing it. Practice patience and allow the saw to cut at its optimal pace, ensuring a smoother and safer cutting experience. Additionally, adapting your technique to match the requirements of the material being cut can also help prevent blade breakage.

Poor Blade Handling

Proper handling and installation of the scroll saw blades are crucial to prevent breakage. Mishandling the blade, such as bending or twisting it during installation, can weaken its structure, making it more prone to breaking. It is essential to follow the manufacturer’s instructions for correctly installing the blade to ensure a secure and stable fit.

Additionally, when changing blades or adjusting the blade tension, always remember to turn off the scroll saw and unplug it from the power source. This simple precaution can prevent accidental injuries and damage to the blade or the machine. Taking care in how you handle and install blades can significantly reduce the risk of breakage.

Insufficient Blade Maintenance

Regular maintenance and inspection of your scroll saw and blades play a crucial role in preventing blade breakage. Over time, sawdust, debris, and resin buildup can affect the blade’s performance and increase the risk of breakage. Therefore, it is important to routinely clean the scroll saw, especially in and around the blade area, to remove any accumulated debris.

In addition to cleaning, performing regular blade inspections can help identify any signs of wear, damage, or dullness. Blades that are worn or dull are more prone to breaking and should be replaced promptly. By staying on top of maintenance and addressing any issues promptly, you can ensure that your scroll saw and blades are in optimal condition and less likely to break.

Additional Tips for Preventing Blade Breakage

In addition to the reasons mentioned above, here are a few extra tips to help prevent scroll saw blade breakage:

Use a slow and steady approach:

Rushing through a cut or applying erratic movements can increase the risk of blade breakage. Take your time, use a steady hand, and maintain a consistent and controlled cutting speed to reduce the strain on the blade.

Choose the right blade for the material:

Each material may require a different type of blade. Research and select the appropriate blade based on the material’s thickness, hardness, and other specific characteristics.

Practice proper blade removal:

When removing a broken or worn-out blade, exercise caution to prevent any injuries. Use protective gloves or tools designed for blade removal to avoid direct contact with the blade’s sharp edges.

Invest in a blade storage system:

Properly storing your scroll saw blades can help maintain their integrity and prevent damage or breakage. Consider purchasing a blade storage system that keeps them organized and protected.

Conclusion

By understanding and addressing the common reasons for scroll saw blade breakage, you can enhance your woodworking experience and minimize frustration. Remember to choose the right blade for your project, maintain proper tension and lubrication, handle the blades with care, and perform regular maintenance. With these practices in place, you can enjoy smooth and successful scroll sawing without the constant fear of broken blades.

Key Takeaways: Why Do I Keep Breaking Scroll Saw Blades?

- Blade tension may be too tight, causing undue stress on the blade.

- Improper blade installation could be a contributing factor.

- Using the wrong type or size of blade for the material being cut can lead to breakage.

- Inadequate blade maintenance and sharpening can weaken the blade and make it more prone to breaking.

- Applying too much pressure or forcing the blade through the material can cause it to snap.

Frequently Asked Questions

In the world of woodworking, breaking scroll saw blades can be a frustrating and common occurrence. But fear not, we’re here to help you understand why this happens and how to prevent it. Below are some frequently asked questions about why scroll saw blades break and the answers you need to keep your blades intact and your projects on track.

Why do scroll saw blades break so easily?

Scroll saw blades are fragile by nature, and there are several reasons why they may break easily. One common reason is improper blade tension. If the blade is not tensioned correctly, it can vibrate or wobble, which puts unnecessary stress on the blade, leading to breakage. Another factor is feeding the material too quickly. Applying too much pressure or trying to cut at a high speed can cause the blade to overheat and become brittle, resulting in breakage. Lastly, using a dull or damaged blade can also contribute to breakage, as it lacks the sharpness needed to cut through material smoothly.

To prevent blades from breaking easily, make sure to properly tension the blade based on the manufacturer’s guidelines. Take your time when cutting, allowing the blade to do the work without forcing it or rushing through the process. It’s also essential to use sharp blades and replace them when they become dull or damaged.

Can the type of material being cut affect blade breakage?

Absolutely! The type of material being cut can have a significant impact on blade breakage. Hardwoods, such as oak or maple, are denser and require a more aggressive cutting action, which can put extra stress on the blade and increase the likelihood of breakage. In contrast, softer materials like pine or plywood are easier to cut and put less strain on the blade. Additionally, the thickness of the material can also play a role. Cutting thick or heavy stock may require a blade designed specifically for such applications to minimize the chances of breakage.

It’s important to choose the right blade for the material you are cutting. Different blades have different teeth configurations and are designed for specific applications. Research the appropriate blade for your project to reduce the risk of breakage. When working with hard or thick materials, take extra care, use a slower cutting speed, and allow the blade to do the work without applying excessive force.

Are there any maintenance tips to prevent scroll saw blade breakage?

Absolutely! Proper maintenance of your scroll saw can go a long way in preventing blade breakage. Regularly inspect the blade for any signs of damage or dullness, and replace it immediately if needed. Lubricating the blade with a small amount of blade wax or silicone-based lubricant can reduce friction, preventing overheating and blade breakage. Ensuring the blade is tensioned correctly and aligned properly with the saw is crucial as well. If the blade is not aligned, it can cause it to twist or bend, leading to breakage.

Moreover, taking the time to learn the correct cutting techniques can also help minimize blade breakage. Practice cutting with a steady hand, guiding the material smoothly without forcing it. If you encounter knots or other imperfections in the material, pause and proceed with caution to avoid damaging the blade.

How can I avoid scroll saw blade breakage when doing intricate cuts?

Intricate cuts call for extra care and attention to prevent blade breakage. First and foremost, choose the appropriate blade for intricate work. Fine-tooth blades with higher tooth counts work well for intricate cuts as they provide more control and a smoother finish. Additionally, slowing down your cutting speed and using a light touch can help prevent breakage. Rushing through intricate cuts or applying too much pressure can cause the blade to snap. Supporting the material with a scroll saw table or a backing board can also help reduce vibrations and minimize the risk of breakage.

Lastly, it’s important to have a sharp blade when working on intricate cuts. Dull or damaged blades will not cut smoothly and are more prone to breakage. Keep spare blades on hand and replace them when necessary to ensure the best performance and reduce the chances of breakage.

Can heat be a contributing factor to scroll saw blade breakage?

Yes, heat can definitely contribute to scroll saw blade breakage. Excessive heat can cause the blade to become brittle and snap. One common cause of heat buildup is friction between the blade and the material being cut. This friction generates heat, wearing down the blade and increasing the chances of breakage. Incorrect blade speed, feeding the material too quickly, or using a blade that is not suitable for the material can all lead to overheating.

To prevent heat-related breakage, take the appropriate precautions. Adjust the blade speed based on the material being cut and the blade’s specifications. Feeding the material at a steady pace without rushing it will also help reduce heat buildup. Additionally, using lubricants like blade wax or silicone-based lubricants can decrease friction and heat. Remember to always monitor the blade’s temperature during cutting and make adjustments as needed to prevent overheating and breakage.

Summary

Sometimes, scroll saw blades break because they are old or made of poor quality materials. You can prevent this by using new, high-quality blades and avoiding putting too much pressure on them.

Using too much force or twisting the blade while cutting can cause it to break. It’s important to let the saw do the work and guide the material gently.

Keeping the blades clean and lubricated with oil can also help prevent them from breaking easily.

If you follow these tips, you’ll be able to enjoy smooth and successful scroll saw projects without constantly breaking your blades.