Are you struggling with your scroll saw blades constantly breaking? Don’t worry, you’re not alone! It can be frustrating when you’re in the middle of a project and your blades keep snapping. But fear not, because I’m here to help you understand why this happens and how you can prevent it.

Scroll sawing is a fascinating craft that allows you to create intricate designs and shapes, but it requires the right tools and techniques to achieve optimal results. One common reason why your scroll saw blades may break is if they are not properly tensioned. Tensioning ensures that the blade is held tightly in place, allowing for precise cuts. If your blade is too loose or too tight, it can put unnecessary stress on the blade and cause it to break.

Another factor that can contribute to blade breakage is the type and thickness of the material you’re cutting. Scroll saw blades are designed to cut through different types of materials with varying thicknesses. Using the wrong blade for the job or pushing the blade too hard against a thick material can lead to breakage.

But don’t worry, there’s no need to get discouraged! By understanding the reasons behind your scroll saw blade breakage and implementing the right techniques, you can enjoy smooth and successful cutting experiences. So let’s dive deeper into these issues and explore effective solutions to keep your scroll saw blades intact and your projects on track.

Are your scroll saw blades constantly breaking? Don’t worry, we’ve got you covered! Discover the top reasons why your scroll saw blades may be breaking and learn how to prevent it. From improper tensioning to using the wrong blade for the material, we’ll provide you with expert tips to keep your blades intact. Save time and money by understanding and avoiding these common mistakes.

Why Do My Scroll Saw Blades Keep Breaking? Understanding the Causes and Solutions

Scroll sawing is a popular and enjoyable woodworking activity, but it can be frustrating when your blades keep breaking. Understanding the reasons behind this issue is crucial for ensuring a smooth and successful scroll sawing experience. In this article, we will explore the various factors that can cause scroll saw blades to break and provide practical solutions to prevent future breakages. Whether you are a beginner or an experienced scroll saw user, this comprehensive guide will help you troubleshoot and overcome the challenges associated with broken blades.

Common Reasons for Scroll Saw Blade Breakage

1. Incorrect Blade Tension: One of the primary reasons for scroll saw blade breakage is improper blade tension. When the tension is too loose, the blade can wander during cutting, leading to unnecessary strain and eventual breakage. On the other hand, excessive tension can cause the blade to heat up and become brittle, making it more prone to breaking. It is essential to find the right balance by adjusting the tension according to the manufacturer’s recommendations.

2. Using the Wrong Blade Type: Choosing the correct blade type for your project is crucial. Different materials and cutting techniques require specific blade types and sizes. Using the wrong blade can result in excessive stress and breakage. For example, a blade designed for intricate and delicate cuts may not be suitable for thicker or harder woods. Always refer to the manufacturer’s recommendations and choose the appropriate blade for the task at hand.

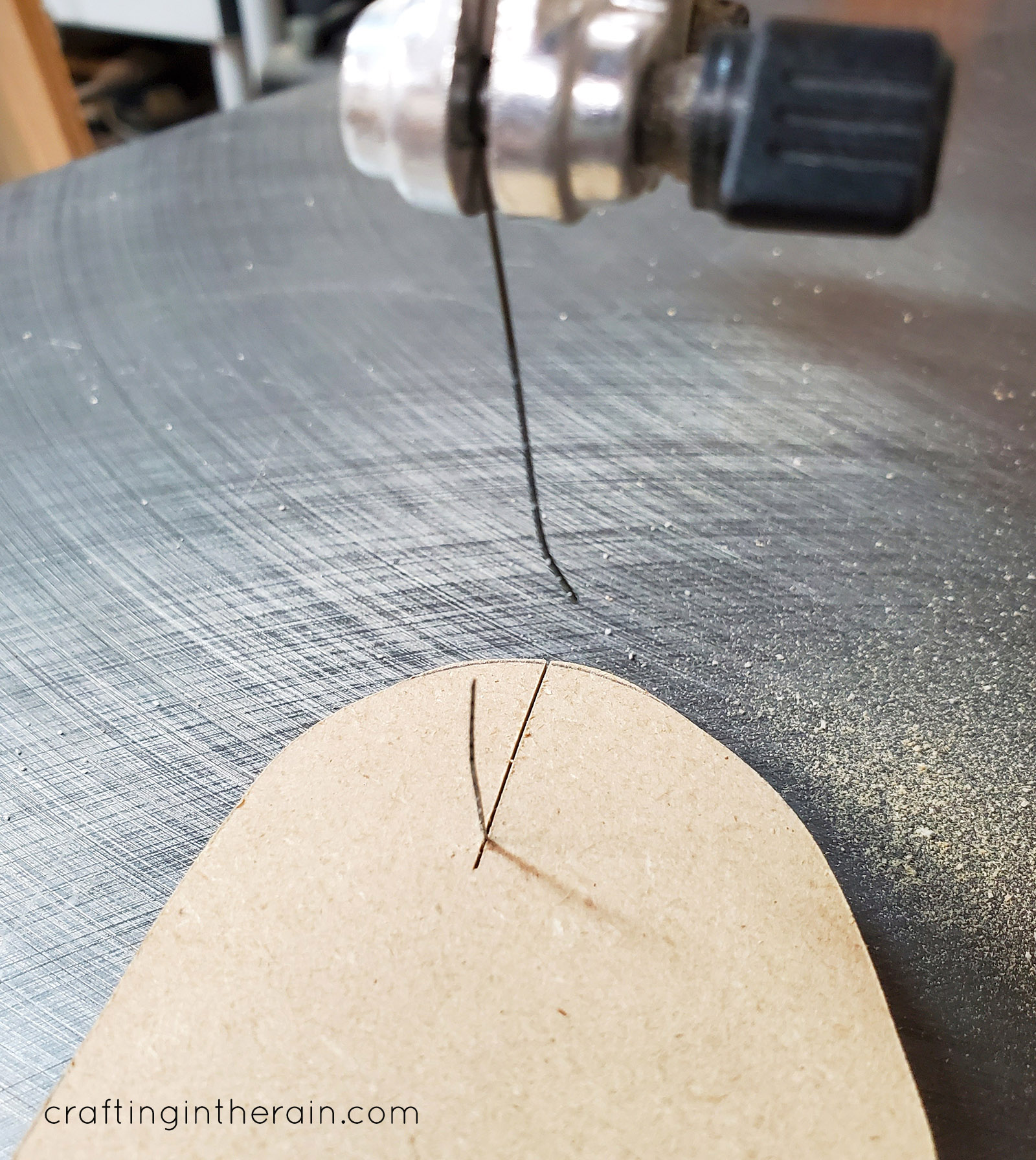

3. Feed Rate and Cutting Speed: The speed at which you feed the material into the scroll saw, coupled with the cutting speed, can significantly impact blade breakage. If you feed the material too quickly or force the blade through the wood, it can cause strain and result in breakage. Similarly, operating the scroll saw at excessively high speeds can generate excessive heat and cause the blade to become brittle. Maintaining a steady feed rate and using an appropriate cutting speed is crucial for preventing blade breakage.

Proper Blade Installation and Maintenance

Proper installation and maintenance of scroll saw blades are essential for minimizing breakages. Here are some key considerations:

1. Correct Blade Orientation: When installing a new blade, ensure that it is facing in the correct direction. The teeth should be pointing downward, with the bottom of the blade facing the table. Installing the blade upside down can result in poor performance and increased breakage risk.

2. Blade Clamping and Tensioning: Take the time to properly clamp the blade in place and adjust the tension to the manufacturer’s recommendations. This will help ensure that the blade is secure and properly tensioned, reducing the risk of breakage during operation.

3. Regular Cleaning and Lubrication: Sawdust and debris can accumulate on the blade, affecting its performance and increasing the likelihood of breakage. Regularly clean the blade with a stiff brush or compressed air to remove any buildup. Applying a small amount of lubricant on the blade can also help reduce friction and prolong its life.

Choosing the Right Scroll Saw Blades

Investing in high-quality blades that are specifically designed for scroll sawing can make a significant difference in preventing breakages. Here are some factors to consider when choosing the right blades:

1. Blade Material: Scroll saw blades are typically made from carbon steel or high-speed steel (HSS). HSS blades tend to be more durable and can withstand higher speeds, making them suitable for heavy-duty cutting. Carbon steel blades are more affordable and suitable for general-purpose cutting.

2. Teeth Configuration: Scroll saw blades come in different teeth configurations, such as plain-end, skip tooth, and spiral. Each configuration has its advantages and is suitable for specific cutting applications. Understanding the different teeth configurations and selecting the appropriate one for your project can help reduce breakage.

3. Blade Thickness: The thickness of the blade also plays a role in its durability and performance. Thicker blades tend to be more robust and suitable for cutting thicker materials, while thinner blades excel at intricate and delicate cuts. Choose the appropriate blade thickness based on the material and cutting requirements.

Proper Cutting Techniques and Safety Precautions

Adopting proper cutting techniques and following essential safety precautions can help minimize blade breakage and ensure a smoother scroll sawing experience. Here are some tips:

1. Start with Test Cuts: Before diving into your project, it is a good practice to make test cuts on scrap material. This allows you to adjust the feed rate, cutting speed, and blade tension, ensuring optimal results without risking damage to your workpiece or blade breakage.

2. Support the Material: Properly supporting the material being cut can prevent vibrations and reduce the risk of blade breakage. Use a scroll saw table insert or a secondary support piece to ensure stability during cutting.

3. Wear Personal Protective Equipment (PPE): Always wear safety glasses or goggles to protect your eyes from flying debris. Additionally, consider using a dust mask to prevent inhalation of sawdust particles, which can affect respiratory health.

In conclusion, several factors can contribute to scroll saw blade breakage. By understanding and addressing these issues, such as incorrect blade tension, using the wrong blade type, improper feed rate, and installation and maintenance mistakes, you can prevent future breakages and achieve better results in your scroll sawing projects. Remember to choose the right blades, practice proper cutting techniques, and prioritize safety to ensure a successful and enjoyable scroll sawing experience.

Key Takeaways: Why Do My Scroll Saw Blades Keep Breaking?

- Blade tension: Ensure your scroll saw blades are properly tensioned to prevent breakage.

- Blade alignment: Check if the blade is properly aligned with the saw’s guides for smooth cutting.

- Speed control: Adjust the speed of your scroll saw to match the thickness and type of material being cut.

- Maintain sharpness: Replace blades when they become dull to prevent them from snapping during use.

- Proper technique: Practice proper cutting techniques such as using a steady hand and following the line closely.

Frequently Asked Questions

Welcome to our FAQ section where we answer your questions about why scroll saw blades keep breaking. Read on to find out more!

1. How can I prevent my scroll saw blades from breaking?

To prevent scroll saw blades from breaking, there are a few things you can do. Firstly, make sure you are using the correct blade for the type of material you are cutting. Different blades are designed for different materials, so using the wrong one can increase the risk of breakage. Secondly, ensure that you are properly tensioning your blades. If the tension is too loose, the blade can twist and snap. On the other hand, if the tension is too tight, it can put unnecessary stress on the blade, causing it to break prematurely. Lastly, check that your blades are sharp and in good condition before using them. Dull or damaged blades are more likely to break, so regularly replace them or sharpen them as needed.

Additionally, be mindful of the speed at which you are cutting and the feed rate of the material. Cutting too quickly or feeding the material too forcefully can put excessive strain on the blade, leading to breakage. Take it slow and steady to prolong the lifespan of your scroll saw blades.

2. Are there any common mistakes that can cause scroll saw blades to break?

Yes, there are a few common mistakes that can lead to scroll saw blade breakage. One of the most common mistakes is using too much force when cutting. Pushing too hard on the material can cause the blade to bend or flex, increasing the likelihood of it breaking. Remember to let the blade do the work and avoid forcing it through the material.

Another common mistake is not properly clearing away sawdust and debris during the cutting process. Build-up of sawdust can cause the blade to overheat or become clogged, straining the blade and potentially causing it to break. Make sure to periodically stop and clear away any debris to keep your blades running smoothly.

3. Can the quality of the scroll saw blades affect their durability?

Absolutely! The quality of the scroll saw blades can greatly impact their durability. Cheap or low-quality blades are more prone to breaking, as they may not be made from the best materials or have the same level of craftsmanship as higher-quality blades. Investing in good-quality blades, even if they are slightly more expensive, can save you money in the long run by reducing the frequency of blade breakage and the need for replacements. Look for blades made from high-quality steel and from reputable brands that have a track record of producing reliable blades.

Remember, the quality of the blades goes hand in hand with the quality of your finished cuts. Better blades often result in cleaner, smoother cuts, further justifying the investment in higher-quality options.

4. Can incorrect blade installation cause breakage?

Improper blade installation can certainly increase the risk of breakage. When installing a scroll saw blade, it’s important to ensure that it is properly seated and secured in the blade holders. If the blade is not installed tightly or properly aligned, it may vibrate or twist during cutting, leading to premature breakage. Take the time to carefully follow the manufacturer’s instructions for installing the blade and use any included tools or mechanisms to secure it firmly in place. Regularly check the blade tension and alignment while using the scroll saw to minimize the chances of breakage due to incorrect installation.

If you are unsure about how to properly install a scroll saw blade, consult the user manual for your specific saw model or reach out to the manufacturer for guidance. They will be able to provide you with the necessary information to ensure proper blade installation and minimize the risk of breakage.

5. Can a dull blade cause other issues aside from breakage?

A dull blade can certainly cause other issues aside from breakage. When a blade is dull, it becomes less effective at cutting through material, often resulting in rough, uneven cuts. This can be frustrating and time-consuming, as you may need to sand or smooth out the edges afterwards. Dull blades can also generate excess heat while cutting, which can lead to burning or scorching of the material. Additionally, a dull blade may be more likely to get stuck in the material, causing it to jam or kickback, potentially leading to accidents or injury. Therefore, regularly inspect your blades and replace or sharpen them as necessary to maintain optimal cutting performance and safety.

Remember, a sharp blade not only cuts more efficiently but also reduces the strain on the blade itself, minimizing the chances of breakage. So, don’t overlook the importance of keeping your blades sharp!

Why Do My Scroll Saw Blades Break? Improper Tension! Here’s How To Do It Right Hegner EthAnswers

Summary

So, why do my scroll saw blades keep breaking? Well, there are a few possible reasons. Firstly, it could be that you’re using the wrong blade for the material you’re cutting. Make sure to choose a blade that is suitable for the type of wood or material you’re working with. Secondly, if your blade tension is too high or too low, it can put unnecessary stress on the blade and cause it to break. Be sure to check your tension and adjust it accordingly. Lastly, dull blades can also lead to breakage. Keep your blades sharp by regularly replacing them or sharpening them yourself.

In conclusion, by using the correct blade, maintaining the proper tension, and keeping your blades sharp, you can minimize the chances of them breaking. Happy scrolling!