Do you ever wonder why planers sometimes make those annoying sniping marks on your wood? Well, you’re in the right place because today we’re going to explore the question, “Why do planers snipe?”

If you’re new to woodworking, snipe refers to those frustrating indentations that can appear at the beginning or end of a board when it’s being planed. It’s like a sneak attack from your planer, leaving you with an unwanted groove that can mess up your project. But fear not, my curious friend, we’re here to uncover the reasons behind this phenomenon.

So, grab your tool belt and let’s dive into the fascinating world of woodworking and the mysteries behind why planers sometimes give us snipe. You’ll soon discover some handy tips and tricks to minimize or even eliminate this pesky issue once and for all!

1. Use additional support with infeed and outfeed tables

2. Feed the board with a slight upward angle

3. Adjust the cutting depth gradually

4. Place sacrificial boards at the beginning and end

By following these steps, you can minimize snipe while planing.

Why Do Planers Snipe? Exploring the Phenomenon

Planers are essential tools for woodworking enthusiasts and professionals alike. They are designed to smooth and shape wood surfaces, but sometimes they can create a frustrating issue known as “snipe.” Snipe refers to the uneven and deeper cuts that occur at the beginning or end of a board when passing through a planer. In this article, we will delve into the reasons why planers snipe, and explore potential solutions to minimize or eliminate this issue.

The Role of Infeed and Outfeed Tables

One of the primary culprits behind planer snipe is the lack of support provided by the infeed and outfeed tables. These tables are designed to provide stability and prevent the board from tilting during the planing process. When the infeed table is not set correctly, it can result in the leading edge of the board being lifted as it enters the planer, leading to snipe. Similarly, if the outfeed table is not properly aligned, it can cause the trailing edge of the board to rise, resulting in snipe at the end.

To prevent snipe caused by inadequate support, ensure that the infeed and outfeed tables are level and aligned with the planer bed. This will help maintain a consistent and smooth feeding of the board, minimizing the chances of snipe. Additionally, using auxiliary supports, such as roller stands or a planer sled, can provide extra stability and prevent the board from sagging during planing.

The Influence of Cutterhead Design

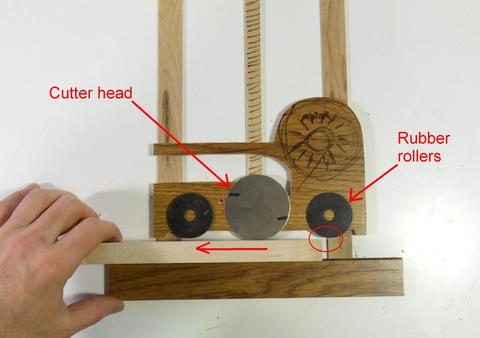

Another factor that can contribute to planer snipe is the design of the cutterhead. The cutterhead is responsible for rotating the blades that cut into the wood surface. If the cutterhead design is flawed or improperly adjusted, it can cause uneven cuts and snipe.

One common design that can lead to snipe is a two-knife cutterhead. A two-knife cutterhead only has two blades, positioned diagonally across from each other. This can result in a gap between the blades, causing a slight dip in the wood surface as the board passes through. As a result, snipe can occur at the beginning and end of the board.

To minimize snipe caused by the cutterhead design, consider upgrading to a planer with a helical cutterhead. Helical cutterheads have multiple small, square-shaped cutters positioned around the circumference, resulting in a smoother and more consistent cut. The staggered arrangement of the cutters also helps distribute the cutting force more evenly, reducing the likelihood of snipe.

The Impact of Feed Rate and Depth of Cut

In addition to the machinery itself, the way the operator handles the planer can also affect the occurrence of snipe. Two key factors to consider are the feed rate and the depth of cut.

A slow or uneven feed rate can increase the likelihood of snipe. If the board is not fed into the planer consistently, it can cause variations in the pressure applied to the wood surface, leading to uneven cuts and snipe. On the other hand, feeding the board through the planer too quickly can overload the cutting mechanism and result in snipe.

Similarly, the depth of cut plays a significant role in snipe. Taking too much material off in a single pass can put excessive strain on the planer, causing it to dig into the wood more aggressively and create snipe. It is advisable to make multiple light passes to gradually achieve the desired thickness and minimize the risk of snipe.

Optimizing Techniques to Reduce Snipe

While understanding the causes of planer snipe is essential, it is also crucial to implement optimization techniques to minimize its occurrence. Here are some tips to help reduce snipe when using a planer:

1. Use longer boards: Using longer boards allows for more stability and support throughout the planing process, reducing the chances of snipe.

2. Joint the boards: Before running boards through the planer, jointing them can help create a flat and level surface, mitigating the risk of snipe.

3. Tape the leading edge: Applying tape along the leading edge of the board can help prevent the blades from digging in too deeply, minimizing snipe.

4. Adjust the planer’s cutting depth: Experimenting with different cutting depths can help find the optimal setting that reduces snipe while still achieving the desired result.

5. Utilize sacrificial boards: Placing sacrificial boards before and after the board being planed can help provide additional support and reduce snipe.

By implementing these techniques, woodworkers can significantly reduce the occurrence of planer snipe and enjoy smoother and more professional-looking results.

The Importance of Proper Maintenance and Blade Alignment

To keep your planer running smoothly and minimize the chances of snipe, it is crucial to perform regular maintenance and ensure the blades are properly aligned. Over time, the blades can become dull and misaligned, leading to uneven cuts and snipe.

Regularly inspect the blades for signs of wear and tear, and replace them when necessary. It is also essential to check the blade alignment to ensure they are parallel and at the correct cutting angle. Blade alignment jigs can aid in this process, providing a precise and easy way to adjust the blades.

In conclusion, planer snipe is a common issue that can frustrate woodworkers and interfere with the quality of their work. By addressing factors such as inadequate support from infeed and outfeed tables, the design of the cutterhead, feed rate, depth of cut, and proper maintenance and blade alignment, woodworkers can significantly reduce or even eliminate planer snipe. Implementing optimization techniques and utilizing the right tools can lead to smooth and professional woodworking results, allowing woodworkers to focus on their craft without the annoyance of snipe.

Key Takeaways: Why Do Planers Snipe?

- Planers snipe because of the way they are designed.

- Snipe is the term used to describe when a planer cuts deeper at the beginning or end of a board.

- It happens due to the movement of the board as it goes through the planer.

- Snipe can be minimized by adjusting the infeed and outfeed tables of the planer.

- Using sacrificial boards at the beginning and end of the project can also help reduce snipe.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section where we answer common queries related to “why do planers snipe?” Here, we’ll provide you with insights into why planers sometimes leave uneven cuts at the ends of the wood. Read on to learn more!

What causes planers to leave snipe on wood?

Planers are powerful machines that shave off thin layers of wood to achieve a smooth surface. However, sometimes planers can leave what is known as “snipe” at the beginning or end of the wood. Snipe is caused by a few different factors:

Firstly, if the infeed and outfeed tables on the planer are not properly aligned, it can cause the wood to dip slightly, resulting in snipe at the ends. Additionally, when planing long pieces of wood without proper support, it can cause the wood to sag, leading to snipe. Finally, if the blades on the planer are not properly set or are dull, it can also contribute to snipe.

Can snipe be completely eliminated?

While it may be challenging to completely eliminate snipe, there are techniques you can employ to minimize its occurrence:

One effective method is using sacrificial boards. By placing a board before and after the board you want to plane, the sacrificial boards provide extra support, reducing the likelihood of snipe on your desired piece. Additionally, adjusting the infeed and outfeed tables to be perfectly aligned can also help reduce snipe. Another useful technique is to feed the wood through the planer at a slight angle, which can help distribute the pressure and minimize snipe. Lastly, ensuring that your planer blades are sharp and properly set will also help reduce snipe and produce smoother results.

Is snipe more common with certain types of planers?

Snipe can occur with both handheld planers and larger stationary planers, but it is more commonly associated with smaller handheld models. Handheld planers have shorter infeed and outfeed tables, which makes it trickier to manage the wood’s movement through the planer, especially for longer pieces. However, with proper techniques and precautions, snipe can be minimized on both types of planers.

Can snipe be fixed after it occurs?

If you notice snipe on your wood after running it through a planer, there are a few options to fix it. One method is to trim off the sniped edges using a saw or another cutting tool. By removing the uneven sections, you can achieve a smoother and more uniform appearance. Alternatively, you can sand down the sniped areas using sandpaper or a sander until the surface is even. However, prevention is always better than fixing snipe after it occurs, so it’s best to implement techniques to minimize snipe from the start.

Are there any specific safety precautions to take when using a planer?

Absolutely! When using a planer, it’s essential to follow safety guidelines to ensure your well-being:

Firstly, always wear proper eye and ear protection to safeguard against any flying debris and loud noise. Additionally, make sure to keep your hands and fingers away from the planer blades, as they are extremely sharp and can cause severe injuries. It’s also crucial to secure the wood properly when feeding it through the planer, preventing any sudden movements or slips that could lead to accidents. Lastly, be mindful of your surroundings and maintain a clean workspace, free from any hazards that could interfere with the operation of the planer.

Planer Snipe: It happens, get over it…

Summary

When planers snipe, it’s because of the way the machine is designed. Snipe happens when the board gets lifted at the end of the cut, causing an uneven surface. This can happen due to various factors like improper technique or worn-out equipment. To reduce snipe, it’s important to properly support the board and adjust the infeed and outfeed tables. Additionally, maintaining sharp blades and using a slow and steady feed rate can also help minimize snipe. Understanding the causes of snipe and implementing these techniques can lead to smoother and more consistent cuts with your planer.