Got a scrolling saw? Well, you might be wondering why do scroll saw blades break? Let’s dive right in and find out!

Picture this: you’ve got a fantastic project in mind, you fire up your scroll saw, but then disaster strikes – the blade suddenly snaps! What gives? Well, there are a few reasons why scroll saw blades break, and we’re here to shed some light on the matter.

From improper blade installation to pushing the saw too hard, there are various factors that can contribute to blade breakage. So, if you want to avoid those frustrating blade mishaps, keep reading to uncover the secrets behind this pesky problem. Let’s get to it!

Discover the reasons behind scroll saw blade breakage and how to prevent it. When it comes to scroll sawing, blade breakage can be frustrating. One common reason is applying excessive pressure, causing the blade to bend and snap. Another factor is using an incorrect blade for the material being cut. Choosing the right blade type and tensioning it properly can significantly reduce the risk of breakage. Keep your saw blades in top shape by following these tips!

Why Do Scroll Saw Blades Break?

Scroll saws are powerful tools that use a thin, reciprocating blade to make intricate cuts and detailed designs in various materials. However, one common issue that users often encounter is the breaking of scroll saw blades. Understanding why scroll saw blades break is essential for preventing these incidents and ensuring a smooth and efficient cutting process. In this article, we will explore the potential causes of scroll saw blade breakage and provide valuable tips to help you avoid this frustrating problem.

Improper Blade Installation

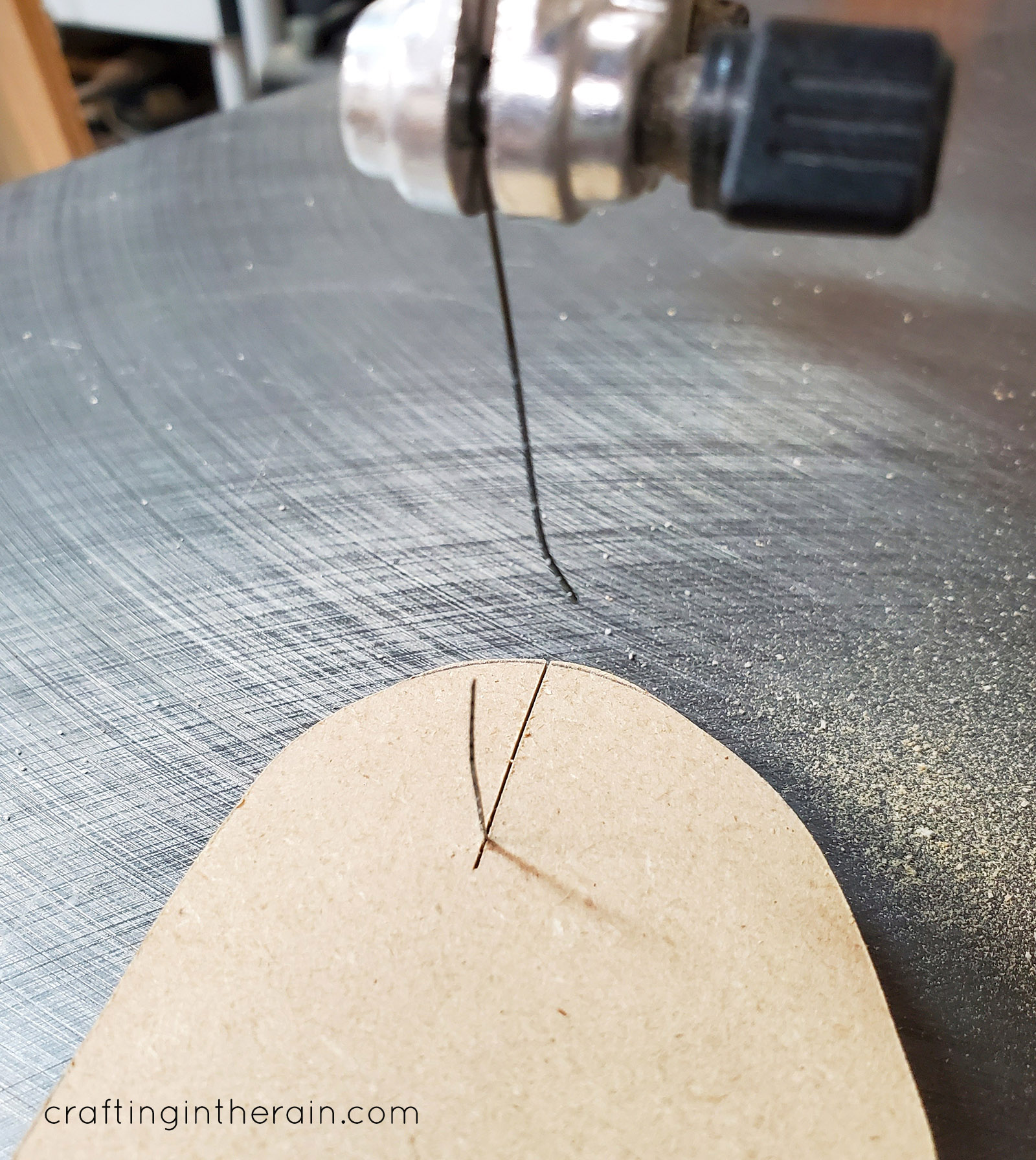

One of the primary reasons why scroll saw blades break is improper installation. It is crucial to ensure that the blade is securely and correctly installed in the scroll saw. If the blade is not properly tensioned or if it is inserted incorrectly, it can lead to excessive vibration and stress, causing the blade to snap. Always refer to your scroll saw’s instruction manual to learn the proper installation process and follow it diligently.

In addition to proper installation, it is important to choose the right blade for your specific project. Different blades are designed for different materials and thicknesses. Using the wrong blade can cause it to break easily. Before starting a new project, consider the material you are working with and select a blade with an appropriate tooth configuration, size, and thickness. This will help ensure that the blade can handle the demands of the job without breaking.

Material Defects

Another factor that can contribute to scroll saw blade breakage is material defects. Even the highest quality blades can sometimes have flaws or weak spots. These defects can cause the blade to weaken and snap during use. To minimize the risk of using a defective blade, it is crucial to purchase blades from reputable manufacturers who prioritize quality control. Look for blades that are made from high-quality materials and undergo rigorous testing to ensure their durability and reliability.

Additionally, it is important to inspect the blade before each use. Check for any signs of damage, such as visible cracks or bends. If you notice any defects or signs of wear, replace the blade immediately. Regularly maintaining and replacing your scroll saw blades will help prevent unexpected breakage and ensure optimal cutting performance.

Poor Cutting Technique and Speed

A common mistake that can lead to scroll saw blade breakage is using incorrect cutting techniques or excessive speed. When using a scroll saw, it is important to let the blade do the work and avoid forcing the material through the blade. Applying excessive pressure or pushing the material too quickly can cause the blade to bend or break. Instead, use a gentle, steady motion and allow the blade to move smoothly and effortlessly through the material.

It is also crucial to adjust the speed of the scroll saw according to the type and thickness of the material being cut. If the speed is too high, the blade can heat up and become more prone to breaking. Conversely, if the speed is too low, the blade may struggle to cut through the material efficiently, increasing the risk of breakage. Take the time to find the optimal speed for each specific application to ensure clean and precise cuts while minimizing the risk of blade breakage.

Proper Blade Maintenance

In addition to the factors mentioned above, proper blade maintenance plays a vital role in preventing scroll saw blade breakage. Here are some key tips to keep your blades in top condition:

- Keep the blade clean and free from debris that can cause it to jam or overheat. Use compressed air or a brush to remove any dust, wood chips, or other particles.

- Regularly lubricate the blade with a specialized blade lubricant to reduce friction and minimize heat buildup.

- Inspect the blade for any signs of wear or damage before each use. Replace any damaged or worn-out blades immediately.

- Store your blades in a dry and clean environment to prevent them from rusting or corroding.

The Importance of Using the Right Blade

Using the right blade is essential for preventing scroll saw blade breakage. Different blades are designed for specific materials and cutting techniques. Here are a few key blade types and their applications:

Standard Blades

Standard or skip-tooth blades are commonly used for general cutting applications. They have widely spaced teeth that help prevent clogging, making them ideal for cutting thicker materials such as hardwoods and plastics.

Precision Blades

Precision blades have closely spaced teeth and are perfect for intricate and detailed cutting. They are commonly used for projects that require delicate and precise maneuvers.

Spiral Blades

Spiral blades are twisted and have teeth on all sides, allowing for cutting in any direction. They are particularly useful when cutting intricate patterns and shapes in thin materials.

Conclusion

By understanding the potential causes of scroll saw blade breakage and implementing the necessary precautions, you can significantly reduce the risk of blade failure. Proper blade installation, choosing the right blade for the job, inspecting for material defects, using the correct cutting techniques and speed, and maintaining the blades are all crucial factors in preventing scroll saw blade breakage. Take the time to follow these tips and best practices to ensure a productive and enjoyable scroll sawing experience. Happy scrolling!

Key Takeaways: Why Do Scroll Saw Blades Break?

- Scroll saw blades can break due to excessive heat generated during use.

- Improper blade tension can cause the blade to break.

- Using the wrong type or size of blade for the material being cut can lead to breakage.

- Applying too much pressure or forcing the blade through the material can cause it to snap.

- Worn-out or dull blades are more prone to breaking, so regular replacement is important.

Frequently Asked Questions

Scroll saw blades are essential tools for woodworking enthusiasts, but they can sometimes break unexpectedly. Here are some common questions and answers related to why scroll saw blades break.

1. What are some reasons why scroll saw blades break?

There are a few reasons why scroll saw blades may break. One possible cause is that the blade tension is too high or too low. If the tension is too high, it can put excessive stress on the blade, causing it to snap. On the other hand, if the tension is too low, the blade may wander off course, leading to uneven pressure and eventual breakage.

Another reason for blade breakage is improper blade installation. If the blade is not securely installed, it can twist or bend during use, leading to premature failure. It’s essential to ensure that the blade is inserted correctly and tightened properly before beginning any cutting tasks.

2. Can the type of material being cut cause scroll saw blades to break?

Yes, the material being cut can play a role in blade breakage. Hardwoods, such as oak or maple, can be particularly challenging for scroll saw blades. The dense fibers in these woods can put a strain on the blade, leading to fractures or breakage. Additionally, cutting through thick or oversized pieces of wood can also increase the risk of blade breakage due to the added resistance faced by the blade.

If you regularly work with dense or challenging materials, it might be worth considering using specialized blades designed to handle such tasks. These blades are often made from stronger materials and have tooth configurations that can withstand the demands of cutting through tough wood.

3. Is improper blade speed a factor in scroll saw blade breakage?

Yes, blade speed can contribute to scroll saw blade breakage. Using a speed that is too high for the particular material being cut can cause the blade to overheat, potentially leading to breakage. Similarly, using a speed that is too low can cause the blade to stall, causing it to bend or become damaged and eventually break.

It is crucial to select the appropriate speed for the material and thickness you are working with. Consulting the manufacturer’s recommendations or experimenting with different speeds can help determine the optimal setting for your scroll saw blade.

4. Can operator error lead to scroll saw blade breakage?

Operator error can indeed contribute to scroll saw blade breakage. Applying too much force or pushing the material too hard against the blade can cause it to bend, twist, or even snap. It is important to let the blade do the cutting and guide the workpiece with gentle, even pressure.

Additionally, using the incorrect blade for the type of cut or not adjusting the blade tension properly can also lead to blade breakage. Taking the time to understand the requirements of the cut and ensuring the blade is properly installed and tensioned can help prevent operator-related blade breakage.

5. How can I prolong the life of my scroll saw blades to prevent breakage?

There are several steps you can take to help prolong the life of your scroll saw blades. First, make sure to use the right blade for the job. Different blades are designed for different materials and cuts, so using the appropriate blade can minimize the risk of breakage.

Regularly cleaning and lubricating your blades can also help extend their lifespan. Sawdust and debris can accumulate on the blade, increasing friction and heat, which can weaken the blade over time. Cleaning the blade after each use and applying lubrication can reduce friction and prevent premature breakage.

Why Do My Scroll Saw Blades Break? Improper Tension! Here’s How To Do It Right Hegner EthAnswers

Summary

Scroll saw blades can break if they are not properly installed or if they are being used incorrectly. It is important to make sure the blade is tight and straight in the saw, and to avoid applying too much pressure while cutting. Choosing the right blade for the material being cut is also crucial. Additionally, if the blade is dull or worn out, it is more likely to break, so it should be replaced when necessary. Taking these precautions can help prevent scroll saw blade breakage and ensure safer and more effective cutting.