Have you ever wondered why scroll saw blades keep breaking? It can be frustrating when you’re in the middle of a project and your blade snaps, causing you to start all over again. But fear not, because in this article, we will explore the reasons behind this common issue and provide you with some helpful tips to prevent it from happening. So let’s dive in and unravel the mystery behind those pesky broken scroll saw blades!

One of the main reasons why scroll saw blades break is due to excessive pressure and stress on the blade. When you push too hard or try to cut too quickly, the blade can’t handle the force and ends up snapping. Another factor that can lead to blade breakage is using the wrong type or size of blade for the job.

Additionally, the quality of the blade itself can play a significant role in its durability. Cheaper blades often lack the necessary strength and sharpness to withstand the demands of intricate scrolling. So, investing in high-quality blades is crucial for achieving smoother cuts and avoiding those dreaded breakages.

Now that we’ve explored some of the reasons why scroll saw blades keep breaking, are you ready to learn how to prevent it from happening? In the following sections, we will delve into practical tips and techniques that will help you extend the lifespan of your blades and ensure a more enjoyable scrolling experience. So, let’s get started!

Why Do Scroll Saw Blades Keep Breaking?

Scroll saws are versatile tools that are commonly used for woodworking projects. However, one common issue that many users encounter is the frequent breaking of scroll saw blades. This can be frustrating and costly, as it disrupts the workflow and requires the constant replacement of blades. In this article, we will explore the various reasons why scroll saw blades keep breaking and provide tips on how to prevent this issue from occurring.

Poor Blade Quality

One of the primary reasons why scroll saw blades break is due to poor blade quality. Low-quality blades are more susceptible to snapping and can quickly become dull, requiring frequent replacements. When purchasing scroll saw blades, it is important to invest in high-quality ones that are made from durable materials and have gone through a reliable manufacturing process. This will significantly reduce the likelihood of blades breaking during use.

Additionally, it is essential to properly store blades to maintain their quality. Exposure to moisture, dust, and extreme temperature fluctuations can deteriorate the blades, making them prone to breakage. Storing blades in a dry and cool environment, such as a blade case or container, will help preserve their integrity and extend their lifespan.

In some cases, blades may also break due to manufacturing defects. If you consistently experience issues with breaking blades despite using high-quality ones and proper storage, it may be worth contacting the manufacturer for assistance or to inquire about a possible defect.

Incorrect Blade Installation

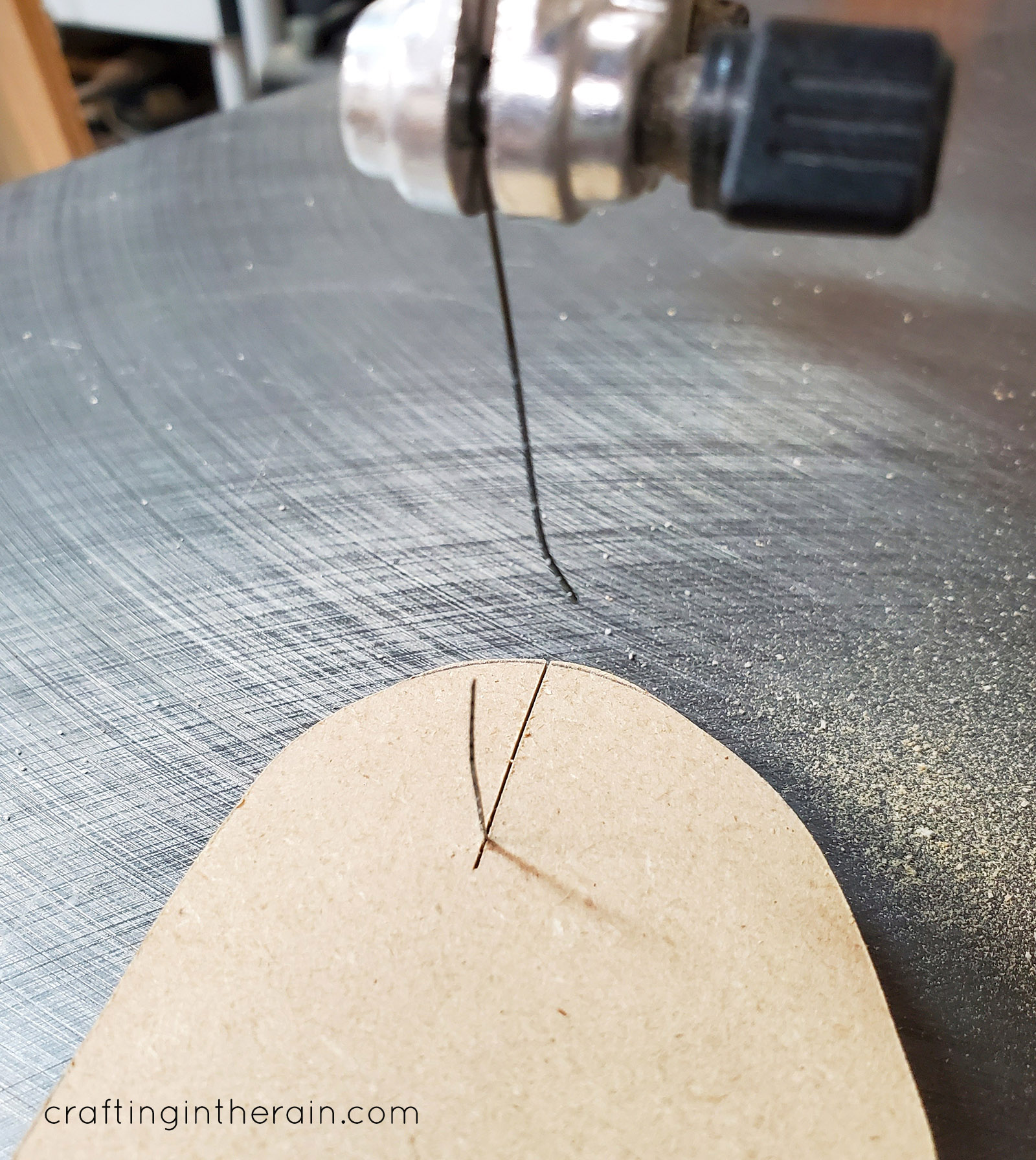

Another common reason for scroll saw blade breakage is incorrect installation. Proper blade installation is crucial for optimal performance and longevity. It is essential to ensure that the blade is securely tightened and properly aligned with the saw’s guides and tensioning mechanism. Failing to do so can result in excessive blade tension or misalignment, leading to blade breakage.

When installing a new blade, carefully follow the manufacturer’s instructions and consult the user manual for your specific scroll saw model. Take the time to understand the correct installation process and make any necessary adjustments before starting a project. This will help prevent unnecessary strain on the blade and minimize the risk of breakage.

In addition to correct installation, it is important to regularly inspect the blade tension and make adjustments as needed. An improperly tensioned blade can cause it to bend or flex too much, increasing the chances of it snapping during use. Periodically check the tension and make any necessary adjustments to maintain a proper balance and reduce blade breakage.

Material and Blade Compatibility

The type of material being cut and the compatibility of the blade with that material can also contribute to blade breakage. Different scroll saw blades are designed for specific applications and materials, such as wood, metal, or plastic.

Using the wrong type of blade for a particular material can put excessive stress on the blade and cause it to break. It is important to select the appropriate blade for the material being cut and ensure that it is designed to handle the specific requirements of the project.

For example, when cutting dense or hardwoods, a blade with higher teeth-per-inch (TPI) and a smaller size might be more suitable to prevent breakage. Conversely, when cutting softwoods or thicker materials, a blade with lower TPI and larger size might be more appropriate. Understanding the characteristics of different blades and their compatibility with materials will help reduce the risk of blade breakage and improve overall cutting performance.

Excessive Feed Rate

Improper feeding techniques can also contribute to scroll saw blade breakage. Pushing the material too forcefully against the blade or feeding it at a high rate can result in excessive stress and strain on the blade, causing it to snap.

When using a scroll saw, it is important to maintain a consistent and controlled feed rate. Allow the blade to do the cutting and guide the material smoothly through the blade without forcing it. Applying gentle pressure and using a slow, steady feed rate will help prevent blade breakage and ensure clean and accurate cuts.

In addition to the feed rate, it is also crucial to choose the appropriate blade speed for the material being cut. Adjusting the blade speed according to the material’s hardness or thickness can help reduce strain on the blade and minimize the risk of breakage.

Lack of Blade Maintenance

Proper maintenance is essential for preventing scroll saw blade breakage. Blades can become dull or damaged over time due to normal wear and tear. Dull or damaged blades are more susceptible to breaking, as they require more force to cut through materials.

Regularly inspecting and replacing worn-out blades is important to avoid excessive strain and potential breakage. It is also recommended to clean the blades after use to remove any debris or buildup that could affect their cutting performance.

Additionally, lubricating the blade periodically with a suitable cutting fluid or wax can help reduce friction and improve cutting efficiency, prolonging the blade’s lifespan and reducing the risk of breakage.

Improper Saw Settings and Techniques

Scroll saw settings and techniques play a significant role in blade durability. Incorrect speed, tension, or blade angle settings can put additional stress on the blade and cause it to break.

Ensure that the scroll saw is set to the appropriate speed for the material and cutting technique being used. High speeds can generate excess heat and cause the blade to become brittle, while low speeds can result in slower cutting and potential blade binding.

Using the correct blade angle is also important. A blade that is set at too steep of an angle can become less stable and more prone to breaking. Adjusting the blade angle to the manufacturer’s recommended setting for the specific material being cut can help prevent breakage and ensure optimal cutting results.

Finally, employing proper cutting techniques, such as using a light touch and avoiding sharp turns or sudden changes in direction, can minimize the risk of blade breakage. Taking care to cut at a consistent pace and allowing the blade to do the work will help protect it from unnecessary strain and potential breakage.

Tips to Prevent Scroll Saw Blade Breakage

Now that we have explored the various reasons behind scroll saw blade breakage, here are some tips to help prevent this issue:

Use High-quality Blades:

Invest in high-quality scroll saw blades that are made from durable materials and have undergone reliable manufacturing processes. Poor-quality blades are more likely to break and require frequent replacements.

Proper Blade Installation:

Take the time to correctly install the scroll saw blade, ensuring it is securely tightened and aligned with the saw’s guides and tensioning mechanism. Regularly inspect and adjust the blade tension to maintain optimal performance.

Choose the Right Blade for the Material:

Select the appropriate blade for the specific material being cut. Different blades are designed for different applications and materials. Using the wrong type of blade can increase the risk of breakage.

Maintain a Controlled Feed Rate:

Feed the material at a consistent and controlled rate without forcing it against the blade. Applying gentle pressure and using a slow, steady feed rate will help prevent excessive strain on the blade.

Regular Blade Maintenance:

Inspect the blades regularly for any signs of wear or damage and replace them as needed. Clean the blades after use and lubricate them with a suitable cutting fluid or wax to reduce friction and prolong their lifespan.

Common Scroll Saw Blade Breakage FAQs

1. How often should I replace scroll saw blades?

The frequency of blade replacement depends on various factors, such as the quality of the blade, the type of material being cut, and the intensity of use. Inspect the blade regularly for signs of wear or damage and replace it as soon as it appears dull or shows signs of weakened integrity.

2. Can blade breakage be prevented entirely?

While it is not possible to completely eliminate the risk of scroll saw blade breakage, following proper usage, maintenance, and safety techniques will significantly reduce the likelihood of it occurring. Regularly assessing the blade’s condition, adjusting settings, and using the correct blade for the material are essential steps in preventing breakage.

3. Why do some blades break more easily than others?

The quality, material composition, and manufacturing process of scroll saw blades can vary significantly. Higher-quality blades are generally more durable and less prone to breakage. Blades that are specifically designed for the intended application or material also tend to have a higher resistance to breaking.

4. Are there any specific safety precautions to take while using a scroll saw?

Yes, it is crucial to follow safety guidelines while using a scroll saw. Wear appropriate safety gear, such as safety glasses and ear protection, to protect your eyes and ears from debris and noise. Keep your hands a safe distance away from the blade and always work on a stable and secure surface. Familiarize yourself with the specific safety precautions outlined in the user manual of your scroll saw.

Key Takeaways: Why do scroll saw blades keep breaking?

- Improper blade installation can cause scroll saw blades to break.

- Using a scroll saw blade with the wrong teeth per inch (TPI) for the material can lead to breakage.

- Excessive blade tension can cause blades to snap.

- Using a dull blade increases the risk of it breaking during use.

- Scrolling too fast or applying too much pressure can also lead to blade breakage.

Frequently Asked Questions

Are you experiencing the frustration of constantly breaking scroll saw blades? Don’t worry, you’re not alone. Scroll saw blades can break for various reasons, but with a little understanding, you can prevent this issue. Check out these commonly asked questions to learn more about why scroll saw blades keep breaking and how to avoid it.

1. What are the main reasons why scroll saw blades keep breaking?

Scroll saw blades can break due to a few common reasons. One common cause is excessive blade tension, which puts unnecessary strain on the blade. Another reason is the type and quality of the blade itself. Using a lower quality or incorrect blade for your project can lead to breakage. Additionally, feeding the material too quickly or applying too much pressure can cause the blades to snap. It’s important to find the right balance of speed and pressure to avoid breakage.

Another possible reason for the breakage is inadequate blade lubrication. Lubrication helps reduce friction and heat during cutting, preventing the blade from getting too hot and breaking. Lastly, an improper technique or incorrect usage of the scroll saw can also contribute to blade breakage. It’s essential to familiarize yourself with the correct cutting techniques and use the saw properly to minimize the risk of blade failure.

2. How can I prevent scroll saw blades from breaking due to excessive tension?

To prevent scroll saw blades from breaking due to excessive tension, it’s crucial to find the right tension for your specific blade and material. Start by loosening the tension and gradually tighten it until you achieve optimal performance. Ensure the blade is properly aligned and centered on the saw, and make adjustments as necessary. Additionally, regularly check the tension throughout your cutting session and adjust if needed, as the blade can loosen over time. By maintaining proper tension, you can avoid unnecessary strain on the blade and reduce the likelihood of breakage.

It’s worth noting that different blades may require different tension levels, so make sure to consult the manufacturer’s guidelines or do some experimentation to find the sweet spot. With the right tension, you’ll not only prevent breakage but also achieve cleaner and more precise cuts.

3. What kind of scroll saw blades should I use to avoid frequent breakage?

The type and quality of scroll saw blades play a significant role in preventing frequent breakage. High-quality blades made from hardened steel are generally more durable and less prone to breaking compared to lower-quality ones. When choosing blades, consider the thickness and teeth per inch (TPI) rating. Thicker blades are sturdier and less likely to break, while higher TPI blades provide smoother cuts. However, keep in mind that thicker blades may restrict intricate cutting, so finding the right balance between thickness and TPI is essential.

Furthermore, selecting the appropriate blade for the specific material you’re working with is crucial. Different materials require different blade types, such as blades with more aggressive teeth for harder materials like metal, and fine-toothed blades for delicate materials like plywood. Using the correct blade for the job will help prevent excessive strain and reduce the risk of breakage.

4. How can I improve lubrication to prevent scroll saw blades from breaking?

Proper lubrication is essential for preventing scroll saw blades from breaking. Lubricating the blade reduces friction and heat buildup during cutting, improving the overall performance and extending the blade’s lifespan. There are various lubricants available, such as specialized scroll saw blade lubricants, beeswax, or even regular candle wax. Apply a small amount of lubricant to the blade before starting your cutting session, ensuring it covers the teeth evenly.

It’s important to keep in mind that excessive lubrication can attract dust and debris, leading to blade clogging and potential breakage. Therefore, apply the lubricant sparingly and clean the blade regularly to remove any buildup. By maintaining proper lubrication, you’ll reduce friction, heat, and the likelihood of blade failure.

5. What are some common mistakes to avoid when using a scroll saw to prevent blade breakage?

When using a scroll saw, it’s crucial to avoid certain common mistakes that can contribute to blade breakage. One mistake to avoid is forcing the material through the blade or applying excessive pressure. Let the saw do the work and allow the blade to cut at its own pace. Pushing too hard can cause the blade to bend or snap.

Another mistake to watch out for is not properly securing the material. If the material isn’t securely fastened to the scroll saw’s table, it can vibrate or move during cutting, increasing the risk of blade breakage. Use clamps or other appropriate methods to ensure the material is stable and doesn’t shift during cutting. Additionally, take your time and practice patience. Rushing through a cut or making abrupt movements can also lead to blade failure. By avoiding these mistakes, you’ll reduce the likelihood of blade breakage and achieve better results with your scroll saw.

Why Do My Scroll Saw Blades Break? Improper Tension! Here’s How To Do It Right Hegner EthAnswers

**

Summary

**

Scroll saw blades can break for a few reasons. One reason is using too much force while cutting, which can stress the blade and cause it to snap. Another reason is using the wrong type of blade for the material being cut, leading to blade failure. Proper maintenance, like keeping blades clean and using the right tension, can help prevent breakage.

To avoid breaking blades, it’s important to apply gentle pressure while cutting and choose the right blade for the task at hand. Taking good care of your blades, such as cleaning them regularly and using the correct tension, can also extend their lifespan. Remember, slow and steady wins the race when it comes to using a scroll saw!