Have you ever wondered why it’s called an engine lathe? Well, get ready to find out! In this article, we’ll explore the origins of the term and shed some light on this fascinating machine. So, if you’re curious about the naming of the engine lathe, you’re in the right place!

When you think of an engine, what comes to mind? Perhaps cars, trains, or even planes! But did you know that the term “engine” originally referred to any contrivance or device? That’s right! And when it comes to the lathe, it’s all about the way it’s powered. This brings us to the first clue about why it’s called an engine lathe.

Now, let’s dive deeper into the history of the engine lathe and how it got its distinctive name. From its early days as a human-powered device to the modern machines we see today, the evolution of the engine lathe is nothing short of fascinating. So, join us in uncovering the mysteries behind this intriguing name!

Why Do They Call It an Engine Lathe?

Engine lathes are a vital tool in the world of machining and manufacturing. But have you ever wondered why they are called “engine” lathes? In this article, we will explore the origins of the term, the history of engine lathes, and their significance in various industries. Whether you are a seasoned professional or a curious enthusiast, join us on this journey to unravel the mystery behind the name.

The Birth of the Engine Lathe

The term “engine lathe” has its roots in the early days of industrial revolution and the evolution of machinery. In the late 18th century, as steam engines became more prevalent, craftsmen needed a tool that could shape and polish metal parts for these powerful engines. Thus, the concept of the engine lathe was born.

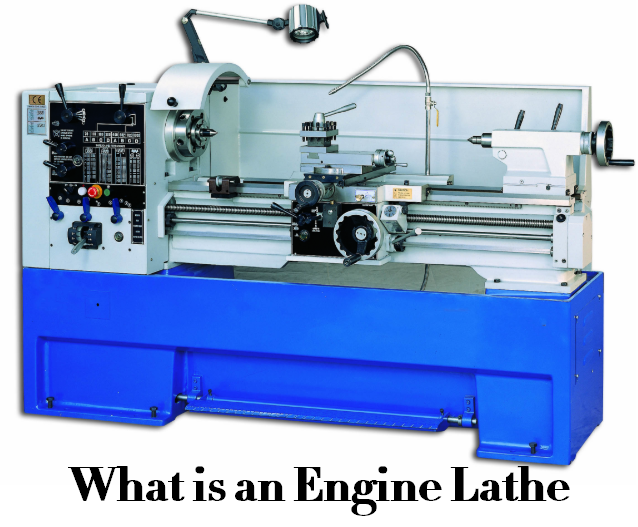

An engine lathe is a type of lathe machine that is specifically designed to handle the turning, shaping, and threading operations of large and heavy metal components. It is equipped with a powerful motor that drives the spindle, allowing for precise rotation and cutting. The introduction of these lathes revolutionized the manufacturing industry, enabling the mass production of intricate parts and components.

While the term “lathe” itself refers to a machine used for shaping and working with various materials, the addition of “engine” to the name distinguished this particular type of lathe designed for heavy-duty operations typically associated with steam engines.

The Evolution of Engine Lathes

Since their inception, engine lathes have undergone significant advancements and improvements to meet the ever-changing demands of industries. Originally powered by steam engines, they later transitioned to electric motors, allowing for greater efficiency and control. The development of automatic and computer numerical control (CNC) features further enhanced the capabilities of engine lathes, enabling precise and automated machining processes.

Over the years, engine lathes have become more versatile, with the ability to handle a wide range of materials, including metals, plastics, and composites. They can perform various operations, such as facing, turning, boring, grooving, and threading, making them indispensable in industries like aerospace, automotive, and construction.

Today, engine lathes come in different sizes and configurations, catering to different manufacturing needs. From small benchtop lathes used in hobbyist workshops to massive floor-mounted models utilized in heavy-duty industrial settings, there is an engine lathe for every application.

The Significance of Engine Lathes

Engine lathes play a critical role in the production of intricate, high-precision components. They are used for manufacturing parts like shafts, gears, pulleys, and engine components, which are essential in industries ranging from automotive to aviation. Engine lathes provide the necessary precision and control required to create accurately dimensioned parts with smooth finishes.

Furthermore, engine lathes offer benefits such as versatility, cost-effectiveness, and the ability to handle both small-scale and large-scale production runs. They allow manufacturers to produce one-off prototypes as well as mass-produced components confidently and efficiently. The availability of various cutting tools and attachments further expands the capabilities of engine lathes, making them indispensable in modern manufacturing processes.

In conclusion, the term “engine lathe” originated from the need to shape and work on metal parts for steam engines. Over time, these lathes evolved to meet the demands of different industries, becoming versatile, automated, and indispensable tools. Whether you are fascinated by the history of machinery or involved in the manufacturing industry, understanding why they are called “engine” lathes gives us a glimpse into the rich heritage and ever-evolving nature of machining technology.

The Anatomy of an Engine Lathe

Engine lathes are complex machines with multiple components working together to perform precise cutting and shaping operations. In this section, we will take a closer look at the key parts that make up an engine lathe and how they contribute to its functionality.

Choosing the Right Engine Lathe for Your Needs

When it comes to selecting an engine lathe, there are several factors to consider to ensure you choose the right one for your specific needs. In this section, we will explore these factors and provide valuable tips to help you make an informed decision.

Tips for Operating an Engine Lathe Safely

Operating an engine lathe requires proper training, knowledge, and adherence to safety guidelines. In this section, we will outline essential tips for operating an engine lathe safely to protect yourself and ensure optimal results.

Common Issues and Troubleshooting for Engine Lathes

Like any complex machinery, engine lathes may encounter issues or malfunctions during operation. In this section, we will discuss some common problems that can arise with engine lathes and provide troubleshooting tips to help you resolve them.

The Future of Engine Lathes

The world of manufacturing is constantly evolving, with advancements in technology shaping the future of engine lathes. In this section, we will explore some emerging trends and innovations that are likely to impact the development and use of engine lathes in the years to come.

Conclusion

Engine lathes have come a long way since their humble beginnings as tools for shaping metal parts for steam engines. They have become an integral part of modern manufacturing processes, offering versatility, precision, and efficiency. Whether you are a machinist, engineer, or simply curious about the history and significance of machinery, understanding why they are called “engine” lathes gives us a deeper appreciation for these vital tools in the industry.

Key Takeaways: Why Do They Call It an Engine Lathe?

- An engine lathe is called so because it is powered by an engine, which drives the lathe’s cutting tools.

- It is a type of lathe machine used for turning or shaping cylindrical objects like metal or wood.

- The engine lathe is also known for its versatility and ability to perform various operations, including facing, drilling, and threading.

- This machine is commonly used in machining processes to create precise and symmetrical parts.

- Engine lathes have been utilized for many years and continue to be an essential tool in manufacturing and engineering industries.

Frequently Asked Questions

If you’ve ever wondered why they call it an engine lathe, we’ve got the answers to your questions right here. Read on to discover the fascinating reasons behind the name of this versatile machine.

1. What is an engine lathe used for?

An engine lathe is a type of lathe machine used for shaping and turning metal. It is commonly used to create cylindrical shapes, such as shafts, rods, and spindles. The lathe spins the workpiece while a cutting tool removes material, allowing for precise machining. Its versatility makes it a fundamental tool in machining processes.

So, why is it called an engine lathe? Well, originally, the term “engine” referred to any kind of mechanical work or machinery. It wasn’t until the 19th century that “engine” became more associated with steam engines. Since the lathe was often used to support the engineering tasks related to steam engine construction and maintenance, it acquired the name “engine lathe.”

2. How does an engine lathe work?

An engine lathe operates by rotating a workpiece against a cutting tool that shapes the material. The workpiece is held securely in a chuck or collet, and the lathe spindle spins it at a controlled speed. The cutting tool is positioned by the operator and incrementally moves along the workpiece to remove layers of material, creating the desired shape.

This process is called turning and can be performed with various cutting tools, such as single-point tools or tool bits. The rotation speed, feed rate, and depth of cut can be adjusted to achieve precise results. The powerful motor of the lathe ensures stability and accuracy during the machining process, making it a reliable tool for creating intricate metal components.

3. Is an engine lathe different from other types of lathes?

Yes, an engine lathe is distinct from other types of lathes, such as a turret lathe or a bench lathe. While all lathes are used for shaping and turning, they differ in terms of their capabilities and applications. An engine lathe is typically larger and more robust, designed for heavy-duty metalworking tasks. It can handle larger workpieces and allows for a wide range of operations.

On the other hand, a bench lathe is smaller and more compact, often used for lighter machining or for working with softer materials. A turret lathe, on the other hand, has a rotating tool turret that can hold multiple cutting tools simultaneously, allowing for faster and more efficient machining. So, while all lathes have the same basic function, an engine lathe is specifically designed for more demanding metalworking tasks.

4. Can an engine lathe be used for non-metal materials?

Yes, an engine lathe can be used for working with non-metal materials as well. While it is commonly associated with metal machining, an engine lathe can also handle other materials, such as wood or plastics. With the appropriate cutting tools and techniques, an engine lathe can shape and turn these materials just as effectively as it does with metal.

For example, in woodworking, an engine lathe can be used to create intricate designs on chair legs or decorative pieces. In the production of plastic components, an engine lathe can shape and refine the material to achieve the desired dimensions. So, while an engine lathe is primarily used for metalworking, it has the versatility to work with various materials.

5. Are there any safety precautions to consider when using an engine lathe?

Absolutely! Safety is paramount when operating an engine lathe or any other machinery. Here are some important safety precautions to keep in mind:

First, always wear appropriate personal protective equipment, such as safety glasses and gloves, to protect yourself from flying chips or debris. Ensure the lathe is properly maintained and in good working condition before using it. Familiarize yourself with the lathe’s controls and operation manual to understand how to use it safely. Always secure the workpiece properly in the chuck or collet to prevent it from coming loose during machining.

Additionally, be mindful of the cutting tool’s sharpness and avoid contact with it while the lathe is running. Finally, practice good housekeeping by keeping the work area clean and free of clutter. By following these safety guidelines, you can minimize the risk of accidents and create a safe working environment when using an engine lathe.

Summary:

So, why do they call it an engine lathe? It turns things and has many uses! This machine helps shape metal by rotating it against a cutting tool. It’s called an engine lathe because it was originally powered by steam engines. Nowadays, it’s powered by electricity. The engine lathe can make intricate cuts and create different shapes, making it an essential tool in industries like manufacturing.

In conclusion, an engine lathe is a powerful machine used to shape metal. Its name comes from the old days when it was powered by steam engines. Today, it plays a vital role in shaping various objects and is crucial in several industries.