Have you ever wondered why a hand saw sometimes gets jammed while you’re using it? Well, wonder no more! In this article, we’ll explore the reasons behind this frustrating situation and give you some insights on how to prevent it from happening. So, if you’re ready to dive into the world of hand saws, let’s get started!

Picture this: you’re in the middle of a DIY project, happily sawing away, when suddenly, your hand saw comes to a screeching halt. What just happened? Why did it jam all of a sudden? Well, my young woodworking enthusiast, there are a few factors that could be causing this annoying issue.

Firstly, let’s consider the type of material you’re cutting. Some woods have a tendency to be less cooperative, with their grain patterns causing the saw teeth to catch or bind. Additionally, if the wood is too wet or has hidden knots, it can lead to a jamming situation. But fear not, there are solutions to these problems, and we’ll explore them together!

So, grab your safety goggles and your favorite carpentry apron, because we’ve got some fascinating insights to share! Whether you’re a beginner or a seasoned woodworker, understanding why your hand saw jams will help you be better prepared and more efficient in your woodworking endeavors. Let’s unlock the secrets behind this common conundrum, shall we?

Why Does a Hand Saw Jam?

A hand saw is a versatile tool that is widely used for cutting wood and other materials. However, there are instances when a hand saw may jam, making it difficult or impossible to continue cutting. Understanding why a hand saw jams can help you troubleshoot the issue and prevent it from happening in the future. In this article, we will explore the various reasons why a hand saw may jam and provide helpful tips to resolve the problem.

1. Dull or Damaged Teeth

The teeth of a hand saw are designed to cut through materials with ease. However, over time, the teeth can become dull or damaged, leading to jamming. A dull hand saw will struggle to make clean cuts, often getting stuck in the material. Similarly, a hand saw with damaged teeth, such as bent or missing ones, can cause jams. To prevent and resolve this issue, it is important to regularly sharpen your hand saw and replace any damaged teeth.

2. Incorrect Blade Tension

The tension of the blade plays a crucial role in the performance of a hand saw. If the blade tension is too loose or too tight, it can result in jamming. A loose blade may buckle or twist while cutting, causing it to bind and jam. On the other hand, an overly tight blade can cause excessive friction, leading to the same problem. It is essential to ensure that the blade tension is properly adjusted according to the manufacturer’s recommendations.

3. Pinching of the Material

Pinching of the material being cut can occur when there is too much pressure on the blade or when the material is not properly supported. This can cause the hand saw to jam as it gets wedged in the material. To prevent pinching, it is essential to apply even pressure and use proper techniques when cutting. Additionally, ensuring that the material is properly secured and supported can help prevent jams caused by pinching.

4. Binding in the Kerf

The kerf refers to the cut made by the hand saw. Sometimes, the kerf can close in on the blade and bind, causing the hand saw to jam. This can happen if the blade is not properly aligned with the kerf or if the width of the kerf is too narrow. To avoid this issue, it is crucial to follow the marked line and maintain proper alignment throughout the cut. If necessary, you can use a small wedge or chisel to slightly widen the kerf and prevent jams.

5. Incorrect Sawing Technique

The way you use the hand saw can also contribute to jams. If you apply too much force or twist the saw while cutting, it can cause the blade to bind and jam. Using the correct sawing technique, such as maintaining a steady and even stroke, can help prevent jams. It is also important to use the appropriate hand saw for the task at hand, as different saws have different cutting capabilities.

6. Buildup of Debris

When cutting through certain materials, such as wet or resinous wood, debris can accumulate on the blade and in the kerf. This buildup can hinder the cutting action and cause the hand saw to jam. Regularly cleaning the blade and clearing the kerf of debris can help prevent jams. You can use a brush or a saw cleaning solution to remove any residue from the blade. Additionally, lubricating the blade with saw wax or a similar product can help reduce friction and prevent jams caused by debris.

7. Incorrect Saw Selection

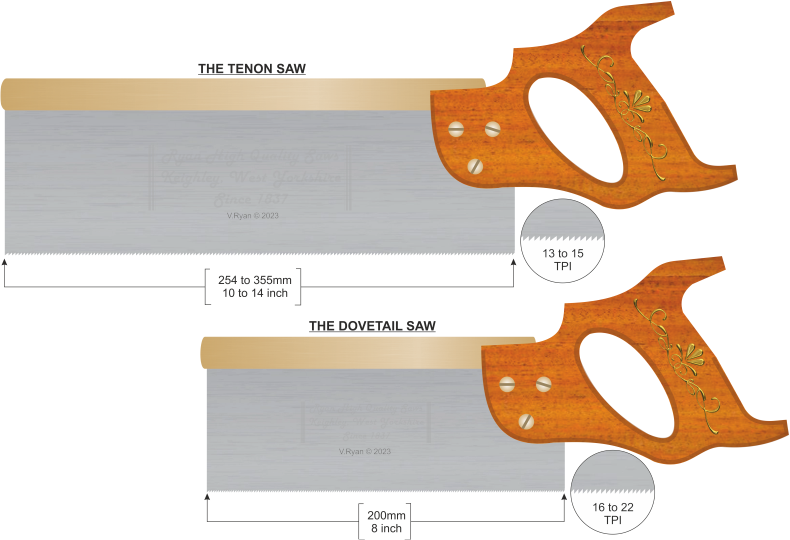

The type of hand saw you choose for a particular job can also determine whether or not it jams. Different hand saws are designed for specific tasks and materials. Using the wrong saw can result in jams and poor performance. It is essential to select the appropriate hand saw based on the material you are cutting and the desired outcome. If in doubt, consult a professional or seek guidance from knowledgeable sources to ensure you have the right tool for the job.

Additional Factors Influencing Hand Saw Jams

8. Material Density

The density of the material being cut can also affect the likelihood of a hand saw jamming. Harder and denser materials, such as hardwood, may place more strain on the saw blade, increasing the risk of jams. It is important to choose a hand saw with teeth designed for cutting the specific material to minimize the chances of jamming.

9. Blade Flexibility

The flexibility of the hand saw’s blade can impact its performance and susceptibility to jamming. A blade that is too flexible may twist or buckle during cutting, leading to jams. On the other hand, a blade that is too rigid may not be able to navigate through tight cuts, resulting in jams. It is essential to match the blade’s flexibility with the intended use to optimize performance and minimize jams.

10. Cutting Speed

The speed at which you are cutting can also affect the likelihood of jams. Cutting too quickly can put excessive strain on the blade and cause it to bind in the material, leading to jams. It is important to find a balance between cutting speed and maintaining a steady and controlled motion to minimize the risk of jams.

11. Blade Quality

The quality of the hand saw blade can significantly impact its performance and susceptibility to jamming. Higher-quality blades are less likely to bend, dull, or chip, reducing the chances of jams. Investing in a high-quality hand saw blade can result in smoother cuts and fewer instances of jamming.

12. Environmental Conditions

The environmental conditions in which you are using the hand saw can also contribute to jams. For example, cutting in high humidity or extreme temperatures can affect the material and the saw blade, increasing the likelihood of jams. It is important to consider the environmental factors and adjust your cutting technique or choose appropriate tools accordingly.

Conclusion

Jamming is a frustrating issue to encounter when using a hand saw. By understanding the various reasons why a hand saw may jam and implementing the appropriate solutions, you can minimize the occurrence of jams and ensure smooth and efficient cutting. Regular maintenance, correct sawing techniques, and using the right tool for the job are key factors in preventing hand saw jams. Remember to stay patient and focused while cutting and make adjustments as necessary to avoid jams and achieve the best results.

Key Takeaways: Why Does a Hand Saw Jam?

- A hand saw can jam when the teeth become clogged with sawdust and debris.

- If the saw blade is dull or damaged, it can also lead to jamming.

- Applying too much pressure or force while cutting can cause the saw to get stuck.

- Using an improper cutting technique may result in the saw jamming.

- Regular maintenance and cleaning can help prevent hand saws from jamming.

Frequently Asked Questions

Have you ever wondered why your hand saw jams while in use? Let’s explore some common questions about hand saws jamming and find out the reasons behind it.

1. How can I prevent my hand saw from jamming?

One of the main reasons a hand saw might jam is due to improper technique or lack of maintenance. To prevent jams, make sure to use the right saw for the job and always ensure your saw is sharp and in good condition. Additionally, proper sawing technique, such as using the correct angle and applying the right amount of pressure, can help prevent jams.

Regular cleaning and lubrication of the saw blade and the saw’s moving parts can also prevent jams. Keep the blade clean from dirt, sawdust, or debris, and apply a suitable lubricant on the blade and the pivot points of the saw. These maintenance practices will greatly reduce the chances of your hand saw jamming.

2. What causes a hand saw to jam while cutting?

A hand saw can jam while cutting due to a few reasons. One common cause is binding, which happens when the blade gets pinched in the kerf, the groove made by the saw. This can occur if you’re not following the proper cutting technique, using too much force, or if the saw’s teeth are dull or damaged.

Another cause of jams is when the teeth of the hand saw become clogged with sawdust, preventing the smooth cutting motion. It’s important to clear the sawdust from the teeth and the cutting area regularly to avoid jams. Lastly, using a hand saw on a material that is too hard or thick for its capabilities can also lead to jamming.

3. How can I fix a jammed hand saw?

If your hand saw becomes jammed, the first step is to stop cutting immediately to avoid further damage or injury. Gently back out the saw following the same cutting path that caused the jam. Avoid forcing the saw or applying excessive pressure, as this can damage the blade or worsen the jam.

Once the jam is cleared, inspect the blade for any damage or bending. If the blade is damaged, it may need to be replaced. If the blade is in good condition, clean it thoroughly, removing any sawdust or debris that may have caused the jam. Applying a lubricant to the blade can also help prevent future jams.

4. Is it possible to prevent all hand saw jams?

While it’s not always possible to completely prevent hand saw jams, following proper sawing techniques, maintaining your hand saw, and using the right saw for the job can greatly reduce the chances of jams occurring. Regularly checking and cleaning your hand saw, keeping the blade sharp, and using the correct cutting angle and pressure can minimize the occurrence of jams.

However, it’s important to remember that certain factors like the type of material being cut, the thickness of the material, or unexpected changes in the wood grain can still potentially cause a hand saw to jam. It’s always best to be prepared and take the necessary precautions to minimize the risk of jamming.

5. Can a jammed hand saw be dangerous?

A jammed hand saw can indeed be dangerous. When a saw jams, there is a risk of sudden release of tension, causing the blade to kickback or jump out of the cut, potentially leading to injuries. Additionally, if excessive force is applied to a jammed saw, it can also result in the blade breaking or the saw causing damage.

That’s why it’s crucial to prioritize safety when using a hand saw and to take immediate action if a jam occurs. Stop cutting, back out the saw carefully, and inspect the blade and saw for any damage before continuing. Always wear appropriate safety gear, such as safety goggles and gloves, when using a hand saw to minimize the risk of accidents.

Does your saw gets stuck in wood Here’s what to do! Saw Hacks

Summary

Hand saws can jam for different reasons, but most commonly it’s because of friction. Friction happens when the saw teeth get stuck in the wood fibers, or when the blade is dull or bent. To prevent jams, it’s important to use a sharp saw, apply proper pressure, and make sure the blade is straight.

Additionally, the type of wood being cut can affect the likelihood of a jam. Softer woods, like pine, are less likely to cause jams, while harder woods, like oak, can be more challenging. It’s also important to clean the saw regularly and remove sawdust from the teeth to keep it in good working condition. With proper care and technique, you can minimize the chances of a hand saw jamming and make your woodworking projects go smoothly.