Why does a bandsaw squeal? Well, imagine you’re working on a woodworking project, and suddenly, the sharp screeching sound of a squealing bandsaw interrupts your concentration. It can be quite annoying, not to mention concerning. But fear not, young woodworker! In this guide, we’ll delve into the reasons behind why your bandsaw might be squealing and how you can fix it.

So, why does a bandsaw squeal? There could be a few culprits causing this ear-piercing noise. From improper blade tension and worn-out bearings to a misaligned blade or even a dusty blade guide, these factors can all contribute to the dreaded squeal. But fret not, young DIY enthusiast! We’ll help you diagnose the issue and provide easy-to-follow solutions to silence your bandsaw’s screechy symphony in no time.

Ready to silence the squeal and get back to your woodworking adventures? Let’s dive right in and discover the reasons behind that ear-splitting bandsaw noise and how to fix it. Stay tuned for some practical tips and tricks that will have your bandsaw running smoothly and quietly, so you can focus on creating your next masterpiece with peace of mind.

Why Does Bandsaw Squeal?

When using a bandsaw, you may have encountered an unpleasant squealing noise. This noise can be quite annoying and may indicate an underlying issue with your bandsaw. Understanding why a bandsaw squeals is essential for proper maintenance and ensuring optimal performance. In this article, we will explore the various reasons why bandsaws squeal and provide practical solutions to address the problem.

1. Dull or Misaligned Blade

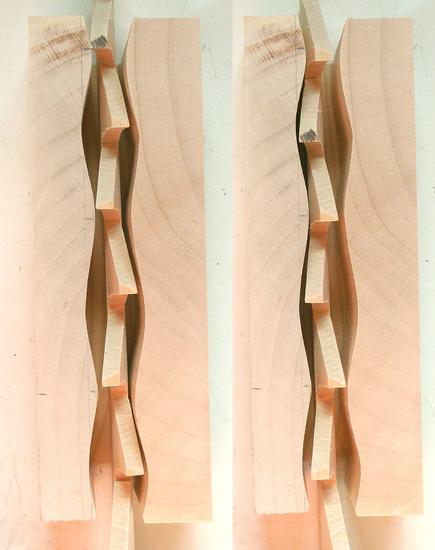

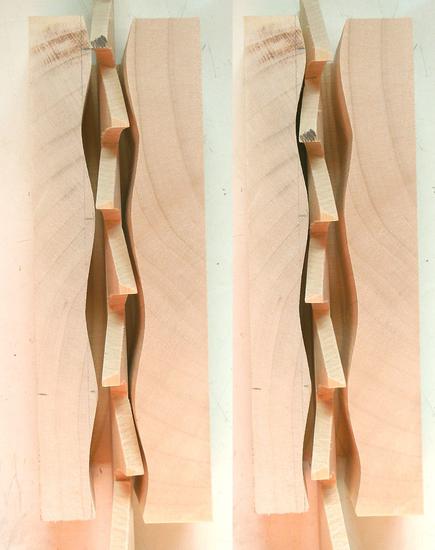

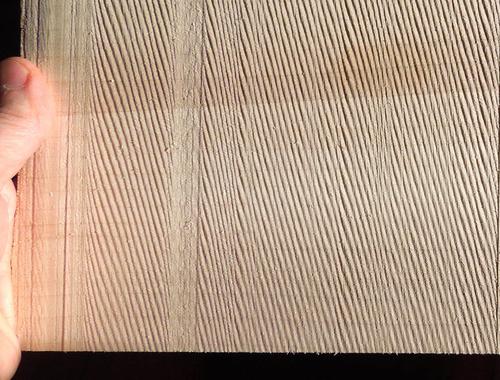

One of the most common reasons for a bandsaw to squeal is a dull or misaligned blade. Over time, the teeth of the blade can become worn out, leading to poor cutting performance and increased friction. This friction can produce a high-pitched squealing sound as the blade struggles to cut through the material efficiently. Additionally, if the blade is not aligned properly, it can rub against the guides, resulting in an irritating noise.

To resolve this issue, you should regularly inspect your bandsaw blade for signs of wear and tear. If the blade is dull, it may need to be sharpened or replaced. Similarly, make sure the blade is correctly aligned by adjusting the guides and tension according to the manufacturer’s recommendations.

If you are unsure how to sharpen or align the blade, it is best to consult the user manual or seek help from a professional. Proper blade maintenance will not only eliminate the squealing noise but also improve the quality of your cuts.

2. Insufficient Lubrication

A bandsaw relies on smooth movement to operate efficiently. Lack of lubrication can cause friction between the moving parts, leading to a squealing noise. The blade guides and bearings require adequate lubrication to reduce friction and ensure smooth operation. Without proper lubrication, the bandsaw motor and components can become strained, resulting in the squealing sound.

Regular lubrication is essential for maintaining a well-functioning bandsaw. Refer to the manufacturer’s guidelines to determine the appropriate lubrication for your specific model. Apply lubricant to the blade guides, bearings, and any other movable parts as recommended. By keeping the bandsaw properly lubricated, you can minimize friction and eliminate the squealing noise.

It is important to note that using the wrong type of lubricant can cause more harm than good. Always use the recommended lubricant to ensure optimal performance and prevent damage to the bandsaw.

3. Loose or Worn Belts

Another potential cause of a squealing bandsaw is loose or worn belts. Bandsaws use belts to transfer power from the motor to the wheels. When these belts become loose or worn, they can slip on the pulleys, creating a high-pitched squealing noise. In addition to the noise, loose or worn belts can also lead to inefficient cutting and reduced performance.

To address this issue, inspect the belts on your bandsaw and ensure that they are tight and in good condition. If they are loose or worn out, you should adjust or replace them accordingly. Consult the user manual for specific instructions on adjusting or changing the belts. By keeping the belts properly tensioned and in good condition, you can eliminate the squealing noise and maintain optimal cutting performance.

Regular belt maintenance, including cleaning and occasional replacement, is crucial for the smooth operation of your bandsaw.

4. Tensioning Issues

The tension of the blade is critical for proper cutting performance on a bandsaw. Incorrect blade tension can cause the blade to vibrate excessively, leading to a squealing sound. Insufficient tension may result in poor cutting performance, while excessive tension can put unnecessary strain on the blade and increase the likelihood of breakage.

To resolve tensioning issues, start by checking the tension of the blade with a tension gauge. Adjust the tension according to the manufacturer’s recommendations. It is important to maintain the proper tension for each specific blade width and material being cut. By ensuring the correct blade tension, you can eliminate the squealing noise and achieve precise cuts.

Regularly monitor the blade tension and make adjustments as needed to prevent any issues that may lead to squealing or compromise the safety of your bandsaw.

5. Blade Speeds and Feeds

The speed at which the blade rotates and the rate at which the material is fed into the bandsaw can also contribute to squealing. Running the blade at inappropriate speeds or feeding the material too quickly can cause the blade to work harder than necessary, leading to increased friction and a squealing noise.

Refer to the manufacturer’s recommendations for the appropriate blade speed and feed rate based on the material being cut. Adjust these settings accordingly to ensure optimal cutting without straining the blade. By using the correct blade speeds and feeds, you can minimize friction and eliminate the squealing noise.

It is important to note that different materials may require different blade speeds and feeding rates. Experiment with different settings to find the best combination for each specific material you are working with.

6. Improper Blade Tension

Similar to tensioning issues, improper blade tension can also lead to a squealing bandsaw. If the blade is not tensioned evenly across its width, it can cause the blade to vibrate or twist during cutting, resulting in noise and poor cutting performance. This issue is commonly known as “blade drift.”

To address improper blade tension, you should first ensure that the blade is installed correctly and centered on the wheels. Adjust the blade tensioning mechanism evenly on both sides until the blade is properly tensioned. Some bandsaws may require additional adjustments to the tracking to avoid blade drift.

Properly tensioning the blade will prevent excessive vibration and ensure a clean and accurate cut, eliminating the squealing noise.

Additional Tips for a Quieter Bandsaw

Now that we have explored the main causes for a squealing bandsaw, let’s discuss some additional tips to help you achieve a quieter and more efficient cutting experience:

1. Regularly clean and maintain your bandsaw to prevent debris buildup and prolong its lifespan.

2. Use the appropriate blade for the specific material you are cutting, ensuring the correct tooth count and tooth configuration.

3. Invest in high-quality blades and replace them as needed to avoid dullness and poor cutting performance.

By following these tips and addressing any underlying issues promptly, you can enjoy smooth and quiet operation from your bandsaw, ensuring optimal cutting results every time.

Key Takeaways: Why Does Bandsaw Squeal?

- A bandsaw may squeal due to improper blade tension.

- Dull or damaged blades can also cause a bandsaw to squeal.

- Lack of lubrication on the blade and guides might result in squealing noises.

- Incorrect blade tracking can lead to squealing on a bandsaw.

- Worn-out or damaged bearings can contribute to the squealing sound in a bandsaw.

Frequently Asked Questions

Here are some common questions about bandsaw squealing and their answers.

Why does my bandsaw make a high-pitched noise?

The high-pitched noise coming from your bandsaw is likely caused by the blade vibrating against the guides or wheels. This can happen when the blade is dull, improperly tensioned, or when there is inadequate lubrication. Dull blades tend to wander from the intended cutting line, causing vibrations and noise. It’s important to have sharp blades, proper tension, and sufficient lubrication to minimize the noise and ensure smooth cutting.

Examining the guides and wheels for damage or misalignment can also help identify the source of the noise. Damaged or worn-out guides and wheels can cause the blade to vibrate and squeal. Regular maintenance and proper blade care are crucial in keeping your bandsaw running smoothly and quietly.

Can blade tension affect the noise my bandsaw makes?

Yes, blade tension can affect the noise your bandsaw makes. Insufficient tension can cause the blade to vibrate, resulting in a squealing sound. On the other hand, excessive tension can distort the blade and cause it to produce a different type of noise. It’s important to find the right tension for your particular blade and cutting requirements. Following the manufacturer’s recommendations for tensioning the blade is a good starting point.

When tensioning the blade, ensure it is not too loose or too tight. A properly tensioned blade will be able to cut smoothly without excessive noise. It’s also important to periodically check the blade tension as it can change over time due to temperature fluctuations or wear and tear. Adjusting the tension based on the specific requirements of your bandsaw and the material being cut will help minimize noise and ensure optimal performance.

Does blade lubrication affect the noise level of a bandsaw?

Yes, blade lubrication plays a role in the noise level of a bandsaw. Inadequate lubrication can result in increased friction between the blade and the material being cut, leading to more noise. Lubricating the blade helps reduce friction and heat, allowing for smoother cuts and minimizing noise levels.

There are various types of lubricants available for bandsaw blades, including oils and sprays designed specifically for this purpose. Applying lubricant to the blade before starting a cutting operation can help reduce noise and improve overall cutting efficiency. Just be sure to follow the manufacturer’s recommendations for the specific lubricant and application method to achieve the best results.

Are there any safety concerns associated with a squealing bandsaw?

While a squealing noise from a bandsaw is typically an indication of a mechanical issue, it’s important to address it promptly to prevent further damage and ensure your safety. A misaligned or poorly maintained bandsaw can put unnecessary strain on the blade, potentially causing it to break or come off during operation.

Regular inspection and maintenance of your bandsaw, including checking for proper blade tension, blade sharpness, and guide and wheel alignment, can help identify and address any issues before they lead to more significant problems. Using appropriate safety measures, such as wearing protective eyewear and keeping hands away from the blade, is also essential to minimize the risk of accidents while operating a bandsaw.

When should I consider seeking professional help for a squealing bandsaw?

If you’ve tried adjusting the blade tension, lubricating the blade, and inspecting the guides and wheels but your bandsaw continues to squeal, it may be time to seek professional assistance. A qualified technician will have the expertise and tools necessary to diagnose and fix more complex issues that may be causing the noise.

Professional help should also be considered if you are unsure about performing maintenance tasks yourself or if you are experiencing other problems with your bandsaw, such as excessive vibration or inconsistent cutting performance. They can ensure that your bandsaw is properly serviced and in safe working condition for optimal performance.

Summary

If your bandsaw is squealing, it could be due to a few different reasons. One possibility is that the blade tension isn’t set correctly, so you should check and adjust it. Another cause could be a worn or damaged blade, so try replacing it. Also, make sure to lubricate the blade and the guides regularly to keep everything running smoothly. Lastly, if none of those fixes work, it might be time to get a professional to take a look at your bandsaw.

Overall, to prevent your bandsaw from squealing, you should maintain it well by checking the blade tension, replacing worn blades, and lubricating it regularly. If all else fails, seek help from a professional.