Why does the circular saw bind? If you’ve ever used a circular saw, you might have experienced this frustrating situation. It’s like the blade gets stuck or refuses to spin freely, causing delays and potential safety hazards. But fear not, young DIY enthusiast! In this article, we’ll dig deep into the causes behind this issue, unleashing the secrets to a smoother cutting experience.

Now, picture this: you’re all set to make a precise cut, and suddenly, your circular saw starts to bind. It’s like a wily puzzle that needs unraveling. Understanding the Why can help you prevent this annoying problem in the future. So, my curious reader, let’s embark on a quest to unravel the mystery behind the binding of the circular saw!

Are you ready to dive into the world of circular saws and uncover the reasons behind their binding antics? Get ready, because we’re about to explore the common culprits of this conundrum. Armed with this knowledge, you’ll be equipped to tackle any binding issues that come your way. Let’s get started!

Why Does a Circular Saw Bind?

In the world of power tools, a circular saw is one of the most versatile and essential tools to have. It can cut through a variety of materials, making it a staple in any carpenter’s toolbox. However, there are times when the circular saw may encounter a problem known as binding. Binding occurs when the blade gets stuck while cutting, which can be frustrating and pose safety risks. In this article, we will explore the reasons behind why a circular saw may bind and provide helpful tips on how to prevent and troubleshoot this issue.

Causes of Circular Saw Binding

1. Dull Blade

One of the primary causes of circular saw binding is a dull blade. Over time, the blade can become worn out and lose its sharpness, making it less effective at cutting through materials. As a result, the blade may get stuck while trying to cut, causing the saw to bind. To prevent this, it is important to regularly inspect and maintain the blade. Sharpen or replace the blade when necessary to ensure smooth and efficient cutting.

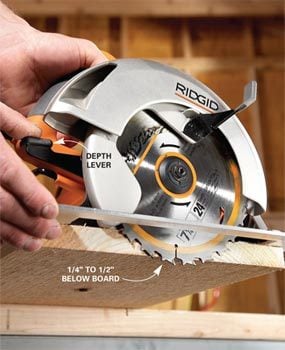

2. Incorrect Blade Depth

Another common cause of circular saw binding is using an incorrect blade depth. If the blade is set too deep, it can cause the saw to bind as it tries to force its way through the material. On the other hand, if the blade is set too shallow, it may not be able to cut through the entire thickness of the material, resulting in binding. To avoid this issue, make sure to adjust the blade depth according to the material being cut.

3. Improper Cutting Technique

Using an improper cutting technique can also lead to circular saw binding. For example, pushing the saw too hard or at the wrong angle can cause the blade to bind. It is crucial to maintain a steady and controlled cutting motion, allowing the saw to do the work without forcing it. Additionally, it is important to ensure that the material being cut is properly supported and secured to prevent any movement that could contribute to binding.

Troubleshooting and Prevention

1. Regular Blade Maintenance

To prevent circular saw binding, it is essential to maintain the blade properly. Keep the blade clean and free from debris by regularly cleaning it after each use. Inspect the blade for any signs of dullness or damage, and sharpen or replace it as needed. Additionally, properly store the saw in a clean, dry area to prevent rust and corrosion.

2. Adjust Blade Depth Correctly

Properly adjusting the blade depth is vital in avoiding binding. Before cutting, take the time to adjust the blade depth according to the material’s thickness. Start with a shallow cut and gradually increase the blade depth if needed. By doing so, you can ensure that the blade moves smoothly through the material without binding.

3. Use the Right Blade

Using the right blade for the job is crucial in preventing binding. Different materials require different types of blades, so make sure to choose the appropriate blade for the material you are cutting. Consult the manufacturer’s recommendations or seek advice from professionals to ensure you have the right blade for your specific needs.

Key Takeaways: Why Does Circular Saw Bind?

- A circular saw can bind when the material being cut pinches the blade, causing it to stop or get stuck.

- Using the wrong blade can also cause a circular saw to bind, as the blade may be too thick or not designed for the material being cut.

- Improper technique, such as pushing the saw too fast or at the wrong angle, can lead to binding.

- Dull or damaged blades are more likely to bind, so regular maintenance and blade replacement are essential.

- Ensuring the saw is properly adjusted and aligned can help prevent binding issues.

Frequently Asked Questions

Welcome to our FAQ section where we address common questions about circular saw binding. If you’re experiencing issues with your circular saw getting stuck while cutting, you’re in the right place. Read on to find answers to your questions.

1. What causes a circular saw to bind?

There are a few reasons why a circular saw may bind while in use. One common cause is using a dull or damaged blade. When the teeth on the blade are worn out or damaged, it can put extra strain on the saw, causing it to bind. Another factor could be using a blade with the wrong type or size for the material you’re cutting. Using the wrong blade can make it difficult for the saw to make clean cuts, resulting in binding. Additionally, insufficient lubrication, such as a lack of oil or wax on the blade, can cause the saw to bind as well.

To prevent binding, make sure you’re using a sharp and appropriate blade for the material you’re cutting. Keep your blades well lubricated and replace them when they become dull or damaged.

2. How can I prevent my circular saw from binding?

Preventing your circular saw from binding is crucial for efficient and safe cutting. One way to prevent binding is by ensuring you have the right blade for the job. Different materials require different types of blades, so make sure to use the appropriate one. Another tip is to keep your blades sharp. Dull blades are more likely to bind, so regularly sharpen them or replace them if necessary.

Proper maintenance is also essential in preventing binding. Keep your saw clean, especially the blade compartment, to avoid any buildup that could interfere with smooth cutting. Lastly, make sure you’re using proper cutting techniques. Applying excessive force or pushing the saw too quickly can increase the likelihood of binding.

3. Can a circular saw bind if it’s overheating?

Yes, overheating can contribute to a circular saw binding. When a saw overheats, its internal components may expand, resulting in increased friction and potential binding. Overheating can be caused by several factors, such as using the saw continuously for an extended period without allowing it to cool down or working in extreme temperatures.

To prevent overheating and subsequent binding, avoid pushing your saw beyond its recommended usage limits. Take breaks during prolonged cutting sessions to allow the saw to cool down. Additionally, ensure proper ventilation in the work area and store your saw in a cool, dry place when not in use.

4. What should I do if my circular saw binds during a cut?

If your circular saw binds during a cut, the first step is to release the trigger and turn off the tool. Do not attempt to force the saw through the bind, as it can be unsafe and potentially damage the saw. Once the saw is off, carefully inspect the blade for any obstructions or debris that may be causing the bind. Remove any foreign objects and clean the blade if necessary.

If the binding persists after cleaning, check the blade for any signs of damage or wear. A dull or damaged blade should be replaced to ensure smooth and safe cutting. Lubricating the blade with oil or wax may also help alleviate binding. Remember to always follow safety precautions while troubleshooting and seek professional assistance if needed.

5. Is circular saw binding a common problem?

Yes, circular saw binding is a common problem that many people encounter. The binding can occur due to various reasons, including blade-related issues, improper cutting techniques, or inadequate maintenance. However, with proper blade selection, regular maintenance, and correct cutting practices, you can greatly minimize the occurrence of binding and enjoy smooth cutting with your circular saw.

If you’re experiencing frequent or severe binding issues, it may be helpful to consult with a professional or seek guidance from experienced users who can provide tips and recommendations specific to your situation.

How to Use a Circular Saw – Change Blades, Prevent Binding and more

Summary

Circular saws can bind when the wood gets pinched, causing the blade to stop spinning. This can happen if the wood is warped or the saw is not properly aligned. Binding can lead to kickback or the saw getting stuck, so it’s important to use caution and take preventive measures. Keeping the saw blade sharp, using the right blade for the job, and using a guide or fence can help prevent binding and ensure safe and smooth cutting. It’s also important to maintain a steady pace and not force the saw through the wood.