Have you ever wondered why your circular saw gets jammed? It’s frustrating when you’re in the middle of a project and your tool decides to take a break. But fear not, because in this article, we’ll explore the reasons behind the dreaded circular saw jam.

When it comes to using power tools, there’s always a chance for things to go awry. And the circular saw is no exception. Whether you’re a beginner or a seasoned DIY enthusiast, understanding why your saw jams can help you prevent it from happening in the first place.

So, why does a circular saw jam? From dull blades to improper cutting techniques, there are several factors that can cause your saw to get stuck. But don’t worry, we’ll delve into each of these reasons and provide you with practical tips to keep your circular saw running smoothly.

Get ready to empower yourself with knowledge and master the art of troubleshooting your circular saw jams. Let’s dive in and discover the secrets to preventing this irksome issue!

Why Does a Circular Saw Jam? Exploring the Common Causes

Are you a DIY enthusiast or a professional carpenter who frequently uses a circular saw? If so, you may have encountered the frustrating issue of your saw jamming. When this happens, you’re left unable to make clean and precise cuts, bringing your project to a halt. But fear not, as we’re here to shed light on the reasons behind this common problem. In this article, we’ll explore the various causes of a jammed circular saw and provide you with practical tips to prevent and resolve the issue.

1. Dull or Damaged Blade

One of the primary reasons why a circular saw jams is a dull or damaged blade. Over time, the blade of your saw can become worn out or suffer from blunt teeth, making it less effective and more prone to jamming. When a blade isn’t sharp enough, it struggles to cut through the material, causing it to bind and ultimately seize up.

To prevent this, it’s crucial to regularly inspect and maintain your saw blade. If you notice any signs of wear or damage, such as missing or bent teeth, it’s time to replace it. Additionally, ensure that you’re using the correct blade for the material you’re cutting, as using the wrong blade can also lead to jamming.

Investing in high-quality blades and taking the time to sharpen them regularly can significantly reduce the chances of your circular saw jamming during your woodworking projects.

2. Incorrect Blade Depth and Angle

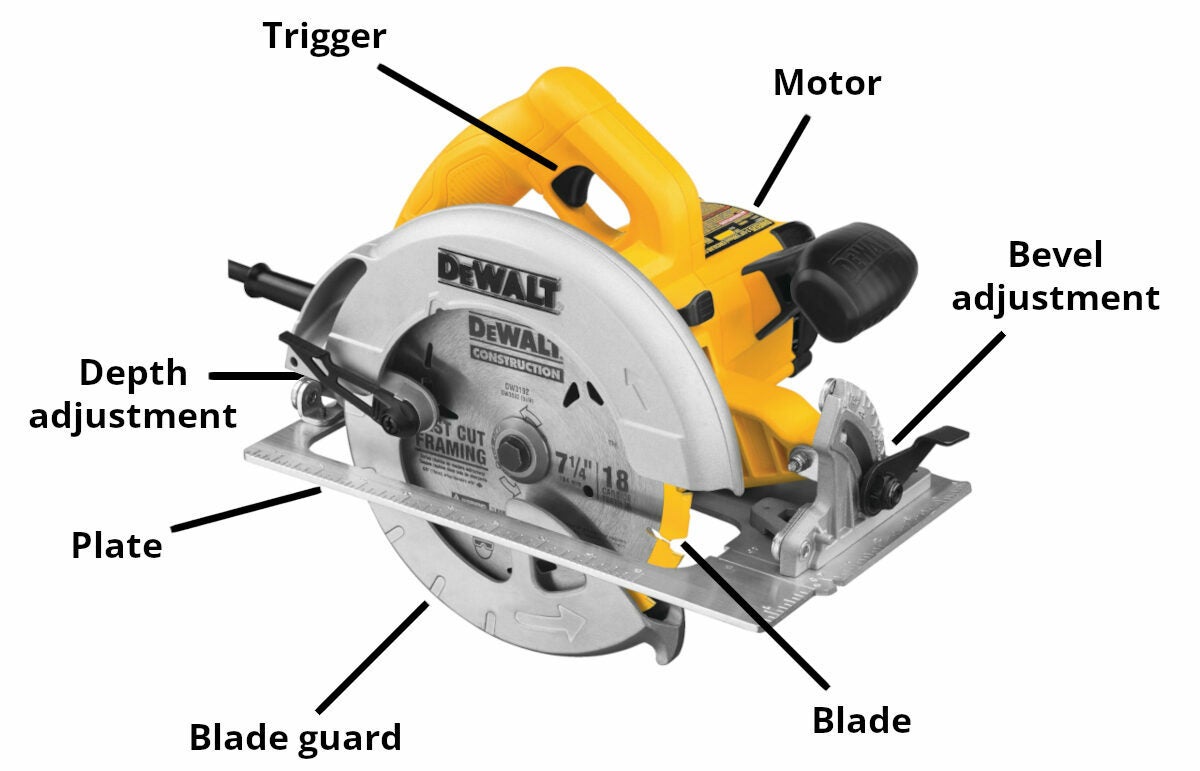

The depth and angle at which your circular saw blade cuts can greatly impact its performance and the likelihood of jamming. If the blade is set too deep or at an incorrect angle, it can put excessive stress on the motor, causing it to struggle and potentially jam.

To ensure optimal cutting performance and minimize the chances of a jam, it’s important to set the blade depth correctly. Ideally, the blade should be set just deep enough to cut through the material without excessive resistance. Similarly, the blade should be aligned parallel to the cutting guide or fence to ensure precise cuts and prevent binding.

Take the time to adjust the blade depth and angle before each cut, and make sure to secure the locking mechanisms on your saw to prevent any unintentional changes while in use.

3. Improper Technique and Feed Rate

Using improper cutting techniques and feeding the material too quickly can also lead to a jammed circular saw. When you force the saw through the material at an accelerated rate, it puts added strain on the blade and motor, increasing the risk of binding and jamming.

Instead, adopt a smooth and controlled cutting technique, allowing the saw blade to do the work at its own pace. Apply steady pressure and maintain a consistent feed rate, ensuring that the blade can cut through the material without any resistance or overheating.

If you’re working with dense or thick materials, consider using multiple shallow cuts instead of trying to make one deep pass. This reduces the strain on the blade and motor, preventing potential jams and producing cleaner results.

4. Incorrect Saw Maintenance

Regular maintenance is essential to keep your circular saw in good working condition and prevent jams. If you neglect maintenance tasks like cleaning, lubricating, and inspecting the saw’s components, it can lead to issues such as sawdust buildup, rust, and misalignment, which can impede the saw’s functionality.

Make it a habit to clean the saw after each use, removing any debris or sawdust that may have accumulated. Lubricate the moving parts, such as the blade arbor and depth adjustment mechanism, to ensure smooth operation. Additionally, inspect the saw’s components for signs of wear or damage and address any issues promptly to prevent potential jams.

A well-maintained circular saw is less likely to jam and will perform optimally, allowing you to complete your woodworking tasks with ease.

5. Impeded Blade Rotation

In some cases, the blade rotation can become impeded, leading to a jammed circular saw. This can occur due to various factors, including a foreign object lodged in the saw’s housing or a seized motor. If the motor struggles to rotate the blade freely, it can result in binding and jamming.

To troubleshoot this issue, start by inspecting the saw’s housing for any foreign objects or debris. Remove anything that may be obstructing the blade’s rotation. If the motor feels strained or doesn’t start smoothly, it may require maintenance or repair by a professional.

Regularly checking for and removing any obstructions to the blade’s rotation can significantly reduce the likelihood of a jammed circular saw.

Key Takeaways: Why Does Circular Saw Jam?

- A circular saw can jam if the blade is dull or damaged.

- Improper positioning of the workpiece can cause the saw to jam.

- A build-up of sawdust or debris can also lead to jamming.

- Using the wrong type or size of saw blade can result in a jam.

- Inadequate maintenance and lack of lubrication can cause the saw to jam.

Frequently Asked Questions

Are you wondering why your circular saw keeps jamming? Check out these commonly asked questions to understand the reasons behind this frustrating issue.

1. How can I prevent my circular saw from jamming?

To prevent your circular saw from jamming, there are a few key steps you can take. First, make sure your blade is properly installed and tightened. A loose blade can cause the saw to jam. Additionally, be mindful of the material you are cutting. If you’re working with thick or dense materials, consider using a blade designed for those specific materials. Lastly, keep the saw blade clean and free of debris. Buildup of sawdust and other particles can lead to jamming.

Regular maintenance is also important in preventing jams. Lubricate the moving parts of the saw regularly and inspect the blade for signs of wear or damage. By following these preventative measures, you can minimize the chances of your circular saw jamming.

2. What should I do if my circular saw constantly jams?

If your circular saw is consistently jamming, there are a few troubleshooting steps you can take. Start by checking the blade to ensure it is not bent or damaged. A damaged blade can cause the saw to bind and jam. If the blade appears to be in good condition, the issue may be with the motor or power source. Inspect the power cord and connections to ensure everything is securely in place.

Another possible cause of frequent jams is an improperly adjusted depth or angle setting. Make sure the saw is properly set up for the specific cut you’re making. Lastly, check the material you’re cutting. If it’s too thick or dense for the blade, it can easily cause the saw to jam. Consider using a different blade suitable for the material. If the issue persists, it may be best to consult a professional to diagnose and repair any underlying problems.

3. Can using a dull blade lead to jamming?

Absolutely! Using a dull blade is one of the main reasons circular saws tend to jam. A dull blade can cause the saw to work harder, increasing the chances of binding and jamming. When the blade is no longer sharp, it struggles to cut through materials smoothly, putting strain on the motor and causing the saw to jam. It’s important to regularly inspect your blade and replace it when it becomes dull or damaged.

Remember, a sharp blade not only helps prevent jams but also ensures cleaner cuts. By investing in high-quality blades and keeping them sharp, you can significantly reduce the likelihood of your circular saw jamming.

4. Are there any safety precautions I should take to avoid jams?

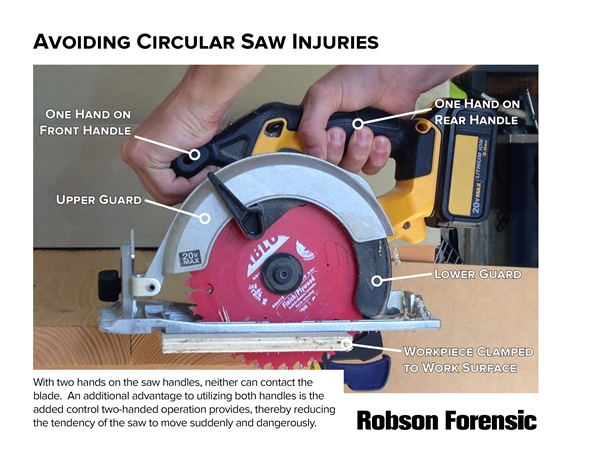

Yes, there are several important safety precautions to take to prevent circular saw jams. Always wear appropriate safety gear, including goggles and ear protection. Make sure the work surface is stable and secure before cutting. Avoid placing your hands too close to the blade and use push sticks or guides when necessary. Additionally, never force the saw through the material or make sudden, aggressive movements that could cause the blade to bind and jam. Lastly, keep the work area clean and free of debris to reduce the risk of jams.

Remember, safety should always be a top priority when using a circular saw. By following these precautions, you can not only prevent jams but also ensure a safer working environment.

5. Can improper maintenance cause a circular saw to jam?

Yes, improper maintenance is a common cause of circular saw jams. Failing to clean the saw regularly can lead to the buildup of sawdust and debris, which can clog the moving parts and cause the saw to jam. It’s important to regularly clean the blade, base, and other components to keep the saw running smoothly.

Additionally, lack of lubrication can also contribute to jams. The moving parts of the saw should be lubricated periodically to prevent friction and ensure smooth operation. By properly maintaining your circular saw, you can avoid many of the issues that can lead to jamming.

11 WORST CIRCULAR SAW MISTAKES!! And How To Avoid them…(DON’T DO THESE THINGS! Kickback/Binding)

Summary

Circular saws can jam for various reasons like using a dull blade, pushing too hard, or misalignment. It’s important to use the right blade, apply steady pressure, and check for any obstructions. Staying safe and maintaining the saw properly will help prevent jams and ensure smooth cutting.

Remember, if your circular saw jams, stop using it immediately, unplug it, and inspect the cause of the jam. And always remember to follow safety guidelines and wear protective gear when working with power tools. Happy cutting!