Have you ever wondered why circular saws have a tendency to kickback? Well, you’re in the right place! In this article, we’ll dive into the reasons behind this unique phenomenon that can make using a circular saw a bit tricky at times. So, let’s get started and uncover the mysteries of why circular saws kickback!

Now, you might be wondering what exactly we mean by “kickback.” Imagine a sudden and unexpected backward motion of the circular saw, often causing it to jump back towards the user. It can be quite startling, not to mention dangerous. But fear not, we’re here to shed some light on the reasons behind it.

Let’s discover the factors that contribute to this phenomenon, from the design of the circular saw to the way it interacts with the material you’re cutting. By understanding why circular saws kickback, we can better equip ourselves with the knowledge to use them safely and efficiently. So, let’s roll up our sleeves and unravel the mysteries of the circular saw kickback!

Why Does Circular Saw Kickback?

A circular saw is a powerful tool used for cutting various materials, but it can sometimes experience kickback, which is a sudden, uncontrollable movement of the saw blade away from the material being cut. Kickback can be dangerous and cause serious injury if not properly addressed. In this article, we will explore the reasons behind circular saw kickback and provide tips on how to prevent it. Understanding the factors that contribute to kickback can help you stay safe and make the most of your circular saw.

Factors Contributing to Circular Saw Kickback

There are several factors that can contribute to kickback when using a circular saw. Understanding these factors can help you take preventive measures and avoid accidents. Let’s take a closer look at the most common causes of circular saw kickback:

Saw Blade Misalignment

One of the main causes of kickback is the misalignment of the saw blade. If the blade is not properly aligned with the fence or guide, it can bind against the material being cut, causing the saw to jerk or kick back. To prevent this, always ensure that the saw blade is aligned correctly before starting a cut. Check for any obstructions or debris that could interfere with the smooth movement of the blade.

Poor Cutting Technique

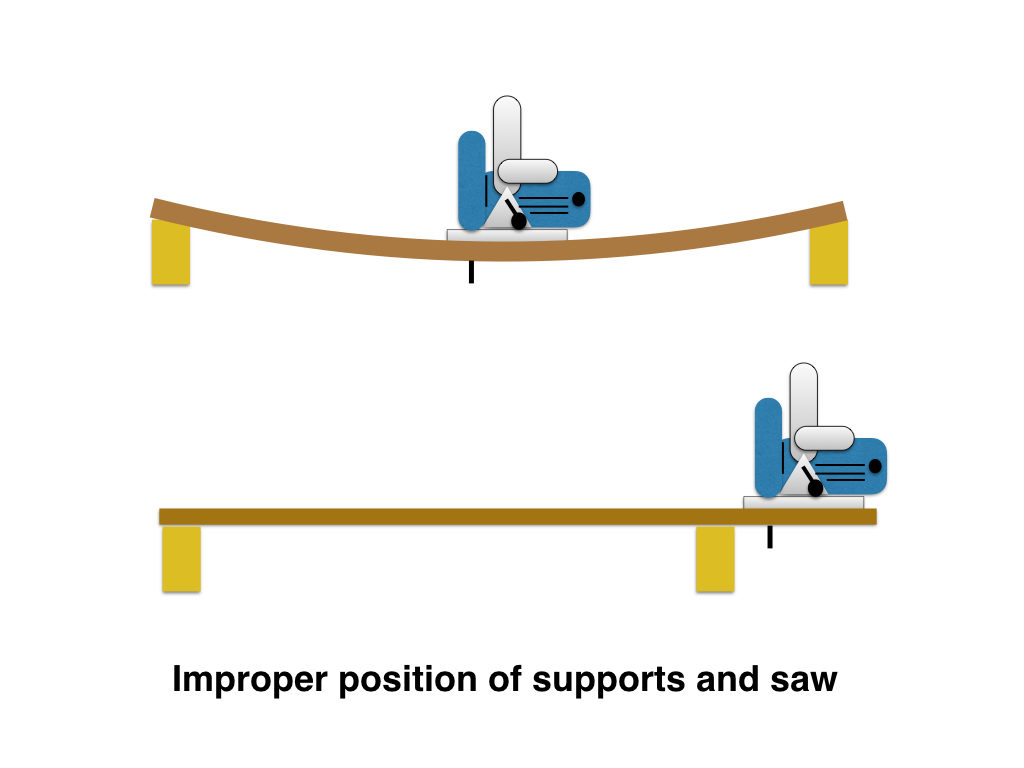

The way you handle the circular saw during a cut can also contribute to kickback. If you push the saw too forcefully or at the wrong angle, it can cause the blade to bind and kick back. Additionally, attempting to make a cut without proper support for the material can also lead to kickback. To prevent this, use a steady and controlled motion when cutting and always ensure that the material being cut is properly supported.

Dull or Damaged Blade

A dull or damaged blade can also increase the risk of kickback. When the blade is not sharp enough, it can put more strain on the motor, causing it to bind and kick back. Additionally, a blade with missing or damaged teeth can cause the saw to jerk and kick back. Regularly inspect your saw blades and replace them when necessary. Using a sharp and properly maintained blade will reduce the chances of kickback.

Inadequate Blade Guard

The blade guard is an important safety feature of a circular saw that helps prevent kickback. If the blade guard is not functioning properly or is not adjusted correctly, it can increase the risk of kickback. Always ensure that the blade guard is in good condition and properly adjusted to provide maximum protection. If you notice any issues with the blade guard, have it repaired or replaced before using the saw.

Inappropriate Blade Selection

Using the wrong type of blade for the material being cut can also contribute to kickback. Different materials require different types of blades with specific tooth configurations and cutting capacities. Using a blade that is not designed for the material can cause the saw to bind and kick back. Always select the appropriate blade for the task at hand to ensure smooth and safe cutting.

Powerful Motor

The power of the motor in a circular saw can also play a role in kickback. If the motor is too powerful for the saw’s design or the material being cut, it can cause the blade to bind and kick back. It is important to choose a circular saw with an appropriate motor size for the tasks you will be performing. If you frequently work with heavy-duty materials, consider investing in a more powerful saw to minimize the risk of kickback.

Lack of Personal Protective Equipment

Not wearing the proper personal protective equipment (PPE) can increase the risk of injury from circular saw kickback. PPE, such as safety goggles, ear protection, and gloves, can help protect you from flying debris and reduce the impact of kickback. Always wear the appropriate PPE when operating a circular saw to ensure your safety.

Why Does Circular Saw Kickback?

- Kickback happens when the saw’s blade gets stuck or pinched, causing it to violently jerk back towards the user.

- It is mainly caused by incorrect cutting technique or using a dull blade.

- Not maintaining a firm grip on the saw and not using a saw with an anti-kickback device can also lead to kickback.

- Uneven pressure applied on the saw can cause it to bind and kickback.

- Always use protective gear like safety glasses and gloves to minimize the risk of injury during kickback incidents.

Frequently Asked Questions

In this section, we will answer some common questions about circular saw kickback.

How does circular saw kickback happen?

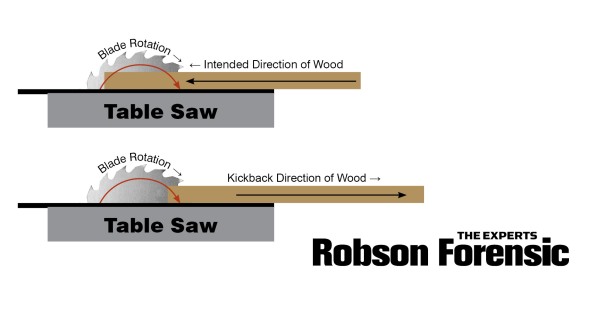

Circular saw kickback occurs when the blade of the saw binds or gets stuck in the material being cut. When this happens, the rotational force of the blade can cause the saw to jerk back towards the user, potentially leading to accidents. Kickback can occur for various reasons, such as improperly aligned or dull blades, cutting warped or twisted wood, or excessive force applied to the saw.

It’s important to note that kickback is more likely to happen when the blade’s path is restricted or pinched, causing tension and binding. Understanding the potential causes and practicing proper cutting techniques is essential in reducing the risk of kickback incidents.

How can I prevent circular saw kickback?

To prevent circular saw kickback, there are several precautions you can take. Firstly, always make sure the blade is sharp and in good condition. Dull blades are more prone to binding and kickback. Additionally, using the appropriate type and size of blade for the material being cut is crucial.

Proper technique is also important in preventing kickback. Maintain a firm grip on the saw with both hands, position yourself in a stable stance, and ensure the material being cut is properly supported. Avoid forcing the saw through the material; instead, let the blade do the work and maintain a steady, controlled pace. Lastly, be aware of potential hazards and always wear appropriate safety gear, including goggles, gloves, and ear protection.

Can kickback be caused by the circular saw’s design?

While kickback is primarily caused by user error or improper technique, certain design features of circular saws can contribute to the occurrence of kickback. For instance, saws with inadequate blade guards or anti-kickback devices may increase the risk of kickback incidents. It’s important to choose a circular saw that has effective safety features and follow the manufacturer’s instructions for safe operation.

However, it’s crucial to note that proper usage and safe practices are the primary factors in preventing kickback. Even with the most advanced safety features, if the saw is used incorrectly, kickback can still occur.

What are the potential dangers of circular saw kickback?

Circular saw kickback can pose significant dangers to the user and those nearby. The sudden backward movement of the saw can cause loss of control, leading to serious injuries or accidents. These injuries can range from minor cuts or bruises to more severe lacerations, broken bones, or even amputations.

In addition to the physical harm, kickback incidents can also cause damage to the material being cut, surrounding objects, or the saw itself. That is why it’s crucial to take preventive measures and follow safe cutting practices to minimize the risk of kickback and ensure a safe working environment.

What other power tools can experience kickback?

While circular saws are commonly associated with kickback incidents, they are not the only power tools that can experience kickback. Other tools, such as table saws, miter saws, and chainsaws, can also be susceptible to kickback if not used properly.

Each tool has its own set of safety considerations and techniques to prevent kickback. It’s important to familiarize yourself with the specific safety guidelines and operational instructions for the power tool you are using to minimize the risk of kickback and ensure safe operation.

How to prevent circular saw from kickback

Summary

Circular saw kickback happens when the saw suddenly jerks back towards the user. It can be dangerous and is usually caused by a few reasons. One reason is using the wrong blade or a dull blade, which can get stuck and cause the saw to kick back. Another reason is not holding the saw with a firm grip, which can lead to losing control of the tool. Additionally, cutting through knots or dense materials can also cause kickback. To avoid this, it’s important to use the right blade, maintain a secure grip, and be cautious when cutting through tough materials.

In conclusion, circular saw kickback can be prevented by following safety guidelines and being aware of the potential causes. By using the correct blade, keeping a firm hold on the saw, and being cautious of dense materials, both professionals and DIY enthusiasts can reduce the risks associated with circular saw kickback. Always prioritize safety and take the necessary precautions to protect yourself when using power tools. Stay safe and happy sawing!