Hey there! Ever wondered why a circular saw sometimes kicks back at the end of a cut? Well, let’s dive into the world of woodworking and explore why this happens.

So, why does a circular saw kickback? When a circular saw kicks back, it means that the spinning blade suddenly gets caught on the material and jerks back towards you. It can be quite dangerous and scary, but understanding why it happens is essential for your safety.

You see, when you’re making a cut with a circular saw, the blade rotates in a forward direction. But as you approach the end of the cut, the blade can bind or snag on the wood, causing it to catch and kick back towards you.

Now that we have a better understanding of the phenomenon, let’s take a closer look at the reasons behind circular saw kickback and how you can prevent it. Strap on your safety gear, grab your circular saw, and let’s get started!

Have you ever wondered why circular saws kickback at the end of a cut? Circular saws can kickback due to various factors such as blade binding, incorrect cutting technique, or using a dull blade. When the blade gets stuck or pinched during the cut, it causes the saw to jerk back towards the user. To prevent kickback, make sure to use a sharp blade, maintain a proper cutting technique, and always wear appropriate safety gear.

Why Does Circular Saw Kickback at End of Cut?

When using a circular saw, it is not uncommon to experience kickback at the end of a cut. This sudden and uncontrollable reaction can be quite dangerous if not properly understood and addressed. In order to prevent kickback and ensure a safe cutting experience, it is important to be aware of the factors that contribute to this phenomenon. This article will delve into the reasons behind circular saw kickback and provide valuable insights on how to minimize its occurrence.

The Physics of Circular Saw Kickback

Circular saw kickback occurs due to a combination of factors, primarily related to the force exerted on the saw blade and the material being cut. When a circular saw is in use, the blade spins at a high speed, cutting through the material with its sharp teeth. As the blade encounters resistance, such as knots in the wood or binding of the blade, the saw may momentarily slow down. However, the saw’s motor continues to exert a significant amount of force, causing the blade to abruptly catch up and propel itself back toward the operator. This sudden rearward movement is known as kickback.

One of the key contributors to kickback is improper alignment of the saw blade. If the blade is not perfectly parallel to the material being cut, it can cause the saw to bind and increase the likelihood of kickback. Additionally, using a dull or inappropriate blade for the material being cut can exacerbate kickback. A dull blade requires more force to cut through the material, increasing the risk of the blade getting stuck and initiating kickback.

Preventing Circular Saw Kickback

While circular saw kickback can be a frightening experience, fortunately, there are several measures that can be taken to prevent it from occurring. First and foremost, it is essential to wear proper safety gear, including safety glasses, ear protection, and gloves. These protective measures can greatly reduce the risk of injury in the event of kickback.

Proper technique and positioning are crucial in preventing kickback. It is important to maintain a firm grip on the saw with both hands, ensuring that the base plate or shoe is firmly pressed against the material being cut. Keeping the saw’s handle close to your body and maintaining a stable stance will provide better control and reduce the likelihood of kickback.

In addition to technique, using the right blade for the task at hand is of utmost importance. A high-quality blade with sharp teeth designed for the specific material being cut will reduce the chance of kickback. Regular maintenance of the saw, such as keeping the blade clean and sharp, will further enhance its performance and minimize kickback.

Additional Factors to Consider

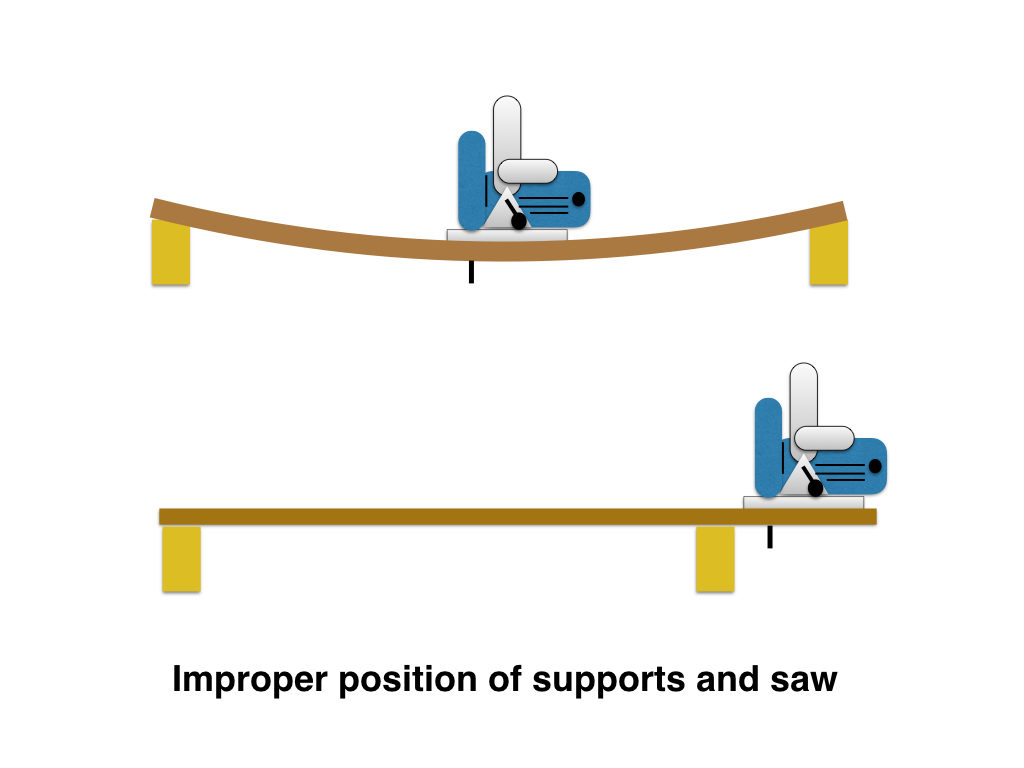

While technique and blade selection are crucial in preventing kickback, there are other factors to consider. One such factor is the use of proper cutting aids and fixtures. Using a straight edge or guide can help control the saw and keep the cut straight, reducing the chances of kickback. Additionally, ensuring that the material being cut is properly supported and secured can significantly minimize kickback.

In conclusion, circular saw kickback is a common occurrence, but it can be prevented by understanding the physics behind it and implementing proper safety measures and techniques. By aligning the saw correctly, using the right blade, maintaining control and stability while cutting, and utilizing cutting aids and fixtures, the risk of kickback can be greatly reduced. Remember, safety should always be the top priority when working with power tools, and taking the necessary precautions will go a long way in preventing accidents and ensuring a safe and enjoyable cutting experience.

The Importance of Proper Saw Blade Maintenance

One of the key factors in preventing circular saw kickback is the use of a sharp and well-maintained saw blade. A dull or damaged blade not only increases the risk of kickback but also compromises the quality of the cut and puts unnecessary strain on the saw motor. In this section, we will explore the importance of proper saw blade maintenance and provide helpful tips on how to keep your blades in optimal condition.

Why Blade Maintenance Matters

A sharp and well-maintained saw blade is essential for achieving clean and precise cuts. When a blade becomes dull, it can tear through the material instead of making a smooth cut, leading to splintering or rough edges. This can not only affect the aesthetic appeal of the final product but also weaken its structural integrity. In addition, a dull blade requires more force to cut through the material, increasing the risk of kickback.

How to Maintain Your Saw Blades

Proper maintenance of saw blades is relatively simple and can significantly extend their lifespan. Here are a few essential tips to keep in mind:

- Regular cleaning: After each use, remove any built-up debris and resin from the blade using a cleaning solution specifically designed for saw blades. Be sure to follow the manufacturer’s instructions.

- Sharpening: Depending on the frequency of use, saw blades may require sharpening periodically. This can be done using a specialized sharpening tool or by taking the blade to a professional sharpening service.

- Resin removal: Over time, resin build-up can occur on the teeth of the blade, affecting its cutting performance. Use a resin remover or a simple solution of warm water and mild detergent to dissolve and remove any resin deposits.

- Storage: When not in use, store your saw blades in a clean and dry environment. Avoid exposure to moisture, which can cause rusting, and keep the blades protected by using blade covers or storing them in their original packaging.

By incorporating these maintenance practices into your routine, you can ensure that your saw blades remain in top condition and deliver optimal cutting performance, while reducing the risk of kickback and achieving clean and precise cuts.

Key Takeaways: Why Does a Circular Saw Kickback at the End of a Cut?

- Kickback happens when the circular saw blade gets stuck and forcefully kicks back towards the operator.

- The most common cause of kickback is improper use or lack of safety precautions.

- Applying too much force or using a dull blade can cause kickback.

- Not using a riving knife or splitter can also increase the risk of kickback.

- Always follow safety guidelines, use proper techniques, and maintain your tools to prevent kickback accidents.

Frequently Asked Questions

In this section, we will explore common questions regarding circular saw kickback at the end of a cut.

What is kickback and why does it happen with a circular saw?

Kickback refers to the sudden, uncontrollable backward movement of a circular saw during or at the end of a cut. It can happen due to several reasons. One common cause is when the saw blade binds or gets pinched in the material being cut. This can cause the saw to jerk back towards the operator. Another cause is improper use of the saw, such as applying excessive force or cutting with the wrong technique. Kickback is a serious safety concern that can result in injuries if not properly addressed.

To minimize kickback, it is important to use a sharp blade that is appropriate for the material being cut. Ensure the material is properly supported to prevent it from pinching the blade. Additionally, maintain a firm grip on the saw with both hands and use the proper cutting technique recommended by the manufacturer. Always exercise caution and follow safety guidelines to reduce the risk of kickback.

Are there any safety measures I can take to prevent kickback while using a circular saw?

Absolutely! Here are some safety measures you can take to minimize the risk of kickback when using a circular saw:

1. Use a sharp blade: A dull blade is more likely to bind and kick back. Keep your saw blade sharp and replace it when necessary.

2. Choose the right blade: Make sure to use a blade that is appropriate for the material being cut, as recommended by the manufacturer.

3. Support the material: To prevent pinching, ensure the material being cut is properly supported and not wedged too tightly against the blade.

4. Maintain a firm grip: Hold the saw with both hands, keeping a firm grip on the handles to maintain control throughout the cut.

5. Follow proper cutting technique: Use the correct cutting technique as advised by the manufacturer. Avoid applying excessive force or twisting the saw, as this can increase the likelihood of kickback.

Remember, your safety should always be the top priority when using power tools like circular saws. Be aware of the potential for kickback and take the necessary precautions to protect yourself.

Can kickback be prevented by using safety features on a circular saw?

Yes, many modern circular saws come equipped with safety features that can help prevent or reduce the risk of kickback. Some common safety features include:

1. Riving knife: A riving knife is a metal plate that sits just behind the blade and helps prevent the material from pinching the blade, reducing the chance of kickback.

2. Blade guards: Blade guards are protective covers that encase the blade during use. They not only protect your fingers but also help prevent material from getting caught and causing kickback.

3. Electric brake: An electric brake stops the rotation of the blade almost instantly when you release the trigger, reducing the chances of kickback and improving overall safety.

While these safety features can greatly reduce the risk of kickback, it is important to remember that they are not foolproof. Proper operation and adherence to safety guidelines are still essential to prevent accidents and ensure your safety.

What should I do if kickback occurs while using a circular saw?

If kickback occurs while using a circular saw, it is important to stay calm and follow these steps:

1. Release the trigger: Let go of the saw’s trigger immediately to stop the blade from spinning.

2. Maintain a firm grip: Hold onto the saw with both hands, maintaining a firm grip on the handles as you regain control.

3. Assess the situation: Check for any injuries or damage caused by the kickback. If needed, seek medical attention for any injuries.

4. Identify the cause: Determine what caused the kickback and address the issue before continuing with your work. This may involve adjusting your cutting technique, using the proper blade, or ensuring the material is properly supported.

Remember, kickback can be dangerous, so always prioritize your safety and take the necessary steps to prevent future incidents.

Can kickback occur with any type of circular saw?

While kickback can occur with any type of circular saw, certain factors may increase the risk. For example, kickback may be more likely with larger, more powerful saws that can generate higher forces. Similarly, kickback may occur more frequently when using a circular saw with a blade that is not suitable for the material being cut. It is vital to select the appropriate saw and blade for the task at hand to minimize the risk of kickback. Regardless of the type of circular saw you are using, it is essential to follow safety guidelines, use proper technique, and remain vigilant to reduce the chances of kickback. Your safety should always be the top priority while operating any power tool.

Summary

When using a circular saw, it’s important to understand why kickback happens. Kickback is when the saw’s blade suddenly jerks back toward the user, which can be dangerous. One of the main reasons for kickback is when the blade gets pinched in the wood at the end of a cut. This can happen if the user doesn’t support the wood properly or if they rush the cut.

To prevent kickback, it’s crucial to take certain precautions. Make sure to use a sharp blade and set the depth properly. Always use both hands to control the saw and maintain a firm grip. Additionally, using a rip fence or guide can help keep the cut straight and prevent the blade from getting stuck. By following these tips, you can safely use a circular saw without worrying about kickback.