Have you ever wondered why your bandsaw blade twists? It can be frustrating when you’re working on a project and your blade starts to veer off course. But don’t worry, in this article, we’ll explore the reasons behind this issue and how you can prevent it from happening. So, let’s dive in and unravel the mystery of why bandsaw blades twist!

Picture this: you’re in your workshop, ready to make precise cuts with your bandsaw. Suddenly, the blade starts to twist, throwing off your carefully planned cuts. What could be causing this? Well, there are several factors that can contribute to this problem. From improper tensioning and worn-out guides to incorrect blade alignment, all these factors can cause your bandsaw blade to twist in unexpected ways.

But fear not! Understanding the root causes of blade twisting will help you solve this issue and get back to smooth, accurate cuts in no time. In the following paragraphs, we’ll walk you through the common culprits behind twisted bandsaw blades and offer practical tips to keep your cuts on track. So, tighten your blade and let’s get started on our quest to banish that frustrating twist!

Why Does My Bandsaw Blade Twist?

Having a bandsaw is a valuable addition to any woodworking or metalworking shop, but it can be frustrating when the blade starts to twist. Understanding why your bandsaw blade twists and how to prevent it can save you time and money in the long run. In this article, we will explore the various factors that can cause a bandsaw blade to twist and provide solutions to help you get the most out of your machine.

Common Causes of Bandsaw Blade Twist

There are several factors that can contribute to a bandsaw blade twisting during operation. Let’s delve into each of these causes and explore how they can be addressed:

1. Tension Issues

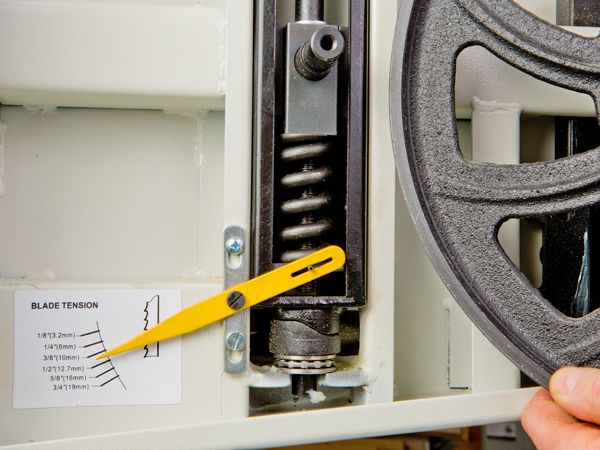

One of the most common causes of blade twist is improper tension. If your bandsaw blade is not properly tensioned, it can lead to uneven cutting and blade drift, resulting in the blade twisting. To prevent this, make sure to follow the manufacturer’s guidelines for blade tension and regularly check and adjust the tension as needed. This will ensure that the blade stays true and cuts smoothly.

Additionally, it’s important to consider the type of material you are cutting. Harder materials may require higher tension to prevent the blade from twisting.

Regular maintenance of your bandsaw, including lubrication and cleaning, can also help prevent blade twist caused by tension issues.

2. Misaligned Guides or Bearings

If the guides or bearings on your bandsaw are not properly aligned, it can cause the blade to twist during operation. Check the alignment of these components regularly and adjust them as needed. Proper alignment will help the blade track correctly and prevent twisting.

It’s a good practice to clean the guides and bearings regularly to remove any debris that can cause misalignment or friction.

If you’re unsure about how to align the guides and bearings, consult your bandsaw’s user manual or seek guidance from a professional.

3. Blade Tension Release

Releasing the tension on your bandsaw blade between uses can lead to twisting. When you finish using your bandsaw, keep the tension on the blade until you are ready to use it again. This will help maintain the blade’s proper shape and prevent it from twisting.

If you frequently release the tension on your blade, consider investing in a tension release lever that allows for quick and easy tension adjustments. This will make it convenient to release and restore tension as needed without causing the blade to twist.

Proper storage of your bandsaw, such as hanging the blade vertically or using a blade storage system, can also help prevent twisting caused by tension release.

4. Blade Quality and Sharpness

The quality and sharpness of the blade can greatly affect its performance and prevent twist. Using a high-quality blade that is appropriate for your cutting needs is essential. Blades with a higher tooth count and finer teeth tend to be more resistant to twisting.

Regularly inspect and replace worn blades to maintain optimal cutting performance. A dull or damaged blade can cause the material to push against the blade, resulting in twisting.

Proper blade maintenance, including sharpening and cleaning, will help extend the life of the blade and reduce the risk of twisting.

5. Feed Rate

The speed at which you feed your material into the bandsaw can also contribute to blade twist. Feeding the material too quickly or unevenly can put excessive pressure on the blade, causing it to twist. Maintain a steady and even feed rate to prevent this issue.

If you’re encountering difficulties with the feed rate, consider using a feed rate calculator or seeking advice from experienced woodworkers or metalworkers.

As with any tool, practice and experience will help you develop a better sense of the optimal feed rate for different materials and cutting tasks.

6. Blade Tensioning Technique

The technique used to tension the blade can also impact its straightness. Uneven tensioning, such as applying more pressure to one side of the blade, can result in twist. Take your time and ensure that the tension is evenly distributed across the blade.

Using a tension gauge, following a step-by-step tensioning process, and checking for any adjustments needed along the way can help achieve optimal blade tension and prevent twisting.

Consult your bandsaw’s user manual for specific instructions on tensioning techniques for your machine.

7. Improper Blade Tracking

Blade tracking refers to the alignment of the blade on the bandsaw’s wheels. If the blade is not properly aligned, it can lead to twisting. Check the blade tracking regularly and make any necessary adjustments to ensure it follows a true path.

Follow the manufacturer’s guidelines for adjusting the blade tracking and use the appropriate tools for making adjustments.

Periodically clean the bandsaw wheels to remove any debris or buildup that can affect blade tracking.

Solutions for Preventing Bandsaw Blade Twist

Now that we have explored the common causes of bandsaw blade twist, let’s discuss some solutions to prevent this issue:

1. Regular Maintenance

Perform regular maintenance tasks such as lubricating the blade, cleaning the guides and bearings, and checking for proper tension. This will help keep your bandsaw in optimal condition and prevent blade twist.

Develop a maintenance schedule and stick to it to ensure that these tasks are not overlooked.

2. Proper Blade Selection

Choose a high-quality blade that is appropriate for the material you are cutting. Consider the tooth count, tooth shape, and blade width when selecting a blade. Using the right blade will reduce the risk of twisting and ensure clean and accurate cuts.

Consult blade manufacturer’s guidelines or seek advice from professionals to choose the best blade for your specific cutting needs.

3. Correct Tensioning

Follow the manufacturer’s guidelines for blade tension and use a tension gauge to ensure accurate tensioning. Apply even pressure across the blade to prevent uneven tension and twisting.

If in doubt, consult the bandsaw’s user manual or seek guidance from an experienced user or professional.

In Conclusion

Understanding the causes of bandsaw blade twist and implementing the appropriate solutions can greatly improve your bandsawing experience. From proper tensioning to regular maintenance, these steps will help keep your blade true and ensure precise cuts. By following these tips, you’ll be able to enjoy the full potential of your bandsaw without the frustration of blade twist.

Key Takeaways: Why Does My Bandsaw Blade Twist?

- A dull blade can cause the bandsaw blade to twist while cutting.

- Incorrect blade tension can also lead to blade twisting.

- Improper feeding and incorrect cutting technique may contribute to blade twisting.

- Inconsistent blade guides can result in blade twisting.

- Using a lower quality or worn-out blade can cause twisting issues.

Frequently Asked Questions

In this section, we will address some common concerns regarding bandsaw blade twisting.

1. What causes bandsaw blades to twist?

Bandsaw blades can twist due to various reasons. One common cause is improper tensioning of the blade. If the tension is too loose or uneven across the blade, it can twist during operation. Another factor is feeding the material too aggressively. Applying excessive force can cause the blade to twist and lead to poor cutting performance.

Additionally, worn or damaged blade guides and thrust bearings can contribute to blade twisting. When these components are not functioning properly, they can exert uneven pressure on the blade, resulting in twists. Lastly, incorrect blade selection for the material being cut can cause the blade to twist. Using a blade with the wrong length or tooth configuration for the specific material can lead to twisting issues.

2. How can I prevent bandsaw blades from twisting?

To minimize bandsaw blade twisting, start by ensuring proper blade tension. Follow the manufacturer’s guidelines and adjust the tension according to the blade’s width and the material being cut. Additionally, make sure the blade guides and thrust bearings are properly adjusted and in good condition. Regularly inspect and replace any worn or damaged components.

Another key factor is controlling the feeding speed. Take care not to feed the material too quickly or apply excessive force. Allow the blade to do the work without forcing it. Furthermore, it’s crucial to choose the right blade for the job. Consider factors such as tooth pitch, blade width, and blade type that are suitable for the material you are cutting. Using the correct blade will help minimize twisting issues.

3. Can improper blade installation cause twisting?

Improper blade installation can indeed contribute to bandsaw blade twisting. When installing a blade, ensure it is properly seated on the wheels and the teeth are facing in the right direction. Improper installation can lead to a misaligned blade, causing it to twist during operation.

Make sure the blade is tensioned correctly after installation and check that it is tracking properly on the wheels. Any misalignment or incorrect tracking can lead to increased blade stress, resulting in twisting. Proper blade installation and alignment are crucial to prevent twisting issues.

4. Are there any maintenance practices that help prevent twisting?

Regular maintenance plays a vital role in preventing bandsaw blade twisting. One important aspect is keeping the blade clean. Residue from the material being cut, such as pitch or sawdust, can accumulate on the blade and affect its performance. Clean the blade regularly using a blade cleaning solution to remove any build-up.

Another maintenance practice is ensuring the bandsaw is properly lubricated. Lubrication helps reduce friction, heat, and wear on the blade. Follow the manufacturer’s recommendations for lubrication, and regularly check and replenish the lubricant as needed. Proper maintenance, including cleaning and lubrication, can help extend the lifespan of the blade and minimize twisting issues.

5. Can blade quality affect twisting?

Blade quality can have an impact on bandsaw blade twisting. Low-quality or worn-out blades are more prone to twisting during operation. Investing in high-quality blades made from durable materials can greatly improve cutting performance and reduce twisting issues.

Additionally, blade thickness and design also play a role. Thick blades tend to be more rigid and less prone to twisting compared to thinner ones. Choosing blades with the appropriate tooth configuration for the material being cut is also important. High-quality blades matched with the right specifications can help minimize blade twisting and improve overall cutting results.

Adjust Bandsaw | Drift, Resaw, Blade Guides, Tension, Sharpening

Summary

Lemme sum up what we talked about. Bandsaw blade twisting is a pretty common problem. It can happen because of improper tension, worn-out guides, or using the wrong blade for the job. Make sure you check and adjust the tension properly, replace worn-out guides, and use the right blade. Oh, and don’t forget about keeping the blade clean and lubricated!

Now, when your bandsaw blade twists, don’t panic! Remember to take it slow and steady, use even pressure, and let the blade do the work. If you’re still having trouble, don’t hesitate to ask for help from an adult or a woodworking pro. Practice makes perfect, so keep at it and enjoy your woodworking adventures!