Do you ever wonder why your bandsaw seems to have a mind of its own, cutting crooked lines instead of straight ones? Well, you’re in the right place! In this article, we’ll explore the reasons why your bandsaw might be cutting crooked and give you some tips to fix the issue. So, let’s dive in and unravel the mystery of the crooked bandsaw cuts!

You’ve probably experienced the frustration of making a cut with your bandsaw, only to find that it comes out all wonky. But fear not, there are a few common culprits behind this issue. One possible reason is that your bandsaw blade might be dull or worn out. A dull blade can easily wander off course, resulting in cuts that are anything but straight.

Another factor that can cause crooked cuts is improper tensioning of the blade. If the blade is not properly tensioned, it can twist or bow during the cutting process, leading to inaccurate cuts. So, it’s crucial to ensure that your bandsaw blade is tight and properly tensioned before each use.

Lastly, the guides and bearings on your bandsaw can also contribute to crooked cuts. If they are not properly adjusted or if they are damaged, they can cause the blade to veer off track. Regular maintenance and adjustment of these components are essential to keep your bandsaw cutting straight.

Now that we’ve explored some of the possible reasons why your bandsaw might be cutting crooked, let’s move on to the next section, where we’ll dive deeper into each of these issues and discuss how to fix them. So, stay tuned and get ready to straighten out those cuts!

Why Does My Bandsaw Cut Crooked?

A bandsaw is an essential tool in any woodworking shop, allowing for precision cuts and intricate designs. However, if you’ve noticed that your bandsaw is cutting crooked, it can be frustrating and affect the quality of your projects. In this article, we will explore the possible reasons behind this issue and provide solutions to help you troubleshoot and fix the problem. Whether you are a seasoned woodworker or just starting out, understanding why your bandsaw cuts crooked is crucial for achieving accurate and professional-looking cuts.

Uneven Blade Tension

One of the most common causes of a crooked cut on a bandsaw is uneven blade tension. When the blade is not properly tensioned, it can veer off course, resulting in uneven cuts. To ensure an even blade tension, start by checking the tension setting on your bandsaw. Refer to your bandsaw’s manual for the recommended tension for the type and width of the blade you are using. Use a blade tension gauge to measure the tension accurately. If the tension is not balanced, adjust the tension accordingly using the tensioning mechanism on your bandsaw. Once you have achieved even blade tension, try making a test cut to see if the issue has been resolved.

In addition to checking the tension, also inspect the blade for any signs of damage or wear. A dull or worn-out blade can cause the bandsaw to cut crooked. If you notice any chips, cracks, or missing teeth, it is time to replace the blade. Using a sharp and properly maintained blade is essential for clean and accurate cuts.

Another aspect to consider is the blade tracking. Improper blade tracking can also lead to crooked cuts. Make sure the blade is properly aligned on the bandsaw wheels, with the teeth centered and tracking in the middle of the wheels. Adjust the tracking knob or lever to achieve proper alignment. It is recommended to check the blade tracking regularly, especially after changing or replacing the blade, to ensure consistent and accurate cuts.

Improper Blade Guides

The blade guides on your bandsaw play a crucial role in keeping the blade aligned and preventing it from wandering off course. If your bandsaw is cutting crooked, it could be due to improper blade guide setup. The blade guides consist of side guides and a back guide that help support the blade during operation.

Start by checking the side guides. Ensure that they are adjusted properly and providing adequate support to the blade without causing excessive friction. The side guides should be set close to the blade without actually touching it. Make sure to adjust both upper and lower side guides symmetrically to ensure even support. Also, check the back guide to ensure it is properly aligned with the blade and not causing it to deflect.

If your bandsaw is equipped with ceramic guides, they may provide more accurate and consistent support compared to traditional guide systems. Consider upgrading to ceramic guides to improve the performance and accuracy of your bandsaw cuts.

Incorrect Blade Tensioning Techniques

While having proper blade tension is important, it is also essential to use the correct technique when tensioning the blade. Applying too much or too little tension can result in crooked cuts. When tensioning the blade, start by orienting the teeth correctly. The teeth should face downward and towards the front of the bandsaw. This ensures proper cutting action and prevents the blade from wandering off course.

Next, use a tensioning gauge or the recommended tension setting provided by the manufacturer to tension the blade. Avoid over-tightening the blade, as this can lead to excessive stress and premature failure. On the other hand, an under-tensioned blade can result in a lack of control and accuracy. Find the right balance and tension the blade accordingly.

Additionally, pay attention to the blade tracking while tensioning. If the blade is not properly aligned, it can affect the tensioning process and lead to crooked cuts. Always double-check the blade tracking before and after tensioning the blade to ensure optimal performance.

Bandsaw Blade Drift

Bandsaw blade drift is a phenomenon where the blade tends to veer off to one side during cuts, resulting in a crooked cut. Blade drift can occur due to various factors, including uneven tooth set, blade fatigue, or improper blade tracking.

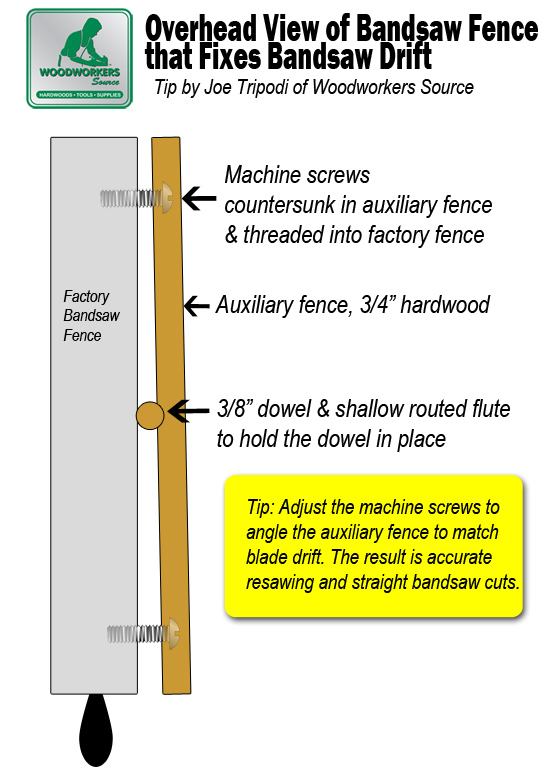

To correct blade drift, start by identifying the direction in which the blade tends to drift. This can be determined by making a straight cut on a scrap piece of wood. Once you have determined the direction of drift, adjust the fence or miter gauge on your bandsaw accordingly. By angling the fence or miter gauge in the opposite direction of the drift, you can guide the blade back on track and achieve straighter cuts.

In addition to adjusting the fence or miter gauge, you can also experiment with different blade types and tooth configurations to minimize blade drift. Some blades are specifically designed to reduce drift and provide more control during cuts. By using a blade with a wider kerf or more aggressive tooth set, you may be able to minimize the effects of blade drift and achieve straighter cuts.

Inaccuracy in Blade Guides

The blade guides on your bandsaw need to be accurately adjusted to ensure straight and precise cuts. Misalignment or improper adjustment of the blade guides can result in a crooked cut. Start by checking the alignment of the guides with the blade. They should be positioned close to the blade without touching it, providing optimal support and control.

If your bandsaw is equipped with ball bearing guides, make sure they are in good condition and properly lubricated. Worn or damaged ball bearings can affect the performance of the blade guides and lead to inaccurate cuts. Replace any worn or damaged ball bearings and keep them well lubricated for smooth operation.

Another consideration is the guide blocks. Guide blocks are made of materials such as graphite, ceramic, or phenolic, and they help stabilize the blade during cuts. Ensure that the guide blocks are properly adjusted and in good condition. If you notice any signs of wear or damage, replace them with new ones to maintain accurate cuts.

Blade Sharpness

The sharpness of the blade plays a crucial role in achieving accurate and clean cuts on a bandsaw. A dull blade can cause the bandsaw to cut crooked and leave rough edges. If you’ve ruled out other potential issues and your bandsaw is still cutting crooked, it may be time to sharpen or replace the blade.

To sharpen a dull blade, you can use a bandsaw blade sharpener or take it to a professional sharpening service. If the blade is excessively worn or damaged, it is recommended to replace it with a new one. Using a sharp blade not only improves the accuracy of your cuts but also extends the life of the blade.

Regular maintenance and inspection of the blade, such as cleaning off resin buildup and checking for any signs of wear or damage, is essential for achieving clean and accurate cuts. A well-maintained and properly sharpened blade will ensure that your bandsaw cuts straight and true.

Summary:

Ensuring that your bandsaw cuts straight and avoids any crooked cuts is important for achieving high-quality woodworking projects. By paying attention to blade tension, blade guides, tensioning techniques, blade drift, guide accuracy, and blade sharpness, you can troubleshoot and resolve the issue of a crooked cut on your bandsaw. Regular maintenance and proper blade selection are also key factors in achieving accurate and precise cuts. Remember to check and adjust the various components of your bandsaw regularly to ensure optimal performance and enjoy the full potential of this versatile tool.

Key Takeaways: Why Does My Bandsaw Cut Crooked?

- 1. Misaligned blade can cause crooked cuts on a bandsaw.

- 2. Tension issues with the blade can also result in crooked cuts.

- 3. Uneven pressure applied to the workpiece can cause the bandsaw to cut crooked.

- 4. Dull or damaged blade teeth may lead to crooked cuts.

- 5. Insufficient blade tracking adjustment can cause the bandsaw to cut crooked.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section where we address common concerns about bandsaws cutting crooked. Read on to find answers to your burning questions.

1. Why is my bandsaw cutting crooked?

There can be a few reasons why your bandsaw is cutting crooked. One possible cause is improper blade tension. When the blade is too loose or tight, it can cause the cut to veer off course. Another factor could be worn or dull blade teeth, leading to an uneven and crooked cut. It’s important to regularly check and maintain your blade to ensure it’s sharp and in good condition. Additionally, a misaligned or skewed blade guide can cause the cut to go off track. Be sure to properly align and adjust the blade guides for optimal performance.

Furthermore, an incorrectly set fence or miter gauge can contribute to crooked cuts. Make sure the fence or miter gauge is properly aligned and adjusted to maintain accuracy. Lastly, operator error can also be a factor. Pushing the material too hard or at the wrong angle can cause the cut to go off course. Slow and steady pressure with proper technique is crucial for a straight cut.

2. How can I fix a crooked cut on my bandsaw?

If you’ve encountered a crooked cut on your bandsaw, there are several steps you can take to fix the issue. Firstly, check the blade tension and make sure it’s within the manufacturer’s recommended range. Adjust the tension accordingly if needed. Secondly, inspect the blade teeth for any signs of damage or dullness. If necessary, replace or sharpen the blade to ensure clean and accurate cuts.

Next, evaluate the alignment of the blade guides. Adjust them as necessary, making sure they’re properly aligned with the blade. Additionally, check the position and alignment of the fence or miter gauge. Ensure they are parallel to the blade and properly adjusted for accurate cuts. If all else fails, it might be beneficial to seek guidance from an experienced bandsaw operator or consult the manufacturer’s instructions for troubleshooting tips specific to your model.

3. Can the type of material I’m cutting affect the crookedness of the bandsaw cut?

Yes, the type of material you’re cutting can influence the accuracy of the bandsaw cut. Some materials, such as certain types of hardwood or dense materials, can exert more resistance on the blade, causing it to deflect or veer off course. It’s important to adjust the blade tension, feed rate, and cutting speed based on the material you’re working with.

Additionally, the thickness and width of the material can also impact the cut. Thicker or wider pieces may require slower feed rates and adjustments to the blade tension to ensure a straight cut. It’s crucial to familiarize yourself with the characteristics of the material you’re working with and make necessary adjustments to achieve optimal results.

4. How often should I check and maintain the blade on my bandsaw to avoid crooked cuts?

To avoid crooked cuts, it’s recommended to regularly check and maintain the blade on your bandsaw. The frequency may vary depending on the frequency of use and the types of materials you work with. However, as a general guideline, inspecting the blade before each use is advisable.

Regular maintenance tasks include checking and adjusting the blade tension, inspecting the teeth for sharpness and damage, and ensuring the blade guides are properly aligned. Keep in mind that a sharp and well-maintained blade not only prevents crooked cuts but also enhances the overall performance of the bandsaw.

5. Are there any safety precautions I should consider when troubleshooting a crooked cut on my bandsaw?

When troubleshooting a crooked cut on your bandsaw, it’s important to prioritize safety. Ensure the bandsaw is turned off and unplugged before conducting any maintenance or adjustments. Always wear appropriate safety gear, including safety glasses and gloves, to protect yourself during the troubleshooting process.

Additionally, carefully follow the manufacturer’s instructions and guidelines when making adjustments to the blade tension, blade guides, fence, or miter gauge. Take your time and proceed methodically to avoid any accidents or injury. If you’re unsure about any aspect of troubleshooting, it’s advisable to seek guidance from an expert or the manufacturer’s customer support.

Summary

So, why does your bandsaw cut crooked? There could be a few reasons. First, check if your blade is sharp and properly tensioned. A dull or loose blade can cause the cuts to go off track. Second, make sure your bandsaw table is flat and adjusted correctly. An uneven or misaligned table can lead to crooked cuts. Lastly, pay attention to your feed rate. Pushing the material too fast can cause the blade to twist and cut crooked. Remember to take things slow and steady!

In conclusion, to get straight cuts on your bandsaw, keep your blade sharp and tight, adjust the table properly, and feed the material at a steady pace. With these tips, you’ll be able to make accurate and straight cuts with your bandsaw. Happy cutting!