If you’ve ever found yourself wondering, “Why does my bandsaw drift?” then you’re in the right place! Drifting is a common frustration among bandsaw users, but fear not, we have the answers you’re looking for. In this article, we’ll delve into the reasons behind this issue and provide you with some practical solutions to get your bandsaw cutting straight as an arrow. So let’s dive right in and unravel the mystery of bandsaw drift together!

Now, you might be wondering, “What exactly is bandsaw drift?” Well, my friend, it’s when your bandsaw veers off course and doesn’t cut in a straight line. It’s like trying to draw a straight line but ending up with a zigzag instead—frustrating, right? The good news is that this problem is fixable, and with a little know-how, you’ll be able to tame your bandsaw and achieve precise cuts every time.

So why does bandsaw drift happen in the first place? There are several factors involved, from blade tension and alignment to the type of wood you’re cutting. Understanding these reasons will empower you to take control of your bandsaw’s performance and eliminate drift for good. So buckle up, my friend, as we embark on a journey to uncover the secrets behind bandsaw drift and equip you with the knowledge to overcome it once and for all!

Is your bandsaw drifting? Discover the reasons behind this common issue. Bandsaw drift can be caused by various factors, including blade tension, blunt or incorrectly set blade teeth, improper feed rate, or inadequate tracking. To fix the problem, start by adjusting the blade tension and checking for blade irregularities. Ensure correct blade tracking and adjust the blade guide if necessary. Experiment with different feed rates to find what works best for your woodworking projects. Remember to always prioritize safety and follow manufacturer guidelines.

Why Does My Bandsaw Drift? – An Essential Guide for Woodworkers

For woodworkers, a bandsaw is an indispensable tool that allows them to make precision cuts. However, one frustrating issue that many woodworkers encounter is bandsaw drift. Bandsaw drift refers to the phenomenon where the blade veers off course, resulting in inaccurate cuts and wasted materials. In this comprehensive guide, we will delve into the various factors that cause bandsaw drift and provide practical solutions for eliminating this problem. Read on to discover the secrets behind bandsaw drift and how to overcome it!

Understanding the Mechanics of Bandsaw Drift

Before we dive into the reasons behind bandsaw drift, it is important to understand the mechanics of this phenomenon. Bandsaw drift occurs when the blade does not travel in a perfectly straight path but instead deviates to the left or right during a cut. This can be frustrating for woodworkers as it leads to uneven cuts and a waste of materials. Several factors contribute to bandsaw drift, and understanding these factors is crucial to finding effective solutions.

Blade Tension and Tracking

The tension and tracking of the blade play a significant role in bandsaw drift. If the blade is not properly tensioned, it can lead to wandering cuts. Similarly, improper blade tracking, where the blade is not aligned with the center of the wheels, can cause the blade to drift off course. To minimize bandsaw drift, ensure that the blade is correctly tensioned and properly tracked. Regularly check the tension and alignment of the blade to maintain optimal performance.

Blade Selection and Maintenance

The type and condition of the blade can also impact bandsaw drift. Using a blade that is not suitable for the task at hand or one that is worn out can increase the likelihood of drifting. Different blades have varying tooth patterns and widths, and choosing the right blade for the specific cut is essential. Additionally, blades should be regularly inspected and maintained. Keep the blade sharp, replace worn-out blades, and clean it regularly to prevent debris accumulation, which can affect its performance.

Feed Rate and Cutting Techniques

The way you feed the material into the bandsaw and your cutting techniques also contribute to bandsaw drift. Feeding the material too quickly can cause the blade to deflect, leading to drifting. Similarly, using excessive force or improper cutting techniques can result in the blade veering off course. Take the time to understand the correct feed rate for different materials and adopt proper cutting techniques, such as using steady pressure and maintaining consistent control, to reduce bandsaw drift.

Table Alignment and Setup

The alignment and setup of the bandsaw table can significantly impact its cutting accuracy. A misaligned or poorly calibrated table can cause the blade to drift. Ensure that the table is aligned parallel to the blade, and the blade is at the correct tension and tracking. Additionally, check for any damage or wear on the table, as this can also affect its performance. Taking the time to properly set up and align the bandsaw table will help minimize drift and ensure precise cuts.

Resawing and Blade Guides

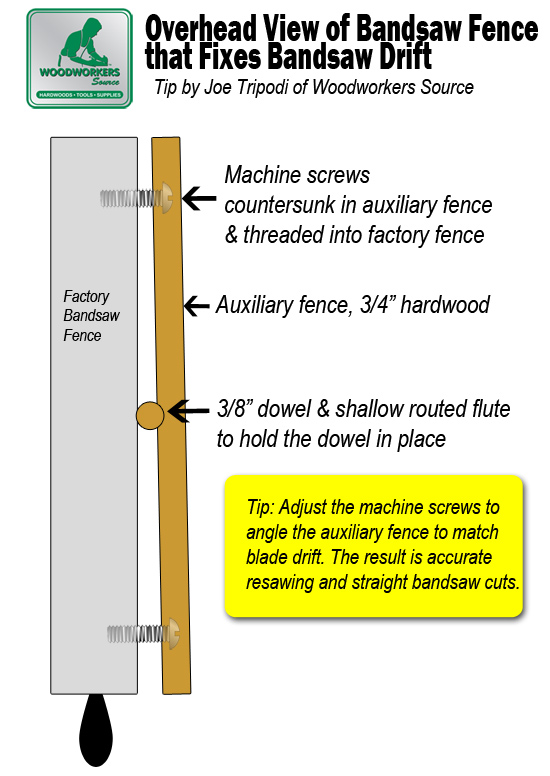

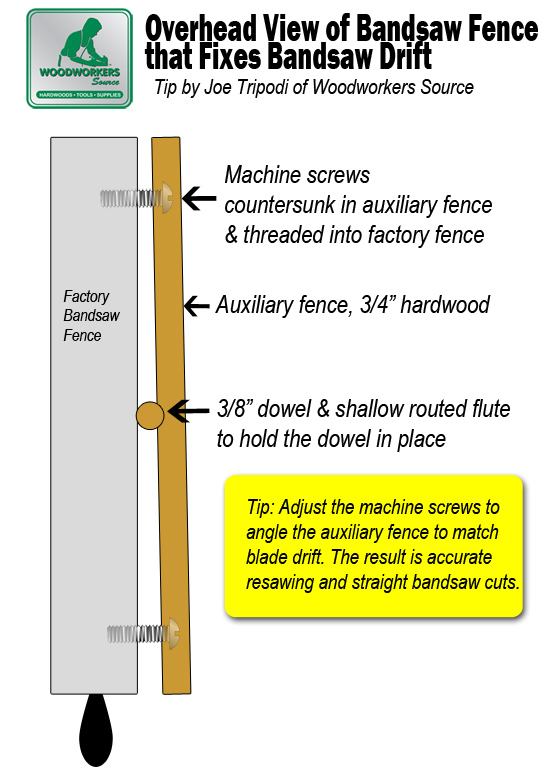

Resawing, which involves cutting a board into thinner pieces, is a common task where bandsaw drift often occurs. The pressure exerted during resawing can cause the blade to deflect, leading to drifting. Proper blade guides and support systems are essential for minimizing drift during resawing. Ensure that the blade guides are adjusted correctly and provide adequate support to reduce blade deflection. Additionally, using a fence or guide system can enhance stability and improve the accuracy of cuts.

Material Characteristics

The characteristics of the material being cut can also contribute to bandsaw drift. Variations in density, hardness, and grain direction can impact the blade’s cutting path. For example, if the material has irregular grain patterns or knots, it can cause the blade to deflect and drift off course. In such cases, adjusting the feed rate, adopting proper cutting techniques, and using appropriate blade selection become even more critical.

Maintenance and Blade Care

Maintaining your bandsaw and taking care of your blades is crucial for preventing bandsaw drift. Regularly clean the bandsaw, remove any debris, and lubricate moving parts. Check for any signs of wear or damage and address them promptly. Proper maintenance extends the lifespan of your bandsaw and ensures optimal performance. Additionally, invest in high-quality blades and store them properly to prevent any damage that could contribute to drifting.

Tips for Eliminating Bandsaw Drift

Now that we have explored the various factors behind bandsaw drift, let’s discuss some practical tips for eliminating this frustrating issue:

1. Maintain proper blade tension and tracking.

2. Choose the right blade for the task at hand and keep it sharp.

3. Slow down your feed rate, especially when resawing or cutting challenging materials.

4. Invest in a reliable fence or guide system for added stability.

5. Ensure the bandsaw table is aligned and set up correctly.

6. Adopt proper cutting techniques, applying steady pressure and maintaining control.

7. Regularly clean and maintain your bandsaw and blades for optimal performance.

Common Mistakes to Avoid

1. Neglecting to check and adjust blade tension and tracking regularly.

2. Using a dull or unsuitable blade for the task.

3. Rushing through cuts without proper feed rate control.

4. Ignoring the importance of proper table alignment and setup.

5. Neglecting to adjust or maintain blade guides and support systems.

6. Performing cuts without considering the material characteristics.

7. Failing to conduct regular maintenance on the bandsaw and blades.

Conclusion

Understanding why your bandsaw drifts is the first step in combating this common issue. By addressing factors such as blade tension, blade selection, feeding techniques, table alignment, blade guides, material characteristics, and regular maintenance, you can minimize bandsaw drift and achieve accurate cuts. Remember to follow the practical tips provided to eliminate bandsaw drift and avoid common mistakes. With the right knowledge and attention to detail, you can unlock the full potential of your bandsaw and enjoy precise and efficient woodworking.

Key Takeaways: Why Does My Bandsaw Drift?

- The blade tension might not be properly adjusted.

- The blade might be dull or improperly installed.

- The blade guides might be incorrectly set.

- The bandsaw tires might be worn out or damaged.

- The workpiece might not be properly aligned or supported during cutting.

Frequently Asked Questions

Welcome to our FAQs section where we answer common questions about bandsaws and why they tend to drift. If you’ve ever experienced your bandsaw drifting off course, causing uneven cuts, you’re not alone. Read on to learn more and find solutions to this frustrating problem.

1. What causes a bandsaw to drift?

There are a few reasons why a bandsaw may drift during operation. One common cause is an improperly tensioned blade. If the blade tension is too low or uneven, it can cause the blade to veer off course. Other factors include a dull or improperly set blade, misaligned guides, or inadequate feed pressure. These issues can lead to the blade getting deflected, resulting in drift.

To combat drift, make sure to properly tension the blade, ensuring it is parallel to the blade guides. Regularly sharpen or replace the blade, and make sure the guides are correctly adjusted. Applying consistent, firm feed pressure will also minimize drift, producing clean and accurate cuts.

2. How can I align my bandsaw to prevent drifting?

Aligning your bandsaw can significantly reduce or eliminate drift. Start by checking the alignment of the blade to the miter slot or fence. Use a straight edge or a specialized alignment tool to ensure the blade is perfectly parallel to the miter slot. You may need to adjust the position of the table or the entire saw to correct any misalignment.

Additionally, check the alignment of the guides. The blade should track smoothly through the guides, without rubbing against the side or back. Adjust the guides as needed to ensure they are properly aligned with the blade. By taking these alignment steps, you’ll ensure a straight and drift-free cut on your bandsaw.

3. Can the type of blade affect bandsaw drift?

Absolutely! The type of blade you use can have a significant impact on drift. Different blades have varying tooth configurations, set angles, and sharpness. Choosing the right blade for your specific application is crucial to minimize drift. For example, a blade with a wide tooth set might be better suited for resawing, while a blade with a narrow tooth set is ideal for intricate curves.

Consider the thickness and hardness of the material you’re cutting, and choose a blade with the appropriate tooth count and set. A sharper blade will also provide better control and reduce drift. Experiment with different blade configurations to find the right one for your specific needs and minimize drift on your bandsaw.

4. How can I prevent my bandsaw from drifting when making curved cuts?

When making curved cuts on your bandsaw, there are a few additional steps you can take to prevent drift. Firstly, use a narrower blade with a higher TPI (teeth per inch) count. This will provide more control and precision for intricate cuts. Ensure the blade is properly tensioned and the guides are adjusted to accommodate the narrower width.

Next, take your time while feeding the material through the blade. Applying steady but gentle pressure will prevent the blade from deflecting and drifting off course. Additionally, using a fence or a miter gauge to guide your material can help maintain a consistent cutting line and reduce drift. With proper technique and attention to detail, you’ll be able to achieve accurate and drift-free curved cuts on your bandsaw.

5. Can dust buildup contribute to bandsaw drift?

Yes, dust buildup can be a contributing factor to bandsaw drift. As dust accumulates on the blade, guides, and wheels, it can affect the blade’s performance and lead to drift. The dust particles can interfere with the blade’s movement and cause it to veer off course.

To prevent dust buildup, it’s essential to keep your bandsaw clean and well-maintained. Regularly remove dust and debris from the blade and guides using a brush or compressed air. Additionally, consider using a dust collection system or attaching a shop vacuum to your bandsaw to capture dust at the source. By keeping your bandsaw clean, you’ll minimize the chances of drift and ensure smooth and accurate cuts.

Summary

Why does your bandsaw drift? Well, there could be a few reasons why this happens. First, check if your blade is properly tensioned. Next, make sure the blade guides are set correctly. Finally, examine the tires on the wheels to see if they need replacing.

Remember, a bandsaw drifts when it doesn’t cut straight. So, if you follow these steps and address these possible causes, you’ll be on your way to getting that straight cut you’ve been aiming for. Happy woodworking!