Are you wondering why your drill press is stalling? Well, fear not, young DIY enthusiast! It can be quite frustrating when your trusty tool starts acting up, but I’m here to shed some light on the issue. Let’s dive in and unravel the mystery of why your drill press might be stalling.

Now, imagine this: you’re working on a cool project, drilling holes like a pro, and suddenly, your drill press comes to a screeching halt. What gives? It turns out there are a few common reasons why this might be happening.

First and foremost, it could be due to a lack of power. Just like us humans need fuel to function, your drill press needs proper power to keep spinning. If you’re using an extension cord that’s too long or not providing enough electricity, it can cause your drill press to stall.

Why Does My Drill Press Stall? Troubleshooting Common Issues

Drill presses are a valuable tool in any workshop, but encountering issues such as stalling can be frustrating. If you’ve been asking yourself, “Why does my drill press stall?” you’re not alone. In this article, we will delve into the common reasons behind drill press stalling and provide you with troubleshooting tips to help you resolve the issue.

1. Dull or Damaged Drill Bit

One of the main culprits behind a stalling drill press is a dull or damaged drill bit. When the cutting edges of the bit become worn down or chipped, it can struggle to make clean cuts and may even get stuck. To fix this issue, try replacing the drill bit with a new one or have it professionally sharpened. Remember to choose the right drill bit for the material you’re working with, as using the wrong type can also lead to stalling.

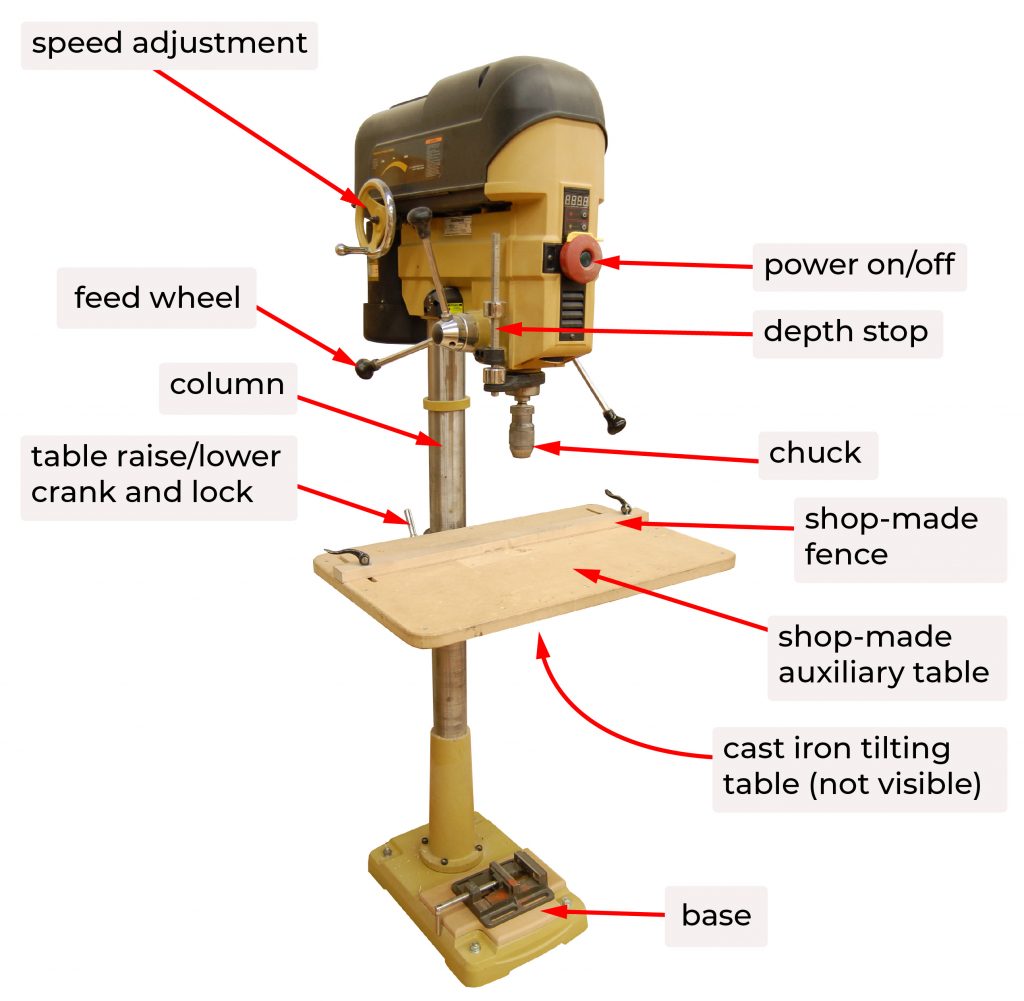

In addition, always ensure that the drill bit is securely tightened in the chuck. A loose bit can wobble and cause the drill press to stall. Use the chuck key to tighten the bit properly, but be careful not to overtighten and risk damaging the chuck.

2. Insufficient Power Supply

Another common reason for a stalling drill press is an insufficient power supply. If the circuit you’re using is overloaded or if there are voltage fluctuations, the drill press motor may not receive enough power to operate smoothly. Check the power outlet and ensure that it can handle the required amperage for your drill press. Consider using a dedicated circuit or a surge protector to prevent power fluctuations.

It’s also essential to check the power cord for any damage. If the cord is frayed or worn, it may not be delivering the necessary power to the drill press. In such cases, replace the power cord to ensure a reliable power supply.

3. Incorrect Feed Pressure

The feed pressure applied while drilling can greatly impact the performance of a drill press. Applying too much pressure can overload the motor and cause the drill press to stall. On the other hand, applying too little pressure can result in inefficient drilling and may lead to stalling as well.

When using a drill press, it’s crucial to find the right balance of feed pressure. Let the drill bit do the work and avoid forcing it into the material. Apply consistent and firm pressure, allowing the drill bit to cut through the material at its own pace. This will prevent stalling and ensure smooth drilling operations.

4. Belt Tension Issues

The belt that drives the spindle of a drill press plays a vital role in its performance. If the belt is loose or worn, it can slip or lose traction, causing the drill press to stall. To address this issue, check the belt tension and adjust it if necessary. Different drill presses may have different mechanisms for adjusting belt tension, so consult your drill press manual for specific instructions.

Inspect the belt for signs of wear or damage and replace it if needed. Regular maintenance and lubrication of the belt can also help prevent stalling and extend its lifespan.

5. Motor Overheating

Operating a drill press for extended periods without allowing the motor to cool down can result in overheating, leading to stalling. The motor needs sufficient airflow to dissipate heat, so avoid blocking the cooling vents on the drill press. If you notice excessive heat or a burning smell, turn off the drill press and allow it to cool down before using it again. Consider using a fan to improve ventilation in your workshop and prevent motor overheating.

Regular maintenance, such as cleaning the motor and lubricating moving parts, can also help prevent overheating and stalling issues.

6. Incorrect Speed Settings

The speed at which the drill press operates should be optimized based on the type of material and drill bit being used. Operating at too high of a speed can cause the drill press to stall, especially when drilling through denser materials. Similarly, using a low speed setting on a material that requires high-speed drilling can also result in stalling.

Refer to the drill press manual or manufacturer guidelines for recommended speed settings for different materials and drill bit sizes. Adjust the speed accordingly to prevent stalling and enhance drilling performance.

7. Other Possible Causes

While the reasons mentioned above are some of the most common causes of a stalling drill press, there can be other factors at play. For instance, a misaligned drill press or a damaged spindle may also lead to stalling. In such cases, it’s best to consult a professional or contact the manufacturer for assistance.

Preventing Drill Press Stalling: Tips and Best Practices

Now that you’re familiar with the common reasons behind drill press stalling, let’s explore some preventive measures and best practices to ensure smooth and efficient drilling operations:

1. Use Sharp Drill Bits:

Regularly inspect and maintain your drill bits to ensure they are sharp and undamaged. Dull or damaged drill bits are more likely to cause the drill press to stall. Use the appropriate drill bit for the material you’re working with.

2. Secure Your Material:

Ensure that the material you’re drilling into is securely clamped or held in place. This minimizes movement and reduces the chances of stalling. Use clamps, vices, or other appropriate holding mechanisms.

3. Do Test Drills:

Before drilling into a larger or more critical surface, it’s always a good practice to do a test drill on a scrap piece of material. This allows you to fine-tune your feed pressure, speed settings, and technique, reducing the risk of stalling on your actual project.

4. Clean and Lubricate:

Regularly clean and lubricate your drill press to prevent the accumulation of debris and ensure smooth operation. Pay particular attention to the chuck, spindle, and motor components.

5. Follow Manufacturer Guidelines:

Always refer to the drill press manual for specific maintenance instructions, speed settings, and safety guidelines. Following the manufacturer’s recommendations can help prevent stalling and prolong the lifespan of your drill press.

By following these tips and troubleshooting techniques, you can overcome the issue of a stalling drill press and enjoy seamless drilling experiences in your workshop.

Key Takeaways:

- A drill press may stall due to dull drill bits that struggle to penetrate the material.

- Insufficient power supply can also cause a drill press to stall.

- Using the wrong cutting speed or applying too much pressure can lead to stalling.

- Improper technique, such as off-center drilling or not securing the material properly, can contribute to stalling.

- Regular maintenance, including lubricating moving parts and cleaning dust and debris, can prevent stalling.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section dedicated to troubleshooting stall issues with your drill press. Below, you’ll find answers to common queries that will help you understand why your drill press may be stalling and how to resolve the issue.

1. Why is my drill press stalling?

The main reasons why a drill press may stall include improper belt tension, dull drill bits, and inadequate motor power. When the belts are loose or too tight, they can affect the proper rotation of the spindle, leading to stalling. Additionally, if the drill bits are dull or the motor doesn’t have enough power to drive the bit through the material, the drill press can stall.

To identify the exact cause, check the belt tension, sharpen or replace dull drill bits, and ensure that your drill press has sufficient power for the job. Following these steps will help eliminate stalling issues and ensure smooth operation.

2. How can I check the belt tension on my drill press?

To check the belt tension on your drill press, start by turning off and unplugging the machine. Locate the motor and the pulleys that drive the spindle. If you have a belt cover, remove it to access the belts. Using a finger or a ruler, press down on the middle section of each belt. They should have a slight give, but not be too loose or too tight.

If the belts are too loose, you’ll need to adjust the tension. Refer to your drill press manual for specific instructions on how to adjust the tension. Generally, this involves loosening the motor mounting bolts, sliding the motor to increase or decrease tension, and tightening the bolts back up. Make sure to recheck the tension after making adjustments.

3. What can I do if my drill press’s motor lacks power?

If your drill press motor lacks power, check to ensure it is receiving the proper voltage and that the power cord is undamaged. If the motor is running on insufficient voltage or the power cord is damaged, it can result in reduced power and stalling.

If both the voltage and power cord are fine, the motor might be faulty or worn out. In this case, consult a professional or contact the manufacturer for motor repair or replacement options. It’s important not to attempt motor repairs yourself unless you have the necessary skills and knowledge.

4. How can I prevent my drill bits from dulling?

To prevent your drill bits from dulling, it’s crucial to use them with proper technique and care. Apply moderate and consistent pressure while drilling, allowing the drill bit to cut through the material at its optimal pace. Avoid excessive force that can cause overheating and premature dulling.

Additionally, ensure that you’re using the correct type of drill bit for the material you’re working with. Different materials require specific drill bits designed for their hardness and properties. Using the wrong drill bit can lead to increased friction, heat, and rapid dulling.

5. Why does my drill press stall when drilling thicker materials?

If your drill press stalls specifically when drilling thicker materials, it’s likely due to insufficient power. Thick materials require more force and torque to drill through, which can overwhelm a drill press with lower motor power. In such cases, the motor may struggle and stall.

To resolve this issue, consider upgrading to a drill press with a more powerful motor or one specifically designed for heavy-duty tasks. Alternatively, you can try drilling in smaller increments, removing the material in stages, and using sharp, high-quality drill bits. These steps will help reduce the strain on the drill press and minimize the chances of stalling.

Summary

So, why does your drill press stall? There are a few possible reasons. One, the drill bit may be dull or bent. Two, the material you’re drilling into may be too hard or thick. Three, the speed setting on your drill press may be too high. Four, there could be a problem with the motor or the belts. Whatever the cause, it’s important to address it so you can get back to drilling smoothly and safely. Remember to always use proper safety precautions when using power tools.