Why does my lathe chatter? If you’re wondering about the annoying noise your lathe makes, you’re in the right place! Chattering is a common issue faced by many lathe users, and it can be frustrating. But fear not, in this article, we’ll uncover the reasons behind this pesky problem and provide you with some helpful solutions.

Imagine this: you’re working on your lathe, trying to create something amazing, when suddenly, the machine starts making an unpleasant rattling or vibrating sound. It’s like a DJ remix gone wrong! But why does it happen? Well, my young friend, there are several factors that can contribute to the chatter of a lathe. Let’s delve into them and find out how to put an end to this disruptive symphony!

When it comes to lathes, precision is paramount. Even the slightest imbalance in your lathe’s setup can cause it to chatter like a chatty parrot. So, be sure to check for any misalignment, worn-out parts, or loose components that could be throwing off the machine’s balance. Stay tuned as we explore more reasons behind the enigmatic lathe chatter and discover how to silence it once and for all!

Why Does My Lathe Chatter? Understanding the Causes and Solutions

Lathe chatter is a frustrating issue that can affect the quality of your machining work. If you’ve ever experienced your lathe making strange vibrations or producing rough finishes, you know the frustration it can bring. In this article, we will delve into the reasons why your lathe may chatter and explore some solutions to help you eliminate this problem. By understanding the causes and taking appropriate actions, you can ensure smooth, precise, and high-quality machining results.

Common Causes of Lathe Chatter

When it comes to lathe chatter, several factors can contribute to the problem. Here are some of the most common causes:

1. Improper Tooling and Setup

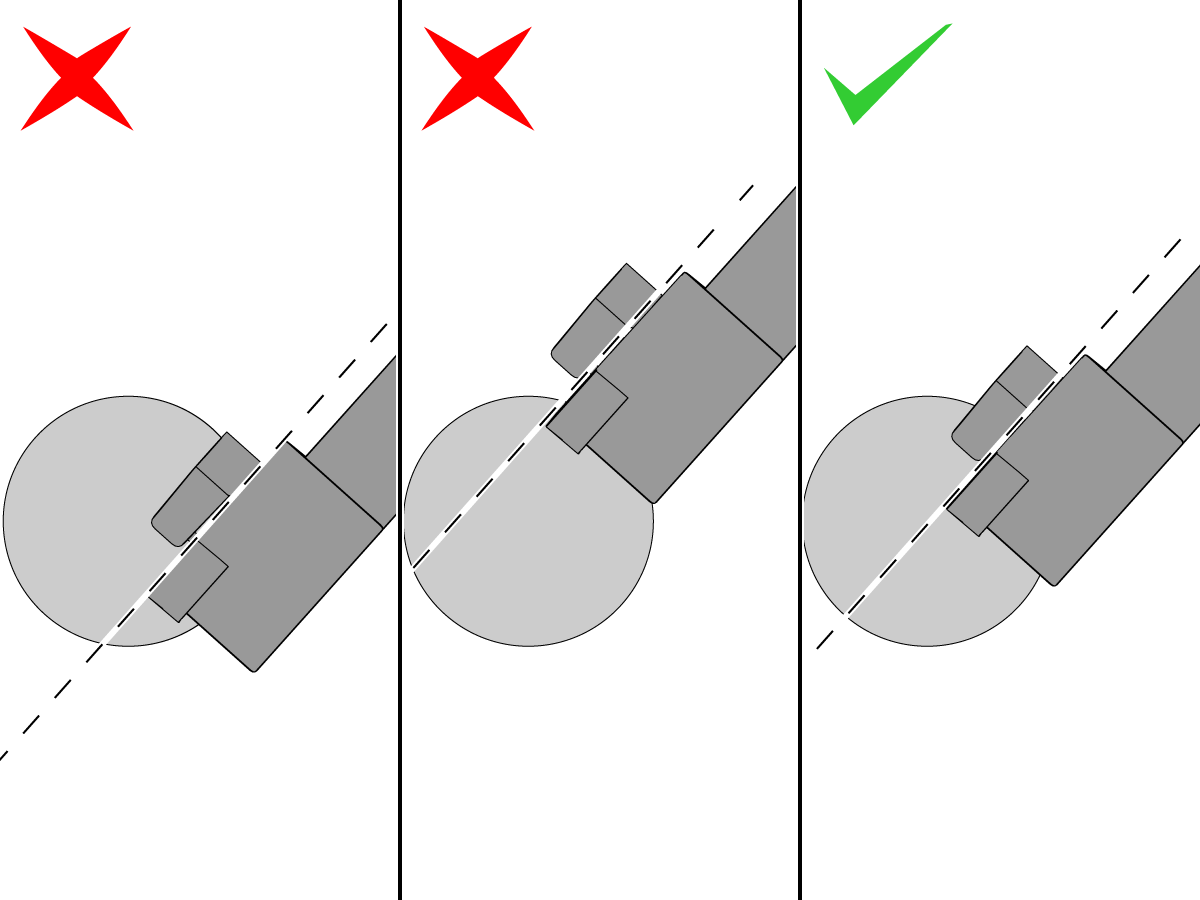

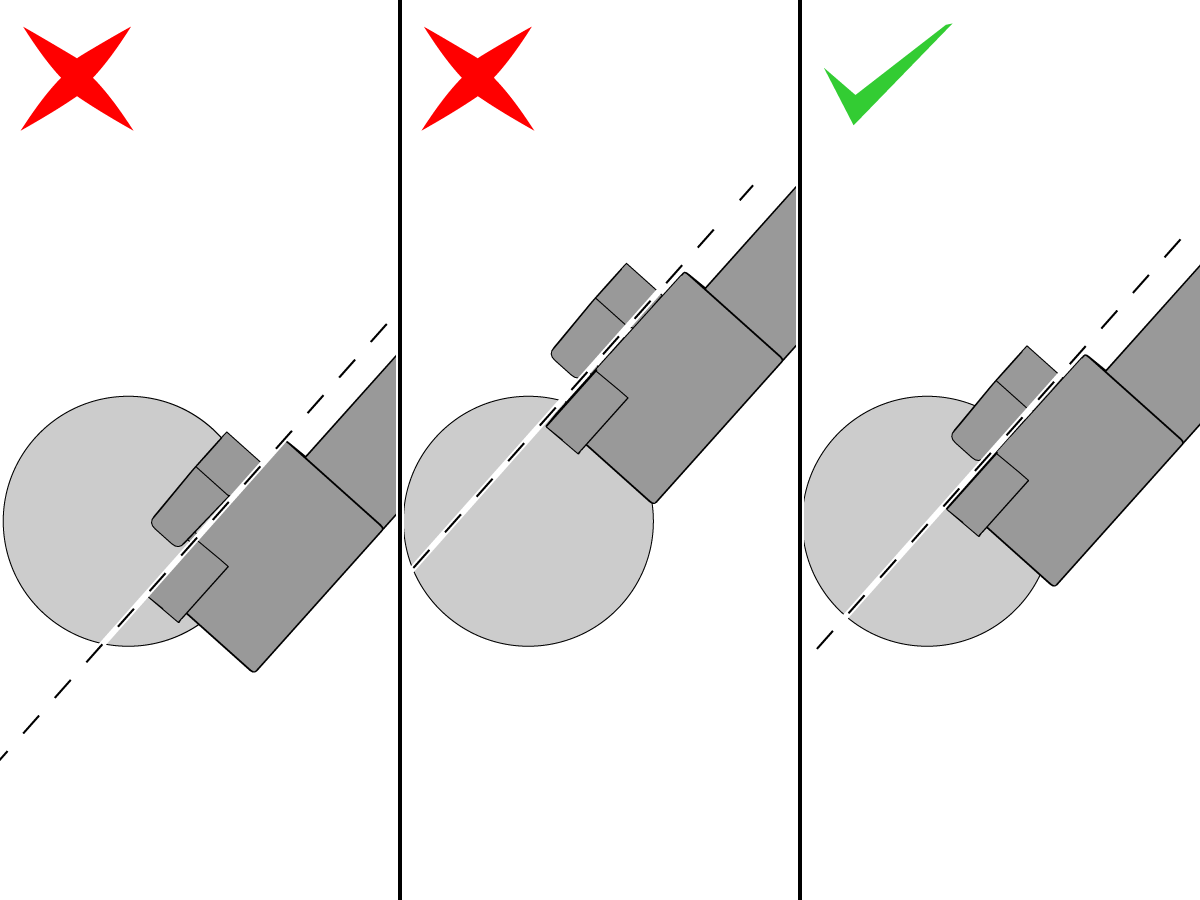

One of the primary causes of lathe chatter is using improper tooling or incorrect setup. The tool being used may be dull, misaligned, or not suitable for the specific machining operation. Similarly, if the lathe’s workholding setup is not secure or aligned properly, it can result in chatter. To overcome this issue, it’s essential to ensure you have the right tooling for the job and that it is correctly set up and positioned.

2. Excessive Cutting Speed

Another common cause of lathe chatter is running the lathe at excessive cutting speeds. When the cutting speed is too high, it puts excessive strain on the tool and workpiece, causing vibrations and chatter. It’s crucial to select the appropriate cutting speed based on the material being machined, the tool being used, and the desired results. Adjusting the cutting speed to a more suitable level can significantly reduce chatter and improve the machining process.

3. Inadequate Rigidity

Poor rigidity of the lathe or its components can also contribute to chatter. If the lathe bed is not solid or the spindle bearings are worn out, it can result in excessive movement and vibrations. Additionally, if the toolholder or tool post is not properly tightened or lacks rigidity, it can exacerbate the chatter problem. Regular maintenance and inspection of the lathe’s components can help identify and address any rigidity issues.

4. Insufficient Cutting Fluid

Lack of proper lubrication and cooling can lead to chatter during the machining process. Insufficient cutting fluid can cause heat build-up, which can result in increased friction and vibrations. It’s essential to use an adequate amount of cutting fluid, ensuring that it reaches the cutting zone effectively. This helps in reducing heat, lubricating the cutting edge, and improving chip evacuation, all of which contribute to minimizing chatter.

5. Improper Feeds and Speeds

Incorrect feeds and speeds can play a significant role in lathe chatter. If the feed rate is too high or the depth of cut is too deep, it increases the chances of chatter occurring. Similarly, using inappropriate speeds for the material being machined can also lead to chatter. It’s crucial to consult the appropriate references and resources to determine the optimal feeds and speeds for your specific machining operations.

6. Material Selection

The type of material being machined can also impact the likelihood of lathe chatter. Some materials, such as those with irregular grain structures or high levels of internal stress, are more prone to chatter. In such cases, using the right cutting tools, feeds, and speeds, as well as employing effective workholding techniques, can help mitigate the problem and achieve better machining results.

7. Machine Condition

The overall condition of your lathe can also contribute to chatter. If the machine is not properly maintained, with worn-out or misadjusted components, it can lead to increased vibrations and chatter. Regular maintenance, lubrication, and calibration of the lathe are essential to keep it in optimal working condition.

How to Address Lathe Chatter

Now that we’ve explored the causes of lathe chatter, let’s discuss some effective solutions to address this issue:

1. Check and Sharpen Cutting Tools

Regularly inspect and sharpen your cutting tools to ensure they are in optimal condition. Dull or damaged tools can contribute to chatter, so it’s essential to maintain sharp cutting edges. Invest in high-quality tooling and follow proper tool sharpening techniques.

2. Secure Workholding Setup

Ensure that your workholding setup is secure and properly aligned. Use appropriate clamping techniques to hold the workpiece firmly. Consider using vibration-dampening pads or jaws to mitigate chatter. Tighten all fasteners adequately to prevent any movement during machining.

3. Optimize Feeds and Speeds

Refer to manufacturer recommendations and machining references to determine the appropriate feeds and speeds for your specific applications. Optimize these parameters to minimize chatter while maintaining productivity and achieving desired surface finishes.

4. Increase Damping

To reduce vibrations and improve stability, increase the damping in your lathe setup. This can involve the use of vibration dampeners, anti-vibration boring bars, or adding mass to your lathe bed. These modifications help absorb vibrations and reduce chatter.

5. Use Suitable Cutting Fluids

Ensure that you are using the right cutting fluid for your machining application. Different materials and cutting operations require specific types of cutting fluids. Select a fluid that provides adequate lubrication, cooling, and chip evacuation to minimize heat and vibrations.

6. Check and Maintain Machine Rigidity

Regularly inspect your lathe for any signs of wear or damage that may compromise rigidity. Pay attention to the lathe bed, spindle bearings, tool post, and toolholders. Make any necessary repairs or replacements to maintain optimal rigidity.

7. Consider Machine Upgrades

If you consistently experience lathe chatter despite taking appropriate measures, it may be worth considering machine upgrades or modifications. This could include investing in a higher-quality lathe with better rigidity and damping properties or retrofitting your existing lathe with vibration-dampening features.

By addressing the causes of lathe chatter and implementing effective solutions, you can significantly improve the quality of your machining work. Always prioritize proper tooling, setup, and maintenance, and be mindful of feeds, speeds, and cutting fluids. With these measures in place, you’ll be well on your way to achieving smooth, precise, and chatter-free lathe operations.

Key Takeaways: Why Does My Lathe Chatter?

- Lathe chatter occurs when the tool vibrates against the material being worked on.

- Uneven cutting speeds and feeds can cause lathe chatter.

- Using dull or improperly sharpened tools can contribute to lathe chatter.

- Inadequate machine rigidity or excessive tool overhang can lead to lathe chatter.

- Improper setup or misalignment of the lathe can result in lathe chatter.

Frequently Asked Questions

Here, we have compiled a list of five frequently asked questions about lathe chatter and provided detailed answers to help you understand why it happens and what you can do about it.

1. What causes lathe chatter?

Lathe chatter is usually caused by a combination of factors, such as improper tool geometry, dull cutting tools, excessive feed rate, and improper workpiece support. When any of these factors are present, they can lead to vibrations in the lathe, resulting in chatter. Chatter can also be caused by resonance, where the natural frequency of the lathe and the workpiece coincide, causing increased vibrations.

To minimize lathe chatter, it is important to ensure that your cutting tools are sharp and have the correct geometry for the task at hand. Additionally, maintaining the right feed rate, properly supporting your workpiece, and avoiding resonance by altering the speeds and feeds can significantly reduce or eliminate chatter.

2. How does lathe chatter affect my workpiece?

Lathe chatter can have several negative effects on your workpiece. When chatter occurs, you may experience poor surface finish with rough, uneven surfaces, as well as dimensional inaccuracies. The vibrations can cause the cutting tool to dig into the workpiece or make intermittent cuts, leading to an inconsistent finish. Chatter can also accelerate the wear and tear on your lathe and cutting tools.

Furthermore, if prolonged chatter occurs, it can damage the lathe’s spindle bearings and other critical components, leading to costly repairs and downtime. It is essential to address lathe chatter promptly to avoid these issues and ensure high-quality workpiece output.

3. Can lathe chatter be reduced with different materials?

While the choice of materials can have some impact on lathe chatter, it is usually not the sole factor. Softer materials, such as aluminum or brass, tend to be less prone to chatter compared to harder ones like steel. However, other factors, such as tool geometry, cutting speed, and workpiece support, still play significant roles in minimizing or eliminating chatter.

It is important to select the right cutting tools, feeds, and speeds for the specific material you are working with. Experimenting with different combinations and optimizing the machining parameters can help reduce chatter, regardless of the material being machined.

4. How can I troubleshoot lathe chatter?

The first step in troubleshooting lathe chatter is to inspect your lathe setup. Check if the cutting tools are sharp and have the correct geometry. Verify that the workpiece is properly supported and securely clamped. Adjust the feed rate and spindle speed to minimize vibrations. If the lathe is secured to a workbench, ensure it is stable and not causing additional vibrations.

If you still experience chatter, try reducing the depth of cut and increasing the rigidity of the setup. Applying cutting fluids or using vibration-damping tool holders can also help. It’s a process of trial and error, so make incremental changes until you find a setup that minimizes chatter and improves the machining results.

5. Can a lathe retrofit or upgrade help reduce chatter?

Yes, upgrading or retrofitting your lathe can help reduce chatter. Modern lathes often come with enhanced vibration damping features, improved spindle bearings, and advanced control systems that can help minimize vibrations and chatter. Retrofitting options, such as adding vibration-damping accessories or upgrading the tool post and tool holders, can also aid in reducing chatter.

However, it is important to evaluate the costs and benefits before considering a retrofit or upgrade. Depending on the severity of the chatter and your specific machining needs, it may be more cost-effective to optimize the lathe setup, tooling, and machining parameters rather than investing in a complete upgrade. Consulting with an experienced machinist or lathe manufacturer can provide valuable guidance in making the right decision.

Metal Lathe Tutorial 6: Chatter

Summary

So, now you know why your lathe chatters! Chatter happens when the lathe isn’t stable or sharp enough. It can be caused by various factors like improper tooling, incorrect speed or feed rates, or worn-out parts. The good news is, by making some adjustments and taking care of your lathe, you can prevent or reduce chatter. Just remember to use sharp tools, choose the right speed and feed rates, and keep your lathe well-maintained. Happy turning!

In conclusion, a lathe chatters when it vibrates or makes an annoying noise. This happens due to instability or dull tools. By keeping your lathe in good shape and using sharp tools, you can eliminate or minimize chatter. So, get your lathe ready for smooth and precise turning!