Are you frustrated with your scroll saw blade constantly breaking? It can be a real hassle when you’re in the middle of a project and your blade just snaps. But don’t worry, we’re here to help you uncover the reasons behind this common issue.

Now, you might be wondering, “Why does my scroll saw blade keep breaking?” Well, my friend, there could be several factors at play. From improper blade installation to using the wrong type of blade, these mistakes can lead to frequent breakages.

But fear not! In this article, we’ll dive into the world of scroll saw blades and explore the top reasons why they tend to break. So, put on your safety glasses and let’s find the answers you’ve been seeking!

Is your scroll saw blade constantly breaking? There could be a few reasons behind this frustrating issue. First, check if you’re using the correct blade for the material you’re cutting. Make sure the blade tension is properly set and that you’re not putting too much pressure on the saw. Additionally, a dull or damaged blade can cause breakages, so make sure to replace it when necessary. Finally, vibrations or misalignment may also be contributing factors. Taking these steps can help prevent your scroll saw blade from breaking.

Why Does My Scroll Saw Blade Keep Breaking?

Scroll saws are valuable tools for creating intricate and detailed cuts in various materials. However, one frustrating issue that many scroll saw users encounter is the frequent breaking of their saw blades. Understanding the reasons behind this problem and learning how to prevent it can save both time and money. In this article, we will explore the common causes of scroll saw blade breakage and provide practical tips on how to avoid it.

Common Causes of Scroll Saw Blade Breakage

1. Incorrect Blade Selection:

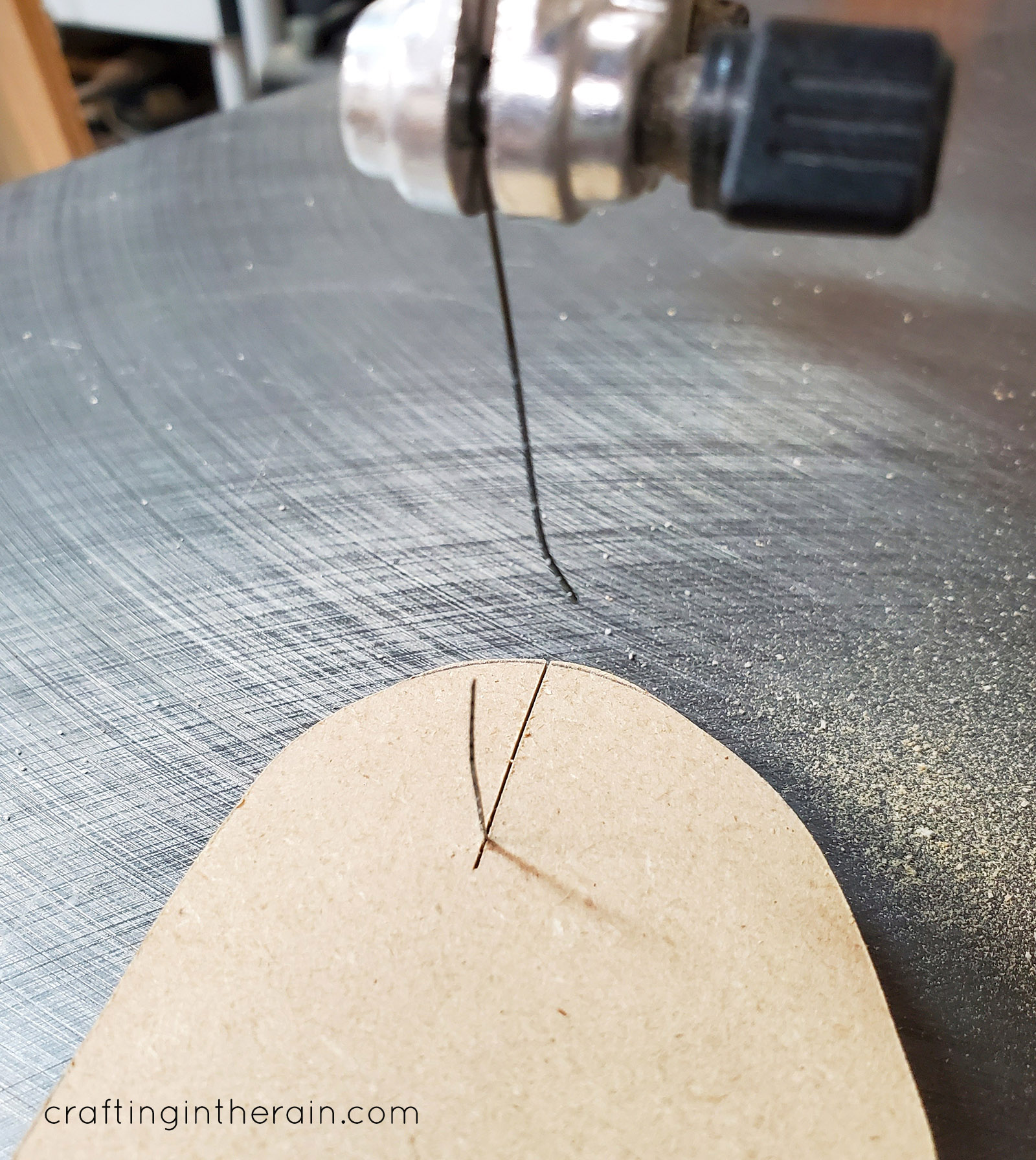

The type of material you are cutting determines the appropriate blade to use. Using the wrong blade can lead to excessive strain on the blade, resulting in breakage. For example, a fine-tooth blade is suitable for intricate cuts in thin plywood or veneer, while a skip-tooth blade is better for thicker and harder materials like hardwoods. Make sure to choose the right blade for the job to prevent breakage.

2. Blade Tension:

Inadequate or excessive blade tension can cause breakage. Insufficient tension allows the blade to move around and bend while cutting, making it more prone to breaking. On the other hand, over-tightening the blade increases the chances of it snapping under stress. Maintaining the proper tension, as recommended by the manufacturer, is crucial for preventing blade breakage.

3. Feed Rate:

Pushing the material too forcefully into the blade or cutting at a high speed can overload the blade and cause it to break. It is important to find the right balance in the feed rate, allowing the blade to cut smoothly without putting excessive strain on it. Experimenting with different speeds and pressures can help you identify the optimal feed rate for your specific material and blade combination.

Tips to Prevent Scroll Saw Blade Breakage

1. Use a Blade Lubricant:

Using a lubricant such as beeswax or silicone spray on the blade can reduce friction and heat buildup, preventing blade breakage. Apply the lubricant periodically during your cutting session for smoother and more effortless cutting.

2. Take Breaks:

Continuous cutting can cause the blade to overheat, leading to breakage. Take short breaks during extended cutting sessions to allow the blade to cool down. This will prolong the life of the blade and reduce the likelihood of it breaking.

3. Keep the Blade Clean:

Resin buildup on the blade can cause it to become dull and increase the risk of breakage. Regularly clean your scroll saw blade with a blade cleaner or denatured alcohol to remove any residue and maintain its sharpness. A clean blade will cut more efficiently and experience fewer instances of breakage.

Conclusion

By understanding the common causes of scroll saw blade breakage and implementing the preventive measures discussed in this article, you can maintain a smooth and uninterrupted cutting experience. Choosing the right blade, maintaining proper tension, and using appropriate feed rates are essential for preventing breakage. Additionally, incorporating tips like using lubricants, taking breaks, and keeping the blade clean will contribute to a longer blade life and improved cutting results. Remember to always prioritize safety and practice good maintenance habits to ensure the longevity of your scroll saw blades.

Key Takeaways: Why Does My Scroll Saw Blade Keep Breaking?

- Incorrect blade tension can cause the scroll saw blade to break.

- Choosing the wrong blade type or size for your project may lead to blade breakage.

- Using excessive force or pushing the material too fast can put too much stress on the blade, causing it to break.

- Using a dull or worn-out blade can increase the likelihood of breakage.

- Improperly installing the blade on the scroll saw can also lead to frequent blade breakage.

Frequently Asked Questions

Here are some frequently asked questions about scroll saw blades constantly breaking and their answers:

1. Why do my scroll saw blades break so easily?

There could be a few reasons why your scroll saw blades keep breaking. One possible reason is the excessive tension on the blade. If the blade is too tight, it can lead to excessive stress and breakage. Another reason could be the speed of your saw. If the speed is too high, it can cause the blade to overheat and break. It’s also possible that you are using the wrong type of blades for the material you are cutting, which can lead to premature breakage. Lastly, worn-out or damaged blades can be more prone to breaking, so it’s important to regularly inspect and replace them.

To prevent blade breakage, make sure to properly tension your blade, use the appropriate speed for the material you’re cutting, choose the right blades for the job, and replace worn-out or damaged blades regularly. Taking these precautions should help reduce the breakage of your scroll saw blades.

2. Can the material I’m cutting be causing the blade to break?

Yes, the material you’re cutting can affect the breakage of your scroll saw blades. Harder materials like metals or dense hardwoods can put more strain on the blade and cause it to break more easily. Additionally, materials with knots, resin pockets, or other irregularities can cause the blade to catch or bind, increasing the risk of breakage. It’s important to choose the appropriate type of blade for the material you’re cutting to minimize breakage. For example, for thicker or harder materials, you may need to use a blade with fewer teeth per inch (TPI) to reduce strain on the blade.

Always consider the nature of the material you’re cutting and choose the right scroll saw blade to handle the job. This will help prevent excessive breakage of your blades and ensure smoother and more efficient cutting.

3. Could improper blade installation be causing the breakage?

Improper installation of the blade can indeed contribute to breakage. If the blade is not properly seated in the blade holders or if the tension is not evenly distributed along the blade, it can lead to increased stress and breakage. Make sure to follow the manufacturer’s instructions for installing the scroll saw blade correctly, ensuring that the teeth are pointing downward and the blade is secure. Additionally, check that the tension is evenly distributed along the entire length of the blade to avoid any weak spots.

By paying attention to the proper installation of your scroll saw blade, you can minimize the risk of breakage and ensure smoother cuts.

4. Are there any maintenance tips to prevent scroll saw blade breakage?

Yes, proper maintenance can help prevent scroll saw blade breakage. One important maintenance tip is to regularly lubricate your blade with a lubricant specifically designed for scroll saws. This helps reduce friction and heat build-up, which can contribute to blade breakage. Additionally, make sure to keep the saw clean and free from debris that can hinder smooth cutting or put added stress on the blade. It’s also important to inspect your blade regularly for any signs of wear or damage and replace it as needed.

By regularly lubricating, cleaning, and inspecting your scroll saw, you can extend the life of your blades and minimize the chances of them breaking.

5. Can operator error be a factor in scroll saw blade breakage?

Operator error can certainly contribute to scroll saw blade breakage. Pressing too hard against the blade or forcing the material through the saw can put excessive stress on the blade and cause it to break. Additionally, not using the appropriate cutting technique, such as trying to make exceptionally tight or intricate cuts, can increase the risk of blade breakage. It’s important to let the saw and the blade do the work and guide the material gently, allowing the teeth to do the cutting.

By using proper cutting techniques, applying the right amount of pressure, and letting the saw and blade do their job, you can reduce operator error and minimize the breakage of your scroll saw blades.

Why Do My Scroll Saw Blades Break? Improper Tension! Here’s How To Do It Right Hegner EthAnswers

Summary

Do you keep breaking your scroll saw blade? Here are some things to keep in mind. First, make sure your blade tension is just right. Too loose or too tight can cause breakage. Second, check if your blade is properly installed and centered. If it’s off, this can put extra strain on the blade and cause it to break. Lastly, pay attention to the type of wood you’re cutting. Some woods are harder and may require a different blade. Take these steps and say goodbye to broken blades!