If you’ve ever wondered, “Why does my scroll saw blade twist?” then you’ve come to the right place! We’re here to explore this common issue and shed some light on what might be causing it. So, let’s dive in and uncover the reasons behind this frustrating twist!

Picture this: you’re working on a beautiful scroll saw project, and suddenly, your blade starts to twist. It can be incredibly frustrating, right? But don’t worry, it happens to the best of us. We’re going to uncover the mystery behind this twist and give you some tips on how to prevent it.

So, why does your scroll saw blade twist? One possible reason is improper tensioning. If your blade isn’t properly tensioned, it can start to twist and turn while cutting. Another culprit could be the feeding speed – if you’re pushing the wood too fast through the blade, it can cause twisting. But fear not! We’ll discuss these reasons and more in detail, and provide you with effective solutions to keep your scroll saw blade running smoothly.

Now that we have piqued your curiosity, stay tuned as we delve deeper into the causes and solutions of scroll saw blade twisting. Get ready to uncover the secrets of keeping your scroll saw blade in tip-top shape, so you can create amazing projects without any unwelcome twists! Let’s get started!

Scroll saw blades can sometimes twist when in use, causing frustration for users. There are a few reasons why this might happen:

- Improper tension: Ensure that the blade is properly tensioned to prevent twisting.

- Blade dullness: A dull blade can lead to twisting, so ensure your blade is sharp.

- Material type: Different materials may require different blade types. Make sure you’re using the correct blade for the material you’re cutting.

- Feed rate: Pushing the material too fast can cause the blade to twist. Maintain a steady and controlled feed rate.

- Blade alignment: Incorrect blade alignment can contribute to twisting. Check the alignment and make adjustments if necessary.

By addressing these factors, you can minimize blade twisting and improve your scroll sawing experience.

Why Does My Scroll Saw Blade Twist?

Scroll saws are popular tools used by woodworkers and hobbyists to create intricate cuts and designs in various materials. However, one common issue that many users face is a twisted scroll saw blade. This can lead to inaccurate cuts and frustration during projects. In this article, we will explore the reasons why scroll saw blades twist and offer tips on how to prevent and fix this problem.

Improper Blade Tension

One of the most common reasons why scroll saw blades twist is improper blade tension. If the blade is not tightened correctly, it can cause the blade to wander and twist during use. It is important to make sure that the blade is properly tensioned before starting your project. Most scroll saws have a tensioning mechanism that allows you to adjust the blade tension. Refer to your scroll saw’s manual for instructions on how to properly tension the blade.

Additionally, it’s important to regularly check the blade tension throughout your project. As you cut through different materials, the blade can heat up and expand, causing the tension to change. By regularly monitoring and adjusting the tension, you can prevent the blade from twisting and ensure accurate cuts.

Another factor to consider is the type of blade you are using. Different blades have different tension requirements. Make sure to choose a blade that is compatible with your scroll saw and follow the manufacturer’s recommendations for blade tension.

Material Vibration

Another cause of scroll saw blade twisting is material vibration. When working with certain types of wood or other materials, vibrations can occur, causing the blade to twist and wander off course. This is especially common when cutting thick or dense materials.

To minimize material vibration, it is important to secure your workpiece properly. Use clamps or a vice to hold the material firmly in place, ensuring that it does not move or vibrate during the cutting process. Additionally, using a stable work surface can help reduce vibrations. Consider using a scroll saw stand or a sturdy workbench to minimize any movements that could affect the blade.

Another tip is to select the appropriate blade for the material you are cutting. Some blades are specifically designed for cutting certain types of wood or materials. Choosing the right blade can minimize vibrations and prevent blade twisting.

Blade Alignment

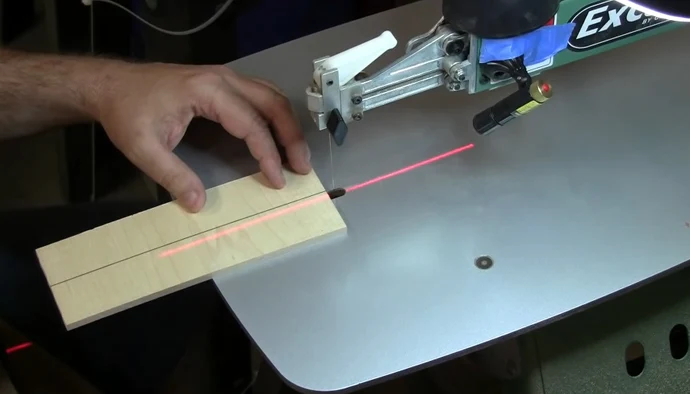

Blade alignment is another important factor that can cause scroll saw blades to twist. If the blade is not aligned properly with the saw’s guides, it can lead to twisting and wandering during cuts. It is essential to check the blade alignment regularly and make adjustments as needed.

To align the blade, start by loosening the blade tension and gently pushing the blade against the saw’s guides. Gradually tighten the tension while keeping the blade pressed against the guides. This ensures that the blade is properly aligned and centered in the guides.

Additionally, make sure that the saw’s guides are clean and free from debris. Dust or residue build-up can affect the blade’s movement and alignment. Regularly clean the guides to ensure smooth and accurate cuts.

Additional Tips for Avoiding Scroll Saw Blade Twisting

Choose the Right Blade

Selecting the right blade for your project is crucial in preventing blade twisting. There are various types of scroll saw blades with different tooth sizes and configurations. Consider the thickness and hardness of the material you are cutting and choose a blade that is suitable for those characteristics. Experiment with different blades to find the one that provides the best results for your specific needs.

Take It Slow

Using a high speed or rushing through cuts can increase the likelihood of scroll saw blade twisting. Take your time and maintain a steady pace when cutting. This allows the blade to glide smoothly through the material, reducing the risk of twisting. Applying excessive force or pushing too hard can also cause the blade to twist. Let the saw do the work, and avoid putting unnecessary pressure on the blade.

Maintain Your Scroll Saw

Regular maintenance of your scroll saw can help prevent blade twisting. Keep the saw clean by removing dust and debris after each use. Lubricate the moving parts according to the manufacturer’s recommendations to ensure smooth operation. Inspect the blade regularly for any signs of wear or damage and replace it if necessary. By keeping your scroll saw in good condition, you can minimize the chances of blade twisting.

Conclusion

Scroll saw blade twisting can be a frustrating issue, but with the right knowledge and precautions, it can be easily prevented. Ensuring proper blade tension, minimizing material vibration, and maintaining blade alignment are key factors to consider. Additionally, choosing the right blade, taking your time, and properly maintaining your scroll saw can contribute to a more enjoyable and accurate cutting experience. By implementing these tips and techniques, you can create beautiful and precise cuts with your scroll saw without having to worry about blade twisting.

Key Takeaways: Why Does My Scroll Saw Blade Twist?

- A scroll saw blade may twist because it is installed incorrectly.

- Using too much force or pushing the wood too hard can cause the blade to twist.

- Improper tension on the blade can lead to twisting, so make sure it is tightened correctly.

- Blade defects or damage can also cause twisting, so inspect the blade for any issues.

- Using the wrong type or size of blade for your project can result in twisting.

Frequently Asked Questions

Here are some common questions related to scroll saw blades twisting:

1. Why does my scroll saw blade keep twisting?

Scroll saw blades can twist for several reasons. One possible cause is improper tensioning of the blade. If the blade is too tight or too loose, it can twist while cutting. Make sure to adjust the tension according to the manufacturer’s guidelines.

Another reason for blade twisting is using the wrong blade type for the material you’re cutting. Different blade types are designed for specific materials, so using the wrong one can cause the blade to twist. Ensure you’re using the appropriate blade for the material you’re working with.

2. How can I prevent my scroll saw blade from twisting?

To prevent your scroll saw blade from twisting, start by ensuring proper tension. Adjust the tension according to the manufacturer’s recommendations to avoid over-tightening or under-tightening. This will help keep the blade straight and prevent twisting during cuts.

Another preventive measure is using the correct blade for the material being cut. Research and select the appropriate blade type based on the material’s thickness and hardness. Using the right blade will minimize the chances of it twisting while in use.

3. Can a dull blade cause twisting?

Yes, a dull blade can contribute to blade twisting. When a blade becomes dull, it may have difficulty gripping the material, causing it to twist while cutting. Regularly check the sharpness of your blade and replace it when necessary to maintain optimal cutting performance.

Additionally, a dull blade may exert more force on the material, increasing the likelihood of twisting. Keep your blades sharp to ensure clean, precise cuts and reduce the risk of twisting.

4. Are there any techniques to minimize blade twisting?

Yes, there are techniques you can employ to minimize blade twisting. One effective technique is using a slower cutting speed. Reducing the speed allows the blade to cut smoothly without twisting, especially when working with more intricate patterns or dense materials.

Another technique is ensuring proper blade alignment. Make sure the blade is centered and aligned correctly in the saw’s clamp. Any misalignment can cause the blade to twist during cutting, so take the time to align it properly before starting your project.

5. Could using low-quality blades be a reason for blade twisting?

Using low-quality blades can indeed contribute to blade twisting. These blades may be poorly manufactured, resulting in inconsistent tension or irregular tooth patterns, leading to twisting during cutting. It’s important to invest in high-quality blades from reputable manufacturers to minimize the risk of blade twisting.

Quality blades are made with precision, ensuring uniform tension and sharp teeth that can withstand the cutting forces. Choosing reliable brands that specialize in scroll saw blades will help you achieve better results and reduce the likelihood of blade twisting.

Why Do Scroll Saw Blades Break? And how do I prevent it?

Summary

Sometimes, scroll saw blades can twist while you are using them. There are a few reasons why this might happen. One reason is that the blade tension might not be set correctly. Another reason could be that the blade is dull or damaged. Additionally, if you are applying too much pressure or moving the wood too quickly, the blade can twist. It’s important to check the tension, keep the blade sharp, and use the right amount of pressure to avoid this problem.

In conclusion, it’s essential to pay attention to the tension, sharpness, and pressure when using a scroll saw. By taking care of these factors, you can prevent the blade from twisting, ensuring a smooth and successful cutting experience. So, happy scrolling and keep those blades straight!