Have you ever wondered why your scroll saw doesn’t cut straight? It can be frustrating when you’re trying to make precise cuts, but the results just aren’t coming out the way you want them to. Don’t worry, though! We’re here to help you figure out what might be causing this issue and how you can fix it.

When it comes to scroll saws, there are a few common reasons why they might not be cutting straight. One possibility is that the blade tension isn’t properly adjusted. Another potential culprit could be a dull or damaged blade. And sometimes, it’s simply a matter of technique. But fear not! We’ll walk you through each of these possibilities and give you some tips and tricks to get your scroll saw cutting straight in no time.

So, whether you’re a beginner or a seasoned woodworker, stick around to find out why your scroll saw might not be cutting straight and discover the solutions that will have you creating beautiful, precision cuts in no time. Get ready to take your scroll saw skills to the next level!

Is your scroll saw failing to cut straight? It can be frustrating, but there are a few common reasons behind this issue. First, check if the blade is properly tensioned and installed. Ensure the blade teeth are facing in the right direction and not dull or damaged. Additionally, make sure the table and fence are properly aligned. Lastly, slow down your cutting speed and use steady, controlled movements. By addressing these factors, you can improve the straightness of your scroll saw cuts.

Why Does My Scroll Saw Not Cut Straight? Troubleshooting Tips and Solutions

Scroll saws are versatile tools that are commonly used in woodworking and crafting projects. However, many users often encounter the frustrating issue of their scroll saw not cutting straight. This can lead to misaligned cuts, jagged edges, and overall poor craftsmanship. In this article, we will explore the various reasons why your scroll saw may not be cutting straight and provide you with troubleshooting tips and solutions to help you achieve accurate and precise cuts. Whether you are a beginner or an experienced woodworker, understanding the potential causes of this issue can greatly improve your scroll sawing experience.

Improper Blade Tension

One of the most common reasons why a scroll saw may not cut straight is improper blade tension. When the blade is not properly tensioned, it can lead to wandering cuts and a lack of control. To address this issue, start by ensuring that your blade is correctly installed and tensioned. Follow the manufacturer’s instructions for your specific scroll saw model. Use a tension gauge or the pluck test to check the tension of the blade and adjust it accordingly. Remember, the right tension can vary depending on the type of blade you are using and the material you are cutting.

Additionally, if you notice that your blade is dull or worn out, replace it with a fresh, sharp blade. Dull blades can cause the scroll saw to veer off course and result in uneven cuts. Regularly inspect your blades and replace them as needed to maintain optimal cutting performance.

Inaccurate Blade Alignment

Another potential culprit behind your scroll saw not cutting straight is inaccurate blade alignment. If the blade is not properly aligned with the saw’s guides or is not perpendicular to the table, it can cause the saw to veer off track. To correct this issue, start by checking the alignment of the saw’s upper and lower blade holders. Ensure that they are aligned parallel to each other and perpendicular to the table surface. You can use a square or a straightedge to aid in this alignment process.

In addition, take a moment to verify that your blade is properly seated in the blade clamp. If it is not securely held in place, it can lead to blade slippage and result in crooked cuts. Make sure the blade is tightened securely in the clamp, but be cautious not to overtighten, as this can cause undue stress on the blade.

Uneven Feed Pressure

Uneven feed pressure is another factor that can contribute to your scroll saw not cutting straight. When applying uneven pressure to the material being cut, the saw may veer off course, resulting in irregular cuts. To avoid this issue, practice maintaining consistent and even pressure on the material as you guide it through the saw. This will help keep the saw blade on its intended cutting path and produce straighter cuts.

Another tip is to use a smooth and controlled motion when feeding the material into the scroll saw. Avoid sudden jerks or movements, as this can also cause the saw to deviate from a straight path. Take your time and maintain a steady pace to ensure precise cuts.

Poor Blade Selection

The type of blade you choose for your scroll saw can greatly impact the quality of your cuts. Using the wrong blade for the specific material or cut being performed can result in a lack of precision and straightness. Different blades are designed for different purposes, such as cutting through thick wood or making intricate curves.

Refer to the blade manufacturer’s recommendations and select the appropriate blade for your specific cutting needs. Experiment with different blades to find one that provides the best performance for your desired outcome. By using the right blade, you can significantly improve the straightness of your cuts.

Inadequate Saw Maintenance

Regular maintenance of your scroll saw is essential for optimal performance and accurate cuts. Over time, sawdust, debris, and dirt can accumulate in various parts of the saw, affecting its functionality. Inspect your scroll saw regularly and clean it thoroughly to remove any buildup that may be hindering its performance.

Additionally, check for any loose or worn-out components, such as belts or pulleys, and replace them as needed. Lubricate the moving parts of the saw to ensure smooth operation. Proper maintenance will not only help your scroll saw cut straight but also extend its lifespan.

Incorrect Blade Tensioning Techniques

While improper blade tension was mentioned earlier as a possible cause for a scroll saw not cutting straight, it is important to delve into this issue further. Understanding the correct techniques for tensioning the blade can greatly improve your cutting results.

Firstly, familiarize yourself with the tensioning method recommended by the manufacturer of your scroll saw. Different models may have different guidelines, so it is crucial to follow the instructions specific to your machine. Some manufacturers provide tensioning gauges to ensure accurate tensioning.

When tensioning the blade, start by loosening the tension control knob. This will release any residual tension from the previous blade. Next, place the new blade in the blade clamps and tighten them slightly. Gradually increase the tension until the blade can be plucked to produce a clear, high-pitched sound. Avoid overtightening, as this can cause blade breakage or excessive lateral movement during cutting.

Key Takeaways: Why does my scroll saw not cut straight?

- Check the blade tension: Make sure the blade is properly tensioned to avoid it wandering off the desired cutting line.

- Blade selection: Ensure you are using the appropriate blade type for the material you are cutting.

- Blade alignment: Make sure the blade is aligned properly with the scroll saw’s throat plate.

- Guide adjustment: Adjust the guides on the scroll saw to ensure the blade is straight and not drifting off.

- Practice and technique: Improving your cutting technique and practicing more will help you achieve straighter cuts with the scroll saw.

Frequently Asked Questions

Scroll saws are a popular tool for woodworkers, but sometimes they don’t cut straight. Here are some common questions and answers to help you understand why this may happen and how to fix it.

1. What could be causing my scroll saw to veer off course while cutting?

There are a few reasons why your scroll saw may not be cutting straight. Firstly, check if the blade is installed properly and if it is sharp. Damaged or dull blades can cause the saw to veer off course. Additionally, make sure the blade tension is set correctly. Too much or too little tension can affect the saw’s performance. Lastly, check the table and make sure it is level and the blade is aligned with the table slot.

If you’ve checked all these factors and your scroll saw is still not cutting straight, it could be a sign of a mechanical issue. Consider consulting a professional or contacting the manufacturer for further assistance.

2. Why is my scroll saw creating burn marks on the wood?

If your scroll saw is leaving burn marks on the wood, it may be due to several reasons. First, check the blade you are using. A dull or worn-out blade can generate more friction, leading to burn marks. Make sure you are using a sharp, high-quality blade suitable for the type of wood you are cutting.

Another factor to consider is the speed at which you are operating the saw. Higher speeds can generate more heat and increase the chances of burn marks. Experiment with different speeds to find the optimal setting for your specific project. Finally, make sure you are not applying too much pressure on the wood. Let the blade do the work and guide the wood smoothly without excessive force.

3. Why is my scroll saw making a loud noise while cutting?

If your scroll saw is making a loud noise during operation, it could indicate a few different issues. First, check if the blade is properly tensioned. An incorrectly tensioned blade can cause vibrations and result in noise. Adjust the tension until the noise is minimized.

Another possible cause is a loose or worn-out blade clamp. Ensure that the blade is securely clamped in place and consider replacing the clamp if necessary. Additionally, check if there are any loose parts or screws on the saw. Tightening any loose components can often eliminate the noise. If the problem persists, it is advisable to seek assistance from a professional or contact the manufacturer.

4. How can I improve the accuracy of my scroll saw cuts?

To improve the accuracy of your scroll saw cuts, there are a few steps you can take. Firstly, make sure you are using the right blade for the job. Different blades have different tooth configurations, suitable for different materials and cut styles. Choosing the appropriate blade can greatly enhance the precision of your cuts.

Next, practice proper feeding techniques. Avoid forcing the wood through the blade and let the saw do the work. Take your time and guide the wood smoothly to maintain control and achieve accurate cuts. Additionally, ensure that the table surface is clean and free of debris that could interfere with the wood movement or blade performance. Regular maintenance and lubrication of the scroll saw can also contribute to better accuracy.

5. What can I do if my scroll saw blade keeps breaking?

If your scroll saw blade keeps breaking, there are a few potential causes to consider. First, make sure you are using the correct blade for the material you are cutting. Different materials require different blade types and tooth configurations. Using the wrong blade can put excessive stress on the blade and cause it to break.

Additionally, check the blade tension. If the tension is too tight, it can lead to premature breakage. Adjust the tension to the manufacturer’s recommended setting. Finally, examine your cutting technique. Applying excessive lateral pressure or not letting the blade do the cutting can also contribute to blade breakage. Experiment with different cutting techniques and find a balance that works for you.

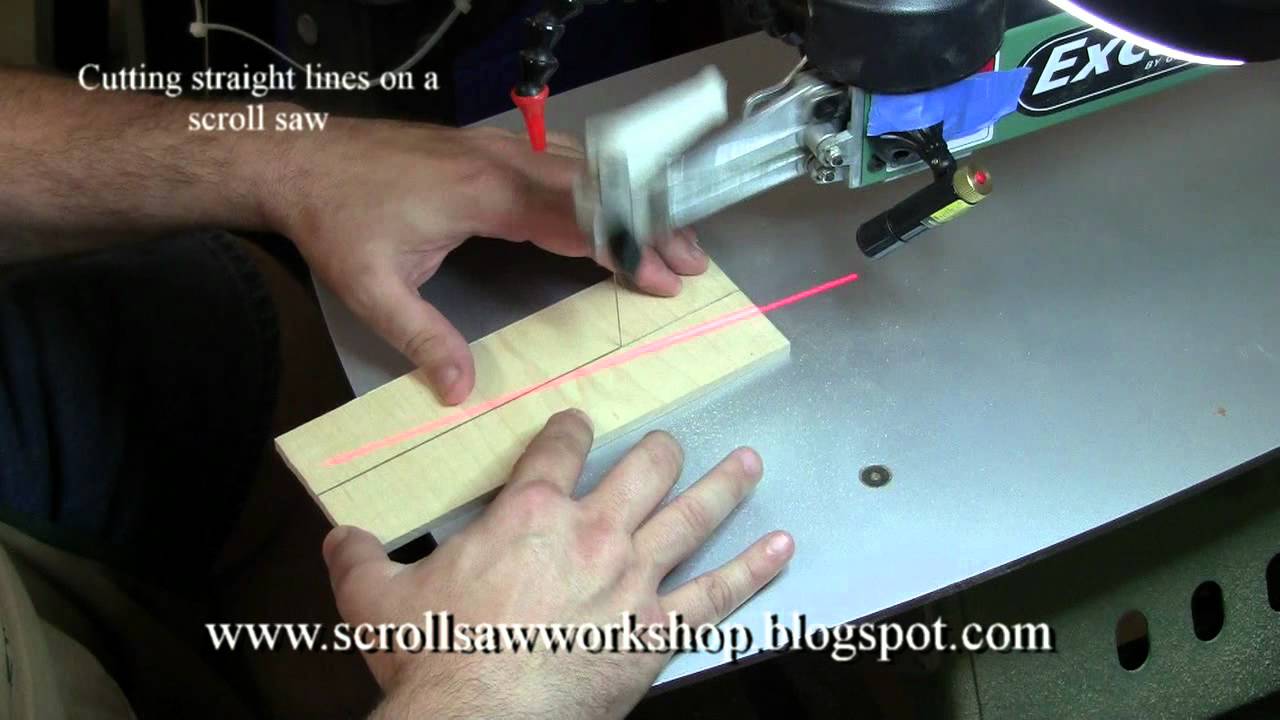

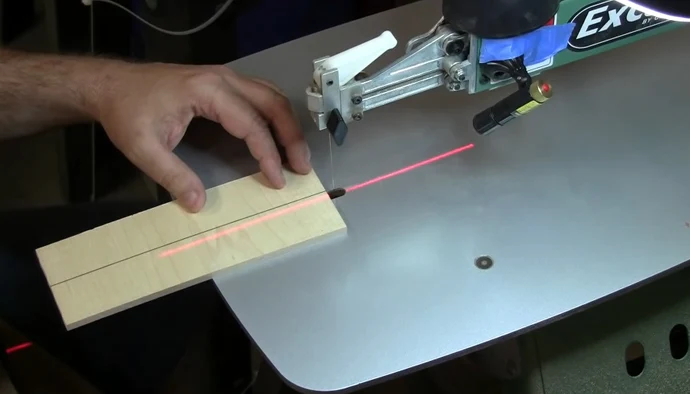

Cutting straight lines on a scroll saw.

Summary

Sometimes, a scroll saw may not cut straight due to various reasons. One common reason is an improper blade tension, which can cause the blade to veer off course. Additionally, using dull blades or incorrect blade types can also result in crooked cuts. It’s important to make sure the saw table is level and that the workpiece is properly secured. Taking these steps can help you achieve straighter cuts with your scroll saw.

Remember to always prioritize safety when using power tools like scroll saws. Follow the manufacturer’s instructions, wear appropriate protective gear, and ask an adult for help if needed. With practice and patience, you’ll be able to improve your scroll saw skills and create straight cuts for your woodworking projects. Happy scrolling!