Have you ever wondered why your scroll saw vibrates? It can be frustrating when your tool doesn’t perform as expected. But don’t worry, I’m here to help you understand why this happens and what you can do about it. So, let’s dive in and explore the reasons behind that annoying vibration in your scroll saw!

When your scroll saw vibrates, it can affect the quality of your cuts and make your woodworking experience less enjoyable. But why does it happen in the first place? Well, there could be several reasons. It could be due to an unbalanced blade, improper tensioning, or even an issue with the motor itself.

But don’t worry, we’ve got you covered! In this article, we’ll walk you through the common causes of scroll saw vibrations and provide you with some troubleshooting tips to help eliminate the problem. So, let’s get started and bring tranquility back to your woodworking projects!

Understanding the Reasons Behind Scroll Saw Vibration

Scroll saws are versatile and powerful tools that allow woodworkers to create intricate and precise cuts. However, sometimes these machines can exhibit vibrations that can affect the quality of the cuts and the overall user experience. In this article, we will explore the various reasons why scroll saws may vibrate and provide solutions to help you minimize or eliminate this issue. Whether you are a professional woodworker or a hobbyist, understanding the causes of scroll saw vibrations can greatly improve your woodworking outcomes.

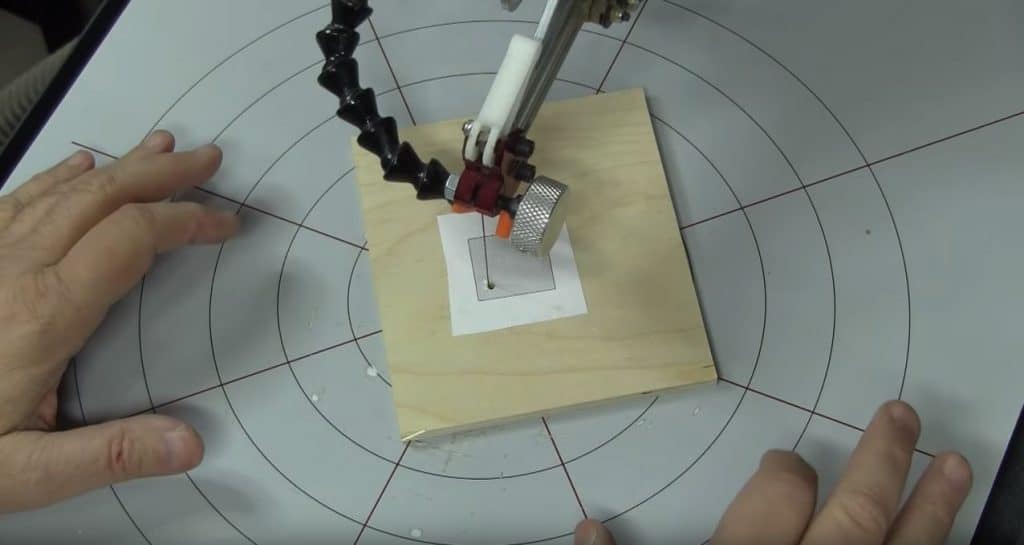

Improper Blade Installation

One of the most common causes of scroll saw vibrations is improper blade installation. If the blade is not properly tensioned or aligned, it can result in unwanted vibrations. To ensure correct blade installation, start by loosening the tension knob or lever on your scroll saw. Next, carefully insert the blade into the blade holders, making sure it is seated securely. Tighten the tension knob or lever to the manufacturer’s recommended tension. If the blade is still not properly tensioned or aligned, consult your scroll saw’s user manual for specific instructions or seek professional assistance.

Additionally, it is important to choose the right blade for the task at hand. Different types of blades are designed for specific materials and cutting techniques. Using the wrong blade can cause excessive vibrations and can lead to poor-quality cuts. Refer to the manufacturer’s guidelines or seek advice from experienced woodworkers to select the appropriate blade for your project.

Regular blade maintenance is also crucial in minimizing scroll saw vibrations. Over time, blades can become dull or damaged, leading to increased friction and instability. Make sure to regularly inspect your blades for signs of wear or damage and replace them as needed. Proper blade maintenance will not only improve the performance of your scroll saw but also reduce vibrations.

Uneven Table Surface

The surface on which your scroll saw is placed can significantly impact its stability and vibration levels. Uneven tables or workbenches can cause the scroll saw to wobble or vibrate during operation. To minimize vibrations caused by an uneven table surface, consider using leveling tools such as shims or adjustable feet to ensure a stable and flat working area. Alternatively, you can invest in a dedicated scroll saw stand or table with adjustable legs for added stability and precision.

It is also essential to secure the scroll saw to the table or workbench properly. Loose fasteners or unstable mounts can lead to increased vibrations. Check that all the screws and bolts are tightened securely, and if necessary, use additional clamps or supports to stabilize the scroll saw. Ensuring a secure and level working surface is crucial in reducing unwanted vibrations and achieving accurate cuts.

Another factor to consider is the overall weight distribution of your scroll saw setup. Placing heavy materials or excessive weight on one side of the scroll saw can cause imbalances and vibrations. When working with larger or heavier projects, distribute the weight evenly on the table or workbench to promote stability and minimize vibrations.

Imbalance in Wheels or Pulleys

Scroll saws are equipped with wheels or pulleys that rotate the blade. If there is an imbalance in these components, it can lead to vibrations during operation. To address this issue, you should inspect the wheels or pulleys for any signs of wear, damage, or misalignment. Tighten any loose components and replace any damaged parts as necessary.

Lubrication is another essential aspect of maintaining a smooth-running scroll saw. The lack of proper lubrication can cause increased friction, leading to vibrations and other operational issues. Refer to your scroll saw’s user manual for specific lubrication requirements and make sure to regularly clean and lubricate the wheels, pulleys, and moving parts with the recommended lubricant. Proper lubrication will not only reduce vibrations but also extend the lifespan of your scroll saw.

If you have checked the blade installation, table surface, and wheels or pulleys, and your scroll saw still vibrates excessively, it is advisable to consult a professional or contact the manufacturer for further guidance. They may be able to diagnose any underlying mechanical issues or offer specific solutions to resolve the vibration problem.

Ensuring Proper Power Supply

Insufficient or inconsistent power supply can also contribute to scroll saw vibrations. If your scroll saw is not receiving adequate power, it may struggle to maintain a consistent speed, resulting in vibrations. Make sure to connect your scroll saw to a stable power source, such as a dedicated outlet or a surge protector. Avoid using extension cords or power strips that may cause voltage drops or fluctuations, as these can affect the performance of the scroll saw.

In addition to the power source, be mindful of any electrical issues within the scroll saw itself. Inspect the power cord for any visible damage or frayed wires, and replace it if necessary. Faulty wiring or loose connections can result in unstable power supply and increased vibrations. If you are unfamiliar with electrical work, it is best to consult a professional to address any internal electrical issues.

Proper power supply is crucial in maintaining consistent and reliable performance from your scroll saw, minimizing vibrations, and ensuring accurate cuts.

Noise Dampening Techniques

Vibrations from a scroll saw can not only be felt but also heard. The noise generated by the machine can be an indicator of excessive vibrations. While it is challenging to completely eliminate all noise and vibrations, there are techniques that can help mitigate their effects and improve your working environment.

A common method of reducing noise and vibrations is to use a suitable scroll saw stand or table that incorporates vibration-dampening materials. These materials can absorb and dissipate vibrations, resulting in a quieter and more stable working experience. Alternatively, you can place the scroll saw on a rubberized mat or use anti-vibration pads underneath the machine to reduce vibrations transmitted to the table or workbench.

Proper maintenance and regular cleaning of the scroll saw can also contribute to noise reduction. Dust and debris can accumulate in the machine’s moving parts, leading to increased friction and vibrations. Clean the scroll saw regularly, and use appropriate dust collection systems or attachments to minimize debris buildup.

Conclusion

Vibrations in a scroll saw can be frustrating and affect the quality of your woodworking projects. By understanding the potential causes and implementing the appropriate solutions, you can minimize or eliminate unwanted vibrations. Proper blade installation, a level work surface, balanced wheels or pulleys, reliable power supply, and noise dampening techniques all play a crucial role in achieving smooth and precise cuts. Regular maintenance and proper care will keep your scroll saw running smoothly for years to come. Happy scrolling!

Key Takeaways: Why Does My Scroll Saw Vibrate?

- A scroll saw may vibrate due to an imbalanced blade, which can be fixed by adjusting the tension and position of the blade.

- Loose or worn-out parts in the scroll saw, such as the blade holder or blade clamp, can also cause vibration and should be checked and replaced if necessary.

- Using low-quality or dull blades may contribute to vibration, so it’s important to use high-quality blades and keep them sharp.

- Inadequate lubrication can cause friction and vibration, so make sure to regularly lubricate the moving parts of the scroll saw.

- Excessive speed or incorrect blade choice can lead to vibration, so adjust the speed according to the material being cut and use the appropriate blade for the task.

Frequently Asked Questions

Welcome to our FAQ section where we answer common inquiries about scroll saw vibrations. If you’re experiencing vibrations while using your scroll saw, we’ve got you covered. Check out the questions and answers below to find out what might be causing the issue and how to address it.

1. What could be causing my scroll saw to vibrate?

Scroll saw vibrations can be caused by various factors. One common reason is an unbalanced blade. If the blade is not properly tensioned or has worn out, it can create vibrations. Another possibility is an issue with the motor or the overall stability of the machine. If the saw is not firmly anchored or the motor is experiencing problems, vibrations can occur.

To resolve the issue, start by ensuring that the blade is correctly tensioned and securely attached. If the problem persists, try mounting the scroll saw on a sturdy surface or check if the motor needs maintenance or replacement. If all else fails, it’s best to consult a professional for further assistance.

2. Is it normal for a scroll saw to vibrate?

While a certain amount of vibration is expected with any mechanical device, excessive vibrations are not normal for a scroll saw. Ideally, a well-maintained scroll saw should produce minimal vibrations, allowing for precise and smooth cutting. If you notice significant shaking or rattling, it’s important to address the issue to ensure optimal performance and safety.

Regular maintenance and proper usage can help minimize vibrations. Keeping the blade tensioned, using sharp blades, and lubricating the moving parts can all contribute to reducing vibrations. If you’ve followed these steps and the vibrations persist, it may indicate a more significant problem that requires professional attention.

3. Can a dull blade cause vibrations in a scroll saw?

Yes, a dull blade can contribute to vibrations in a scroll saw. When a blade becomes blunt, it requires more force to cut through the material, which can result in increased vibrations. Dull blades also tend to wander and deviate from the intended cutting line, leading to additional shaking.

To prevent vibrations caused by a dull blade, it’s crucial to regularly inspect and replace worn-out blades. Keep spare blades on hand, and change them as soon as you notice a decrease in cutting performance or an increase in vibrations. A sharp blade will not only enhance the cutting experience but also reduce strain on the scroll saw, minimizing vibrations.

4. How can I minimize vibrations while using my scroll saw?

To minimize vibrations while using a scroll saw, there are several steps you can take. First, ensure that the scroll saw is placed on a stable and level surface. This will help reduce any unwanted movement and shaking. Additionally, make sure the blade is correctly tensioned and securely attached.

Using the right blade for the desired cutting task is also important. Different blades are designed for specific materials and thicknesses, so choosing the appropriate blade will result in smoother cuts and fewer vibrations. Finally, maintaining the scroll saw properly by lubricating the moving parts and regularly cleaning the machine can also help reduce vibrations and ensure optimal performance.

5. When should I seek professional help for scroll saw vibrations?

If you’ve tried all the troubleshooting steps and the vibrations in your scroll saw persist, it may be time to seek professional assistance. An experienced technician will have the knowledge and expertise to diagnose the underlying issue and provide suitable solutions.

Professional help may also be necessary if you’re unsure about performing maintenance tasks or adjusting the scroll saw’s components yourself. Remember, the safety and functionality of your scroll saw are paramount, so don’t hesitate to reach out to a professional for guidance when needed.

Summary

Your scroll saw might vibrate because of an unbalanced blade or loose blade tension. Vibrations can also be caused by using the wrong blade type or cutting material. To fix it, make sure the blade is properly tensioned and balanced. Choose the right blade for your project and use a steady cutting technique.

Additionally, the scroll saw table should be level and secure, and the machine should be clean from dust and debris. If the problem persists, it might be worth getting professional help or considering a new scroll saw model. Remember, safety always comes first, so be cautious when working with power tools and ask an adult for assistance if needed.