Hey there, curious DIY-ers! Ever wondered why your table saw sometimes decides to act up and bind? Don’t worry, we’ve got you covered! In this article, we’ll delve into the reasons why your table saw might bind up and what you can do about it. So, why does my table saw bind up? Let’s find out!

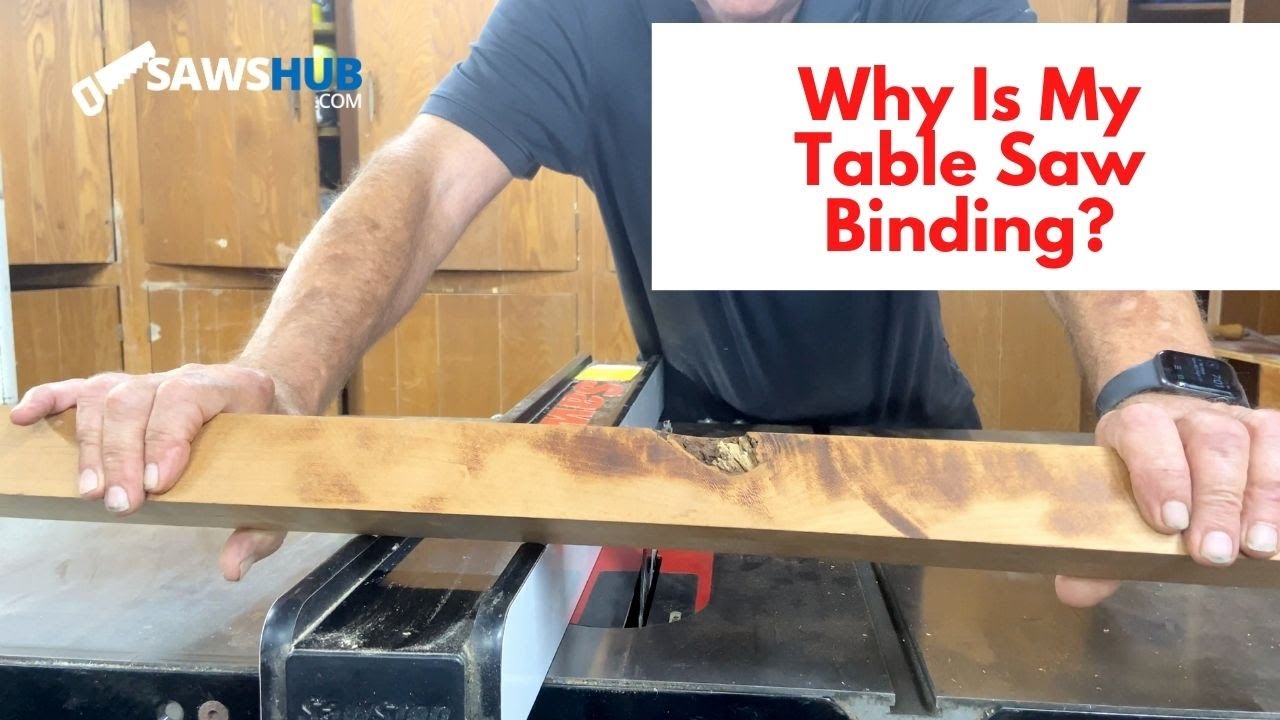

Now, imagine this: you’re all set to tackle your woodworking project, and suddenly, your table saw refuses to budge smoothly. It’s frustrating, right? Well, the binding of a table saw can occur due to a variety of factors. It could be because of improper alignment, worn-out parts, or even excessive moisture affecting the wood. But fret not, we’re here to shed some light on these issues.

Picture this scenario: you’re about to make a precise cut, but your table saw seems to have a mind of its own, binding up and ruining your plans. What a buzzkill! But fear not, young craftsmen and craftswomen. We’re here to help you understand the reasons behind this irritating problem and how you can fix it. So, let’s get started and untangle the mystery of why your table saw binds up. Ready? Let’s dive in!

Why Does My Table Saw Bind Up?

The Importance of Proper Alignment

One of the primary reasons why a table saw may bind up is improper alignment. The alignment of the blade and fence is crucial for smooth and accurate cuts. If the blade is not parallel to the fence, it can cause the material to bind against the blade, resulting in ineffective cutting and potential safety hazards. It’s important to regularly check and adjust the alignment of your table saw to ensure optimal performance.

To align your table saw properly, start by unplugging the machine and removing the blade guard. Use a trusted straightedge or a precision square to check if the blade is parallel to the fence. If it isn’t, consult your table saw’s manual for specific instructions on how to adjust the alignment. Taking the time to align your table saw correctly will not only prevent binding but also enhance the overall accuracy of your cuts.

In addition to aligning the blade and fence, it is crucial to check the alignment of other components such as the miter gauge and the blade tilt. Any misalignment in these components can contribute to binding issues and compromise the performance of your table saw.

The Effect of Dull or Improperly Maintained Blades

A dull or improperly maintained blade can also cause a table saw to bind up. As the blade loses its sharpness, it struggles to cut through the material smoothly, resulting in increased friction and binding. It’s important to regularly inspect and clean your blades, ensuring that they are free from pitch buildup and any other debris that may affect their performance.

To maintain the sharpness of your blades, consider investing in a quality blade sharpener or using professional sharpening services. Additionally, it’s crucial to understand the appropriate speed and feed rates for different materials. Pushing the material too quickly into a dull blade or using the wrong blade for a specific task can lead to binding and other complications.

Proper maintenance of your blades, including regular cleaning, sharpening, and replacement when necessary, will not only improve the performance of your table saw but also prevent binding issues and promote safety during operation.

The Impact of Incorrect Material Support and Techniques

Another common cause of table saw binding is inadequate material support and improper cutting techniques. When working with long or heavy pieces of material, it’s crucial to have proper supports in place to prevent the material from sagging or shifting during the cut. Without adequate support, the material may bind against the blade, making it difficult to achieve clean and accurate cuts.

Using push sticks or featherboards to guide the material through the cut can also help reduce the risk of binding. These tools provide additional control and stability, ensuring that the material is securely guided through the blade without binding or kickback. It’s essential to familiarize yourself with various cutting techniques and safety practices to optimize your table saw’s performance and minimize the risk of binding.

Additionally, always be mindful of the material’s moisture content and stability. Working with wet or warped wood can significantly increase the likelihood of binding and compromising the effectiveness of your table saw. Taking the time to properly prepare your materials and ensuring adequate support and cutting techniques will go a long way in preventing binding issues.

Proper Dust Collection and Maintenance

Often overlooked but equally important is the role of dust collection and regular maintenance in preventing table saw binding. Dust and debris can accumulate around the blade and other moving parts of the saw, impeding its smooth operation and causing binding. Regularly clean your table saw and ensure that the dust collection system is functioning properly.

Investing in a high-quality dust collection system, such as a shop vacuum or dust extractor, can significantly reduce the buildup of dust and debris, ensuring your table saw operates at its best. Furthermore, it’s important to check and replace the throat plate and splitter as needed. If these components are worn or damaged, they can contribute to binding issues.

By incorporating proper dust collection practices and regular maintenance into your table saw routine, you can minimize the risk of binding and prolong the lifespan of your equipment.

Key Takeaways: Why Does My Table Saw Bind Up?

- A table saw can bind up if the blade is misaligned or dull.

- Improper technique, such as pushing too hard or not using proper push sticks, can cause the table saw to bind up.

- Dust and debris can accumulate in the table saw, causing it to bind up.

- Incorrect fence or miter gauge adjustments can lead to binding in a table saw.

- Regular maintenance, including blade sharpening and cleaning, can help prevent a table saw from binding up.

Frequently Asked Questions

Here are some common questions about table saws binding up and their answers:

1. What causes a table saw to bind up?

There are a few reasons why a table saw may bind up during use. One common cause is a misaligned blade or fence. If the blade isn’t straight or the fence is not parallel to it, the wood can get stuck, causing the saw to bind. Another reason could be a dull blade. When the teeth of the blade are worn down, they have a harder time cutting through the wood, which can lead to binding. Lastly, if the wood being cut is too thick for the saw or if it contains foreign objects like nails or knots, it can also cause the saw to bind up.

To avoid binding, make sure your blade and fence are properly aligned, and use a sharp blade appropriate for the type of wood you’re cutting. Check for any foreign objects before cutting, and if the wood is too thick, consider using a different type of saw or making multiple passes to avoid binding.

2. How can I prevent my table saw from binding up?

Preventing a table saw from binding up begins with proper maintenance. Regularly check and align the blade and fence to ensure they are straight and parallel. Clean your saw frequently to remove dust and debris that can cause binding. Using a sharp blade is also essential in preventing binding. A dull blade puts unnecessary stress on the motor, leading to binding. If the wood you are cutting is known to cause binding, consider using a different type of saw or adjust the feed rate to avoid putting excessive pressure on the blade.

Additionally, make sure the table saw is properly set up and that all safety precautions are followed. Keep the saw clean and lubricate any moving parts regularly. By maintaining your table saw and using it correctly, you can significantly reduce the chances of it binding up during use.

3. Is it safe to continue using a table saw that binds up?

No, it’s not safe to keep using a table saw that binds up. When a table saw binds up, it can cause kickback, which is when the wood is forcefully thrown back towards the operator. Kickback can result in serious injuries. Binding can also damage the motor and other components of the saw, leading to further problems and potentially costly repairs.

If your table saw is binding up, it’s important to identify and address the cause of the binding before continuing to use it. This may involve adjusting the blade or fence, sharpening or replacing the blade, or addressing any other issues that may be causing the binding. Always prioritize safety and don’t take any chances with a table saw that is not functioning properly.

4. Can table saw binding be fixed by the user?

In some cases, table saw binding can be fixed by the user. As mentioned earlier, misaligned blades or fences, dull blades, or foreign objects can cause binding. By properly aligning the blade and fence, using a sharp blade, and checking for any foreign objects before cutting, you may be able to fix the binding issue. Additionally, adjusting the feed rate or using a different type of saw for thicker wood can also help prevent binding.

However, if the binding persists or if you are unsure about how to fix it, it is recommended to seek professional help. A qualified technician or a professional woodworker can diagnose and address the issue effectively and safely. It’s always better to seek assistance when dealing with complex machinery like table saws to avoid any further damage or risk of injury.

5. Are there any precautions I should take to avoid table saw binding?

Yes, there are several precautions you can take to avoid table saw binding. Firstly, always wear appropriate safety gear, including safety glasses, hearing protection, and possibly a dust mask. This will help protect you from any potential injuries or health hazards.

Secondly, make sure to use the appropriate blade for the type of wood you are cutting. Different blades are designed to cut different materials effectively. Using the wrong blade can lead to binding.

Lastly, do not force the wood through the saw. Apply a steady and even feed rate, allowing the blade to cut through the wood at its own pace. Forcing the wood can cause the saw to bind up. By following these precautions, you can minimize the chances of table saw binding and work more safely and efficiently.

Summary

Hey there! So, here’s the deal with why your table saw might be getting stuck. Basically, it could be because of a few different things. First, check if the blade is bent or dull. If it is, that could be causing the binding. Second, make sure the fence is aligned properly. If it’s not straight, it can mess with the smoothness of your cuts. Lastly, keep an eye on the drive belt. If it’s worn or loose, it can cause the blade to bind up. So, those are the main things to look out for when your table saw is acting up. Happy woodworking!

Remember, safety always comes first! Make sure to turn off the saw and unplug it before inspecting anything. And if you’re not sure how to fix the problem, ask an adult or someone with experience to help you out. With a little troubleshooting, you’ll be back to making those awesome cuts in no time. Keep on sawing!