If “Why does my table saw keep stopping?” is a question buzzing in your mind, you’re in the right place! Table saws are awesome tools, but it can be frustrating when they keep stopping unexpectedly. In this guide, we’ll explore the common reasons behind this issue, empowering you with the knowledge to troubleshoot and fix your table saw like a pro. So, let’s dive in and get those blades spinning smoothly again!

When it comes to the mysteries of a stalling table saw, there are a few potential culprits. From a faulty power supply to an overloaded motor, we’ll break down each possible cause and equip you with the troubleshooting steps you need. Together, we’ll unravel the secrets behind a table saw that just won’t stay on track, ensuring you can get back to your woodworking projects in no time.

Whether you’re a seasoned DIY enthusiast or just starting to explore the fascinating world of table saws, understanding why your tool keeps stopping is crucial. Stick around to uncover the solutions to this frustrating problem so you can unleash the full potential of your table saw. Get ready to master the art of troubleshooting and wave goodbye to those pesky interruptions!

Why Does My Table Saw Keep Stopping? Common Causes and Solutions

Table saws are a versatile and essential tool in many woodworkers’ arsenals. However, it can be frustrating when your table saw keeps stopping unexpectedly during use. Not only does it disrupt your workflow, but it can also jeopardize the quality and safety of your work. In this article, we will delve into the common causes of why your table saw keeps stopping and provide practical solutions to help you troubleshoot and resolve the issue.

1. Overloaded Circuit

One common reason why your table saw may keep stopping is an overloaded circuit. Table saws are powerful machines that require a significant amount of electrical power to operate. If multiple high-powered tools or appliances are running on the same circuit, it can exceed the circuit’s capacity and trigger it to trip, causing your table saw to stop abruptly.

To prevent this, check if your table saw is sharing a circuit with other power-hungry devices. If so, try plugging it into a dedicated circuit or disconnecting other devices temporarily to reduce the load. If the issue persists, consult an electrician to ensure your circuitry can handle the power demand of your table saw.

Table saws also require a stable power supply. Using extension cords that are too long or of insufficient gauge can lead to voltage drops and cause the saw to stop intermittently. Use a heavy-duty extension cord of adequate length to maintain a consistent power supply to your table saw.

2. Faulty Motor or Power Switch

If you have eliminated the issue with the circuit, a faulty motor or power switch could be the culprit for your table saw’s intermittent stopping. The motor is the heart of the table saw, and any issues with its components can cause it to lose power abruptly.

Start by examining the power switch for any visible damage or loose connections. Ensure that the switch is securely connected and functioning correctly. If you notice any issues, replacing the power switch might be necessary.

When to Consult a Professional

If the issue persists after checking the power switch, it may indicate a problem with the motor. Addressing motor issues can be complex and potentially dangerous. Unless you have experience with motor repairs, it is recommended to consult a professional technician or the manufacturer’s customer service for guidance.

3. Dull or Misaligned Blade

A dull or misaligned blade can also be a culprit behind your table saw’s frequent stalling. When the blade is dull, it requires more effort from the motor to make cuts, leading to overheating and motor burnout. Additionally, a misaligned blade can result in binding or rubbing against the table, causing the saw to stop unexpectedly.

To troubleshoot this issue, inspect the blade for dullness or damage. If needed, replace the blade with a sharp and properly aligned one. Regularly maintaining and sharpening your blades will not only prevent frequent stopping but also ensure cleaner and safer cuts.

Moreover, check the alignment of the blade with the miter gauge and the fence. Misalignment can cause the blade to bind, resulting in stalling. Adjust the blade accordingly or seek professional assistance if needed.

4. Safety Mechanism Activation

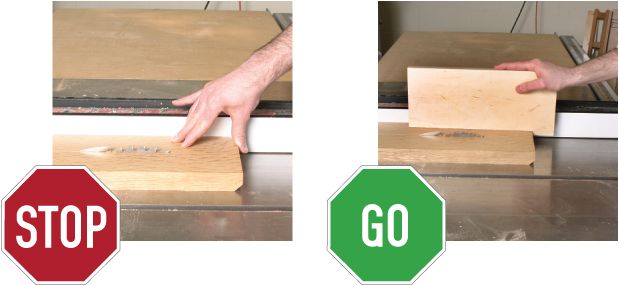

Many table saws are equipped with safety mechanisms designed to protect users from potential accidents. These mechanisms can be triggered by various factors, causing the saw to stop abruptly. One common safety feature is the blade guard, which can activate if it detects excessive pressure or improper positioning of the workpiece.

Ensure that you are using the appropriate blade guard for your cutting needs and that it is properly adjusted. Follow the manufacturer’s instructions to set up and use the safety mechanisms correctly. If needed, review the user manual or consult the manufacturer’s customer service to troubleshoot specific safety features.

5. Dust and Debris Buildup

Dust and debris can accumulate in the motor housing, gears, and other critical components of your table saw, impeding its performance. Over time, this buildup can cause the saw to bog down and stop unexpectedly. Regular cleaning and maintenance are crucial to prevent this issue.

Start by disconnecting the saw from the power source and using compressed air or a brush to remove dust and debris from the motor and other areas. Lubricate the moving parts according to the manufacturer’s instructions to ensure smooth operation. Regularly cleaning and maintaining your table saw will not only prevent frequent stopping but also prolong its lifespan.

6. Loose or Worn Parts

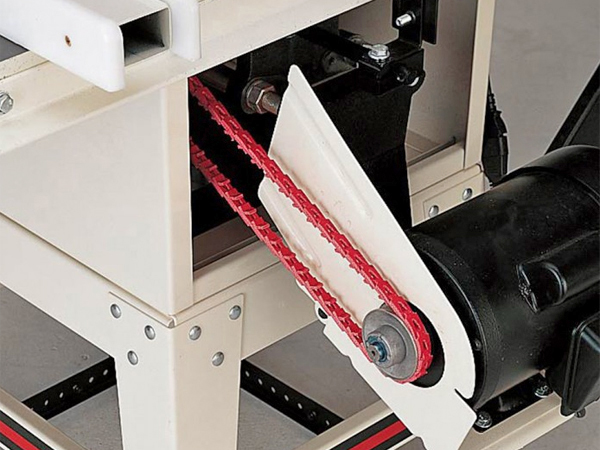

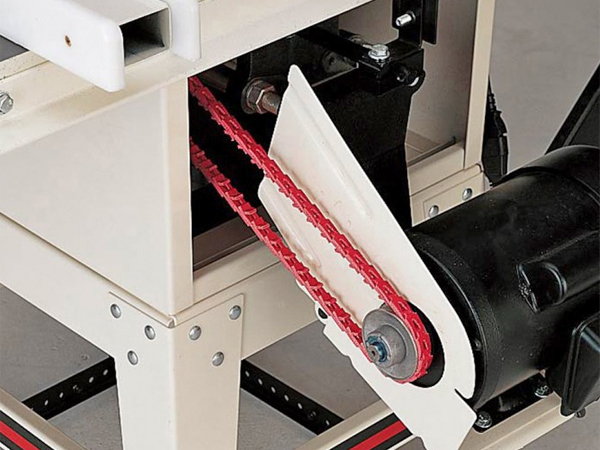

Loose or worn parts can contribute to a table saw frequently stopping during use. Vibrations and repeated usage can cause bolts, screws, and other fasteners to become loose over time. This can affect the stability and overall performance of the saw.

Regularly inspect your table saw for any loose or worn parts, especially around the motor, blade, and fence. Tighten or replace any necessary components to ensure a secure and stable setup. Consider using locking mechanisms, such as thread locker or lock washers, on critical fasteners to prevent them from loosening.

In conclusion, a table saw that keeps stopping can be frustrating, but identifying and resolving the problem is crucial for optimal performance and safety. By addressing common causes such as an overloaded circuit, faulty motor or power switch, dull or misaligned blade, safety mechanism activation, dust buildup, and loose or worn parts, you can ensure smooth and uninterrupted operation of your table saw. Regular maintenance and following the manufacturer’s guidelines will help prevent issues and prolong the lifespan of your valuable tool. Happy woodworking!

#Three Relevant H2 Headings:

Essential Safety Tips for Working with Table Saws

When operating a table saw, prioritizing safety should be your utmost concern. Here are some essential safety tips to keep in mind:

- Wear appropriate safety gear, including safety glasses, ear protection, and a dust mask.

- Ensure the table saw is properly grounded and connected to a stable power source.

- Follow proper ergonomic practices and maintain a comfortable stance while using the saw.

- Always use the appropriate blade guard and push sticks or guides to protect your hands and fingers.

- Keep the workspace clean and free of clutter to prevent tripping hazards and ensure smooth operation.

- Regularly inspect and maintain your table saw, including blade sharpening, alignment checks, and cleaning.

The Benefits of a Well-Maintained Table Saw

Proper maintenance of your table saw offers several benefits that contribute to efficient and successful woodworking projects. Some key advantages include:

- Enhanced safety: Regular maintenance ensures that safety mechanisms are functioning correctly, reducing the risk of accidents.

- Consistent performance: A well-maintained table saw operates smoothly and reliably, providing consistent and accurate cuts.

- Extended lifespan: Cleaning, lubricating, and tightening components helps prevent premature wear and prolongs the saw’s lifespan.

- Improved efficiency: A sharp blade, aligned fence, and clean cutting surface minimize wasteful cuts and maximize material usage.

- Higher quality outputs: Well-maintained equipment produces cleaner cuts with less tear-out, improving the overall quality of your woodworking projects.

Common Table Saw Problems and Solutions

While a table saw that keeps stopping is a common issue, there are other problems you may encounter. Here are some common table saw problems and their solutions:

1. Blade wobbling:

Check if the blade is securely mounted and tightened. If the arbor or blade is damaged, replace them accordingly.

2. Burning smell:

Ensure the blade is sharp and properly aligned. Clean any debris from the motor and other areas. If the issue persists, consult a professional.

3. Fence misalignment:

Check if the fence is parallel to the blade. Adjust or recalibrate the fence if necessary. Clean any debris interfering with the fence’s movement.

4. Uneven cuts:

Inspect the blade for damage or dullness. Adjust the blade height and ensure the fence is properly aligned. Use a miter gauge or sled for accurate cuts.

5. Excessive noise or vibrations:

Check for loose or worn parts. Tighten or replace any necessary components. If the issue persists, seek professional assistance.

#Wrap-Up:

In conclusion, when your table saw keeps stopping, it can be frustrating. However, by addressing common causes such as an overloaded circuit, faulty motor or power switch, dull or misaligned blade, safety mechanism activation, dust buildup, and loose or worn parts, you can troubleshoot and resolve the issue. Regular maintenance, adherence to safety guidelines, and implementing effective solutions will ensure the smooth operation and longevity of your table saw. Happy woodworking!

Key Takeaways: Why Does My Table Saw Keep Stopping?

1. Check the power source to ensure it is not fluctuating or insufficient.

2. Examine the saw’s motor for any signs of overheating or damage.

3. Clean the saw’s components regularly to prevent debris from causing blockages.

4. Adjust the tension on the saw’s drive belt to ensure proper operation.

5. Consult the user manual or contact a professional if the issue persists.

Frequently Asked Questions

Here are some common questions people have about table saws that keep stopping, along with their answers:

1. Why does my table saw keep turning off suddenly?

There could be a few reasons why your table saw keeps stopping. One possibility is that the motor is overheating, which can happen if you’ve been working for extended periods without giving the motor a chance to cool down. Another reason could be a faulty power supply or an issue with the wiring. It’s also worth checking if there’s a safety feature that automatically shuts off the saw when certain conditions are met, such as a loose blade guard or a tripped circuit breaker.

If you’ve ruled out these common causes, it’s best to consult a professional technician who can diagnose and fix the specific problem with your table saw.

2. Can a dull blade cause a table saw to stop running?

Yes, a dull blade can cause a table saw to stop running. When a blade is dull, it requires more power to cut through the material, straining the motor. This increased workload can cause the motor to overheat and shut down. Additionally, a dull blade may cause the wood to bind or kickback, triggering safety mechanisms that stop the saw. It’s important to regularly inspect and sharpen your blades to ensure smooth and safe operation of your table saw.

If you suspect your blade is dull, you can try replacing it with a new, sharp blade and see if the problem persists. If it does, it’s recommended to have a professional assess the situation to determine the underlying cause.

3. Could a faulty switch be the reason why my table saw keeps shutting off?

A faulty switch can indeed be a reason why your table saw keeps shutting off. The switch is responsible for controlling the power supply to the motor. If the switch is damaged, worn out, or wired incorrectly, it can cause intermittent power interruptions, resulting in your table saw stopping unexpectedly. To troubleshoot this issue, you can try replacing the switch with a new one of the same specifications. However, if you’re not comfortable working with electrical components, it’s best to consult a professional.

Remember, safety should always be a priority. Whether it’s a faulty switch or another issue, if you’re unsure how to fix it, it’s better to seek professional help rather than attempting repairs yourself.

4. Is a clogged dust collection system the reason behind my table saw stopping frequently?

A clogged dust collection system can potentially cause your table saw to stop frequently. When the dust collection system is clogged, it restricts the airflow, leading to poor ventilation and increased heat buildup within the motor and other components. This can trigger automatic thermal protection mechanisms that shut down the saw to prevent overheating or damage. Regularly cleaning and maintaining your dust collection system is crucial to ensure proper airflow and prevent frequent power interruptions.

Make sure to follow the manufacturer’s recommendations for cleaning your specific table saw model and check for any blockages that may be affecting the dust collection system’s performance.

5. How can I prevent my table saw from stopping frequently?

To prevent your table saw from stopping frequently, it’s important to follow some preventive measures. First, ensure that you are not overloading the saw by trying to cut materials beyond its capacity. Use the appropriate blade for the material you are cutting and check for any damage or wear on the blade regularly. Keep the saw clean from dust and debris, and maintain a well-functioning dust collection system to prevent clogs. Additionally, allow for cool-down periods during prolonged use to prevent the motor from overheating. Regularly inspect the electrical components, such as the switch and wiring, for any signs of damage or malfunction and address them promptly.

By following these preventive measures and performing regular maintenance, you can minimize the chances of your table saw stopping frequently and ensure safer and uninterrupted operation.

5 Things NOT to do at the Table Saw!

Summary

So, if your table saw keeps stopping, it could be due to a few common reasons. First, check the power supply and make sure it’s securely connected. Next, inspect the blade for any damage or issues. Lastly, ensure that the motor is properly lubricated and not overheating.

If you’re still having trouble, it might be best to consult a professional or contact the manufacturer for further assistance. Remember, safety should always come first when working with power tools, so take the necessary precautions and be careful!