When it comes to using a lathe, safety should always be the top priority. So, why is a lathe dangerous? Let’s dive into the world of lathes and uncover the potential risks involved. Whether you’re a curious hobbyist or a seasoned professional, understanding these dangers is crucial for a safe and enjoyable experience.

Now, you might be wondering what exactly makes a lathe dangerous. Well, it’s all about the power and speed at which it operates. With its spinning cutting tools and rotating workpiece, a lathe can cause serious harm if not handled with care. But fear not, we’re here to unravel the hazards and equip you with the knowledge to work safely.

So, join us as we explore the reasons why lathes can be dangerous and discover the precautions you need to take when operating this powerful machine. From flying debris to entanglement hazards, we’ll cover it all. Stay tuned and let’s learn how to handle a lathe like a pro while keeping ourselves out of harm’s way. Shall we begin?

When it comes to working with a lathe, there are several reasons why it can be dangerous. The rotating machinery poses a risk of entanglement, leading to serious injuries. Additionally, sharp tools used with the lathe can cause lacerations or flying debris. Improper handling or lack of protective gear can further increase the hazards. Safety precautions, such as proper training, wearing protective equipment, and maintaining a clean work area, are crucial to minimize the risks associated with lathes.

The Dangers of Operating a Lathe: A Comprehensive Guide

Operating a lathe can be a fascinating and useful skill to possess. It allows individuals to shape and cut materials with precision, opening up a world of opportunities. However, it’s important to acknowledge the potential dangers that come with using a lathe. In this article, we will explore why the lathe can be dangerous, discuss the risks involved, and provide essential safety tips to ensure a secure working environment. Let’s dive in!

The Hazards of Rotating Machinery

One of the primary reasons why a lathe can be dangerous is the rotating nature of its machinery. A lathe typically consists of a spinning workpiece and a rotating cutting tool. This constant movement, if not properly controlled or protected against, can pose significant risks to operators. The high speeds involved in lathe operations can lead to severe injuries or even fatalities.

One common hazard associated with rotating machinery is the potential for entanglement. Loose clothing, jewelry, or long hair can get caught in the rotating parts, causing the operator to be pulled into the machine. This can result in devastating injuries, including amputations or crushing injuries.

Additionally, the rotational force of a lathe can lead to flying debris and projectiles. Tools, workpieces, or fragments can break off and be ejected at high speeds, posing a serious threat to the operator and anyone nearby. Eye injuries, lacerations, or blunt-force trauma can occur as a result.

Electrical and Chemical Dangers

While the physical hazards of a lathe are significant, it’s essential not to overlook the electrical and chemical dangers that can be present. Many lathes are powered by electricity, and faults in the electrical system can lead to electric shocks or fires. It’s crucial to ensure that the lathe is properly grounded and that all electrical components are in good working condition.

In some instances, operators may need to use lubricants, solvents, or other chemicals during lathe operations. These substances can present health hazards if inhaled, ingested, or come into contact with the skin. It’s vital to follow proper safety protocols and use personal protective equipment, such as gloves and masks, when working with chemicals.

Furthermore, the buildup of dust or debris in and around the lathe can be a fire hazard. Regular cleaning and maintenance are necessary to prevent the accumulation of combustible materials that could ignite and cause a fire.

Effective Safety Measures

Given the potential dangers associated with operating a lathe, it’s crucial to implement effective safety measures to mitigate risks. Here are some essential precautions to consider:

- Training: Ensure that all operators receive proper training on lathe operation, safety procedures, and emergency protocols.

- Protective Equipment: Operators should wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and closed-toe shoes.

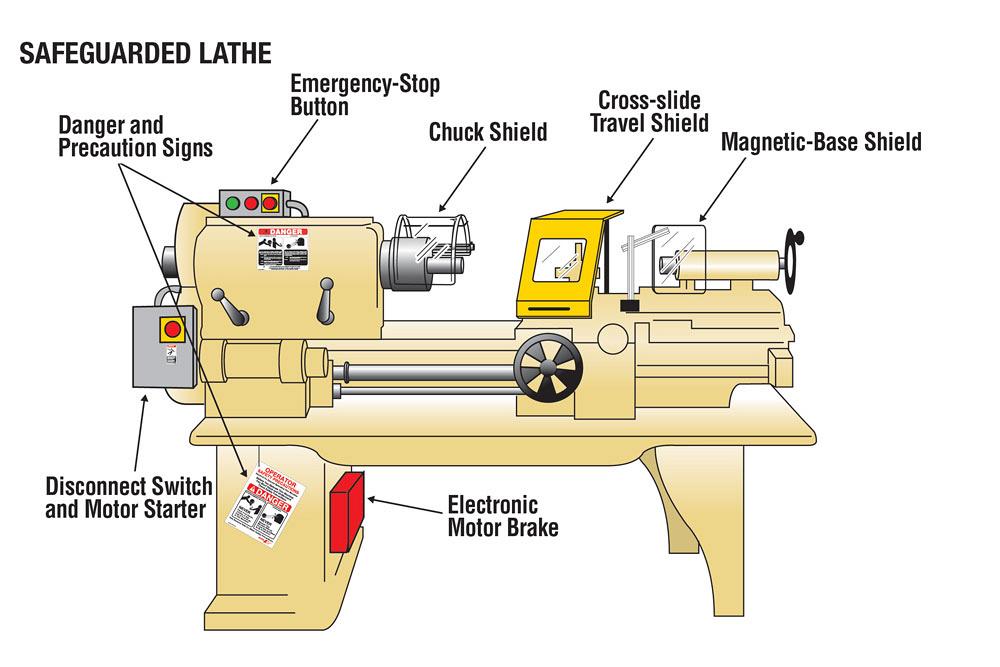

- Machine Guarding: Install appropriate machine guards, such as splash guards or chip shields, to prevent contact with rotating parts.

- Workspace Organization: Keep the lathe area clean and free from clutter to minimize the risk of trips and falls.

- Regular Maintenance: Perform routine inspections and maintenance on the lathe to identify and address any potential hazards or mechanical issues.

By implementing these safety measures and emphasizing the importance of a secure working environment, the risks associated with operating a lathe can be significantly reduced. It is crucial to prioritize safety at all times and remain vigilant when using this powerful machinery.

Other Risks to Consider

While we have covered the most significant dangers of operating a lathe, it’s crucial to mention a few additional risks that operators should be aware of:

Kickback:

Kickback occurs when the workpiece is forcefully thrown back toward the operator. This can happen if the cutting tool catches the material or if the lathe is not properly secured. Operators should always ensure that the workpiece is securely fastened and make precise, controlled cuts to minimize the risk of kickback.

Heat and Sparks:

During lathe operations, heat and sparks may be produced. It’s important to be cautious around these potential fire hazards and ensure that there are no flammable substances nearby. Keep a fire extinguisher readily available and follow proper procedures for handling heat and sparks.

Noise Exposure:

The noise produced by a lathe can reach levels that may cause hearing damage over time. Operators should use appropriate hearing protection, such as earplugs or earmuffs, to prevent long-term hearing loss.

Safe Operation Guidelines: Protecting Yourself and Others

Practical Safety Tips for Lathe Operators

Common Mistakes to Avoid When Operating a Lathe

Key Takeaways: Why is Lathe Dangerous?

- A lathe is a dangerous machine that can cause serious injuries if not used correctly.

- The rotating parts of a lathe, such as the chuck and the spindle, can catch loose clothing or hair, leading to accidents.

- The sharp cutting tools used in a lathe can cause severe cuts and lacerations if mishandled.

- Improperly secured workpieces can become projectiles, posing a risk of injury.

- It is crucial to receive proper training and follow safety protocols when operating a lathe to minimize the risk of accidents.

Frequently Asked Questions

Welcome to our FAQ section, where we will address some common concerns regarding lathe safety. Below, you’ll find answers to important questions about why a lathe can be dangerous and how to stay safe while using one.

What are the potential dangers of using a lathe?

While lathes are incredibly useful machines, they can pose various hazards if not operated with care. Some potential dangers include getting caught in the rotating parts, flying debris, and entanglement in the machine’s mechanisms. The sharp tools used with lathes can also cause cuts or puncture wounds if mishandled. Additionally, lathe work often involves working with heavy materials, which can lead to injuries if not handled or supported properly.

To mitigate these risks, it’s crucial to follow strict safety protocols, wear appropriate protective gear, and receive proper training on lathe operations. Being aware of the potential dangers and taking the necessary precautions is essential for safe lathe usage.

Can the speed of a lathe be dangerous?

Yes, the speed of a lathe can present a significant danger. The rotating parts of a lathe can reach high speeds, and if not controlled properly, can cause severe injury. Excessive speed can lead to the loss of control over the workpiece, resulting in accidents. Equally dangerous is suddenly stopping the lathe while it’s spinning at high speeds, as this can cause the workpiece to become a projectile.

To ensure safety, it’s vital to always follow the recommended speed settings for the specific workpiece. Additionally, take measures to secure the workpiece properly, avoid sudden stops, and use appropriate safety guards. Adhering to these precautions can help prevent accidents related to lathe speed.

Why is proper training essential for lathe operators?

Proper training is crucial for lathe operators due to the potential dangers associated with lathe use. Operators need to understand the safe operation of the machine, including how to handle tools, set speeds, secure workpieces, and use safety precautions. Training helps operators develop the skills necessary to identify hazards, mitigate risks, and respond appropriately in case of emergencies.

By receiving proper training, lathe operators can enhance their knowledge of safety practices and become familiar with the specific features and controls of the lathe they are using. This training provides operators with the necessary skills and confidence to operate the machine safely, reducing the likelihood of accidents and injuries.

What safety precautions should be taken when using a lathe?

When using a lathe, several safety precautions should be taken. First and foremost, always wear appropriate protective gear, such as safety glasses or goggles, hearing protection, and a face shield. Ensure that loose clothing, jewelry, and long hair are secure and cannot get caught in the moving parts of the lathe.

It’s also essential to inspect the lathe before each use, checking for any damaged or worn-out parts. Always follow the manufacturer’s guidelines and recommendations for operating the lathe, including proper mounting and securing of the workpiece, using safety guards, and correct tool usage. Regular maintenance and cleaning of the lathe are also important to keep it in optimal working condition and reduce the risk of accidents.

How can I stay safe while operating a lathe?

To stay safe while operating a lathe, it’s imperative to prioritize safety at all times. This includes following the recommended safety protocols, staying focused, and never rushing through tasks. Always be aware of your surroundings and keep a clear workspace free from clutter.

Additionally, ensure you have received proper training on lathe operations, including how to use the machine and its tools correctly. Familiarize yourself with the lathe’s safety features and emergency shut-off procedures. Finally, trust your instincts – if something doesn’t feel safe, stop and address the issue before continuing.

My Lathe Injury (aka: Sometimes You Should Just Walk Away)

Summary

Using a lathe can be dangerous because it spins fast and has sharp tools. It’s important to follow safety rules, wear protective gear, and receive proper training. Accidents can cause serious injuries, so caution is crucial.

Always keep hands away from the spinning parts, don’t wear loose clothing, and pay attention. Safety should never be taken lightly when using a lathe.