Have you ever noticed that your bandsaw blade tends to drift while you’re working? It can be frustrating, but don’t worry, you’re not alone! Many woodworkers face this issue and wonder why it happens. In this article, we’ll explore the reasons behind why your bandsaw blade might be drifting and what you can do to fix it.

When your bandsaw blade drifts, it means that it deviates from its intended path while cutting. This can result in uneven cuts and a less-than-perfect finished product. But why does it happen? Well, there are several factors that can contribute to blade drift, such as improper blade tension, worn-out or dull blades, incorrect blade tracking, or even a misaligned bandsaw wheel.

But don’t worry, we’ve got you covered! In the following paragraphs, we’ll dive deeper into each of these causes and provide you with some simple troubleshooting tips to get your bandsaw blade back on track. So, let’s get started and find out why your bandsaw blade is drifting and how you can fix it!

Why is My Bandsaw Blade Drifting? – Causes and Solutions

Discover the reasons behind your bandsaw blade drifting and learn effective solutions to fix this common issue. Whether you’re a beginner or an experienced woodworker, understanding why your bandsaw blade is drifting will help you achieve accurate and precise cuts. In this in-depth guide, we will explore the various factors that can cause your bandsaw blade to drift and provide practical tips on how to address them.

Common Causes of Bandsaw Blade Drifting

Incorrect blade tension, worn out or incorrect blade, improper blade tracking, inadequate guide setup, and feeding rate are some of the most common causes of bandsaw blade drifting. Let’s delve into each of these causes in detail:

1. Incorrect Blade Tension

Insufficient or excessive blade tension can lead to blade drifting. When the tension is too loose, the blade will not have enough rigidity to remain on the intended cutting path, resulting in wandering cuts. Conversely, if the tension is too tight, excessive strain can cause the blade to veer off course. It’s essential to follow the manufacturer’s recommendations for blade tension and regularly check and adjust it accordingly.

Regularly inspect the blade for signs of wear or damage and replace it if necessary. A dull or damaged blade can cause the blade to deflect, leading to drifting. Selecting the appropriate blade for your cutting needs is also crucial to ensure optimal performance.

Proper blade tracking is essential to prevent drifting. When the blade is not tracking correctly, it can gradually move off its intended path, resulting in inaccurate cuts. Ensure that the blade is properly aligned with the wheels and tracking guides. Regularly check and adjust the tracking to maintain the correct path.

3. Inadequate Guide Setup

The guides on a bandsaw play a crucial role in blade stability and preventing drifting. If the guides are not properly set up, the blade can move side to side, leading to off-course cuts. Adjust the guides to the correct position according to the manufacturer’s guidelines. Properly set up guides will provide support and stability, reducing the chances of blade drifting.

Another factor that can contribute to blade drifting is the feeding rate. Feeding material too quickly through the bandsaw can cause the blade to deviate from the intended path. Maintain a steady and controlled feeding rate to ensure the blade can cut smoothly and accurately. Take your time and let the bandsaw do the work.

Solutions for Bandsaw Blade Drifting

Now that we understand the causes of bandsaw blade drifting, let’s explore some effective solutions:

1. Proper Blade Tension

Ensure the blade tension is within the recommended range. Use a tension gauge to achieve the correct blade tension and adjust as necessary. Regularly check the tension as it may change over time due to blade fatigue or temperature variations. Maintaining the appropriate blade tension will significantly reduce the chances of blade drifting.

Choosing the right blade for the specific cutting task is crucial. Consider the type of material being cut, the desired cut quality, and the blade’s teeth per inch (TPI) when selecting a blade. A blade with a higher TPI will be more suitable for precise and intricate cuts, while a blade with a lower TPI will be better for rougher cuts.

Proper blade tracking is essential to prevent drifting. Regularly check the tracking adjustment and make necessary corrections. Adjust the guides to ensure they are supporting the blade properly without exerting excessive pressure. A well-tracked blade will stay on the correct cutting path, resulting in accurate cuts.

3. Guide Setup and Adjustment

Properly set up the guides according to the manufacturer’s guidelines. Ensure that the guides are aligned with the blade and provide adequate support. Avoid positioning the guides too close or too far from the blade. Regularly inspect the guides for wear and replace them if necessary. Well-maintained guides will minimize blade drift and improve cutting accuracy.

Adjust the feeding rate to a controlled and steady pace. Avoid forcing the material through the blade or feeding too quickly. Let the blade do the cutting work while guiding the material smoothly. Maintaining a consistent feeding rate will help reduce the chances of blade drift and produce clean and precise cuts.

4. Additional Tips and Considerations

Here are some additional tips to consider when dealing with bandsaw blade drifting:

- Keep the bandsaw clean and free from debris. Accumulated sawdust and waste material can interfere with the blade’s performance.

- Regularly lubricate the blade and the guides to minimize friction and ensure smooth operation.

- Inspect and maintain the bandsaw regularly. Check for any loose components, misalignments, or signs of wear.

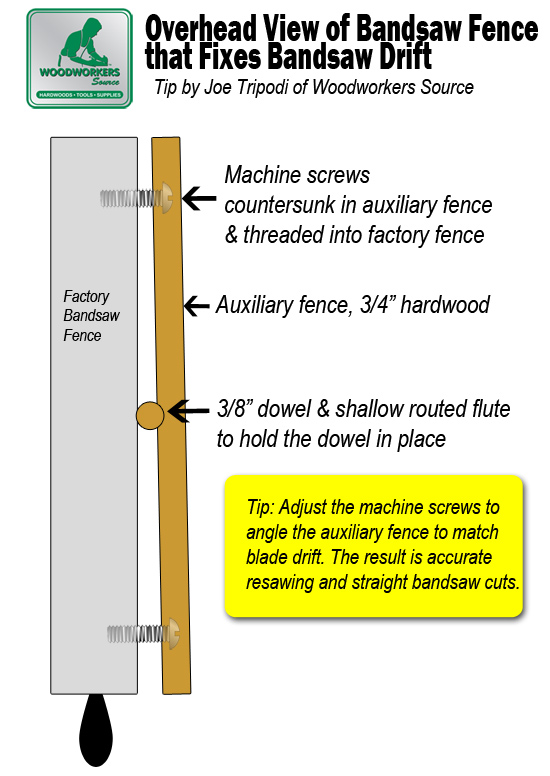

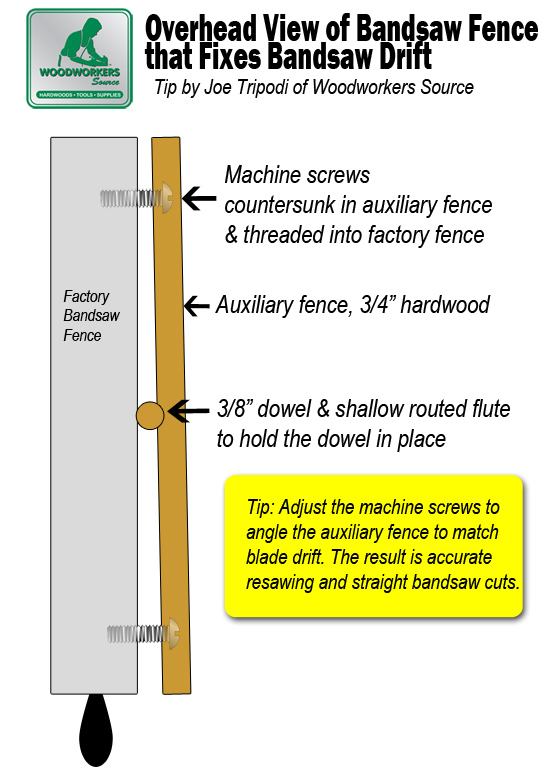

- Consider using a resaw fence or a guide block to enhance blade stability and control when making precise cuts.

- Invest in high-quality blades. Cheaper blades may wear out quickly, leading to more frequent drifting issues.

- Seek guidance from experienced woodworkers or professionals if you’re new to bandsaw operation. They can provide valuable insights and tips on blade control and maintenance.

Conclusion

Understanding the causes behind bandsaw blade drifting is essential for achieving accurate and precise cuts. By addressing issues such as blade tension, tracking, guide setup, and feeding rate, you can significantly minimize blade drifting and improve your overall bandsaw performance. Regular maintenance, proper blade selection, and adopting good cutting practices will help ensure optimal results. With these tips and solutions, you can overcome the challenges of bandsaw blade drifting and enhance your woodworking experience.

Key Takeaways: Why is my bandsaw blade drifting?

- A drifting bandsaw blade could be caused by improper tensioning.

- Inadequate blade guides or worn bearings can also contribute to blade drift.

- Using the wrong type or size of blade can cause the blade to drift.

- Incorrect blade tracking or misaligned guides can lead to blade drift.

- Understanding proper blade alignment and tensioning is crucial to prevent blade drift.

Frequently Asked Questions

Are you finding that your bandsaw blade is drifting? Don’t worry, you’re not alone. Drifting is a common issue that many bandsaw users face. Let’s dive into some frequently asked questions to understand why this happens and how to fix it.

1. How does a bandsaw blade drift?

When a bandsaw blade drifts, it means that it is not cutting straight but instead veering off to one side. There are a few reasons why this can happen. Firstly, improper blade tension is a common culprit. If the tension is too loose or too tight, it can cause the blade to veer off course. Another factor is blade alignment. If the blade is not properly aligned with the saw’s guides and wheels, it can cause drifting. Finally, dull or damaged blades can also contribute to drifting as they are not able to cut through the material smoothly.

To fix the drifting issue, start by checking the blade tension and making sure it is within the recommended range for your specific bandsaw. Next, ensure that the blade is properly aligned by adjusting the guides and wheels as necessary. Lastly, inspect the blade for any signs of damage or dullness. If it is damaged, replace it with a new, sharp blade.

2. Can the type of material being cut affect blade drifting?

Yes, the type of material being cut can have an impact on blade drifting. Harder materials like thick hardwood or metal can put more strain on the blade and increase the chances of it drifting. When cutting these materials, it is important to make sure that the blade is properly tensioned and aligned. Using a blade with the appropriate teeth per inch (TPI) for the material can also help reduce drifting. Additionally, feeding the material at a steady pace and using proper cutting techniques can minimize drifting.

If you frequently work with challenging materials, it may be worth investing in specialized blades designed for those materials. These blades are often made with a specific tooth geometry or a more durable construction to handle the demands of the material effectively.

3. How can improper blade tracking contribute to blade drifting?

Improper blade tracking is another factor that can contribute to blade drifting. Blade tracking refers to how the blade is positioned on the saw’s wheels. If the blade is not properly aligned with the wheels, it can cause the blade to drift. This can happen if the blade is riding too far forward or backward on the wheels. It can also occur if the blade is not centered properly.

To check and adjust the blade tracking, start by turning off the bandsaw and opening the blade tracking window if your saw has one. Use the adjustment knobs or screws provided to make small adjustments to the blade’s position on the wheels. Keep testing the blade’s tracking after each adjustment until it is properly aligned and no longer drifting.

4. Could improper blade tensioning technique be causing my blade to drift?

Yes, improper blade tensioning technique can definitely contribute to blade drifting. When tensioning the blade, it is important to achieve the right balance. Over-tensioning the blade can cause excessive stress and lead to drifting, while under-tensioning can result in a loose blade that is prone to drifting as well. Follow the manufacturer’s recommendations for tensioning your specific blade and instrument.

Using a tension gauge or deflection testing method can help ensure that the blade is properly tensioned. Avoid relying solely on visual estimation as it can be misleading. If you’re unsure about the correct tension for your blade, consult the bandsaw’s manual or seek guidance from experienced bandsaw users.

5. Are there any maintenance tips to prevent blade drifting?

Regular maintenance is essential for preventing blade drifting and ensuring optimal performance. Here are a few maintenance tips to keep in mind:

Firstly, keep your bandsaw clean and free of dust and debris. Buildup can affect the blade’s movement and contribute to drifting. Regularly clean the saw’s guides, wheels, and table.

Secondly, lubricate the blade and guides as recommended by the manufacturer. Proper lubrication reduces friction and helps the blade cut smoothly. Be sure to use the appropriate lubricant for your specific bandsaw.

Lastly, check your bandsaw regularly for any signs of wear or damage. Replace worn-out parts, such as guides or tires, to maintain optimal performance. By following these maintenance practices, you can minimize the chances of blade drifting and prolong the life of your bandsaw.

Summary

If your bandsaw blade is drifting, it may be due to improper blade tension or dull teeth. Make sure to adjust the tension properly and replace a worn-out blade. Misalignment of the blade can also cause drifting, so check if it’s aligned correctly. Another common issue is using the wrong type of blade for the material you’re cutting. Remember to choose the right blade for the job. Finally, the blade guides may need adjustment to prevent wandering. By addressing these factors, you can fix the problem of your bandsaw blade drifting.

In summary, to stop your bandsaw blade from drifting:

– Check blade tension and replace dull blades

– Ensure proper blade alignment

– Use the correct blade for the material being cut

– Adjust the blade guides as necessary.