Having trouble with your bandsaw cutting crooked? Don’t worry, we’ve got you covered!

In this guide, we’ll explore the possible reasons behind why your bandsaw might not be cutting straight, and we’ll provide you with some helpful tips to troubleshoot and fix the issue.

From misalignment to dull blades, there are a few common culprits that can contribute to a crooked cut. So, let’s dive in and get your bandsaw back on track for smooth and accurate cuts!

Why Is My Bandsaw Cutting Crooked?

Have you noticed that your bandsaw is cutting crooked? It can be frustrating and can negatively impact the accuracy of your cuts. In this article, we will explore the various reasons why your bandsaw may be cutting crooked and provide you with practical solutions to fix the issue. Whether you are a professional woodworker or a hobbyist, understanding the causes behind this problem will help you improve the performance of your bandsaw and achieve precise and straight cuts. Let’s dive in and uncover the reasons behind a crooked bandsaw cut.

Incorrect blade tension

One of the primary reasons why your bandsaw may be cutting crooked is incorrect blade tension. When the blade on your bandsaw is too loose or too tight, it can result in uneven cuts. A loose blade can cause the blade to wander off course, leading to crooked cuts. On the other hand, an overly tight blade can put excessive pressure on the wood, causing it to drift during the cut. To ensure proper tension, refer to your bandsaw’s manual for the recommended tension settings. It’s crucial to check and adjust the blade tension regularly to maintain optimum performance.

Additionally, make sure that the blade itself is in good condition. A dull or damaged blade can also contribute to crooked cuts. If necessary, replace the blade with a new, sharp one that is appropriate for the type of material you are cutting.

Blade drift

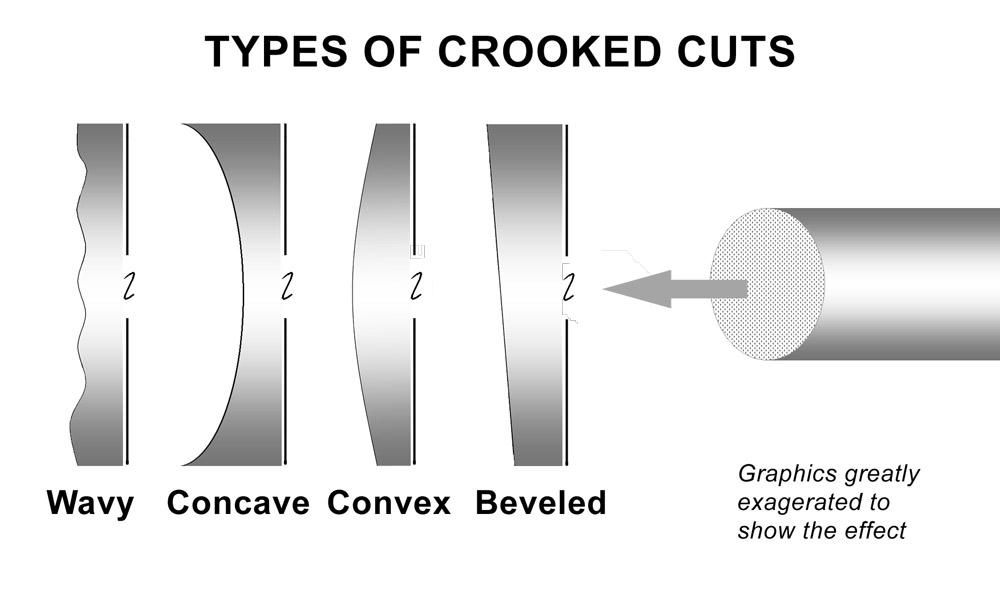

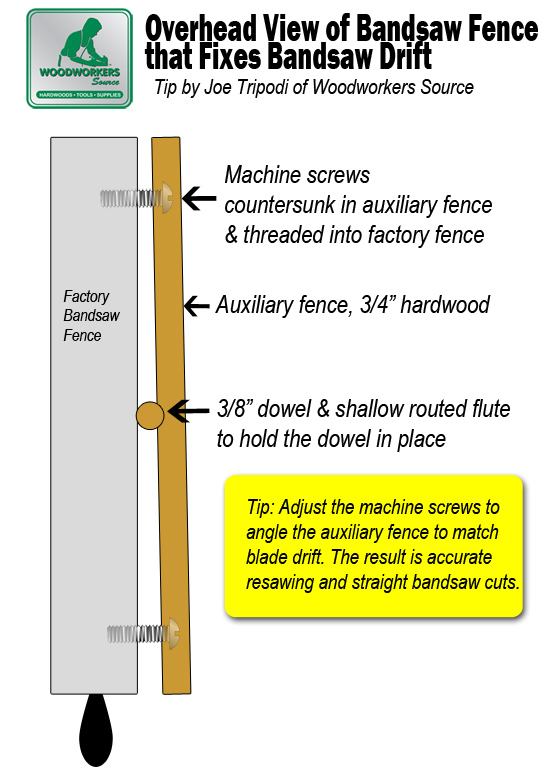

Another common culprit behind a crooked bandsaw cut is blade drift. Blade drift refers to the tendency of the blade to veer off course while cutting. It often occurs due to tension imbalances in the blade or irregularities in the saw’s setup. To mitigate blade drift, you can try adjusting the blade tracking. Refer to your bandsaw’s manual for instructions on how to set up the blade tracking correctly. Additionally, experiment with different blade guides and make sure they are properly aligned to minimize blade drift. Taking the time to properly set up and align your bandsaw can significantly improve the cutting accuracy.

If you are consistently experiencing blade drift despite proper setup, it may be worth considering a bandsaw with a built-in blade drift adjustment mechanism. These models allow you to fine-tune the blade alignment, reducing the possibility of drift and resulting in straighter cuts.

Improper blade alignment

Improper blade alignment is another factor that can lead to crooked cuts on a bandsaw. If the blade is not aligned parallel to the fence or miter gauge, it can cause the wood to veer off course during the cut. To rectify this issue, start by ensuring that the blade is tracking correctly. Check if the blade is centered on the wheel and running in the middle of the tire. Next, adjust the table and fence or miter gauge to ensure they are properly aligned with the blade. This alignment will help guide the wood straight during the cut, resulting in cleaner and more accurate cuts.

Regular maintenance and cleaning of your bandsaw also play a crucial role in maintaining proper blade alignment. Remove any sawdust or debris that can affect the blade’s movement or interfere with its alignment. Keeping your bandsaw clean and well-maintained will contribute to better cutting performance.

Key Takeaways: Why is My Bandsaw Cutting Crooked?

- Check if the blade is properly tensioned.

- Inspect the blade for damage or dullness.

- Ensure the blade guides are properly adjusted.

- Check if the workpiece is securely held in place.

- Verify if the bandsaw table is level and the fence is aligned.

Frequently Asked Questions

Welcome to our FAQ section dedicated to answering your questions about bandsaws and why they may cut crooked. Below are five common questions and detailed answers to help you troubleshoot and resolve this issue.

1. Why is my cutsaw cutting crooked?

When a bandsaw cuts crooked, several factors may be at play. One common cause is improper blade tension. If the blade is too loose, it can drift off course and result in crooked cuts. Ensure the blade is properly tensioned according to your bandsaw’s specifications. Another factor to consider is the blade’s condition. A dull or damaged blade can cause the bandsaw to cut crooked. Check the blade for any signs of wear and tear, and replace it if necessary.

Additionally, the bandsaw’s guides and bearings may need adjustment or replacement. These components help keep the blade aligned and cutting straight. If they are worn or misaligned, the bandsaw may cut crooked. Check the guides and bearings for any damage or misalignment and make the necessary adjustments or replacements. Finally, feeding the material too quickly or applying uneven pressure can also cause crooked cuts. Ensure you feed the material at a steady pace and apply equal pressure to avoid this issue.

2. What should I do if my bandsaw cuts crooked even after adjusting the blade tension?

If your bandsaw continues to cut crooked even after adjusting the blade tension, there are a few other factors to consider. Check the blade alignment to ensure it is running parallel to the bandsaw’s fence or guide. If it is not aligned, adjust the blade tracking to correct the alignment. Additionally, inspect the bandsaw’s drive and idler wheels. If these wheels are out of alignment or damaged, they can cause the blade to veer off track. Check for any misalignment or damage and make the necessary adjustments or replacements.

Another potential cause of crooked cuts is an uneven or worn-out bandsaw table. If the table is not flat or smooth, it can affect the accuracy of the cuts. Ensure the table is clean, flat, and well-maintained. If it is damaged or uneven, consider replacing or resurfacing it. Lastly, always check the bandsaw blade for any defects or irregularities. A faulty blade can contribute to crooked cuts even after adjusting other factors. If you notice any issues with the blade, replace it with a high-quality and properly sized blade suitable for your bandsaw.

3. Can improper blade tension cause the bandsaw to cut crooked?

Yes, improper blade tension can cause the bandsaw to cut crooked. When the blade tension is too loose, it can lead to blade drift, where the blade veers off course during the cut. This results in crooked cuts. To avoid this issue, make sure to tension your bandsaw blade according to the manufacturer’s recommendations. Generally, a properly tensioned blade should have a slight, even deflection when pressed lightly with your finger. Finding the optimal tension for your specific bandsaw may require some trial and error, but once achieved, it will help ensure straighter cuts.

On the other hand, over-tensioning the blade can also lead to crooked cuts. Excessive tension can put too much stress on the blade, causing it to distort or buckle during the cut. It is essential to strike a balance and maintain the proper tension for optimal cutting performance. Always refer to your bandsaw’s manual or consult with a knowledgeable expert to determine the appropriate blade tension.

4. Are there any maintenance steps I can take to prevent my bandsaw from cutting crooked?

A well-maintained bandsaw is less likely to cut crooked and will provide better cutting performance overall. Here are a few maintenance steps you can take to prevent crooked cuts:

– Regularly clean and inspect the bandsaw’s guides and bearings, ensuring they are in good condition and properly aligned.

– Keep the bandsaw blade clean, free from pitch or debris, and regularly sharpen or replace it when necessary.

– Check the bandsaw table for flatness and smoothness. If needed, resurface or replace the table.

– Maintain proper tension on the blade, adjusting as necessary.

– Lubricate moving parts, such as the blade guides and wheels, to ensure smooth operation.

– Follow the manufacturer’s recommendations for routine maintenance and make any required adjustments or repairs promptly.

5. Can the type or thickness of material affect the bandsaw’s tendency to cut crooked?

Absolutely! The type and thickness of the material being cut can influence a bandsaw’s tendency to cut crooked. Certain materials may have inherent characteristics that make them more prone to causing crooked cuts. For example, dense or resinous woods can put more strain on the blade and lead to drifting or crooked cuts. Similarly, thick or heavy materials may require adjustments to the bandsaw’s feed rate and blade tension to prevent crooked cuts.

It’s important to understand the characteristics of the material you are cutting and adjust your bandsaw accordingly. Experiment with different blade types, tooth configurations, and cutting speeds to find the optimal setup for the specific material. Taking the time to understand and adapt to the material’s behavior can greatly improve your bandsaw’s cutting accuracy and minimize the occurrence of crooked cuts.

Summary

So, if your bandsaw is cutting crooked, there are a few common reasons why. First, make sure your blade is properly tensioned and aligned. Check for any damage or dullness on the blade. Next, take a look at your guides and bearings to ensure they are properly adjusted. Additionally, make sure your table is flat and not warped. Finally, pay attention to your feed rate and how you are handling the material. By addressing these issues, you can get your bandsaw cutting straight and smooth again.

Remember, it’s important to regularly maintain your bandsaw to ensure optimal performance. Make sure to follow the manufacturer’s instructions for setup and maintenance. With a little bit of care and attention, you’ll be able to cut with precision and accuracy every time.