When it comes to woodworking, there’s nothing worse than a loose circular saw blade. You’re all set to make precise cuts, only to find your blade wobbling around like a spooked squirrel. So, why is your circular saw blade loose? Let’s dive right in and find out!

Picture this: you’re ready to tackle a woodworking project, armed with your trusty circular saw. But as soon as you start cutting, you notice something’s not quite right. The blade seems to be moving in ways it shouldn’t, causing your cuts to be less precise and potentially dangerous. What’s going on?

Well, my friend, there are a few reasons why your circular saw blade might be loose. One common culprit is a loose arbor nut, which is the nut that holds the blade in place. If this nut isn’t tightened properly or has come loose over time, your blade will feel wobbly and unstable.

But a loose arbor nut isn’t the only possible cause. Sometimes, the blade itself may not be installed correctly, or the saw’s blade clamp might need some adjusting. Or perhaps there’s a buildup of sawdust or debris between the blade and the saw, preventing a tight fit.

Don’t worry, though! We’ve got you covered. In the rest of this article, we’ll explore each of these issues in more detail and give you simple steps to fix them. So, let’s tighten that blade and get back to making those smooth, clean cuts you love!

Is your circular saw blade loose and giving you trouble? Don’t worry, we’ve got the answers! There could be a few reasons why this happens:

- Loose arbor nut: Ensure that the nut securing the blade is tightly fastened.

- Worn arbor hole: Check if the blade’s hole is excessively worn, causing a loose fit.

- Incorrect blade installation: Make sure the blade is properly seated on the arbor.

- Warped blade: A bent or warped blade can cause instability.

- Damaged arbor: Inspect the arbor for any signs of damage.

Why is My Circular Saw Blade Loose?

When working with a circular saw, one of the most frustrating issues is having a loose blade. This can compromise the safety and efficiency of your cuts, not to mention the frustration it can cause. If you’ve ever experienced a loose circular saw blade, you’re likely wondering what causes it and how to fix it. In this article, we’ll explore the reasons behind a loose circular saw blade and provide practical solutions to prevent and resolve this issue.

1. Incorrect Blade Installation

One common reason for a loose circular saw blade is incorrect installation. If the blade is not properly tightened and secured in the arbor, it can result in wobbling and looseness during use. When installing a circular saw blade, it’s important to ensure that it is seated correctly in the arbor and tightened securely. Follow the manufacturer’s instructions for proper installation, which typically involve using a wrench to tighten the arbor nut securely.

To prevent this issue, always double-check the tightness of the blade before every use. If you notice any wobbling or shaking while the saw is running, stop immediately and re-tighten the blade. Regular maintenance and inspection of the blade’s condition and tightness can help prevent this issue from occurring.

2. Worn or Damaged Arbor Nut

Another potential cause of a loose circular saw blade is a worn or damaged arbor nut. The arbor nut is responsible for holding the blade in place on the saw’s arbor. Over time, the arbor nut can become worn or damaged, resulting in a loose blade. Inspect the arbor nut for any signs of wear, such as stripped threads or damage. If you notice any issues, replace the arbor nut with a new one to ensure proper blade tightness.

Regularly checking the condition of the arbor nut and replacing it when necessary can help prevent a loose circular saw blade. It is also important to ensure that the arbor nut is the correct size for your saw’s arbor. Using an incorrect or poorly fitting arbor nut can lead to blade looseness and compromise safety.

3. Dull or Damaged Blade

A dull or damaged blade can also contribute to blade looseness. When the blade is not sharp or is damaged, it can put additional strain on the saw, causing it to vibrate and the blade to become loose. Inspect the condition of your circular saw blade regularly. Look for signs of wear, such as dull teeth or missing carbide tips.

If you notice any damage or dullness, it’s essential to replace the blade with a new one. Using a sharp and properly maintained blade not only helps prevent a loose blade but also ensures clean and efficient cuts. Remember to follow the manufacturer’s recommendations for blade maintenance and sharpening.

4. Excessive Vibration

Excessive vibration during saw operation can also lead to a loose blade. Vibrations can be caused by various factors, such as an unbalanced blade, motor issues, or alignment problems. Regularly inspect your circular saw for any signs of vibration. Check for loose components, damaged parts, or misalignment.

If you identify any sources of excessive vibration, address them promptly to prevent blade looseness. This may involve balancing the blade, repairing or replacing faulty parts, or adjusting the saw’s alignment. Regular maintenance and proper handling of the circular saw can significantly reduce the risk of excessive vibrations and a loose blade.

5. Insufficient Blade Tension

Insufficient blade tension can also lead to a loose circular saw blade. The tensioning mechanism of the saw, such as a tensioning knob or lever, may not be properly adjusted. Refer to your saw’s user manual for instructions on how to adjust the blade tension correctly.

Ensure that the saw’s tensioning mechanism is properly adjusted to provide the necessary tension for the blade. A properly tensioned blade will have minimal play and be held securely in place, minimizing the risk of it coming loose during operation.

6. Use of Incorrect Blade Type

Using an incorrect blade type for your specific application can also result in a loose blade. Circular saw blades are designed for various materials and cutting tasks, such as wood, metal, or masonry. Using a blade that is not appropriate for the material being cut can cause excessive strain and vibration, leading to a loose blade.

Always select the correct blade for the material you are cutting. Check the blade’s specifications to ensure it is suitable for the task at hand. Using the right blade not only ensures clean and accurate cuts but also minimizes the risk of blade looseness.

Preventing and Resolving Circular Saw Blade Looseness

Now that we’ve explored the various causes of a loose circular saw blade, let’s discuss some preventive measures and solutions to resolve this issue:

Regular Maintenance and Inspection

Perform regular maintenance on your circular saw, including blade inspections, tightening of components, and lubrication of moving parts. Inspect the blade before each use and ensure it is securely tightened in the arbor.

Proper Blade Installation

Always follow the manufacturer’s instructions for installing the blade correctly. Use a wrench to tighten the arbor nut securely, ensuring the blade is seated properly in the arbor.

Replace Worn or Damaged Parts

If you notice any worn or damaged parts, such as the arbor nut or blade, replace them promptly. Using worn or damaged parts can lead to blade looseness and compromise saw safety.

Use the Correct Blade

Choose the appropriate blade for the material you are cutting. Using the wrong blade type can result in excessive strain and vibration, leading to a loose blade.

Address Excessive Vibration

If you experience excessive vibration during saw operation, identify and address the source promptly. This may involve balancing the blade, repairing or replacing faulty parts, or adjusting the saw’s alignment.

Caution and Safety

Always prioritize safety when operating a circular saw. Wear appropriate protective gear, follow safety guidelines, and exercise caution to prevent accidents and injuries.

By implementing these preventive measures and solutions, you can minimize the risk of a loose circular saw blade and ensure safe and efficient cutting operations. Remember to consult the manufacturer’s instructions and seek professional assistance if needed.

Key Takeaways: Why is My Circular Saw Blade Loose?

- Your circular saw blade may be loose due to a loose arbor nut, so make sure to tighten it properly.

- If the arbor hole in the blade is too large for the arbor shaft, it can cause the blade to become loose.

- Uneven or worn arbor washers can also contribute to a loose circular saw blade.

- Inspect the blade’s arbor shaft for any damage or wear that could cause the blade to become loose.

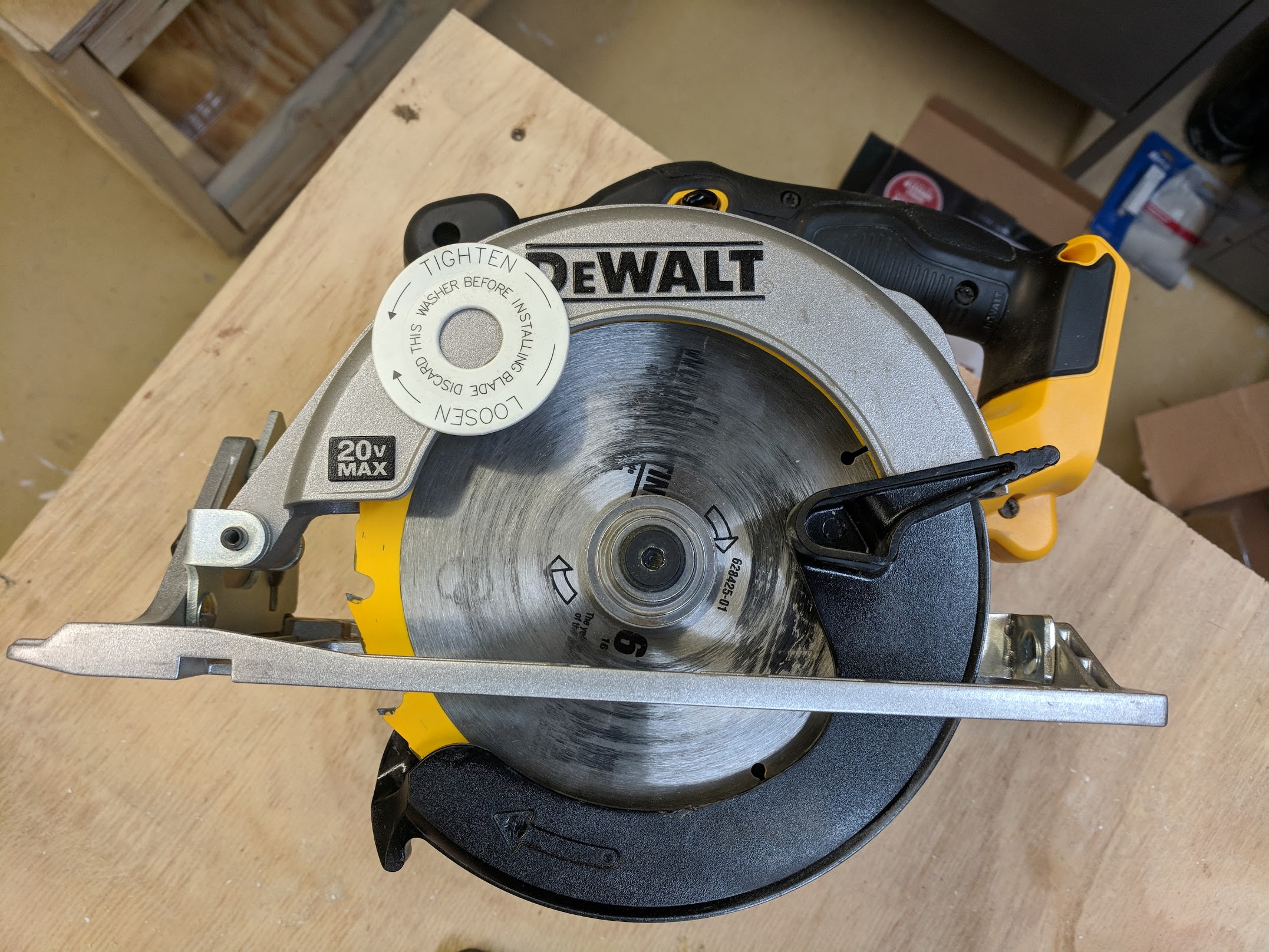

- Using a blade stabilizer or a stabilizing washer can help prevent the blade from getting loose during operation.

Frequently Asked Questions

In this section, we will address common concerns related to circular saw blades becoming loose during operation.

What could cause my circular saw blade to become loose?

There are a few reasons why your circular saw blade may become loose. One possibility is that the arbor nut, which holds the blade in place, has become loose due to vibrations during use or if it was not tightened properly. Another reason could be that the blade itself is worn or damaged, which can lead to it becoming loose over time. It’s also important to check if the blade is compatible with your saw, as using the wrong size or type of blade can cause it to become loose.

To ensure your circular saw blade stays securely in place, always check and tighten the arbor nut before and during use. Additionally, inspect the blade regularly for any signs of wear or damage and replace it if necessary. Using a blade that is specifically designed for your saw will also help prevent it from becoming loose.

Can a loose circular saw blade be dangerous?

Yes, a loose circular saw blade can be extremely dangerous. When a blade is loose, it can wobble or even detach from the saw during operation, increasing the risk of accidents and injuries. A loose blade can cause kickback, which is when the blade forcefully pushes the saw back towards you. This can result in loss of control and potentially serious harm.

It’s crucial to always ensure that your circular saw blade is securely tightened before using it. Regularly inspecting the blade and replacing it when necessary is also important to guarantee safe operation. If you notice any issues with your saw blade becoming loose, address them immediately to minimize the risk of accidents.

How can I prevent my circular saw blade from becoming loose?

To prevent your circular saw blade from becoming loose, there are a few steps you can take. First, make sure to properly tighten the arbor nut. Use a wrench or the proper tool provided with your saw to securely tighten the nut, ensuring the blade is held firmly in place.

Regular maintenance is also key. Inspect the blade for signs of wear or damage, and replace it if necessary. Make sure to use a blade that is compatible with your saw, as using the wrong size or type can cause it to become loose. Finally, always operate your saw with care, avoiding excessive force or sudden movements that could put additional strain on the blade.

Is there a recommended torque setting for tightening the arbor nut?

While there may not be a specific torque setting recommended for tightening the arbor nut on your circular saw, it’s important to ensure that it is tightened securely. Using a wrench or the appropriate tool, tighten the nut firmly until the blade is held in place with no wobble or movement.

It’s important to strike a balance between tight enough to keep the blade securely in place and not overly tight, which could potentially damage the nut or the saw. If you’re unsure, consult your saw’s user manual or contact the manufacturer for guidance on properly tightening the arbor nut.

Are there any safety precautions I should take if my circular saw blade becomes loose?

If you notice that your circular saw blade has become loose during use, it’s important to take immediate action to prevent any accidents or injuries. Stop using the saw and turn it off before attempting to address the issue.

First, visually inspect the arbor nut and ensure that it is tightened securely. If it has become loose, use a wrench or the appropriate tool to tighten it. Additionally, check the blade itself for any signs of wear, damage, or misalignment. If the blade is damaged or worn, replace it with a new one before continuing to use the saw.

Causes for Blade Wobble

Summary

So, if your circular saw blade is loose, you should check a few things. First, make sure the arbor nut is tightened properly. If it’s loose, use the wrench to tighten it clockwise. Also, check if the blade is inserted correctly and not upside down. Lastly, examine the blade for any damage or wear, as this can cause it to become loose. Remember to always follow safety guidelines and get help from an adult if needed. Stay safe and happy sawing!

In conclusion, a loose circular saw blade can be fixed by tightening the arbor nut, making sure the blade is inserted correctly, and checking for any damage. Safety should always be a priority and seeking assistance from an adult is recommended. Keep practicing and enjoy your woodworking projects!