Is your table saw acting sluggish and not performing at its best? Wondering why it’s suddenly bogging down? Well, you’re in the right place! In this article, we’ll delve into the reasons behind why your table saw might be experiencing this issue and what you can do about it.

So, why is your table saw bogging down? There could be a few factors at play here. From a dull blade to improper motor settings, we’ll explore the common culprits that can cause your trusty table saw to lose its cutting power.

Don’t worry, though. We’ve got your back! By understanding these potential causes, you’ll be equipped with the knowledge needed to diagnose and solve the problem, getting your table saw back in tip-top shape in no time. Let’s dive right in, shall we?

Is your table saw bogging down? Don’t worry, we’ve got the answers. When your table saw starts to slow down or struggle, there are a few common reasons why this might be happening. First, check your blade to make sure it’s sharp and clean. Next, inspect the motor and belts for any issues. Finally, make sure you’re using a suitable power source. By following these steps, you can troubleshoot and fix the problem, getting your table saw back up to speed in no time.

Why Is My Table Saw Bogging Down? Common Causes and Solutions

If you’re experiencing your table saw bogging down during use, it can be frustrating and potentially dangerous. Understanding the possible causes and solutions for this issue is essential for maintaining optimal performance and safety. In this article, we will explore the reasons behind a table saw bogging down and provide practical tips and solutions to help you address the problem effectively.

Poor Blade Alignment

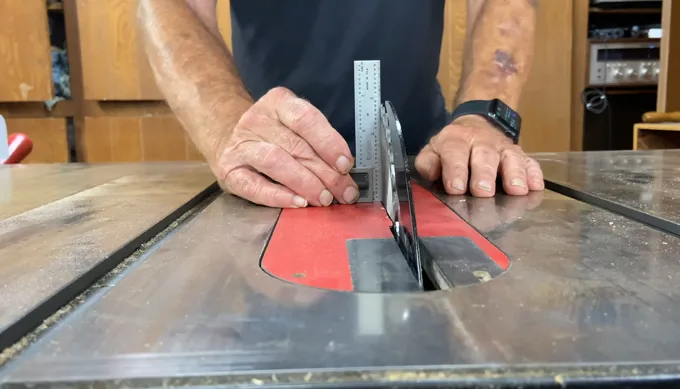

Poor blade alignment is one of the most common causes of a table saw bogging down. When the blade is not properly aligned with the table or miter slots, it can create excessive friction and resistance, causing the motor to work harder. To check the alignment, start by unplugging your table saw and removing the blade guard. Use a straight-edge to measure the distance between the blade and the miter slot at different points. If you notice any variations, you may need to adjust the alignment using the saw’s adjustment mechanisms or consult the manufacturer’s guide for specific instructions. Proper alignment can significantly improve the saw’s performance and prevent bogging down.

Another consideration regarding blade alignment is the blade tilt. If your blade is tilted at an angle, it can cause more resistance when cutting, leading to bogging down. Check that the blade is set to a proper 90-degree angle, or the angle required for the specific cut you’re making. Adjust the blade tilt as necessary to ensure optimal performance.

Dull or Improperly Set Blade

A dull or improperly set blade can also contribute to table saw bogging down. Over time, the cutting teeth on the blade can become dull, resulting in inefficient cutting and increased strain on the motor. It’s important to regularly inspect and sharpen your table saw blades to maintain their cutting efficiency. Additionally, make sure the blade is properly set to the appropriate depth and tension. A blade set too deep or with excessive tension can create unnecessary resistance and cause the motor to bog down. Follow the manufacturer’s recommendations for blade maintenance and adjustment to ensure optimal performance.

Inadequate Power Supply

Insufficient power supply is another common factor behind table saws bogging down. Table saws typically require a significant amount of power to operate efficiently, and if the power supply is inadequate, it can result in the motor struggling and bogging down. Ensure that your table saw is connected to a dedicated circuit with the appropriate voltage and amperage capacity. Avoid using extension cords or sharing outlets with other high-powered tools or appliances, as this can reduce the available power supply. If you frequently experience bogging down, consider upgrading your power supply or consulting an electrician to evaluate and optimize your electrical setup.

Clogged or Dirty Dust Collection System

A clogged or dirty dust collection system can impede the performance of your table saw and contribute to bogging down. When sawdust accumulates in the dust collection system, it can restrict airflow and cause overheating, which may result in the motor struggling to maintain its speed and power. Regularly clean and maintain your dust collection system to ensure proper airflow and efficient dust removal. Clear out any debris or obstructions in the dust collection ports, hoses, and filters. Consider using a dust separator or a shop vacuum with strong suction to enhance the effectiveness of your dust collection system and prevent clogs that can lead to bogging down.

Overloading the Saw

Overloading the table saw is another common mistake that can cause a bogging down issue. Pushing the saw too hard by feeding stock too quickly or attempting to cut materials beyond the capabilities of the saw can overload the motor, causing it to struggle and potentially bog down. Remember to always work within the recommended capacity of your table saw. Refer to the manufacturer’s guidelines to determine the maximum thickness and type of materials that your saw can handle. When making cuts, apply even pressure and feed the stock at a steady pace to avoid overloading the motor and experiencing bogging down.

Insufficient Lubrication

Inadequate lubrication can also lead to table saw bogging down. Without proper lubrication, the moving parts of the saw can experience increased friction and resistance, impeding their function and causing the motor to work harder. Regularly lubricate the necessary components, such as the arbor bearings, elevation and tilt mechanisms, and any other moving parts specified by the manufacturer. Use the appropriate lubricant recommended for your table saw, and follow the instructions for application. Proper lubrication will reduce friction, improve performance, and help prevent bogging down.

Worn or Damaged Motor

If you’ve checked and addressed all the aforementioned causes and your table saw still bogs down, it may be an indication of a worn or damaged motor. Over time, the motor can wear out or suffer damage due to factors such as excessive heat, overload, or general wear and tear. A worn or damaged motor may struggle to generate sufficient power to maintain its speed, resulting in bogging down. In this case, it’s advisable to consult a professional or the manufacturer for further assessment and potential motor replacement.

Additional Considerations for Optimal Table Saw Performance

Understanding and addressing the causes of a table saw bogging down is key to ensuring optimal performance and prolonging the lifespan of your equipment. Here are a few additional tips and considerations to keep in mind:

Regular Maintenance:

Perform regular maintenance on your table saw, including cleaning, lubricating, blade sharpening, and alignment checks. This will help prevent issues and ensure smooth operation.

Proper Technique:

Use proper cutting techniques, such as utilizing a push stick or push block to feed stock and preventing kickback. This will help reduce strain on the motor and minimize the risk of bogging down.

Dust Collection:

Invest in a reliable dust collection system or use appropriate dust extraction methods to keep the work area clean and prevent sawdust buildup that can affect the saw’s performance.

Quality Blades:

Investing in high-quality, well-maintained blades suited for your specific cutting needs can significantly improve the performance of your table saw and reduce the likelihood of bogging down.

Know Your Limits:

Always work within the limits of your table saw and avoid pushing it beyond its capabilities. Pushing the saw too hard or attempting to cut materials it isn’t designed for can lead to bogging down, increased wear and tear, and potential safety hazards.

Safety First:

Always prioritize safety when working with a table saw. Wear appropriate protective gear, follow safety guidelines, and never hesitate to seek professional assistance if you’re unsure about a particular issue or maintenance task.

By understanding the common causes and implementing the appropriate solutions, you can maintain optimal performance, prevent table saw bogging down, and ensure a safer and more efficient woodworking experience.

Key Takeaways: Why is my table saw bogging down?

- A table saw can bog down due to a dull blade, incorrect blade height, or improper feeding technique.

- A build-up of sawdust in the motor or a faulty motor can also cause a table saw to bog down.

- Using the wrong type of wood or pushing the saw too hard can lead to bogging down.

- Regular maintenance, such as cleaning the saw and ensuring proper blade alignment, can prevent bogging down.

- When experiencing bogging down, check the blade, feeding technique, and motor for any issues before continuing to use the saw.

Frequently Asked Questions

Are you facing issues with your table saw bogging down? Don’t worry, we’ve got you covered! Check out these answers to common questions about why table saws might bog down and how you can resolve the issue.

1. What are some possible reasons why my table saw is bogging down?

There are several factors that can cause your table saw to bog down. One common reason is a dull blade, which is unable to cut through the material smoothly and puts strain on the motor. Another reason could be improper alignment of the blade, causing it to drag and slow down. Additionally, feeding the material too quickly or using a blade with a low tooth count can also lead to the saw bogging down. Finally, a worn-out motor or power supply issues can contribute to the problem as well.

To determine the exact cause, inspect the blade for sharpness and check that it is properly aligned. Make sure to feed the material at a steady pace, giving the blade enough time to cut through. If the issue persists, consider getting a professional evaluation to identify any motor or power supply problems.

2. How can I prevent my table saw from bogging down?

To prevent your table saw from bogging down, there are a few steps you can take. First and foremost, ensure you are using a sharp and suitable blade for the material you’re cutting. A blade with a higher tooth count will provide smoother cuts. Proper alignment of the blade is crucial as well, so regularly check and adjust it if needed. It’s also important to maintain a consistent feed rate, allowing the blade to work efficiently. Additionally, keeping the saw clean and free from debris will help prevent any unnecessary strain on the motor.

Regular maintenance of your table saw is key to its performance. Lubricate the moving parts and check the motor for any signs of wear. Clean the dust collection system to prevent clogs and overheating. By following these preventive measures, you can keep your table saw running smoothly and avoid the frustration of it bogging down during your projects.

3. Can a faulty power supply cause a table saw to bog down?

Yes, a faulty power supply can indeed cause a table saw to bog down. If the power supply does not provide a consistent flow of electricity, it may result in insufficient power reaching the motor, causing it to struggle and bog down. In such cases, you may notice a drop in speed or a loss of power, even when the saw is not under heavy load.

If you suspect a power supply issue, start by checking the power cord for any visible damage or loose connections. Ensure that the table saw is plugged into a dedicated circuit, free from other high-powered devices that can cause power fluctuations. If the problem persists, it’s recommended to consult an electrician to evaluate the power supply and make any necessary repairs or adjustments.

4. Does humidity affect a table saw’s performance?

Humidity can indeed affect a table saw’s performance, including the potential for it to bog down. High humidity levels can cause wood to absorb moisture from the air, leading to swelling and increased density. This can make the wood harder to cut through, putting additional strain on the saw’s motor. As a result, the saw may slow down or struggle to make clean cuts.

If you’re working in a humid environment, it’s essential to acclimate your wood to the same humidity level as the surroundings before starting your project. This allows the wood to stabilize and reduce the chances of it bogging down the table saw. Consider using a dehumidifier or working in a well-ventilated area to control humidity levels. Additionally, periodically cleaning and lubricating the saw’s moving parts can help maintain its performance in humid conditions.

5. When should I consider seeking professional help for my table saw bogging down?

If you’ve tried all the troubleshooting steps and your table saw still continues to bog down, it may be time to seek professional help. A professional technician can diagnose the root cause of the issue and provide the necessary repairs or maintenance. They have the expertise to inspect and repair the motor, power supply, or other components that could be contributing to the problem.

By contacting a professional, you can save time and ensure that the problem is correctly addressed, eliminating any risk of damaging the saw further. Additionally, a professional can offer guidance on preventive maintenance and share best practices to avoid future bogging-down issues. Remember, it’s essential to prioritize safety and consult a qualified expert when needed.

Summary

If your table saw is slowing down or getting stuck, there are a few possible reasons. First, check if the blade is dull or dirty. Cleaning or sharpening it can help. Also, make sure the wood is properly supported and not putting too much strain on the saw. Lastly, check the motor and belt for any issues.

Remember, it’s important to take proper safety precautions when working with power tools. Always wear protective gear and be cautious of your surroundings. Happy woodworking!