Have you ever wondered why plywood is measured in 32? Well, you’re about to find out! In this article, we’re going to delve into the fascinating world of plywood measurements and uncover the reasons behind this unique standard. So let’s dive right in and satisfy your curiosity!

When it comes to plywood, there are different thicknesses available, ranging from 1/8 inch to 1 inch. But why is 32 used as the measurement? Is there a special reason behind it or just a random choice? We’ll explore that in a moment.

But first, let’s get a better understanding of what plywood actually is. Plywood is a versatile building material made from thin layers of wood veneer glued together. It’s known for its strength, durability, and ability to resist warping. Now, back to the main question at hand: why 32? Let’s uncover the mystery together!

Why is Plywood Measured in 32?

Plywood is an essential material used in construction, crafting, and furniture-making. It comes in various sizes and measurements, but one common measurement that often raises questions is why plywood is measured in 32. In this article, we will explore the origins of this measuring convention and uncover the reasons behind it. Whether you’re an aspiring DIY enthusiast or a professional carpenter, understanding the reasoning behind plywood measurements can enhance your woodworking projects and help you make more informed decisions. Let’s dive in!

The History of Plywood Measurement

Prior to exploring why plywood is measured in 32, it’s important to understand the history of this measurement convention. The origins of plywood can be traced back to ancient Egypt, where thin wooden veneers were used to create furniture and decorative items. Over time, plywood evolved into a more advanced construction material, particularly during World War II when it was widely used in military applications. As the demand for plywood increased, standardization became necessary to ensure consistency and compatibility in the construction industry.

Standardization efforts led to the creation of various thickness measurements, including the 32nd-inch measurement. This 32nd-inch measurement system is commonly used in North America and is based on the Imperial system of measurement. By dividing an inch into 32 equal parts, plywood manufacturers were able to produce plywood sheets with consistent thicknesses, allowing for easier integration into construction projects and ensuring compatibility with other materials.

The Benefits of the 32nd-Inch Measurement System

The decision to measure plywood in 32 brings several benefits to both manufacturers and end-users. Let’s explore some of these benefits:

- Consistency: By using a standardized measurement system, plywood sheets of the same thickness can be easily reproduced, ensuring consistent results in construction projects.

- Compatibility: The 32 measurement system allows plywood to be seamlessly integrated with other construction materials, such as framing and lumber, ensuring a smooth and stable structure.

- Ease of Use: The 32nd-inch measurement system allows for precise and accurate installations, as it aligns with common building practices and ensures a snug fit with other components.

Understanding Plywood Thickness in the 32nd-Inch Measurement System

Now that we understand why plywood is measured in 32, let’s take a closer look at how to interpret and understand plywood thicknesses within this measurement system:

Plywood sheets with a 32nd-inch measurement are commonly denoted by fractions, such as 1/32, 1/16, 1/8, 1/4, and so on. These fractions represent the thickness of the plywood sheet in relation to the 32nd-inch measurement system. For example, a plywood sheet labeled as 1/8 would mean that it is 1/8 of an inch thick.

It’s important to note that while the 32nd-inch measurement system is widely used, there are alternative measurement systems in different regions and countries. For example, in Europe, metric measurements are commonly used, such as millimeters or centimeters.

Choosing the Right Plywood Thickness

When selecting plywood for your projects, it’s crucial to choose the right thickness to ensure structural integrity and desired results. The appropriate thickness will depend on the specific use and requirements of your project. Here are a few tips to guide you:

- Consider the Application: Determine the intended use of the plywood, whether it’s for sheathing, flooring, cabinetry, or crafting. Different applications may require different thicknesses for optimal performance.

- Consult Building Codes and Standards: If you’re working on a construction project, familiarize yourself with local building codes and standards that dictate the minimum plywood thickness for specific applications.

- Seek Expert Advice: If you’re unsure about the appropriate plywood thickness for your project, consult with professionals or experienced woodworkers who can provide guidance based on their expertise.

Impact of Plywood Measurements on Project Success

Understanding why plywood is measured in 32 can greatly contribute to the success of your woodworking projects. By selecting the right plywood thickness, ensuring compatibility, and utilizing precise measurements, you can achieve better structural integrity, smoother installations, and overall superior project outcomes. So the next time you embark on a woodworking adventure, take a moment to appreciate the significance of plywood measurements in enhancing your craftsmanship.

The Evolution of Plywood Measurement

Over time, the measurement of plywood has evolved to meet the changing needs of the construction industry and adapt to new technologies. Let’s explore the different phases of plywood measurement evolution:

New Innovations in Plywood Measurement

In recent years, there have been exciting new innovations in plywood measurement that have further enhanced the versatility and efficiency of this construction material. Here are a few examples:

Plywood Measurement: Looking Ahead

As technology and construction practices continue to evolve, so will the measurement of plywood. Advancements in precision engineering, automation, and manufacturing processes will likely lead to even more accurate and standardized measurement systems in the future. Stay tuned for exciting developments that will shape the future of plywood measurement!

Remember, understanding the ins and outs of plywood measurement is key to maximizing the potential of this versatile material in your construction and crafting projects. By comprehending the history, benefits, and applications of measuring plywood in 32, you can confidently select the right thickness, ensure compatibility, and achieve outstanding results. So go ahead, embrace the world of plywood and create something amazing!

Key Takeaways – Why is plywood measured in 32?

- Plywood is measured in 32 because it refers to the thickness of the plywood in fractions of an inch.

- 32 equals 1/32 of an inch, which is the smallest common measurement used for plywood thickness.

- Using fractions of an inch makes it easier to calculate and discuss plywood thickness accurately.

- Plywood thickness can vary based on the number of sheets glued together, and 32 provides a convenient standard.

- Understanding the measurement system helps when choosing the right plywood for a project.

Frequently Asked Questions

Welcome to our FAQ section where we answer common questions about why plywood is measured in 32.

1. How is plywood measured in the context of “32”?

Plywood is measured in 32 because it refers to the thickness of the plywood panel. The “32” measurement represents 1/32 of an inch, which is the standard unit used for measuring plywood thickness. This measurement is also known as a “ply” or “ply rating,” indicating the number of sheets used to make up the plywood panel. For example, a 4-ply plywood panel would have four sheets laminated together, resulting in a thickness of 1/8 inch.

By using the “32” measurement, it allows for greater flexibility in specifying plywood thickness, accommodating a wider range of applications and construction needs. It provides a standard reference point for manufacturers, builders, and consumers to ensure consistency in plywood thickness across the industry.

2. Does the “32” measurement apply to all types of plywood?

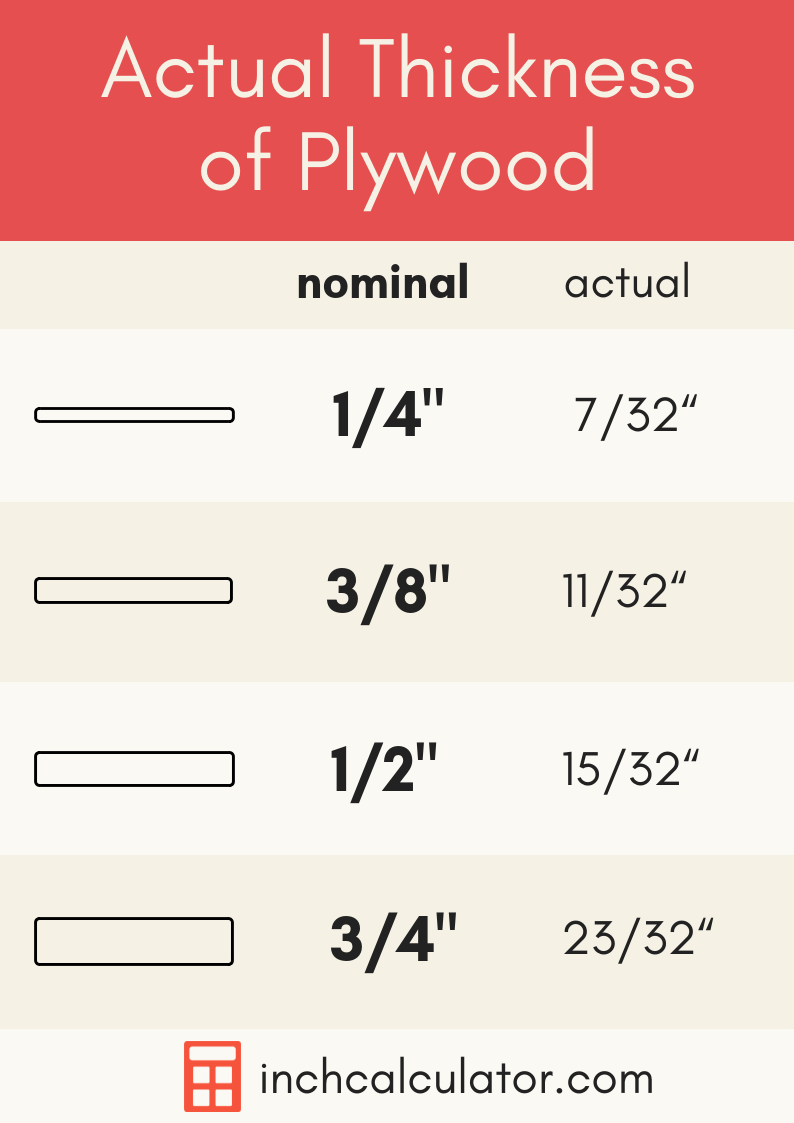

Yes, the “32” measurement applies to most types of plywood. Whether it’s structural plywood, hardwood plywood, or marine plywood, the “32” measurement is commonly used to indicate the thickness. However, it’s essential to note that plywood can come in varying thicknesses, such as 1/4 inch, 1/2 inch, 3/4 inch, etc.

While the “32” measurement is the standard unit for plywood thickness, variations can occur based on the specific type and intended usage of the plywood. Therefore, it’s always important to refer to the manufacturer’s specifications or seek professional advice to ensure the plywood meets the required thickness for your project.

3. What are the advantages of measuring plywood in “32”?

Measuring plywood in “32” offers several advantages. Firstly, it provides a standardized method for specifying and manufacturing plywood thickness, ensuring consistency and accuracy throughout the industry. This standardization simplifies the procurement and use of plywood for builders, manufacturers, and consumers.

Additionally, measuring plywood in “32” allows for greater flexibility and precision in meeting specific project requirements. Different thickness options are available, ranging from 1/32 of an inch up to several inches, allowing for customization based on structural needs, weight considerations, and other factors.

4. Can plywood be measured using different units?

While the “32” measurement is the most common unit for measuring plywood thickness, other measurement systems may be used in some regions or industries. For example, metric units like millimeters or centimeters are sometimes used, especially in countries where the metric system is the standard. In such cases, the measurement would be converted to the nearest equivalent in the chosen unit of measurement.

However, it’s essential to note that regardless of which unit of measurement is used, the fundamental concept of plywood thickness remains the same. Whether measured in “32” or metric units, the key is to ensure accuracy, consistency, and adherence to industry standards when specifying and using plywood in construction or manufacturing projects.

5. How do I determine the thickness of plywood in “32”?

To determine the thickness of plywood in “32,” you can count the number of plies or layers within the panel. Each ply adds approximately 1/32 of an inch to the total thickness. For example, if a plywood panel has 7 plies, it would have a thickness of approximately 7/32 of an inch.

However, it’s important to note that variations in plywood manufacturing processes, such as variations in adhesives, may impact the actual thickness. Therefore, it’s recommended to rely on the manufacturer’s specifications and guidelines to accurately determine the plywood’s thickness in “32” in order to ensure proper selection and usage for your project.

Summary

So, here’s what we learned about why plywood is measured in 32: it goes way back to the olden days when wood was measured by fractions. One 32nd of an inch was the thinnest a piece of wood could be measured accurately.

Nowadays, plywood is still measured in 32 because it’s just easier that way. It helps us know the thickness of the plywood without having to use long decimal numbers. So, next time you see plywood, remember that the measurements are based on fractions, and 32 is the magic number.