Have you ever wondered why the lathe is called the “father of all operations”? Well, let me tell you! The lathe is an amazing machine that has been around for centuries, and it has played a crucial role in shaping our world. In this article, we will explore the reasons behind the lathe’s prestigious title and uncover the fascinating history behind its significance.

So, what exactly makes the lathe the “father” of all operations? To put it simply, the lathe is a versatile and indispensable tool that forms the foundation of many other machining operations. It is capable of performing a wide range of tasks, such as cutting, drilling, facing, turning, and threading, making it an essential machine in various industries like manufacturing and engineering.

But why is it called the “father” specifically? Well, think of it like this: just as a father is responsible for nurturing and shaping the development of their children, the lathe has been instrumental in the birth and growth of other machines and operations. It has paved the way for countless innovations and is often the starting point for turning raw materials into intricate and functional products.

So, whether you’re a history enthusiast, a budding engineer, or simply curious about the world around you, join us as we delve into the fascinating world of the lathe and discover why it rightfully holds the esteemed title of the “father of all operations.” Let’s embark on this journey together and uncover the secrets of this remarkable machine!

Have you ever wondered why lathe is referred to as the “father of all operations”? Well, the lathe is a versatile machine that is widely used in various industries. It can perform a wide range of machining operations, including turning, boring, threading, and more. The lathe’s ability to shape and manipulate different materials with precision and efficiency has earned it the title of the “father of all operations.” Its importance and contribution to the manufacturing industry cannot be overstated.

Why Lathe is Called the Father of All Operations?

Lathe, often referred to as the “Father of All Operations,” holds a prominent position in the world of manufacturing and engineering. With its versatility and capability to perform a wide range of operations, the lathe machine has become an essential tool in various industries. In this article, we will explore the reasons behind why the lathe machine is bestowed with this honorable title.

Historical Significance of Lathe

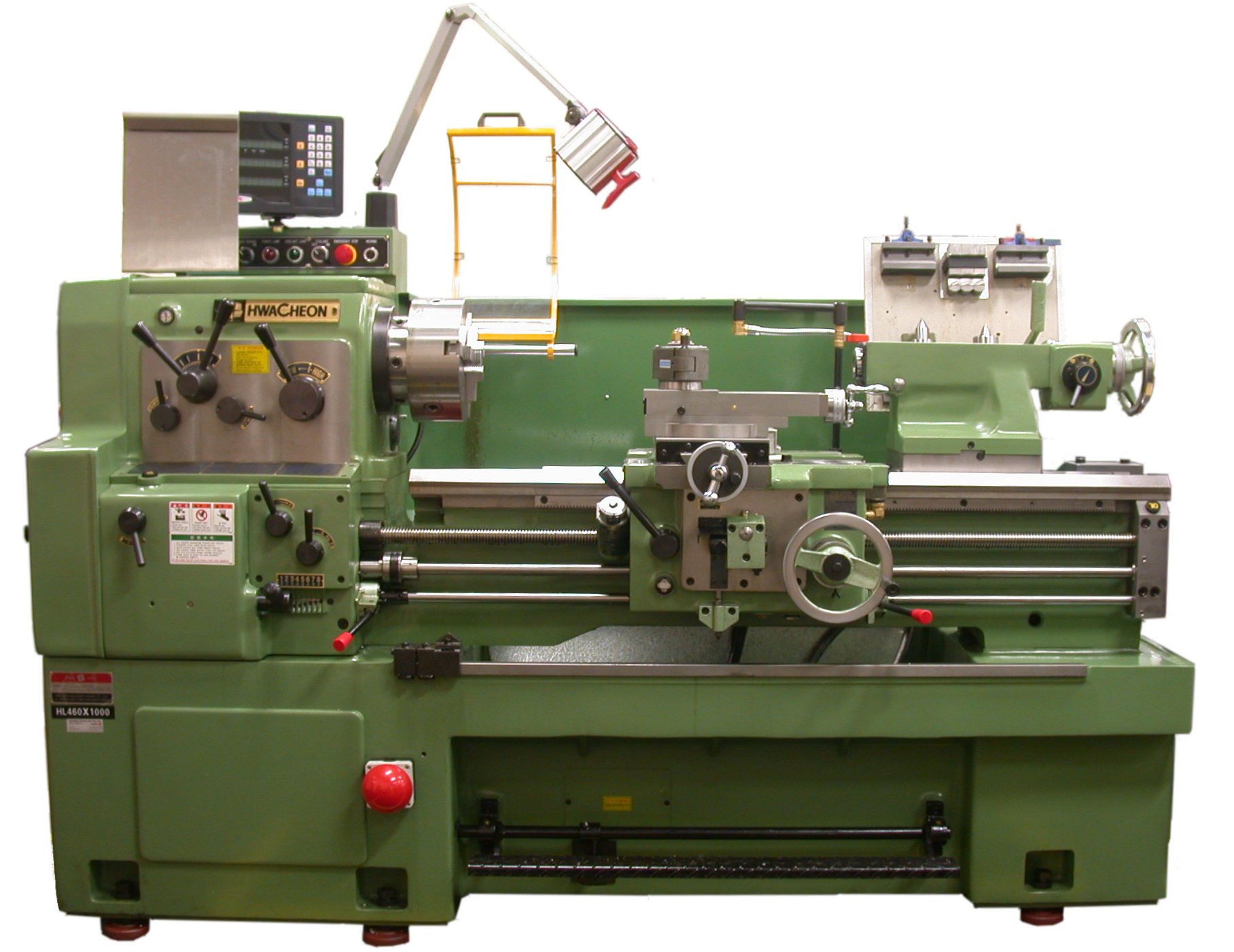

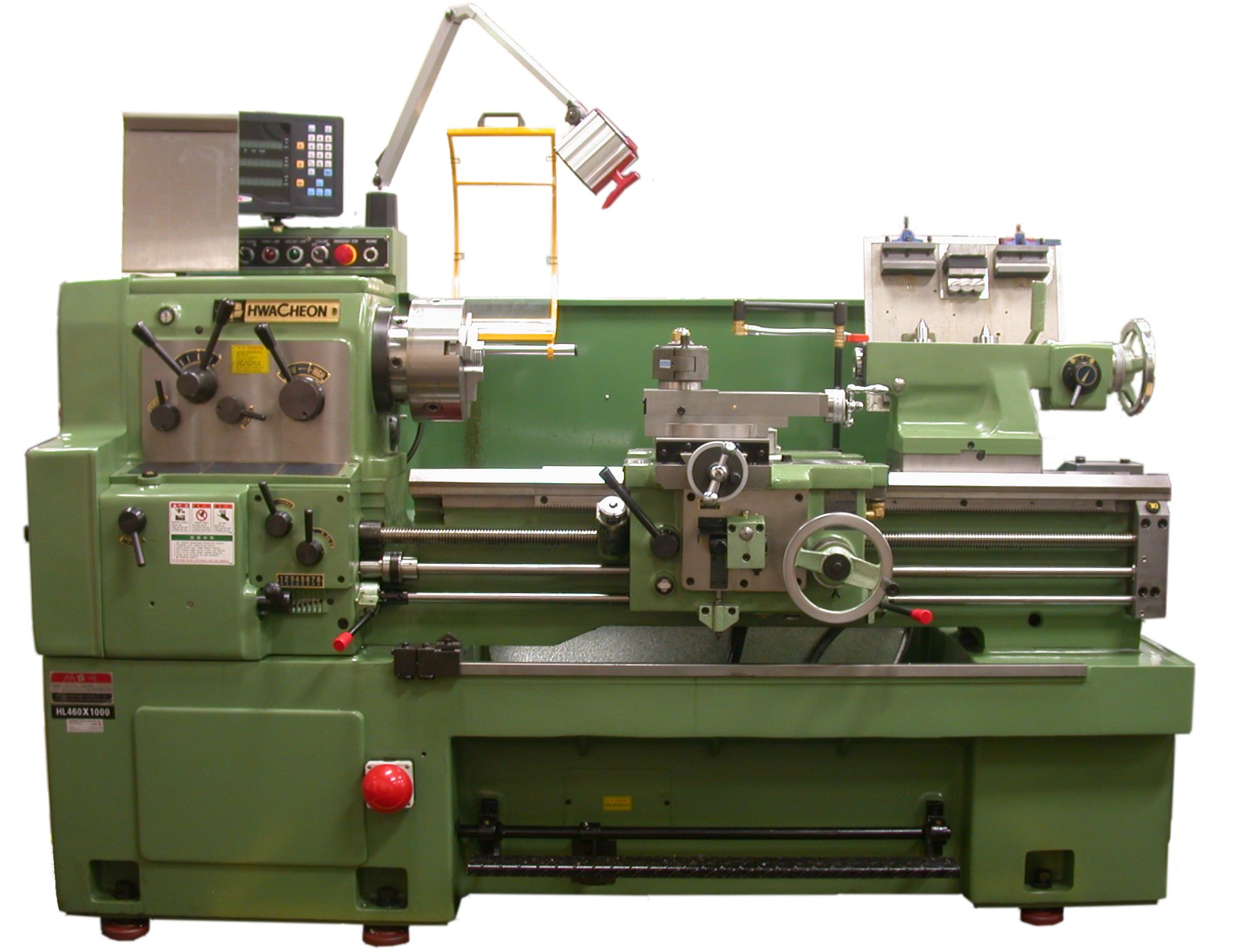

The history of the lathe dates back to ancient Egypt and Greece, where craftsmen utilized primitive versions of the machine for wood and metalwork. However, it was during the Industrial Revolution in the 19th century that the lathe machine underwent significant advancements. The introduction of power-driven machinery revolutionized the manufacturing process and led to the development of modern lathes.

The lathe machine played a crucial role during this period by enabling the production of various components and products on a large scale. Its ability to shape, cut, drill, and turn materials with precision made it an indispensable tool in the manufacturing industry. As technology progressed, the lathe machine continued to evolve, incorporating new features and capabilities, further solidifying its status as the “Father of All Operations.”

Versatility and Applications

One of the main reasons why the lathe machine is considered the “Father of All Operations” is its versatility. The lathe can perform numerous operations, making it a versatile tool for a wide range of applications. It can be used for shaping, cutting, drilling, sanding, knurling, and turning materials such as wood, metal, and plastic. This versatility makes the lathe an indispensable tool in industries such as automotive, aerospace, construction, and furniture manufacturing.

The lathe’s ability to create complex shapes and intricate designs makes it ideal for producing various components like shafts, cylinders, and threads. Its precision and accuracy ensure that these components meet the desired specifications, leading to high-quality products. Furthermore, the lathe machine’s adaptability allows operators to perform both simple and complex operations with ease, making it a valuable asset in any manufacturing setting.

The Lathe Machine and Automation

With the rise of automation and the integration of advanced technologies in manufacturing, the lathe machine has adapted to meet the changing demands of the industry. Today, computer numerical control (CNC) lathe machines have become prevalent, offering increased precision, efficiency, and productivity.

CNC lathes are equipped with computer-controlled systems that allow for automated operation and programming. This advancement has significantly enhanced the capabilities of the lathe machine, enabling it to produce intricate designs and complex geometries with utmost precision. CNC lathes have revolutionized industries such as aerospace and automotive, where high-quality components and parts are crucial.

In addition to CNC capabilities, modern lathes also incorporate features such as live tooling, multi-axis movement, and automatic tool changers. These advancements further boost the lathe machine’s ability to perform multiple operations and increase productivity.

Benefits of Using a Lathe Machine

Precision and Accuracy

The lathe machine is known for its ability to produce precise and accurate components. The controlled movements and adjustable settings allow for tight tolerances, ensuring that the final product meets the required specifications. This precision is essential in industries where quality and performance are of utmost importance.

Efficiency and Productivity

With its ability to perform multiple operations, the lathe machine offers enhanced efficiency and productivity. The integration of automation technologies further streamlines the manufacturing process, reducing human error and increasing output. This efficiency translates into cost savings and faster turnaround times.

Versatility and Adaptability

The versatility of the lathe machine allows for a wide range of applications and materials. It can be used to work on different shapes, sizes, and materials, making it a versatile tool for various industries. The adaptability of the lathe machine to changing technological advancements ensures that it remains a valuable asset in the ever-evolving manufacturing landscape.

Tips for Using a Lathe Machine

1. Safety First

Before using a lathe machine, always prioritize safety. Familiarize yourself with the machine’s safety features and use personal protective equipment like goggles and gloves. Follow proper operating procedures and adhere to all safety guidelines.

2. Understand the Material

Different materials require different cutting speeds, feed rates, and tooling. Before starting a lathe operation, ensure that you understand the properties of the material being worked on. Adjust the lathe machine’s settings accordingly to achieve optimal results.

3. Regular Maintenance

To ensure the longevity and optimal performance of the lathe machine, regular maintenance is essential. Clean the machine regularly, lubricate moving parts, and inspect for any signs of wear or damage. Addressing maintenance issues promptly can prevent breakdowns and extend the machine’s lifespan.

In conclusion, the lathe machine is rightfully called the “Father of All Operations” due to its historical significance, versatility, and adaptability in various industries. Its ability to perform multiple operations, precision, and the integration of advanced technologies like CNC have solidified its position as an indispensable tool in manufacturing. By understanding its capabilities and following proper operating procedures, users can harness the full potential of the lathe machine and achieve optimal results.

Key Takeaways: Why Lathe is Called Father of All Operations?

- A lathe is a machine used for shaping and cutting various materials.

- It is called the “father of all operations” because it is the oldest and most fundamental machine tool.

- Lathe operations include turning, facing, drilling, threading, and more.

- Lathe machines have been used for centuries and are still widely used today.

- With a lathe, craftsmen can create intricate and precise parts for various industries.

Frequently Asked Questions

Here are some commonly asked questions about why the lathe is called the father of all operations:

What is the significance of the lathe in manufacturing?

The lathe is considered the father of all operations because of its fundamental role in shaping and machining materials. It is a versatile machine tool that can perform various operations like cutting, drilling, facing, turning, and threading. With its rotating workpiece and stationary cutting tool, the lathe enables precise shaping and finishing of different materials, including wood, metal, and plastic.

Besides its versatility, the lathe is highly efficient and widely used in manufacturing industries. It allows for the production of intricate and complex parts with tight tolerances. Its ability to create symmetrical shapes and threads makes it a cornerstone of modern industrial processes, playing a crucial role in the production of items ranging from furniture to engine components.

How does the lathe impact different industries?

From automotive to aerospace and from construction to jewelry making, the lathe has a significant impact on various industries. In the automotive industry, the lathe is used to create engine parts, including pistons, crankshafts, and camshafts. In aerospace, it helps manufacture critical components like turbine blades and landing gear. The construction industry utilizes the lathe for shaping wooden beams and other structural elements.

The lathe also plays a crucial role in the production of musical instruments, including brass instruments and woodwinds. It assists in the creation of jewelry, such as rings, bracelets, and pendants. The medical field relies on the lathe for producing prosthetic limbs, dental implants, and surgical tools. With its wide-ranging impact, the lathe has rightfully earned the title of the father of all operations.

What are the advantages of using a lathe in manufacturing?

The lathe offers several advantages in manufacturing processes. Firstly, it provides exceptional precision, allowing for the creation of high-quality, finely finished parts. It can achieve tight tolerances, resulting in accurate and reliable components. Additionally, the lathe enables the production of symmetrical shapes and threads, ensuring functional and aesthetically pleasing products.

Secondly, the lathe enhances efficiency and productivity in manufacturing. Its versatility eliminates the need for multiple machines, saving time and resources. It can handle various operations, reducing setup and changeover times. Moreover, with the lathe’s automation capabilities, manufacturers can further optimize production processes, increasing output and reducing human error.

What skills are required to operate a lathe?

Operating a lathe requires a combination of technical skills and precision. Firstly, one must have a good understanding of machining principles, including tool geometry, cutting speeds, and feeds. This knowledge helps in selecting the appropriate cutting tools and optimizing machining parameters for different materials.

Additionally, operators need to interpret engineering drawings and blueprints accurately. They should be able to visualize the desired final part and translate it into specific machining instructions. Skillful hand-eye coordination and attention to detail are crucial to achieving precise and accurate machining results.

Can the lathe be used for both small-scale and large-scale manufacturing?

Yes, the lathe is highly versatile and can be utilized in both small-scale and large-scale manufacturing. For small-scale production or prototyping, lathes offer the flexibility to create custom parts with minimal setup time. They can be easily programmed or manually controlled to produce unique components or small batches.

At the same time, lathes are widely used in large-scale manufacturing due to their efficiency and ability to handle high-volume production. With automated features, such as computer numerical control (CNC), lathes can operate continuously, producing large quantities of parts consistently and accurately. This scalability makes the lathe a valuable machine tool in both small workshops and large factories.

Summary

The lathe machine is often called the “father of all operations” because it serves as the foundation for many other machines and processes. It has been around for centuries and continues to play a vital role in manufacturing and craftsmanship today. The lathe machine is used to shape and cut materials like metal or wood, allowing for the creation of various objects like furniture, tools, and even musical instruments. Its versatility and precision make it an essential tool in many industries.

By using different tools and techniques, the lathe machine can perform a range of operations, including turning, facing, drilling, and threading. This makes it highly versatile and useful for a wide range of projects. The lathe’s ability to create symmetrical and precise shapes is unmatched, making it an important tool for producing intricate designs and detailed work. Its long history and continued use today demonstrate its significance and value in the world of manufacturing and craftsmanship.