Have you ever wondered why a lathe machine is called an engine lathe? Well, let’s find out!

You see, a lathe machine is a fascinating tool used in machining, but it didn’t always have the same name.

In this article, we’ll explore the origin of the term “engine lathe” and discover why it became synonymous with this versatile machine. So, let’s dive right in!

Have you ever wondered why a lathe machine is called an engine lathe? Well, the reason behind this name comes from the historical roots of the machine. Originally, the lathe was powered by a belt-driven engine, hence the term “engine lathe.” Over time, the term stuck and became the common name for this versatile machine. Today, engine lathes are widely used in various industries for shaping and machining materials with precision.

Why is a Lathe Machine Called an Engine Lathe?

History of the Lathe Machine

The lathe machine has been a fundamental tool in machining for centuries. Its development can be traced back to ancient Egypt and the Middle East, where it was initially used for pottery and woodworking. Over time, advancements in metallurgy and engineering led to the development of more sophisticated and versatile lathe machines.

During the Industrial Revolution in the 18th and 19th centuries, lathe machines underwent significant improvements. One notable advancement was the integration of steam engines with lathe machines, enabling them to be powered by external sources of energy. This integration marked the birth of the engine lathe, a powerful and versatile machine used in the manufacturing industry.

Advancements in Lathe Technology

With the advent of steam engines and other external power sources, lathe machines became more efficient and capable of handling larger workpieces. The introduction of the engine lathe revolutionized the manufacturing industry, as it allowed for faster and more precise machining operations.

Engine lathes were equipped with a variety of features that made them incredibly versatile. They had multiple speeds, allowing operators to select the appropriate speed for different materials and machining operations. Moreover, engine lathes were equipped with a variety of cutting tools and attachments, enabling the machining of complex shapes and contours.

Why is it Called “Engine” Lathe?

The term “engine lathe” originated from the integration of steam engines with lathe machines during the Industrial Revolution. The steam engine provided the external power source that drove the lathe’s spindle and enabled it to perform various machining operations. As a result, the lathe machine that incorporated the steam engine became known as the “engine lathe.”

The term “engine” in “engine lathe” can also be attributed to the fact that these machines were primarily used in the manufacturing of engines, such as steam engines and internal combustion engines. Engine lathes played a crucial role in shaping and finishing the components of these engines, making them an integral part of the engineering and manufacturing industry.

In modern times, the term “engine lathe” has evolved to become more synonymous with conventional lathe machines, which are powered by electric motors instead of steam engines. However, the historical significance of the term remains, reminding us of the crucial role lathe machines played in the development of engines and the manufacturing industry as a whole.

The Versatility of Engine Lathes

Engine lathes have remained a vital tool in the manufacturing industry due to their versatility. These machines can handle a wide range of machining operations, including facing, turning, boring, threading, and more. They are capable of machining various materials such as metals, plastics, and even wood, making them indispensable in different industries.

One of the key advantages of engine lathes is their ability to perform both external and internal machining operations. This versatility is achieved by using different types of cutting tools, attachments, and accessories. For example, by using a boring bar attachment, an engine lathe can machine internal bores with high precision and accuracy.

Engine lathes also offer a high degree of customization and adaptability. Operators can adjust the speed, feed rate, and depth of cut to achieve the desired results. Additionally, attachments such as steady rests and follower rests can be used to support and guide long and slender workpieces, ensuring stability and accuracy during machining.

The precision and repeatability of engine lathes make them a preferred choice for manufacturing intricate and complex components. The ability to achieve tight tolerances and smooth surface finishes is crucial in industries such as aerospace, automotive, and medical equipment manufacturing.

Benefits of Using Engine Lathes

1. Versatility: Engine lathes can perform a wide range of machining operations, making them suitable for various applications.

2. Precision: Engine lathes offer high precision and accuracy, allowing for the production of intricate and complex components.

3. Customization: Operators can adjust the speed, feed rate, and cutting parameters to achieve the desired results.

4. Adaptability: Engine lathes can be equipped with different attachments and accessories to enhance their capabilities and accommodate different workpieces.

5. Cost-Effective: Engine lathes provide a cost-effective solution for small to medium-sized manufacturing operations, offering efficiency and versatility without the need for more specialized and expensive machinery.

Engine Lathe Vs. CNC Lathe

While engine lathes are still widely used, they have faced competition from CNC (Computer Numerical Control) lathes in recent years. CNC lathes, controlled by computer programs, offer greater automation, precision, and efficiency in machining operations. However, engine lathes still have their advantages, especially for small-scale manufacturing and applications that require manual control and customization.

Here is a comparison between engine lathes and CNC lathes:

| Feature | Engine Lathe | CNC Lathe |

|---|---|---|

| Operation | Manually operated | Computer-controlled |

| Customization | Highly customizable and adaptable to different machining tasks | Less customizable, but capable of performing complex tasks with precision |

| Automation | Manual operation requires skilled operators | Fully automated, reducing the need for manual intervention |

| Setup Time | Relatively longer setup time | Shorter setup time as programs can be saved and reused |

| Flexibility | Offers greater flexibility for small-scale or custom manufacturing | Ideal for high-volume production runs and repeated tasks |

| Cost | Lower initial cost | Higher initial cost, but potential long-term savings in labor and productivity |

It is essential to choose the right lathe machine based on the specific needs and requirements of the manufacturing operation. For small-scale and customized manufacturing, an engine lathe may be the ideal choice, providing versatility, precision, and customization options. However, for high-volume production and complex tasks, a CNC lathe might offer greater efficiency and automation.

Conclusion

The term “engine lathe” originated from the integration of steam engines with lathe machines during the Industrial Revolution. Over time, the term evolved to encompass conventional lathe machines that are electrically powered. Engine lathes have played a crucial role in the manufacturing industry, offering versatility, precision, and customization options. Despite the emergence of CNC lathes, engine lathes are still widely used, particularly in small-scale manufacturing operations. Choosing the right lathe machine depends on the specific needs of the manufacturing operation, whether it be customization, precision, or automation.

Key Takeaways: Why Lathe Machine is Called Engine Lathe?

- An engine lathe is a type of lathe machine primarily used for shaping metal objects.

- It is called an engine lathe because it was originally powered by a steam engine.

- The term “engine” refers to the machine’s source of power.

- Engine lathes are versatile and can perform various operations like turning, facing, drilling, and threading.

- These lathes have evolved over time and are now powered by electricity or other modern power sources.

Frequently Asked Questions

Welcome to our FAQ section where we answer your questions about why a lathe machine is called an engine lathe!

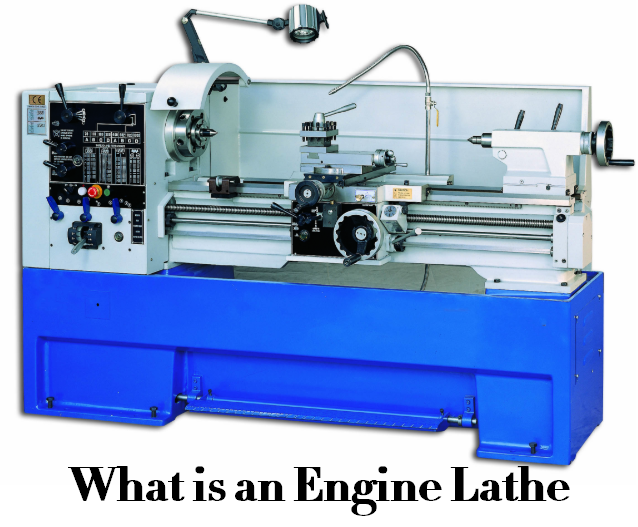

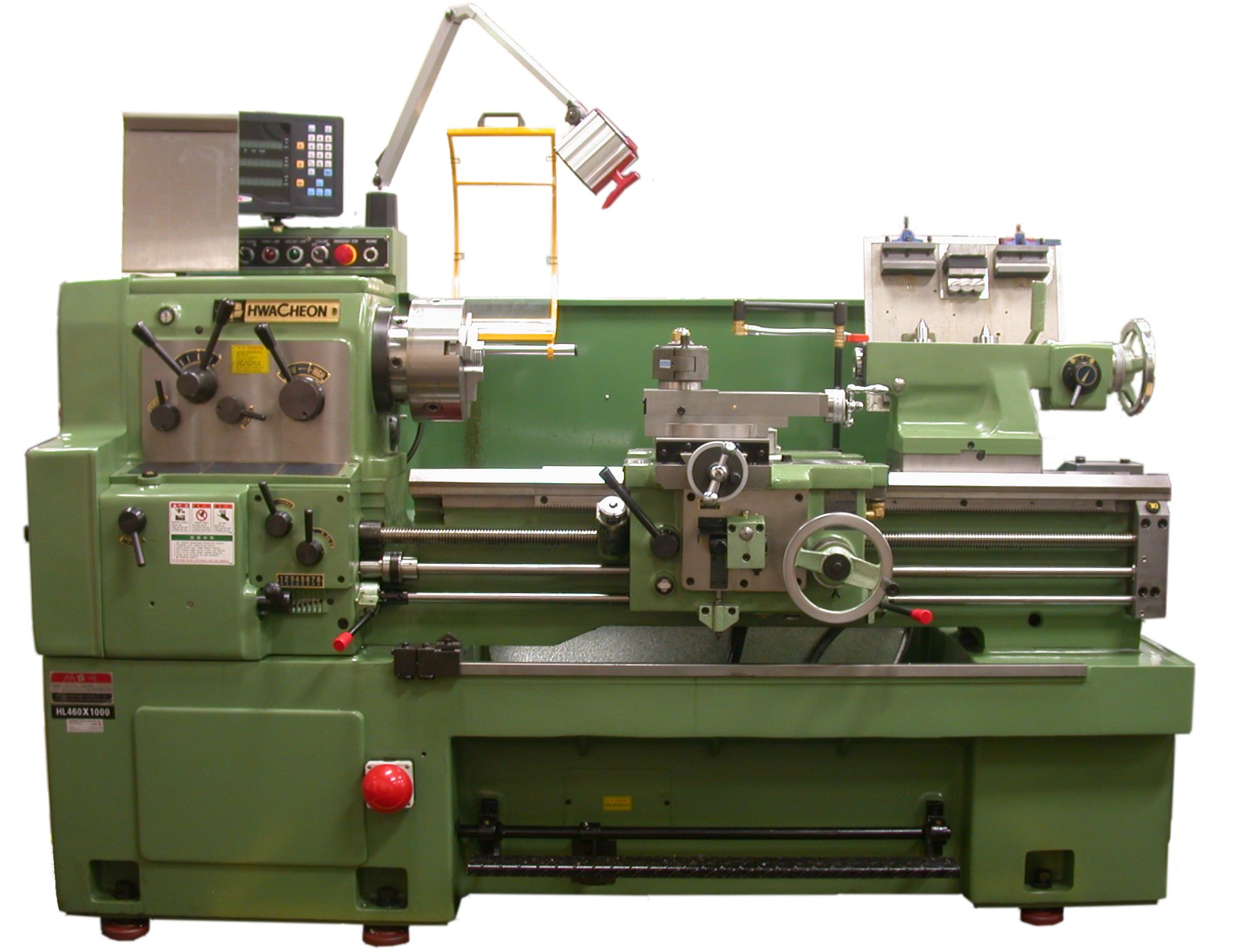

What is an engine lathe?

An engine lathe is a type of lathe machine that is commonly used in metalworking. It gets its name from its historical connection to powering other machines by an engine, such as a steam engine. Engine lathes are known for their versatility and reliability in shaping and machining various materials.

They are typically used to turn, bore, thread, and perform other operations on cylindrical workpieces. Engine lathes are often equipped with a gearbox that allows for different speed settings, making them suitable for a wide range of applications.

Why is it called a lathe machine?

The term “lathe” originated from the Old English word “læððe,” which means “a machine for shaping wood or metal.” In its earliest form, a lathe was primarily used for woodturning. Over time, the design and capabilities of the lathe evolved, and it became widely used for machining and shaping various materials, including metal.

Today, a lathe machine refers to a tool that rotates a workpiece on its axis, allowing for precise cutting, drilling, and shaping. The term “lathe” is more generic, encompassing different types of lathes, including the engine lathe.

What sets the engine lathe apart from other lathes?

The engine lathe is distinct from other lathes due to its versatility and robustness. It is designed to handle a wide range of machining operations and can accommodate larger workpieces with longer lengths. Engine lathes are known for their durability and stability, making them suitable for heavy-duty work.

Furthermore, engine lathes often come equipped with additional features, such as a carriage, tailstock, and various tooling options, allowing for precision and flexibility in machining processes. These characteristics distinguish engine lathes from smaller, more specialized lathes used for specific tasks.

Can an engine lathe be used for other materials besides metal?

While engine lathes are primarily used for machining metal, they can also be employed for working with other materials. Depending on the specific model and attachments, an engine lathe can be used for shaping wood, plastic, and certain composites.

However, it’s worth noting that when machining materials other than metal, specific tooling and cutting techniques might be necessary to achieve optimal results. The versatility of the engine lathe makes it adaptable to different materials, but it’s essential to consider the compatibility of the machine and the cutting tools with the material being machined.

Are engine lathes still widely used today?

Indeed, engine lathes continue to be widely used in various industries today. Despite the advancements in CNC (Computer Numerical Control) technology and automated machining processes, engine lathes are favored for their flexibility, ruggedness, and precision.

Engine lathes are commonly found in machine shops, manufacturing facilities, and maintenance departments where versatile machining capabilities are required. Their durability, ease of use, and ability to handle both small and large-scale projects make them a reliable choice for many machinists and hobbyists alike.

Summary

So, why is the lathe machine called an engine lathe? It’s because this type of lathe was originally powered by an engine, which is a machine that creates power. The engine drives the lathe’s spindle, allowing it to rotate and cut metal or wood into different shapes. This machine is still commonly used today, even though it may be powered by electricity instead of an engine.

In an engine lathe, the material being worked on is clamped to the spindle, which holds it in place while it spins. The cutting tool is then moved against the spinning material to shape it. This allows for precise and accurate cuts to be made, making the engine lathe a versatile and essential tool in various industries.