If you’ve ever wondered why a lathe machine is important, you’re in the right place! In this article, we’ll explore the significance of this incredible tool and why it’s a must-have in various industries.

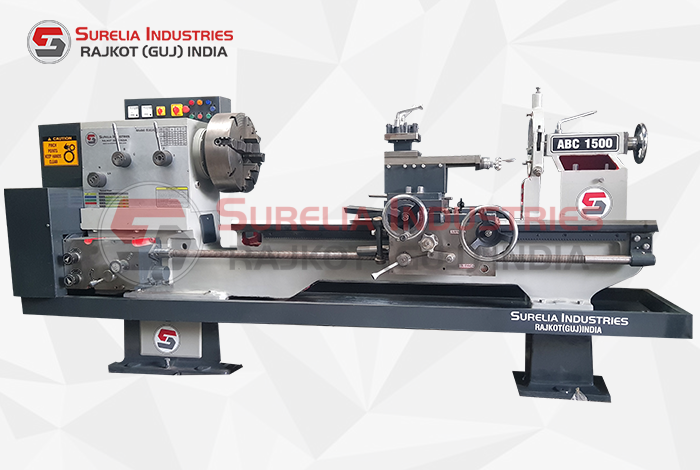

So, what exactly is a lathe machine? Well, picture a machine that spins a workpiece while a cutting tool removes material to shape it. Cool, right? But why is it important? Let’s find out!

Imagine you want to create precise, symmetrical parts for a project. A lathe machine is like your trusty sidekick in achieving that goal. It allows you to turn, cut, shape, and even thread materials, revolutionizing the way we craft objects in industries such as woodworking, metalworking, and even pottery. Exciting, huh? Let’s dive deeper into this fascinating world!

Why Lathe Machine is Important?

Lathe machines are essential tools in the manufacturing and metalworking industry. Their versatility and precision make them indispensable for a wide range of applications. From shaping and cutting materials to creating intricate designs, lathe machines play a crucial role in various industries. In this article, we will explore why lathe machines are important and how they revolutionize the manufacturing process.

The Importance of Lathe Machines in Manufacturing

Lathe machines are highly valued in the manufacturing industry due to their numerous benefits and capabilities. They provide a wide range of functions that contribute to the overall efficiency, accuracy, and quality of the production process. Let’s delve deeper into the significance of lathe machines in manufacturing.

1. Precision Machining

One of the primary reasons why lathe machines are crucial in manufacturing is their ability to deliver precise and accurate machining. These machines enable engineers and machinists to produce components with the exact measurements and specifications required. By using lathe machines, manufacturers can create intricate parts, threads, and tapers with exceptional precision, ensuring that every piece fits perfectly into the assembly. This precision is vital for industries like aerospace, automotive, and medical, where safety and reliability are of utmost importance.

Additionally, lathe machines provide consistent accuracy over extended periods, resulting in consistent quality and reduced scrap rates. This reliability makes them indispensable for mass production and ensures that each finished product meets the highest standards.

2. Versatility and Flexibility

Another reason why lathe machines are highly valued in manufacturing is their versatility and flexibility. These machines can work with various materials, including metal, wood, and plastic, allowing manufacturers to create a wide range of products. From simple cylindrical shapes to complex designs, lathe machines can handle diverse machining tasks.

Moreover, lathe machines come with different attachments and accessories, further enhancing their versatility. Depending on the requirements, operators can attach milling heads, grinding wheels, or boring bars to perform additional operations like drilling, milling, or grinding. This flexibility helps manufacturers optimize their production process, saving both time and resources.

3. Efficient Material Removal

Lathe machines excel in material removal, making them essential for shaping and cutting operations. With their rotating workpiece and cutting tool, lathe machines can efficiently remove excess material, shaping it into the desired form. This material removal process is crucial in manufacturing components like shafts, gears, and pulleys, where precise dimensions and smooth finishes are required.

Lathe machines use various cutting tools, including single-point tools and multi-point tools, to remove material with precision and control. The ability to remove material effectively while minimizing waste makes lathe machines highly efficient and cost-effective.

Advancements in Lathe Machine Technology

The importance of lathe machines in manufacturing continues to grow as technology advances. The constant innovations in lathe machine technology have led to improved precision, efficiency, and speed. Let’s explore some significant advancements in lathe machine technology:

New Tooling Systems

Modern lathe machines incorporate advanced tooling systems that enhance the efficiency and versatility of the machines. Quick-change toolposts, indexable tooling, and tool presetters allow operators to switch between different cutting tools and operations swiftly. These advancements reduce setup times, increase productivity, and improve overall machining accuracy.

CNC Lathe Machines

Computer Numerical Control (CNC) technology has revolutionized the manufacturing industry, and lathe machines are no exception. CNC lathe machines offer automation, precision, and flexibility, making them ideal for high-volume production and complex machining tasks.

CNC lathe machines are programmed to execute specific commands, eliminating the need for manual intervention in every machining operation. This automation significantly reduces human error, increases repeatability, and ensures consistent quality throughout the production process.

The Future of Lathe Machines

The future of lathe machines looks promising, with ongoing advancements aiming to further improve efficiency, accuracy, and automation. Here are three potential areas for development:

1. Integration of Artificial Intelligence

Artificial intelligence (AI) technology has the potential to enhance the capabilities of lathe machines and improve their decision-making abilities. AI algorithms can analyze various parameters during the machining process, optimize tool paths, and adaptively adjust cutting conditions in real-time. This integration of AI can lead to increased productivity, reduced errors, and improved efficiency.

2. Advanced 3D Printing and Additive Manufacturing

The combination of lathe machines with advanced 3D printing and additive manufacturing technologies can revolutionize the production of complex and customized components. By integrating these technologies, manufacturers can create intricate designs, reduce material waste, and achieve faster production times.

3. Internet of Things (IoT) Connectivity

Connectivity through the Internet of Things (IoT) can enable real-time monitoring, predictive maintenance, and remote control of lathe machines. By gathering data and providing actionable insights, IoT connectivity can enhance operational efficiency, reduce downtime, and optimize the overall manufacturing process.

In conclusion, lathe machines are essential tools in the manufacturing industry. Their precision, versatility, and efficient material removal capabilities make them indispensable for a wide range of applications. With advancements in technology, such as new tooling systems and CNC automation, lathe machines continue to evolve, providing even greater efficiency and accuracy. As we look to the future, integration with AI, advanced additive manufacturing, and IoT connectivity present exciting possibilities for the continued growth and importance of lathe machines in the manufacturing sector.

Key Takeaways: Why a Lathe Machine is Important?

- A lathe machine is a vital tool used in various industries to shape, cut, and turn materials.

- It helps in creating precise and intricate parts, making it crucial in manufacturing processes.

- Lathe machines enable the production of customized items, reducing the need for outsourcing.

- These machines improve productivity by automating repetitive tasks and reducing human error.

- Using a lathe machine allows for efficiency and cost-effectiveness in the production of metal components.

Frequently Asked Questions

1. What are the key benefits of using a lathe machine?

Using a lathe machine offers several key benefits. Firstly, it allows for the creation of precise and accurate metal or woodwork. The lathe machine enables you to shape, cut, or drill materials with high precision, ensuring a professional finish. Secondly, a lathe machine enhances productivity by reducing manual labor and speeding up the production process. This saves valuable time and increases overall efficiency. Thirdly, a lathe machine is incredibly versatile, as it can be used to perform a wide range of operations, from facing and threading to tapering and turning. This versatility makes it a valuable tool in various industries, including manufacturing, woodworking, and metalworking.

Furthermore, a lathe machine is crucial for craftsmen and engineers to create intricate and complex designs. Whether you’re working on a small DIY project or manufacturing large-scale components, a lathe machine provides the precision and control necessary to achieve desired outcomes. Additionally, using a lathe machine promotes consistency in production, ensuring that each piece is identical in shape and size. This is particularly useful in mass production scenarios, where uniformity is essential. By streamlining the manufacturing process and producing high-quality outputs, a lathe machine proves itself as an indispensable tool in various industries.

2. How does a lathe machine contribute to the quality of finished products?

A lathe machine plays a crucial role in enhancing the quality of finished products. By offering precise control and accuracy, it ensures that the end result meets the required specifications. The rotary motion of the lathe machine allows for detailed shaping, cutting, and drilling, resulting in a smooth and polished surface on the finished product. This professional finish is highly desirable in industries that prioritize quality and craftsmanship.

Moreover, the precision offered by a lathe machine eliminates the potential for human error. The controlled movement of the lathe machine ensures consistency throughout the production process, which reduces the risk of defects or variations in size and shape. This is particularly important when working on intricate and complex designs, where even the slightest deviation can impact the overall quality of the finished product. Additionally, the versatility of a lathe machine allows for various finishing techniques, such as threading, tapering, and facing, further enhancing the quality of the final product.

3. Can a lathe machine improve productivity in manufacturing processes?

Absolutely! A lathe machine significantly improves productivity in manufacturing processes. By automating the cutting, shaping, and drilling tasks, it reduces the need for manual labor, saving time and effort. As a result, the production process becomes faster and more efficient.

Furthermore, a lathe machine allows for simultaneous machining on different parts of a workpiece, maximizing output and saving valuable production time. The ability to perform multiple operations in one setup enhances productivity, as it eliminates the need for frequent adjustments or repositioning of the workpiece. This streamlines the manufacturing process, leading to increased productivity and reduced production costs.

4. Which industries rely on lathe machines?

Lathe machines are widely used in various industries. In the manufacturing industry, lathe machines are essential for producing precision components and parts used in automobiles, aircraft, and machinery. The woodworking industry also heavily relies on lathe machines for creating furniture, decorative pieces, and intricate woodturning. Metalworking industries, such as foundries and fabrication shops, utilize lathe machines for shaping, cutting, and drilling various metal components.

Moreover, the medical and dental industries utilize specialized lathe machines for producing prosthetics, implants, and custom-made devices. The jewelry industry also extensively uses lathe machines for intricate design work on precious metals. Finally, educational institutions, vocational schools, and research laboratories utilize lathe machines for training students and conducting experiments. With their versatility and ability to handle various materials, lathe machines find applications in a wide range of industries.

5. What considerations should be made when choosing a lathe machine?

When choosing a lathe machine, several factors should be considered. Firstly, it is important to assess the size and weight capacity of the lathe machine, ensuring it can accommodate the workpieces you plan to work on. Additionally, the power and speed options of the machine should align with your specific requirements. Higher power and variable speed options provide greater versatility and flexibility in machining different materials and performing various operations.

Furthermore, the construction and rigidity of the lathe machine should be evaluated. Look for a machine made of durable materials that can withstand heavy use and ensure stability during operation. Additionally, consider the available accessories and attachments that come with the lathe machine, as they can expand its functionality and increase its value. Finally, it’s important to set a budget and find a lathe machine that offers the best balance between cost and performance, ensuring that it meets your needs without exceeding your financial constraints.

Summary

So, why is a lathe machine important? Well, it helps shape and cut materials like wood and metal. This machine is great for creating precise and symmetrical shapes. It’s like a super-powered sculpting tool! With a lathe machine, you can make things like table legs, baseball bats, and even engine parts. It’s a must-have for any craftsman or engineer!

But that’s not all – a lathe machine is also safe and easy to use. It has safety features to protect you from accidents. Plus, it’s designed with user-friendly controls so that even beginners can operate it. So, if you have a creative mind and love building things, a lathe machine can be your best friend in the workshop. Happy crafting!