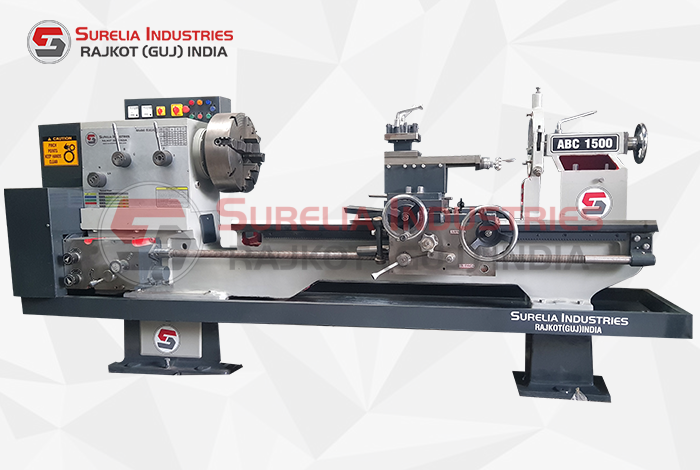

Are you curious about why the lathe machine holds such importance in the industry? Well, let me tell you! The lathe machine is like a master of all trades—the superhero of the manufacturing world. It can shape and cut materials with precision, creating various products we use in our daily lives.

Imagine this: you’re holding a pen, right? Do you ever wonder how it got its shape, how the grooves on its surface were created? Well, my friend, the lathe machine is the magical tool behind it all. With the lathe machine, manufacturers can create intricate designs and precise measurements, turning blocks of metal or wood into astonishingly beautiful objects.

But wait, there’s more! The lathe machine isn’t just about aesthetics; it’s also about functionality. From creating metal parts for engines to crafting wooden furniture and even shaping pottery, the lathe machine gives us the ability to manufacture goods that improve our lives in countless ways. So, without further ado, let’s dive into the mesmerizing world of the lathe machine and discover why it’s such a vital player in the industry!

Discover the immense importance of lathe machines in various industries. These versatile tools play a crucial role in the manufacturing process by shaping and cutting materials with precision. With their ability to create symmetrical and complex shapes, lathe machines enable the production of a wide range of products, from furniture to engine components. They enhance productivity, accuracy, and efficiency, making them indispensable in the industry.

The Importance of Lathe Machines in the Industry

Lathe machines are a vital tool in the manufacturing industry. They play a crucial role in shaping and forming metal, wood, and other materials, making them essential for a wide range of industries, including automotive, aerospace, construction, and more. In this article, we will explore why lathe machines are important in the industry and how they contribute to the production process.

The Functionality of Lathe Machines

Lathe machines are incredibly versatile and can perform various operations, making them indispensable in the industry. Let’s delve into a few key functionalities of lathe machines:

1. Shaping and Cutting

One of the primary functions of a lathe machine is to shape and cut materials with precision, accuracy, and consistency. The machine utilizes a cutting tool that rotates the workpiece while removing excess material, ensuring a smooth and even finish. This capability enables manufacturers to create intricate designs, threads, and other complex shapes, contributing to the production of high-quality products.

Moreover, lathe machines can work with a diverse range of materials, including metals like steel, aluminum, and brass, as well as wood and plastics. This versatility allows manufacturers to cater to various industry requirements, whether it’s crafting automotive parts, building furniture, or producing intricate components for industrial machinery.

2. Turning and Facing

Another essential function of lathe machines is turning and facing. Turning involves rotating the workpiece against a cutting tool to remove excess material and create a cylindrical shape. This operation is commonly used in the production of shafts, rods, and other cylindrical components. On the other hand, facing refers to cutting the surface of a workpiece to create a smooth and flat finish, making it ideal for creating precise and even surfaces for parts like flanges and gears.

The ability to turn and face materials accurately ensures that the final products meet the required specifications and standards. This precision is crucial in industries such as aerospace, where even the slightest deviation can impact the performance and safety of aircraft components.

3. Drilling and Boring

Lathe machines are also equipped to perform drilling and boring operations. Drilling involves creating holes in a workpiece, which is vital for various applications across industries. From creating holes for plumbing fixtures to producing precise openings for electrical wiring, this function helps streamline production and assembly processes.

Additionally, boring is used to enlarge existing holes with precision, contributing to the manufacturing of intricate parts and components. This operation ensures that the final products can accommodate other parts or machinery, making the overall assembly process more efficient.

4. Taper Turning

Lathe machines are capable of taper turning, which involves creating conical shapes on the workpiece. This functionality is useful in industries such as automotive, where components like axles and pins require tapered ends for proper fitting and functionality. By offering the capability to create tapered shapes accurately, lathe machines contribute to the production of well-fitting and high-performance automotive parts.

In conclusion, lathe machines are indispensable in the industry due to their versatility and functionality. From shaping and cutting materials to performing turning, facing, drilling, and boring operations, these machines provide manufacturers with the necessary tools to create precise, high-quality components and products. Whether it’s constructing buildings, producing machinery, or manufacturing intricate parts, the importance of lathe machines cannot be overstated in the world of industry.

Key Takeaways: Why is the lathe machine important in the industry?

- A lathe machine is a vital tool used in various industries.

- It helps to shape and cut materials like wood, metal, and plastic.

- The lathe machine enables precision and accuracy in manufacturing processes.

- It allows for the creation of complex shapes and intricately detailed designs.

- From crafting furniture to constructing parts for machinery, the lathe machine plays a crucial role in the industry’s production processes.

Frequently Asked Questions

Curiosity strikes when it comes to understanding the importance of the lathe machine in the industry. Here are some commonly asked questions that shed light on this topic:

How does a lathe machine contribute to the manufacturing process?

A lathe machine plays a vital role in the manufacturing process by shaping and creating various objects. It enables operators to remove excess material and produce symmetrical, precise components. With its rotating mechanism, a lathe machine can spin a workpiece while it is being cut, allowing for precise shaping and carving. This versatility makes the lathe machine an essential tool for producing a wide range of components and parts in industries like automotive, aerospace, and electronics.

Additionally, the lathe machine facilitates the creation of threads and screws, making it indispensable for manufacturing applications. By utilizing different cutting tools, speed adjustments, and feed rates, the lathe machine ensures efficient and accurate manufacturing processes.

What are the key benefits of using a lathe machine in the industry?

Using a lathe machine in the industry brings numerous advantages. Firstly, it allows for precise shaping and carving, ensuring high-quality end products. The lathe machine’s ability to rotate the workpiece while cutting guarantees symmetric and accurate results, vital in industries where precision is critical.

Moreover, the lathe machine enhances productivity by reducing manual labor. With the automation provided by a lathe machine, operators can create components faster and in larger quantities, meeting market demands more efficiently. This increased productivity ultimately leads to cost savings and improved profitability for businesses.

What are the different types of lathe machines used in the industry?

There are several types of lathe machines utilized in the industry based on specific requirements. The most common ones include engine lathes, bench lathes, turret lathes, and CNC lathes.

Engine lathes are versatile machines suitable for general-purpose machining, while bench lathes are compact and ideal for small-scale operations. Turret lathes, on the other hand, are designed for high-volume production of identical components. Lastly, CNC lathe machines operate using computer numerical control, allowing for precise and automated machining processes.

How does a lathe machine contribute to the precision engineering industry?

The precision engineering industry heavily relies on lathe machines for its manufacturing processes. Lathe machines enable precision engineers to create intricate components with tight tolerances. By using various cutting tools, precision engineering businesses can manufacture parts that align perfectly with the required specifications.

Whether it’s producing micro-components for the medical industry or crafting delicate parts for advanced electronics, the lathe machine plays a crucial role in ensuring precision and accuracy, guaranteeing the functionality and reliability of the final products.

Are there any safety measures to consider when using a lathe machine?

Absolutely, safety should always be a top priority when operating a lathe machine. Some key safety measures to consider include wearing appropriate personal protective equipment (PPE), such as safety glasses and gloves, to protect against flying debris and rotating parts. Operators should also ensure the workpiece is securely clamped to prevent any accidents.

In addition, it’s crucial to familiarize oneself with the lathe machine’s operating manual and receive proper training on its usage. Regular maintenance and inspections of the machine are necessary to identify any potential faults or issues that may compromise safety. Adhering to these safety measures not only safeguards the operator but also prevents accidents and optimizes the efficiency of the lathe machine.

Summary

Having a lathe machine is important in the industry for several reasons. First, it allows workers to shape and smooth materials like metal and wood with precision. This helps create high-quality products that meet specific measurements and requirements. Second, a lathe machine can perform different types of operations such as drilling, cutting, and sanding, making it a versatile tool for various tasks. Lastly, by automating certain processes, a lathe machine increases efficiency and productivity in the workplace. With these benefits, it’s clear why the lathe machine plays a vital role in the industry.