Hey there! Are you curious about why people use engine lathes? Well, you’re in the right place! Let’s dive in and explore the reasons behind using this fascinating tool.

First off, why use an engine lathe? Well, an engine lathe is a versatile machine that has been used for centuries to shape and cut metal. It’s like a superhero in the manufacturing world, capable of performing a wide range of operations with precision and efficiency.

But what exactly can you do with an engine lathe? That’s the exciting part! You can use it to turn cylindrical parts, create threads, bore holes, and even cut gears. Whether you’re a hobbyist working on a small project or a professional in the manufacturing industry, an engine lathe can be your trusty sidekick, helping you transform raw materials into functional components.

Curiosity piqued? Great, let’s take a closer look at the benefits of using an engine lathe and how it can make your machining adventures a breeze. So, grab your safety goggles and let’s embark on this thrilling journey into the world of engine lathes!

Why Use Engine Lathe: Maximizing Precision and Efficiency in Machining

Engine lathes have long been a staple in the world of machining. These versatile machines are used for a wide range of applications, from shaping metalwork to creating intricate designs. But what exactly makes engine lathes so indispensable in the manufacturing industry? In this article, we will explore the various reasons why using an engine lathe is essential for achieving precision and efficiency in machining.

1. Versatility and Flexibility

Engine lathes offer unmatched versatility and flexibility in machining operations. With their ability to rotate workpieces at various speeds, engine lathes can perform a multitude of functions such as turning, facing, drilling, knurling, and threading. This versatility allows machinists to accomplish a wide range of tasks using just one machine, saving time and increasing productivity. Whether it’s creating complex parts for aerospace components or fashioning decorative pieces for the automotive industry, the engine lathe’s adaptability makes it an indispensable tool.

Another aspect of the engine lathe’s flexibility is its capacity to handle different workpiece sizes. Some engine lathes can accommodate workpieces as short as a few inches or as long as several feet. This range allows for the machining of both small precision components and large-scale parts. Machinists can easily adjust the machine’s settings to accommodate different workpiece sizes, making the engine lathe highly adaptable to various project requirements.

2. Precision and Accuracy

One of the primary reasons why engine lathes are widely used is their ability to deliver precise and accurate results. The design of the machine allows for excellent control over the cutting tools, ensuring that the desired dimensions and tolerances are achieved with each operation. Machinists can make incremental adjustments to the cutting depth and speed to achieve the desired surface finishes and dimensions, resulting in high-quality finished products.

Engine lathes are equipped with a variety of advanced features that enhance their precision. These include micrometer dials for precise depth and diameter measurements, adjustable slides, and tailstocks for precise positioning, and quick-change tool holders for efficient tool changes. By leveraging these features, machinists can achieve the level of precision that is essential in industries such as aerospace, automotive, and medical device manufacturing.

3. Cost-Effective Solution

Investing in an engine lathe is a cost-effective solution for manufacturing and machining businesses. Engine lathes offer superior longevity and durability, ensuring a long lifespan and reducing the need for frequent repairs or replacements. Additionally, their versatility and ability to handle a wide range of machining tasks eliminate the need for investing in multiple specialized machines, saving both space and money.

The productivity and efficiency achieved with an engine lathe also contribute to cost savings. Machinists can quickly set up and execute machining operations, reducing the time required to produce each part. This increased efficiency translates to higher productivity and more significant profits for businesses.

In summary, engine lathes are indispensable tools in the manufacturing industry for several reasons. Their versatility and flexibility allow for a wide range of machining operations, while their precision and accuracy ensure high-quality finished products. Additionally, investing in an engine lathe proves to be a cost-effective solution that maximizes productivity and efficiency. Whether you’re a professional machinist or a hobbyist, an engine lathe is a must-have tool for any machining project.

Key Takeaways: Why Use Engine Lathe?

- Engine lathes are versatile machines used to shape and cut metal.

- They allow for precision and accuracy in machining operations.

- Engine lathes can produce threaded parts, taper turning, and facing operations.

- They are commonly used in various industries, such as automotive, aerospace, and manufacturing.

- Engine lathes provide flexibility and can be used for both small and large-scale production.

Frequently Asked Questions

Welcome to our FAQ section where we answer common questions about why you should use an engine lathe. Whether you’re a beginner or a seasoned professional, we’ve got you covered with the information you need to understand the benefits of using an engine lathe.

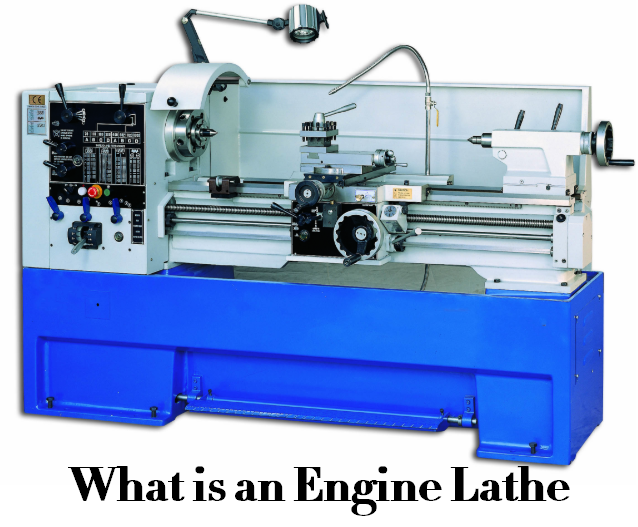

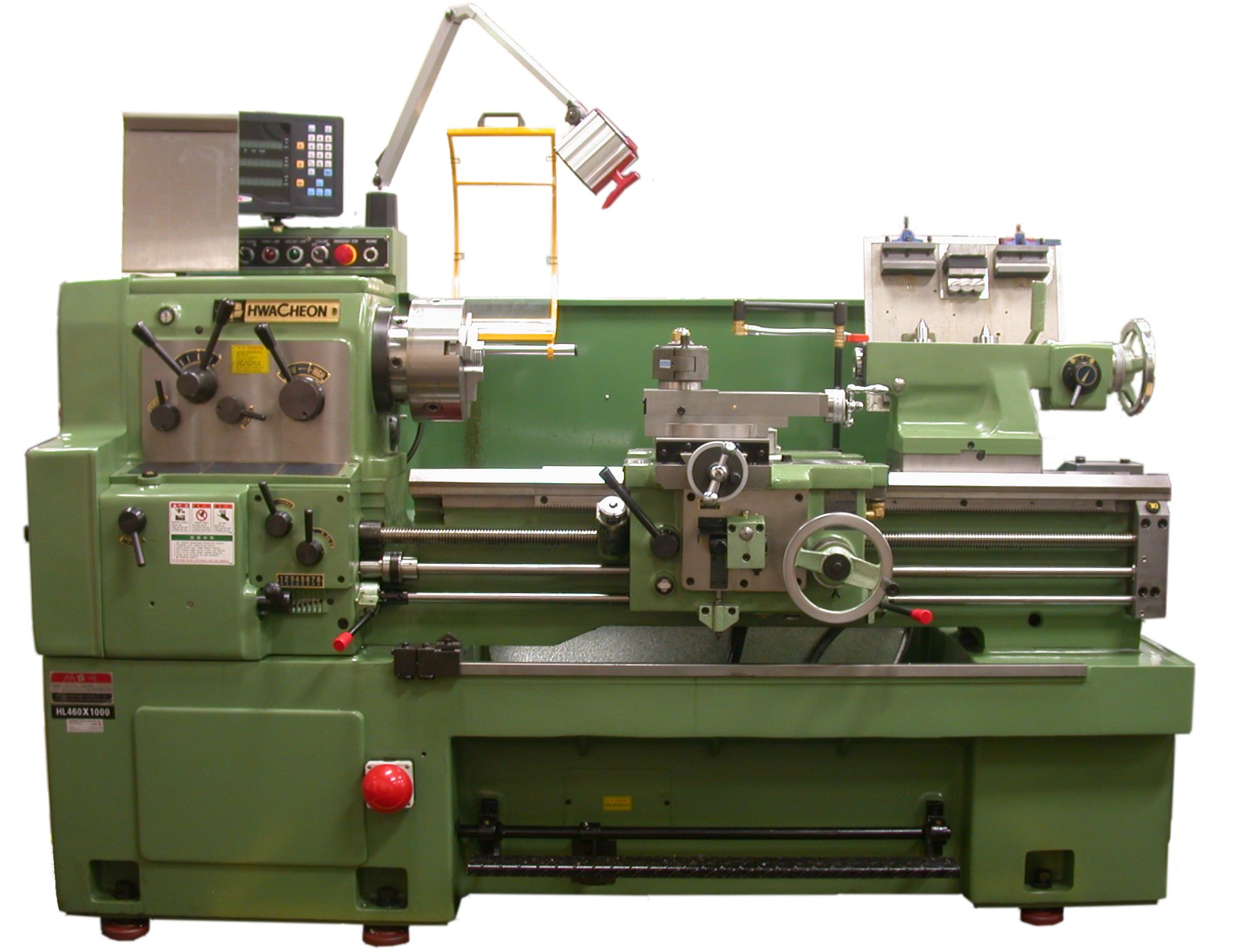

Q: What is an engine lathe and why should I use it?

An engine lathe is a powerful machine used in metalworking to shape, cut, and drill various materials, such as wood, metal, and plastic. Its versatility and precision make it an essential tool for a wide range of applications. By using an engine lathe, you can perform various machining operations with accuracy and efficiency, saving time and effort.

An engine lathe offers numerous advantages. It allows you to create intricate designs, threads, and tapered surfaces. It provides precision and repeatability, ensuring consistent results. Additionally, an engine lathe enables you to work with a wide range of materials, making it suitable for diverse projects.

Q: Can an engine lathe be used for both small and large projects?

Yes, an engine lathe can be used for both small and large projects. Engine lathes come in different sizes, with varying capacities and capabilities. For smaller projects, you can use a compact or benchtop engine lathe, which offers versatility and ease of use. These lathes are ideal for hobbyists or those working on smaller-scale projects.

For larger projects, such as heavy-duty machining or industrial applications, you can utilize a larger engine lathe. These lathes are designed to handle larger workpieces and can withstand high loads and forces. They provide the stability and power needed to tackle more demanding tasks.

Q: What are the advantages of using an engine lathe over other types of lathes?

Engine lathes offer several advantages over other types of lathes. One of the key advantages is their versatility. Engine lathes are capable of performing a wide range of operations, such as facing, turning, threading, drilling, and boring. This versatility eliminates the need for multiple machines, saving space and reducing costs.

Another advantage of engine lathes is their durability. These machines are built to withstand heavy-duty use and can handle high forces and loads without compromising accuracy or performance. Engine lathes also offer precise control over cutting parameters, allowing for greater accuracy and repeatability in your machining operations.

Q: Are engine lathes suitable for beginners?

Yes, engine lathes can be used by beginners. While it may take some time to learn how to operate the machine and master various techniques, engine lathes are designed to be user-friendly. Many models feature intuitive controls and provide guidance for beginners.

Additionally, engine lathes are commonly used in educational settings for training purposes. They are a great tool for learning the basics of metalworking and machining. With proper instruction and practice, beginners can quickly gain the skills and confidence to use an engine lathe effectively.

Q: Can an engine lathe handle different types of materials?

Yes, an engine lathe is capable of handling a wide range of materials. From metals like steel, aluminum, and brass, to plastics and even wood, an engine lathe can effectively shape and cut various materials. The cutting tools and machining techniques can be adjusted to suit the specific material being worked upon.

However, it’s important to consider the hardness and physical properties of the material you plan to work with. Different materials may require specific cutting tools, speeds, and feeds to achieve optimal results. It’s recommended to refer to the lathe’s manual or seek expert advice when working with unfamiliar materials to ensure safety and optimal performance.

Engine Lathe: General Overview

Summary:

Engine lathes are useful machines that can shape and cut metal. They can create precise parts and are commonly used in industries like manufacturing and automotive. By using an engine lathe, you can make different shapes, threads, and holes in metal to meet specific requirements. It saves time and money compared to other methods, making it an essential tool for many professionals. Whether you’re a hobbyist or a professional, an engine lathe can be a valuable addition to your workshop.

Engine lathes have a simple design and are easy to operate, making them suitable for beginners. They are versatile and can be used for various tasks like facing, turning, and tapering. With their strong construction, these lathes can handle heavy workpieces and provide smooth and accurate results. By using an engine lathe, you can unleash your creativity and bring your metalworking projects to life. So, next time you need to shape metal, consider using an engine lathe for a reliable and efficient solution.