Keywords: “will carpentry be automated?”

Introduction:

Paragraph 1:

Can you imagine a world where carpentry becomes automated? Well, that’s the question on everyone’s minds. With technological advancements happening at breakneck speed, it’s only natural to wonder what the future holds for this age-old craft.

Paragraph 2:

But before we dive into the possibilities, let’s take a moment to appreciate the artistry and skill that goes into carpentry. From meticulously crafting furniture to erecting beautiful wooden structures, carpenters possess a unique set of talents that have stood the test of time.

Paragraph 3:

Now, let’s turn our attention to automation. Will machines eventually take over the carpenter’s workshop, or will human expertise always be irreplaceable? Join me as we explore the exciting world of carpentry in the age of automation. Get ready for a fascinating journey!

Carpentry is an age-old craft that requires skill and precision. While automation has made its way into various industries, the future of carpentry remains a topic of speculation. Although there are advancements in technologies like computer-aided design and robotic tools, the intricate nature of carpentry work still relies heavily on human expertise. However, automation may assist with certain repetitive tasks in the future. So while carpentry may benefit from automation in some aspects, it is unlikely to be completely automated anytime soon.

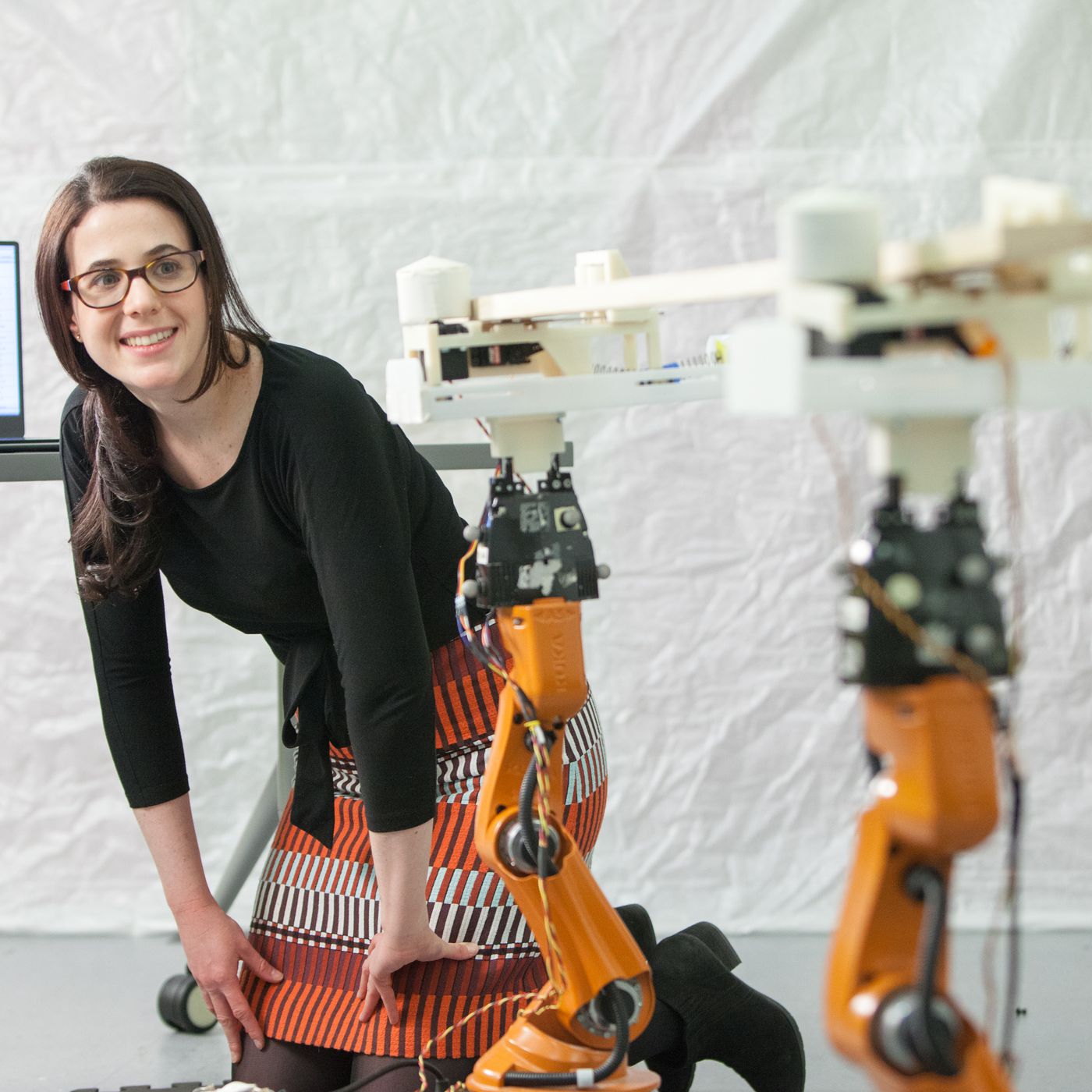

/cdn.vox-cdn.com/uploads/chorus_asset/file/10309507/Adriana_Schulz_05.jpg)

Will Carpentry Be Automated?

Introduction: Carpentry has long been a skilled trade, with craftsmen using their expertise and precision to create beautiful pieces of furniture and structures. However, with advancements in technology, there has been a growing interest in automating various industries, including carpentry. Will the age-old craft of carpentry be fully automated in the future? In this article, we will explore the potential impact of automation on the field of carpentry and discuss the possibilities and challenges it presents.

The Current Role of Technology in Carpentry

Technology has already made its way into the field of carpentry, with many professionals utilizing various tools and software to streamline processes and enhance efficiency. From computer-aided design (CAD) to automated precision cutting machines, these technological advancements have significantly improved the accuracy and speed of carpentry projects. However, despite these advancements, carpenters still play a crucial role in bringing the visions to life, as their expertise and craftsmanship remain irreplaceable.

Automation in carpentry has primarily focused on repetitive and mundane tasks, such as wood cutting and shaping. CNC (Computer Numerical Control) machines have been widely adopted to automate these processes, allowing for increased precision and faster production times. These machines are programmed with specific dimensions and shapes, reducing the margin of error and enabling the fabrication of intricate designs. However, the programming and operation of these machines still require skilled carpenters to ensure optimal results, indicating that full automation is not yet feasible in the field.

The Benefits and Challenges of Automating Carpentry

Benefits:

- Increased Efficiency: Automation can significantly improve the speed of carpentry projects, allowing for faster production and shorter turnaround times.

- Precision and Consistency: Automated tools and machines can produce highly precise and consistent results, minimizing the margin of error and ensuring consistent quality.

- Improved Safety: Automation can help reduce the risk of accidents and injuries by eliminating the need for manual labor in certain tasks.

Challenges:

- Complex Design Challenges: Carpentry often involves creating unique and custom designs that may require a high degree of creativity and problem-solving. Automation may struggle to replicate the creativity and innovative thinking that skilled carpenters bring to their craft.

- Adaptability: Carpentry projects often require on-site adjustments and modifications to accommodate specific conditions or client preferences. Automated systems may not possess the flexibility and adaptability to handle these situations effectively.

- Cost of Implementation: The initial investment in automated machinery and software can be significant, making it a barrier for smaller carpentry businesses or individual craftsmen.

The Future of Carpentry and Automation

While automation is likely to continue playing a role in carpentry, complete replacement of skilled carpenters seems unlikely. The intrinsic value that skilled craftsmen bring to the field, including their creativity, problem-solving abilities, and attention to detail, cannot be replicated by machines. Instead, automation is more likely to be used in collaboration with skilled carpenters to enhance efficiency, precision, and safety.

Advancements in artificial intelligence (AI) and machine learning may further improve the capabilities of automated systems in understanding complex designs and adapting to changing requirements. However, the human touch and personalized expertise of a skilled carpenter will remain vital in delivering unique and high-quality craftsmanship that meets the specific needs and desires of clients.

Automation in Other Industries

Introduction: Automation has been transforming industries across the board, improving efficiency, reducing costs, and streamlining processes. Carpentry is not unique in its potential for automation. Let’s explore how automation has impacted other industries and draw insights for the future of carpentry.

The Impact of Automation in Manufacturing

Introduction: Manufacturing has been at the forefront of automation, with robotic systems and AI-powered machines revolutionizing production lines. The use of automation in manufacturing has led to increased productivity, higher precision, and reduced labor costs. Let’s delve into the specific impacts and challenges of automation in the manufacturing sector.

Increased Productivity and Efficiency

The introduction of automated systems and machinery in manufacturing has significantly increased productivity and efficiency. Robots and AI-powered machines can work around the clock without the need for breaks, resulting in uninterrupted production. Automation also enables the completion of tasks at a faster pace, reducing production time and increasing output. Manufacturers can now meet higher demand with fewer resources and shorter turnaround times.

Furthermore, automation reduces the risk of errors and improves consistency. Machines follow precise instructions, eliminating the chances of human errors and resulting in products with uniform quality. Manufacturers can maintain high standards and reduce waste, enhancing overall efficiency.

Impact on the Workforce

The integration of automation in manufacturing has undoubtedly impacted the workforce. Some manual tasks that were previously performed by humans are now taken over by machines, leading to job displacement. Workers in routine-based jobs may face challenges due to the implementation of automation.

However, it’s important to note that automation also creates new job opportunities. Skilled workers are required to operate and maintain the automated systems, ensuring their smooth functioning. The demand for technicians, engineers, and programmers who specialize in automated machinery has increased. Reskilling and upskilling the workforce to adapt to changing technologies is essential to embrace the advantages offered by automation.

The Future of Automation in Manufacturing

The future of automation in manufacturing looks promising. Advancements in robotics, AI, and machine learning will continue to enhance the capabilities of automated systems. Collaborative robots, or cobots, are gaining popularity as they can work alongside humans, assisting in tasks that require dexterity and decision-making abilities beyond the capabilities of machines alone. The integration of AI will further enable machines to learn and adapt, improving their versatility and reducing the need for constant human supervision.

Ultimately, automation in manufacturing is expected to lead to more efficient, cost-effective, and sustainable production processes. While it may change the nature of certain job roles, it also presents opportunities for innovation and growth in the manufacturing industry.

The Potential of Automation in Construction

Introduction: Much like carpentry, the construction industry has the potential to benefit from automation in various aspects of its processes. From robotic bricklayers to autonomous vehicles, automation is beginning to transform the construction landscape. Let’s explore the current and future applications of automation in construction.

Robotic Construction Technology

Introduction: Construction sites are gradually deploying robotic construction technology to perform tasks traditionally carried out by manual labor. These robots are designed to increase efficiency, reduce costs, and enhance safety on construction sites. In this section, we will discuss the different types of robotic construction technology and their impact on the industry.

Robotic Bricklayers

Robotic bricklayers, also known as bricklaying robots or SAM (Semi-Automated Mason), have been introduced to automate bricklaying tasks in construction. These robotic machines can lay bricks with precision and speed, reducing the need for manual labor. They can work 24/7 and maintain consistent quality, enhancing productivity on construction sites. Robotic bricklayers not only improve efficiency but also minimize the physical strain and potential injuries associated with manual bricklaying.

These machines are programmed with the necessary dimensions and patterns, allowing them to easily adapt to different construction projects. While it is unlikely to completely replace human bricklayers, the deployment of robotic bricklayers can significantly speed up the construction process and address labor shortages in the industry.

Autonomous Construction Vehicles

The use of autonomous construction vehicles is gaining traction in the construction industry. These vehicles, equipped with sensors, GPS technology, and advanced software, can perform tasks such as excavating, transporting materials, and leveling the ground, without the need for human operators. Autonomous vehicles improve efficiency, safety, and precision in construction projects. They can operate around the clock, reducing project timelines, and eliminating the risk of human error.

Moreover, autonomous construction vehicles have the potential to improve sustainability in the industry. By optimizing routes and reducing fuel consumption, these vehicles contribute to the reduction of carbon emissions. The deployment of autonomous vehicles in construction is expected to increase in the coming years, transforming the way construction projects are carried out.

The Role of Skilled Workers

While automation has the potential to enhance many aspects of construction, skilled workers will continue to play a vital role in the industry. Skilled carpenters, electricians, plumbers, and other tradesmen bring their expertise, problem-solving abilities, and attention to detail to construction projects. These skills are difficult to replicate in machines, making human workers essential for ensuring the quality and intricacy of construction work.

Automation in construction will likely work in tandem with skilled workers, augmenting their capabilities and improving overall efficiency. Skilled workers will be required to operate and maintain the robotic systems and autonomous vehicles, ensuring their optimal performance. Additionally, their expertise will be crucial in areas that require creativity, customization, and complex problem-solving.

The Future of Automation in Construction

Introduction: Automation in the construction industry is an exciting area of development. The future of automation in construction holds great potential for improving productivity, efficiency, and safety. Let’s take a closer look at the possibilities that lie ahead.

Modular Construction through Automation

Introduction: Modular construction, also known as off-site construction, involves the manufacturing of building components in a controlled factory environment and their assembly on-site. Automation has the potential to revolutionize modular construction by increasing efficiency, reducing costs, and improving the quality of the finished structures. In this section, we will delve into the potential benefits and challenges of automation in modular construction.

Benefits of Automation in Modular Construction

Automation can greatly enhance modular construction processes, offering several benefits:

- Increased Speed and Efficiency: Automation can accelerate the manufacturing process of building components in a controlled factory environment, allowing for faster on-site assembly and shorter project timelines.

- Improved Quality Control: Automated systems can ensure consistent and precise manufacturing of building components, minimizing errors and defects.

- Cost Savings: Automation can lead to cost savings by reducing labor requirements and optimizing manufacturing processes.

- Enhanced Safety: By automating repetitive and hazardous tasks, automation can improve safety conditions for workers.

Challenges of Automation in Modular Construction

While automation offers significant benefits for modular construction, there are also challenges that need to be addressed:

- Initial Investment: Implementing automated systems and machinery requires a significant initial investment, which may pose a challenge for smaller modular construction companies.

- Complexity of Off-Site Assembly: Automating the assembly of modular components on-site can be complex due to variations in site conditions and specific project requirements. Ensuring the seamless integration of automated processes in the on-site construction process may require further development and innovation.

- Need for Skilled Workers: While automation can streamline many aspects of modular construction, skilled workers will still play a crucial role in overseeing operations, as well as ensuring the quality of the final assembly and addressing any site-specific challenges that may arise.

The Future of Automation in Modular Construction

Automation is poised to transform the modular construction industry, offering faster, more efficient, and higher quality construction solutions. As technology continues to advance, we can expect further innovation and advancements in automated systems, manufacturing processes, and on-site assembly methods. With the ongoing focus on sustainability, automation in modular construction can contribute to reduced waste and increased energy efficiency in the built environment.

Conclusion: While automation holds promising potential for various industries, including carpentry, its complete replacement of skilled workers seems unlikely. The fusion of automation and skilled craftsmanship is likely to be the future of carpentry, as it can enhance efficiency, precision, and safety while preserving the uniqueness and personal touch that skilled carpenters bring to their work. It is important for carpenters and other professionals in the field to embrace and adapt to technological advancements while ensuring the preservation of their invaluable skills and expertise. As the field of automation continues to evolve, it will be exciting to witness the synergistic collaboration between technology and craftsmanship in the world of carpentry and beyond.

Key Takeaways: Will Carpentry Be Automated?

- Carpentry is unlikely to be fully automated in the near future as it requires intricate craftsmanship and problem-solving skills.

- However, automation technologies are being used to enhance certain aspects of carpentry, such as precision cutting and repetitive tasks.

- Robotic systems can assist carpenters by increasing efficiency and reducing physical strain.

- Carpenters will still be needed for complex projects that require creativity and adaptability.

- While automation may change the nature of the carpentry industry, it is unlikely to replace skilled carpenters entirely.

Frequently Asked Questions

Welcome to our FAQ page, where we answer all your burning questions about the future of carpentry and automation.

What is the current state of automation in the carpentry industry?

Automation has made significant strides in the carpentry industry, especially in areas like precision cutting and shaping. CNC machines and robotics have become common tools in many carpentry workshops. These machines can perform repetitive tasks with great accuracy and speed, improving productivity and efficiency. However, complete automation is not yet widespread, as there are still many tasks that require the skill and creativity of human carpenters.

Some companies have experimented with fully automated carpentry, but it is not yet the norm. While automation has its benefits in terms of consistency and speed, there are still challenges to overcome when it comes to replicating the expertise and problem-solving abilities of human carpenters. So, while automation is making its mark in the carpentry industry, human craftsmanship remains an essential component.

What are the advantages of automating certain carpentry tasks?

Automation can bring several benefits to the carpentry industry. Firstly, it can significantly increase productivity by automating repetitive tasks, freeing up human carpenters to focus on more complex and creative aspects of their work. Additionally, automation can improve accuracy and precision, ensuring consistent results and minimizing errors. This can lead to higher quality products and increased customer satisfaction.

Furthermore, automation can offer cost savings in the long run. Despite the initial investment in machinery and technology, automation can reduce labor costs over time, as fewer human workers are needed for certain tasks. This can make carpentry more affordable and accessible for customers while still maintaining a high level of craftsmanship.

Will automation replace human carpenters entirely?

While automation has the potential to replace some aspects of carpentry, it is unlikely to completely eliminate the need for human carpenters. Automation excels in tasks that are repetitive and require precision, such as cutting or shaping materials. However, carpentry is a craft that also involves problem-solving, creativity, and attention to detail, which are skills that machines have yet to fully replicate.

Human carpenters bring unique expertise, experience, and adaptability to their work. They can approach each project with creativity and find innovative solutions to challenges that arise along the way. While automation may continue to advance, the artistry and craftsmanship of human carpenters will always have a place in the industry.

How can human carpenters adapt to automation in the industry?

Human carpenters can embrace the opportunities that automation brings by incorporating it into their workflow. By learning to operate and work alongside automated machinery, carpenters can improve their own efficiency and productivity. They can focus their expertise and creativity on the aspects of carpentry that machines cannot replicate, such as design, customization, and problem-solving.

Additionally, human carpenters can specialize in areas that are less likely to be automated, such as restoration or custom furniture making. These niche areas require a high level of craftsmanship and personalization, making them less suitable for full automation. By adapting their skills and finding unique niches, human carpenters can continue to thrive in the changing landscape of the carpentry industry.

What might the future hold for automation in the carpentry industry?

The future of automation in carpentry is likely to involve a combination of human expertise and machine precision. While machines can continue to take on repetitive and precise tasks, human carpenters will continue to bring their artistic touch and problem-solving abilities to the craft. Collaboration between humans and machines can lead to even greater efficiency, quality, and innovation in the industry.

As technology advances, we may see more advanced robotic systems that can mimic the dexterity and adaptability of human carpenters. These systems could work alongside carpenters, assisting them in complex tasks or taking on physically demanding work. The blending of human creativity and machine precision has the potential to push the boundaries of what is possible in the world of carpentry.

Will automation take away all our jobs? | David Autor

Summary

Imagine a world where carpentry tasks like sawing, sanding, and drilling are done by machines. While some tasks can already be automated, skilled carpenters will always be needed for complex work that requires creativity and problem-solving. New technologies can actually complement and enhance carpenters’ skills, making their work more efficient and precise. So, while automation may change some aspects of carpentry, it won’t replace the need for human craftsmanship and expertise.

In conclusion, carpentry is a profession that combines artistry with practical skills. While automation can assist with certain tasks, it cannot replicate the creativity and problem-solving abilities of skilled carpenters. So, aspiring carpenters need not worry about their future, as their profession will continue to be valued and needed in a world where craftsmanship remains important.