Can you use router bits in a spindle moulder? Well, you’re in for an exciting discussion on woodworking tools and their versatility! If you’ve ever wondered whether you can interchangeably use router bits in a spindle moulder, you’re not alone. The answer might surprise you, and we’re here to spill the beans!

So, picture this: you’re working on a woodworking project, and you have a router and a spindle moulder at your disposal. You start wondering if you can crank up the efficiency by utilizing router bits in your trusty spindle moulder. Is it a stroke of genius or a recipe for disaster? Let’s delve deeper into this topic and find out!

Hold onto your sawdust, because we’re about to demystify the world of woodworking tools and discover if you can use router bits in a spindle moulder without breaking a sweat (or your tools)! Let’s explore the possibilities, uncover potential limitations, and get ready to expand your woodworking horizons!

Did you know it’s possible to use router bits in a spindle moulder? While they are designed for different purposes, with the right adapter, you can use router bits in a spindle moulder. However, it’s important to note that there are limitations and considerations to keep in mind. Make sure to choose appropriate router bits and follow safety guidelines for the best results. Experiment cautiously and enjoy the versatility of your spindle moulder!

Can You Use Router Bits in a Spindle Moulder?

When it comes to woodworking, one of the common questions is whether you can use router bits in a spindle moulder. A spindle moulder, also known as a shaper, is a machine used to shape and mold wood. On the other hand, a router is a versatile power tool used for a variety of tasks, including shaping, cutting, and hollowing out wood. While both tools serve a similar purpose, they have distinct differences. In this article, we will explore whether you can use router bits in a spindle moulder, the benefits and drawbacks of doing so, and alternative options for woodworking tasks.

The Differences Between a Router and a Spindle Moulder

Before we delve into whether you can use router bits in a spindle moulder, it’s crucial to understand the differences between the two tools. A router is handheld and features a rotating bit that spins at high speeds. It can be used freehand or with a router table, depending on the task at hand. On the other hand, a spindle moulder is a stationary machine with a vertically mounted spindle, typically equipped with a set of interchangeable cutters or knives. It is designed for heavy-duty shaping and profiling work.

Router:

– Handheld tool

– Versatile and can be used for a wide range of tasks

– Adjustable depth of cut

– Compatible with a variety of router bits and attachments

– Portable and suitable for on-site work

Spindle Moulder:

– Stationary machine

– Designed for heavy-duty shaping and profiling work

– Typically features a larger table for stability and control

– Accommodates a wide range of cutters and knives

– Suited for precision work and larger woodworking projects

Benefits and Drawbacks of Using Router Bits in a Spindle Moulder

Benefits:

1) Versatility

One of the main benefits of using router bits in a spindle moulder is the added versatility. Router bits come in various shapes and sizes, allowing you to achieve a wide range of profiles and cuts. By using router bits with a spindle moulder, you can expand your options for shaping and profiling wood, giving you more creative freedom in your woodworking projects.

2) Cost Savings

Another advantage of using router bits in a spindle moulder is the potential for cost savings. Router bits are typically less expensive than specialized spindle moulder cutters and knives. By using router bits on your spindle moulder, you can achieve similar results at a lower cost, making it a more budget-friendly option for woodworking enthusiasts.

3) Accessibility

Router bits are widely available and can be found in most woodworking stores and online marketplaces. This accessibility makes it easier to find the specific router bits you need for your projects, eliminating the need to hunt down specific spindle moulder cutters. Additionally, router bits often come with comprehensive instructions and guidelines, making them more beginner-friendly than specialized spindle moulder cutters.

Drawbacks:

1) Safety Concerns

Using router bits in a spindle moulder poses certain safety concerns. Spindle moulders are designed with specific safety features and mechanisms to handle the higher speeds and forces generated by their dedicated cutters. While some router bits can be used in a spindle moulder, they may not be as safe or efficient as the specialized cutters designed for the machine. It is important to ensure that the router bits you use are appropriate for the spindle moulder and that you follow the manufacturer’s instructions for safe usage.

2) Limitations

While using router bits in a spindle moulder can provide versatility, there are limitations to consider. Router bits may not be as effective for heavy-duty shaping and profiling tasks that require the power and precision of specialized spindle moulder cutters. Additionally, the size and shape of the router bit shank may not be compatible with the spindle moulder’s collet, limiting the bits that can be used effectively. It is essential to carefully consider the specific task and requirements before deciding to use router bits in a spindle moulder.

3) Quality of Results

Using router bits in a spindle moulder may yield different results compared to using dedicated cutters. Spindle moulder cutters are specifically designed for the machine, ensuring optimal performance and quality of cuts. While router bits can produce similar profiles, the resulting finish may not be as clean, smooth, or precise. If you require exceptional precision and finish quality, it is advisable to invest in dedicated spindle moulder cutters.

Alternative Options for Woodworking Tasks

If using router bits in a spindle moulder is not ideal for your woodworking tasks, there are alternative options available. Here are a few examples:

1) Dedicated Spindle Moulder Cutters

Investing in a set of dedicated spindle moulder cutters is the most effective option for heavy-duty shaping and profiling work. These cutters are specifically designed for the machine, ensuring optimal performance, safety, and quality of results. While they may be more expensive than router bits, they offer superior precision and finish quality.

2) Combination Machines

If you require both the capabilities of a router and a spindle moulder, consider investing in a combination machine. These machines combine the features of both tools into one unit, allowing you to switch between router and spindle moulder functionalities. While they may come at a higher price point, combination machines offer convenience and space-saving benefits.

3) Handheld Routers

If your woodworking tasks are smaller in scale or require freehand work, handheld routers can be a suitable alternative. Handheld routers offer versatility, portability, and ease of use. They are ideal for tasks like edging, trimming, and creating intricate designs.

In conclusion, while it is possible to use router bits in a spindle moulder to achieve certain woodworking tasks, there are benefits and drawbacks to consider. The versatility and cost savings may be appealing, but safety concerns, limitations, and the quality of results can be limiting factors. It is essential to evaluate your specific needs and prioritize safety and precision when deciding whether to use router bits in a spindle moulder. Exploring alternative options like dedicated spindle moulder cutters, combination machines, or handheld routers can provide additional solutions for your woodworking projects.

Key Takeaways: Can You Use Router Bits in a Spindle Moulder?

- You cannot directly use router bits in a spindle moulder because they are designed for different purposes.

- Router bits have different shank sizes and dimensions compared to spindle moulder tools.

- Router bits are typically used for lighter, precision work, while spindle moulders are designed for heavier, industrial use.

- Using the wrong tool in a machine can lead to accidents or damage to both the machine and the tool.

- It is important to always use the appropriate tools for each machine to ensure safety and optimal performance.

Frequently Asked Questions

Are you wondering about the compatibility of router bits with a spindle moulder? We’ve got you covered! Check out these commonly asked questions:

Can I use router bits in a spindle moulder?

While router bits and spindle moulders may seem similar, they are designed for different purposes. Router bits are made for handheld routers, while spindle moulders are stationary machines specifically built for shaping wood. The main difference lies in the speed and power of the machines.

Router bits typically operate at higher speeds and lower power, which can result in damage or accidents if used on a spindle moulder. Additionally, spindle moulders have a larger cutting capacity and greater stability, allowing them to handle larger and heavier workpieces. To ensure safety and optimal performance, it’s best to use the appropriate tool for each job.

What are the risks of using router bits in a spindle moulder?

Using router bits in a spindle moulder can be risky for several reasons. Firstly, the higher speeds and lower power of router bits can cause them to vibrate excessively when used in a spindle moulder. This can lead to poor quality cuts, compromised workpiece stability, and potential accidents.

Additionally, router bits are typically smaller in size compared to spindle moulder cutters. The smaller size can lead to increased stress on the router bit and decrease its longevity. Moreover, router bits may not be compatible with the collet or arbor size of the spindle moulder, further increasing the risk of accidents and poor performance. It’s crucial to prioritize safety and utilize the appropriate tools for each application.

What can I use in a spindle moulder instead of router bits?

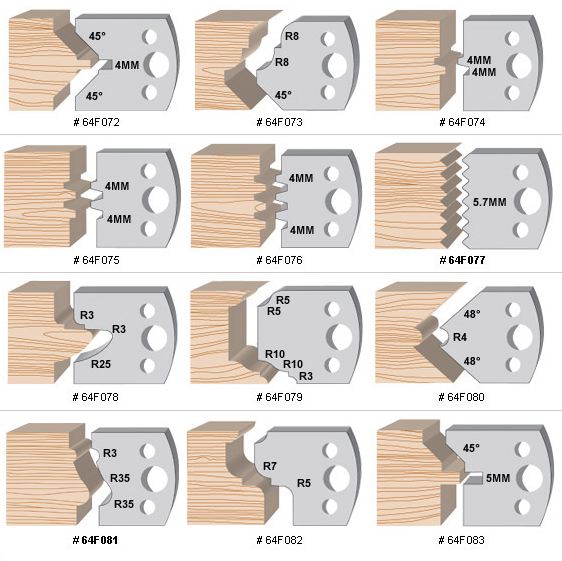

When it comes to a spindle moulder, there are various cutters available that are specifically designed for this machine. These cutters are larger in size, have a higher cutting capacity, and are better suited to the power and stability of a spindle moulder. Some common types of spindle moulder cutters include profiling cutters, rebating cutters, and panel raising cutters.

These cutters offer a wide range of options for shaping wood, allowing you to achieve different profiles and designs. It’s essential to choose the right cutter for your desired outcome and read the manufacturer’s instructions for proper usage and safety guidelines.

Can I modify a router bit to work in a spindle moulder?

Modifying a router bit to work in a spindle moulder is not recommended. The design and construction of router bits differ significantly from spindle moulder cutters. Attempting to modify a router bit to fit a spindle moulder could compromise the tool’s structural integrity, leading to an increased risk of accidents and poor performance.

Instead of modifying tools, it’s best to invest in the right equipment for the task at hand. By using the appropriate spindle moulder cutters, you can ensure safety, improve the quality of your work, and prolong the lifespan of your tools.

How can I ensure the safety of using a spindle moulder?

To ensure the safety of using a spindle moulder, it is crucial to follow the manufacturer’s instructions and safety guidelines. Here are some key safety practices to keep in mind:

1. Familiarize yourself with the machine: Understand how the spindle moulder operates, its specific features, and any safety mechanisms it may have.

2. Wear appropriate safety gear: Always use safety glasses, ear protection, and protective clothing, such as gloves and a dust mask, to protect yourself from flying debris and dust.

3. Secure the workpiece properly: Ensure that the workpiece is firmly secured using clamps or other appropriate methods to prevent it from moving during cutting.

4. Start with light passes: Gradually increase the depth of cut to minimize strain on the machine and prevent potential accidents.

5. Keep the workspace clean: Remove any debris or dust from the spindle moulder to maintain its performance and prevent potential hazards.

By adhering to these safety practices and regularly mai

Summary

You might be wondering if you can use router bits in a spindle moulder. Well, here’s the deal – it’s not recommended. The two machines work differently, and using router bits in a spindle moulder can be dangerous and may not give you the desired results.

Router bits are designed for routers, which spin at high speeds and are not as powerful as spindle moulders. Spindle moulders have slower speeds but higher torque, making them better suited for heavy-duty tasks. So, it’s best to use the right tool for the job and stick to using router bits in routers and spindle moulder cutters in spindle moulders. Stay safe and choose wisely!