Have you ever wondered how much electricity a lathe uses? It’s a fascinating question, especially if you’re interested in woodworking or machining. Well, you’re in luck! In this article, we’ll explore the energy consumption of lathes and provide you with all the information you need. So, let’s dive in and uncover the answers together!

When it comes to electrical devices, understanding their power requirements is crucial. So, let’s start by finding out how much electricity a lathe typically consumes. Whether you’re a beginner or an experienced hobbyist, knowing this information can help you plan your projects more effectively and manage your energy usage. So, let’s get ready to power up our knowledge!

Lathe machines are incredibly versatile tools used in various industries for shaping and cutting materials. But have you ever wondered how much electricity these powerful machines require to operate? Well, in this article, we’ll shed some light on the energy consumption of lathes, giving you a deeper understanding of their electrical needs. So, let’s embark on this electrifying journey!

How Much Electricity Does a Lathe Use?

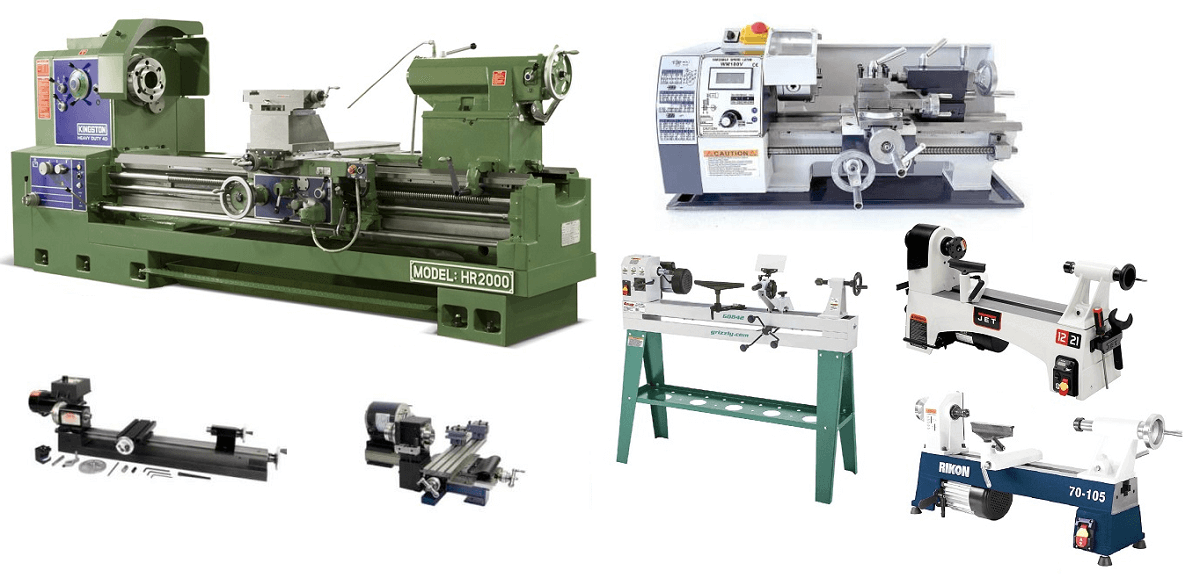

Welcome to our comprehensive guide on the electricity usage of lathes! If you’ve ever wondered about the energy consumption of this versatile machinery, you’re in the right place. In this article, we’ll delve into the factors that determine how much electricity a lathe uses and provide useful information and tips to optimize its energy efficiency. We’ll explore the different types of lathes, their power requirements, and how you can minimize your environmental impact while maximizing productivity. So, let’s get started!

The Factors Influencing Lathe Electricity Usage

When it comes to the electricity consumption of a lathe, several factors come into play. It’s important to understand these variables to estimate the energy consumption accurately and make informed decisions about usage and efficiency. Let’s explore the key factors that influence the electricity usage of a lathe:

1. Motor Power and Horsepower Rating

The motor power and horsepower rating of a lathe are significant factors in determining its electricity consumption. Motors with higher horsepower are generally more powerful and require more energy to operate. The power output is usually measured in watts or kilowatts, and the higher the rating, the more electricity the lathe will consume. It’s important to consider the motor power and horsepower when selecting a lathe to ensure it meets your specific needs without excessive energy usage.

The diameter and length of the workpiece also play a role in the power requirements of the lathe. Larger workpieces may require more torque and horsepower, resulting in higher energy consumption. It’s crucial to match the lathe’s power capabilities to the demands of your projects to avoid overloading the motor and wasting electricity.

2. Cutting Speed and Feed Rate

The cutting speed and feed rate of the lathe are vital considerations when it comes to electricity usage. Cutting speed refers to the rotational speed of the workpiece, while the feed rate determines the rate at which the cutting tool engages with the workpiece. Higher cutting speeds and feed rates generally require more power to drive the lathe. However, finding the optimal balance is crucial to ensure efficient operations without excessive electricity consumption.

By optimizing the cutting speed and feed rate for your specific materials and project requirements, you can reduce the energy usage of the lathe. It’s recommended to consult the lathe’s manual or seek professional advice to determine the most appropriate settings for your applications.

3. Duration of Use

The duration of lathe usage directly impacts the overall electricity consumption. The longer the lathe is in operation, the more energy it will consume. Therefore, it’s essential to consider the planned usage time and incorporate measures to minimize unnecessary usage. For example, turning off the lathe when not in use or during breaks can significantly reduce electricity consumption and lower your energy bills.

If you frequently use the lathe for extended periods, it may be worth considering automated energy-saving features or scheduling regular maintenance to ensure optimal performance and efficiency.

Energy-Efficiency Tips for Lathes

Now that we’ve explored the factors influencing electricity usage in lathes, let’s discuss some practical tips for improving energy efficiency and minimizing your environmental impact:

1. Optimize Tool Selection and Maintenance

Choosing the right cutting tools and ensuring they are properly maintained can enhance the efficiency of your lathe. Dull or damaged tools can increase power requirements, leading to unnecessary energy consumption. Regularly inspect and sharpen your cutting tools, and replace them as needed to maintain optimal performance.

Additionally, selecting the appropriate tool materials and coatings for your specific applications can reduce friction and extend the tool’s lifespan, resulting in energy savings over time.

2. Implement Variable Speed Drives

Variable speed drives (VSD) allow you to adjust the rotational speed and power output of your lathe according to the requirements of each project. By utilizing VSD technology, you can reduce energy consumption during lighter workload operations without sacrificing productivity. VSDs provide better control and flexibility, allowing you to match the lathe’s power output to the demands of each task, ultimately optimizing energy usage.

3. Ensure Proper Lubrication and Cooling

Efficient lubrication and cooling systems are essential for maintaining the performance and longevity of your lathe. Inadequate lubrication can lead to increased friction and higher power demands, resulting in unnecessary energy consumption. Regularly inspect the lubrication systems and ensure they are properly functioning, applying the appropriate lubricants as recommended by the manufacturer.

Similarly, proper cooling is crucial to prevent overheating and optimize performance. Ensure that cooling systems, such as fans or coolants, are functioning correctly and free from obstructions.

By implementing these energy-efficient practices and considering the factors that influence electricity usage, you can minimize the environmental impact of your lathe operations while maximizing productivity. Remember, small changes can make a significant difference in reducing energy consumption and promoting sustainability.

Key Takeaways

- A lathe is a machine used for shaping wood or metal.

- The amount of electricity a lathe uses depends on its size and motor power.

- A small benchtop lathe typically uses around 500 watts of electricity per hour.

- A larger lathe with a more powerful motor can use up to 1,500 watts of electricity per hour.

- It’s important to consider the electricity cost when using a lathe regularly.

Frequently Asked Questions

When it comes to using a lathe, questions about electricity consumption often come up. Here are some frequently asked questions and answers regarding the amount of electricity a lathe uses.

How much power does a lathe consume?

A lathe’s power consumption can vary depending on its size, type, and usage. On average, a small to medium-sized lathe may consume around 1 to 2 kilowatts (kW) per hour of use. However, larger industrial lathes may require more power, sometimes reaching up to 10 kW or more. It’s important to check the lathe’s specifications or consult the manufacturer for accurate power consumption information.

It’s worth mentioning that a lathe’s power consumption isn’t constant throughout its operation. The actual power usage depends on factors such as the type and thickness of the material being machined, the cutting speed, and the load on the motor. Understanding these factors can help you estimate the lathe’s power requirement for your specific machining tasks.

Does the speed at which a lathe is operated affect its power usage?

Yes, the speed at which a lathe operates can impact its power consumption. Generally, higher cutting speeds require more power. When the cutting tool encounters resistance from the material being machined, the motor needs to work harder to maintain the desired speed. This increased workload can result in higher power consumption.

However, it’s important to note that a lathe’s power consumption at different speeds also depends on various factors such as the type of lathe, the material being machined, and the tooling being used. Always refer to the manufacturer’s guidelines for specific power consumption details at different speeds.

Can using certain materials with a lathe affect its electricity usage?

Yes, the type of material being machined can influence the power consumption of a lathe. Some materials, such as softer metals like aluminum, require less power compared to harder materials like steel. Softer materials are easier to cut, resulting in lower resistance and, therefore, reduced power consumption.

It’s also worth noting that the hardness of the material isn’t the only factor that affects power usage. The size and shape of the workpiece, the depth of cuts, and the feed rate also play a role. In general, materials that are more difficult to machine or require more aggressive cutting parameters tend to consume more power.

Does a lathe consume electricity even when it’s not in use?

In most cases, a lathe doesn’t consume a significant amount of electricity when it’s not in use, as long as it’s turned off. When the lathe is completely powered off or unplugged, it should not draw substantial power. However, if the lathe has any standby or sleep modes, there may be minimal electricity consumption.

It’s always recommended to switch off the lathe when it’s not in use to conserve electricity. Unplugging the machine completely can provide even greater energy savings, especially for long periods of inactivity.

Are there any energy-saving techniques for reducing a lathe’s electricity usage?

Absolutely! There are several energy-saving techniques that can help reduce a lathe’s electricity consumption. One effective approach is optimizing cutting parameters such as feed rate, depth of cuts, and cutting speeds. Using the most appropriate tooling and ensuring it’s in good condition can also minimize power consumption.

In addition, keeping the lathe and its components clean and properly lubricated can improve its efficiency, reducing the amount of electricity required to perform each machining operation. Regular maintenance and inspections are crucial for identifying any issues that might impact power usage and resolving them promptly.

How much electricity do my household items use?

Summary

If you’re wondering how much electricity a lathe uses, here’s what you need to know. Lathes use around 500 to 2500 watts of power, depending on their size and usage. It’s essential to consider the motor’s horsepower and the duration of operation to estimate electricity consumption accurately. Additionally, using energy-efficient practices like turning off the lathe when not in use can help save electricity. So, keep these factors in mind when using a lathe and be mindful of energy usage.